Desulfurization specific defoaming agent by using wet flue gas desulfurization processing water as recycled water

A wet flue gas desulfurization and process water technology, applied in liquid degassing, separation methods, foam dispersion/prevention, etc., can solve the problems of complex impurity composition, slow defoaming speed, poor temperature resistance, etc., and achieve chemical stability Good, good defoaming, low-dose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

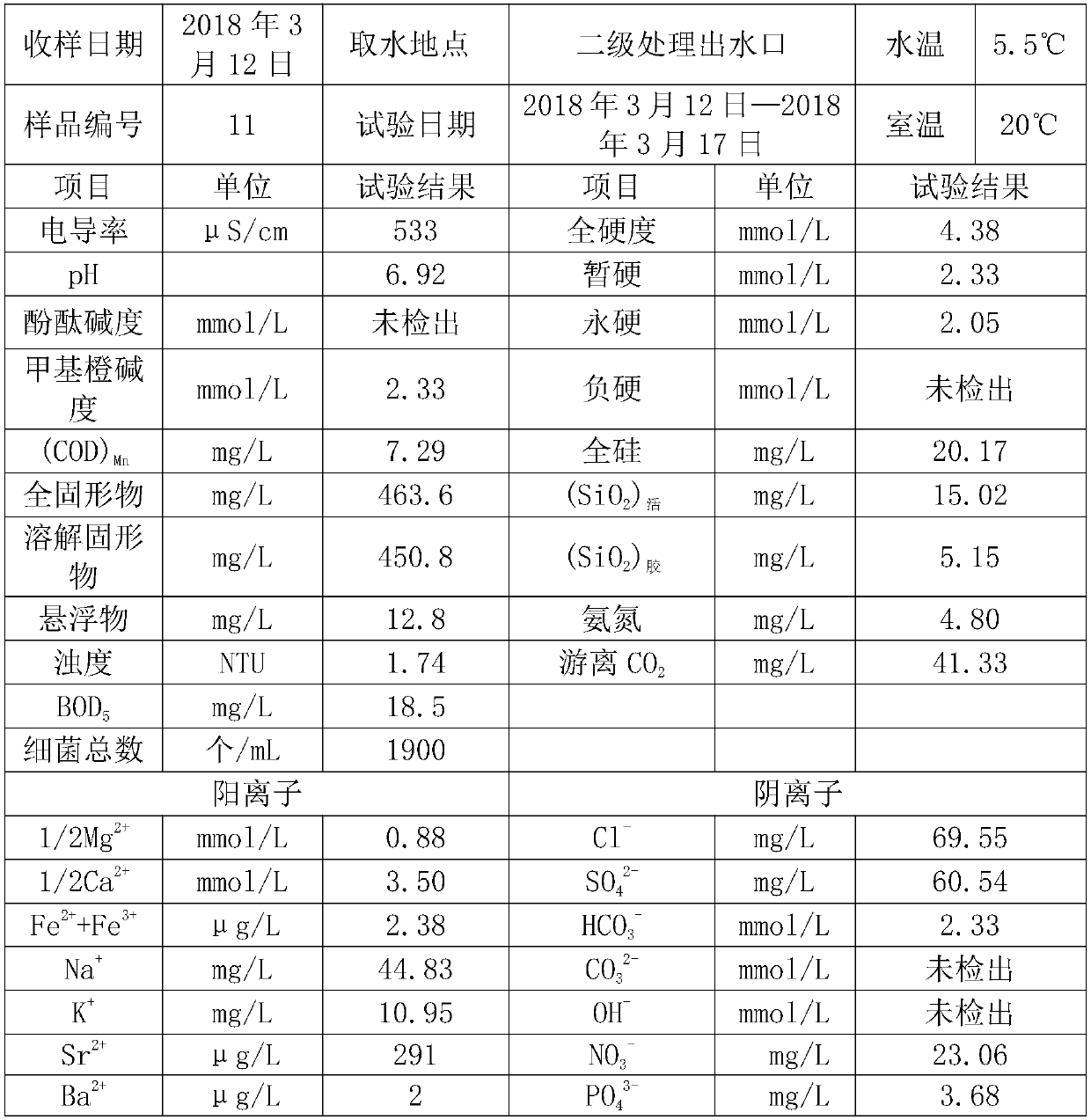

Image

Examples

Embodiment Construction

[0008] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0009] In the embodiment of the present invention, the water used in the wet flue gas desulfurization process is regenerated water, and the desulfurization special defoamer is JDHX-1Z type defoamer. The defoamer consists of four parts: carrier, active substance, emulsifier and emulsification aid. It is specifically composed of the following mass fraction components:

[0010] 1. Carrier: 40%~60% methylpentanone and 10%~30% cyclohexanone;

[0011] 2. Active substances: 10% to 20% sodium dodecylbenzenesulfonate and 8% to 15% sodium cocoyl glutamate;

[0012] 3. Emulsifier: 1% to 5% sodium hydroxyalkylsulfonate;

[0013] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com