Process for producing polyvinyl chloride polymerization organosilicon inarch polyether antifoam agent

A technique for polymerizing silicone and grafted polyether, which is applied in the field of silicone grafted polyether defoamer for polyvinyl chloride polymerization. Effect of good thermal and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

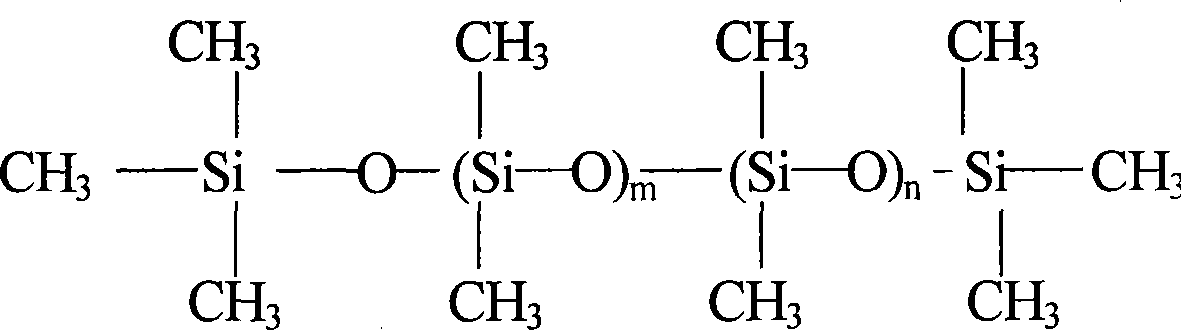

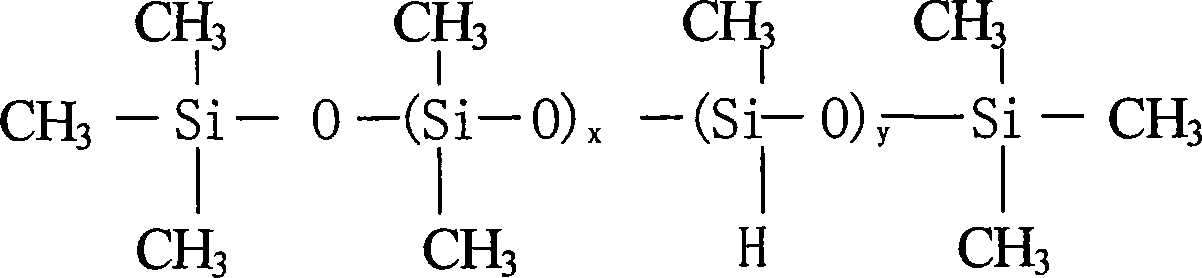

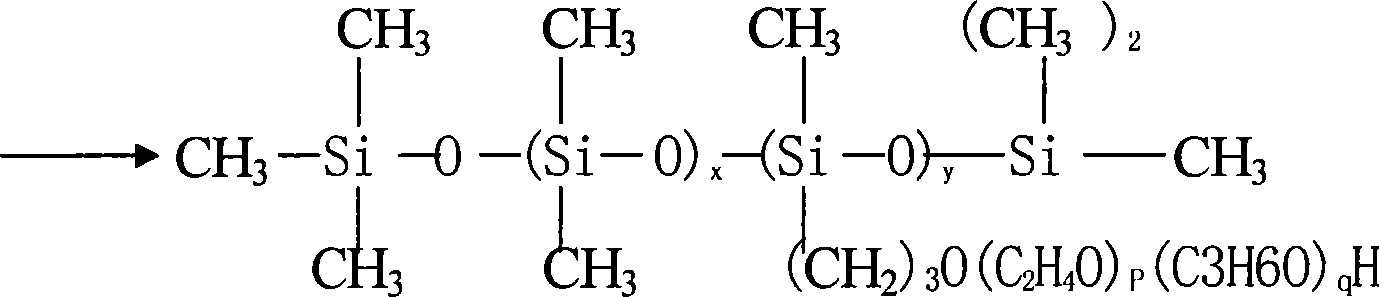

Method used

Image

Examples

Embodiment 1

[0036] The first step, the synthesis of hydrogen-containing intermediates: various raw materials and proportions:

[0037] Octamethylcyclotetrasiloxane (D 4 ) 100 copies

[0038] Hydrogen silicone oil 25 parts

[0039] Hexamethyldisiloxane (MM) 15 parts

[0040] 6 parts concentrated sulfuric acid

[0041] Sodium carbonate 15 parts

[0042] The operation method is as follows:

[0043] Add the raw materials hydrogen-containing silicone oil, octamethylcyclotetrasiloxane and hexamethyldisiloxane into the reaction kettle in portions, pre-mix first, stir for 30 minutes, and then add concentrated sulfuric acid with a concentration of 96-98%. The synthesis reaction was carried out at room temperature. After reacting for 10 hours, sodium carbonate was added to neutralize the sulfuric acid. After 3 hours of neutralization reaction, the material is discharged, filtered and packaged with a 300-mesh stainless steel mesh, and the hydrogen-containing intermediate is obtained.

[0044...

Embodiment 2

[0051] The first step, the synthesis of hydrogen-containing intermediates: various raw materials and proportions:

[0052] Octamethylcyclotetrasiloxane (D 4 ) 100 copies

[0053] 30 parts of hydrogen silicone oil

[0054] Hexamethyldisiloxane (MM) 20 parts

[0055] Concentrated sulfuric acid 8 parts

[0056] Sodium carbonate 18 parts

[0057] The operation method is as follows:

[0058] Add the raw materials hydrogen-containing silicone oil, octamethylcyclotetrasiloxane and hexamethyldisiloxane into the reaction kettle in portions, pre-mix first, stir for 30 minutes, and then add concentrated sulfuric acid with a concentration of 96-98%. The synthesis reaction was carried out at room temperature. After reacting for 10 hours, sodium carbonate was added to neutralize the sulfuric acid. After 3 hours of neutralization reaction, the material is discharged, filtered and packaged with a 300-mesh stainless steel mesh, and the hydrogen-containing intermediate is obtained.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com