Combined type egg beater with rapid defoaming effect

An egg beater and combined technology, which is applied in household appliances, applications, kitchen utensils, etc., can solve the problems of time-consuming and labor-consuming, affect the product's later use effect, and low egg-beating efficiency, so as to achieve convenient use and improve later use The effect of improving the quality and improving the efficiency of beating eggs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

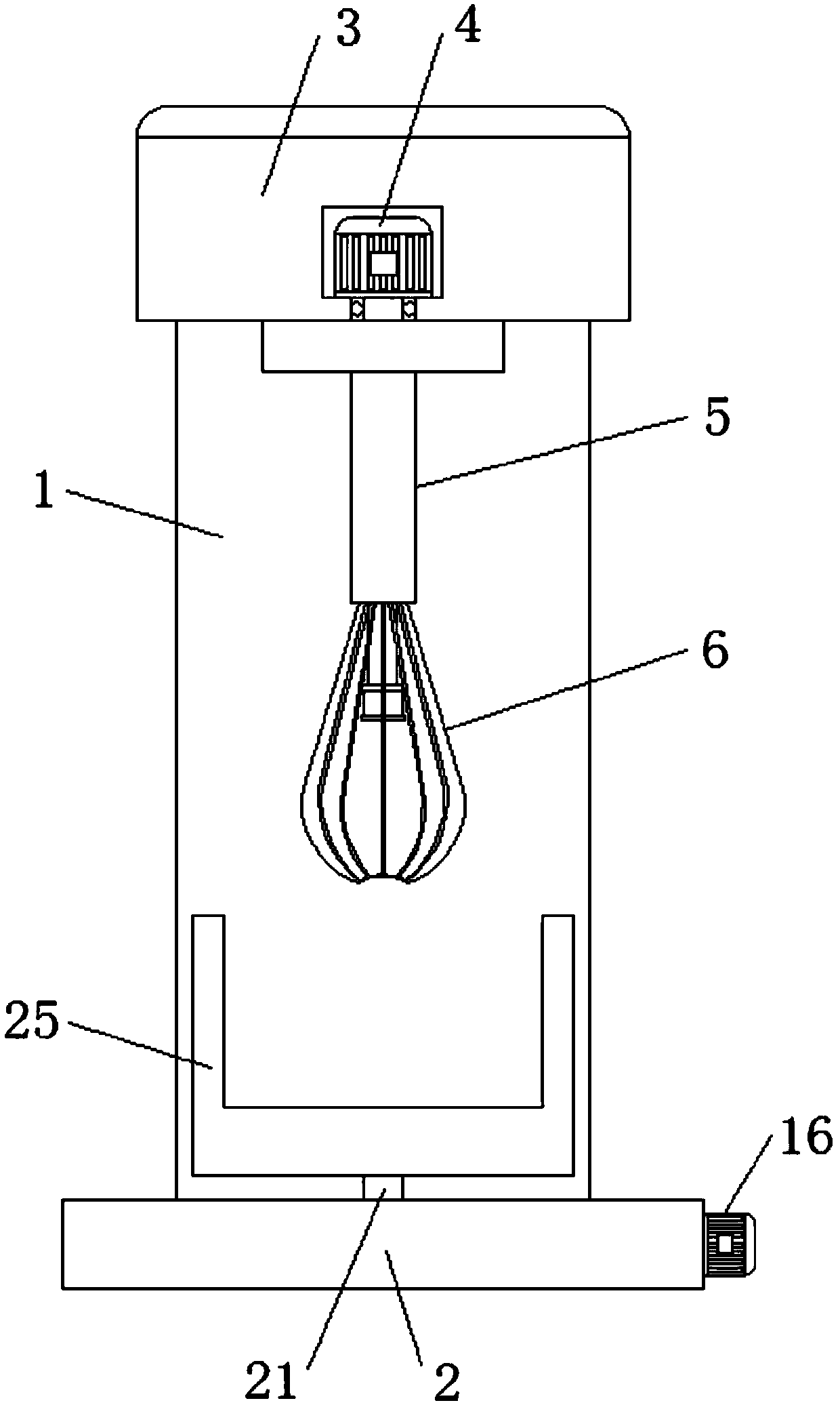

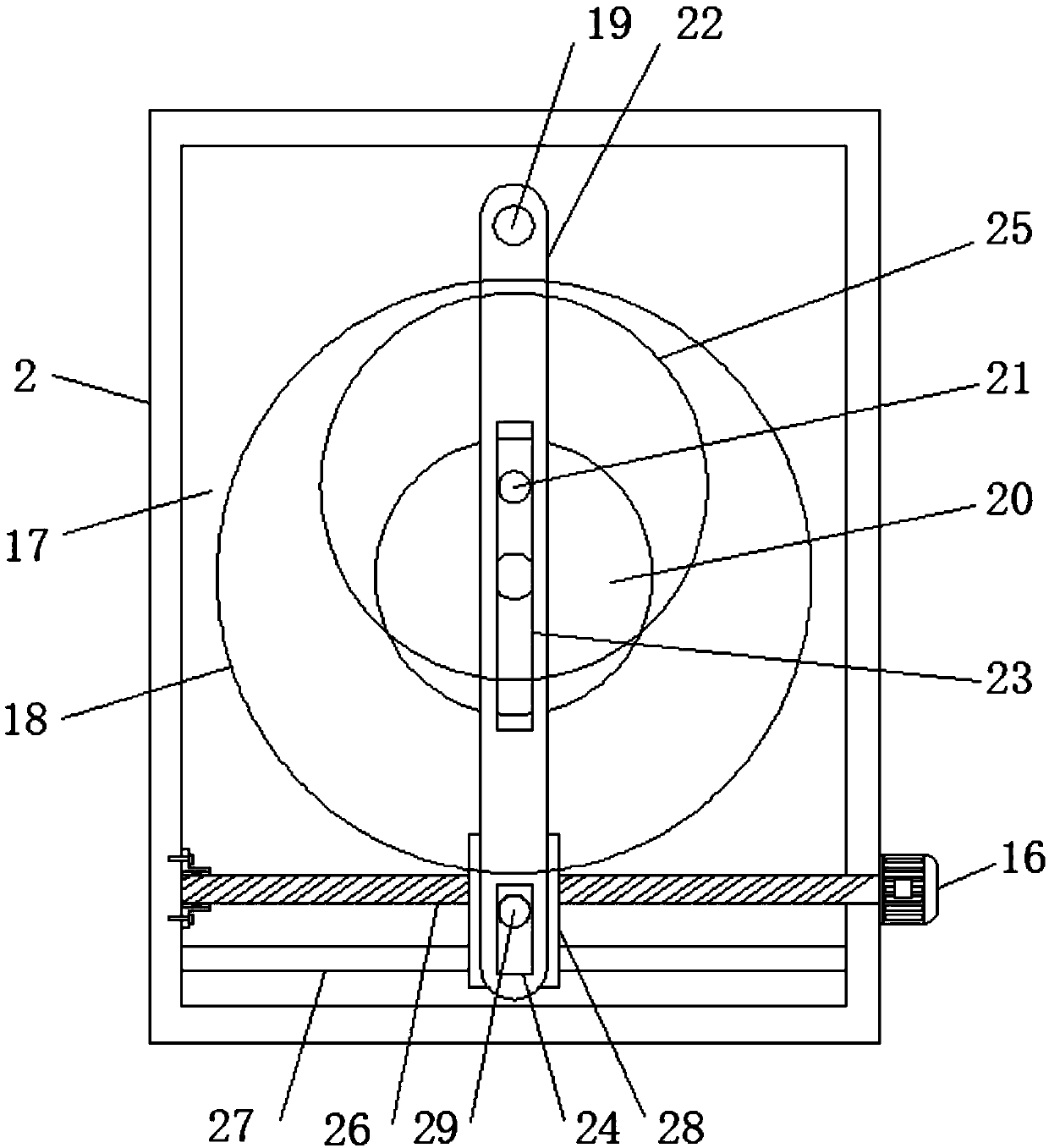

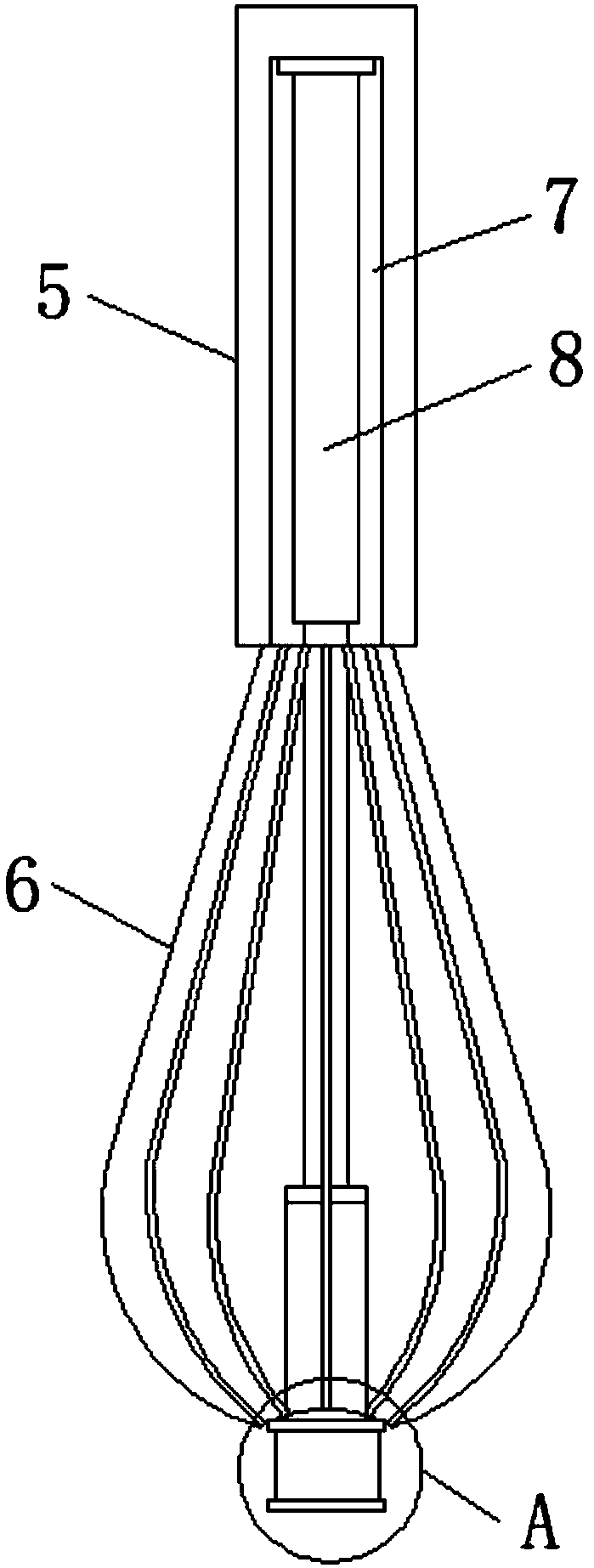

