Automatic cleaning device for inner wall of closed container

A closed container and automatic cleaning technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of manual cleaning, high labor intensity, poor cleaning effect, etc., so as to reduce the quantity, Reduce labor intensity and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

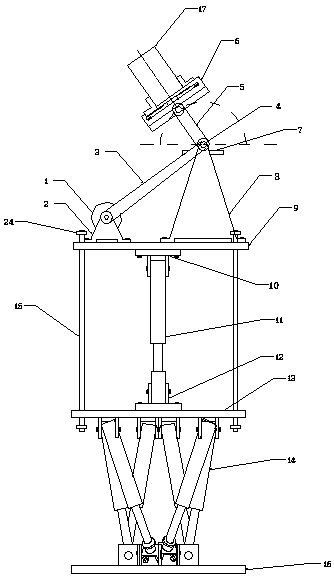

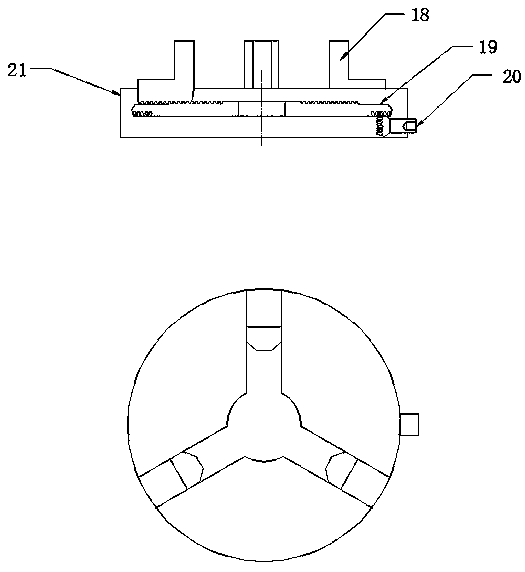