[0026] refer to Figure 1-4 , a combined egg beater for rapid defoaming, including a whisk body 1 and a base 2, the base 2 is located on the bottom side of the egg beater body 1, and a control box 3 is installed on the top of the egg beater body 1 to control The inside of the box 3 is equipped with a first motor 4, and also includes an egg-beating mechanism located at the bottom of the control box 3, wherein the egg-beating mechanism includes a fixed rod 5 and a stirring mesh head 6, and the stirring mesh head 6 is fixedly installed on the bottom of the fixed rod 5 , the inside of the fixed rod 5 is equipped with a defoaming disc 9, the bottom of the defoaming disc 9 is provided with a liquid inlet 10, a filter screen 11 is installed in the liquid inlet 10, and the inside of the defoaming disc 9 is provided with a multi-layer defoaming Cavities 12, a plurality of defoaming ports 13 are provided between adjacent defoaming chambers 12, a plurality of stainless steel needles 14 a...

Embodiment 2

[0032] refer to Figure 5 , a lifting mechanism can be set under the base 2, and the hydraulic cylinder can be used to drive the base 2 to move up and down, so as to facilitate the adjustment of the distance between the circular fixed bracket 25 and the stirring net head 6, and can adapt to different capacities of stirring liquid and different specifications of containers use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com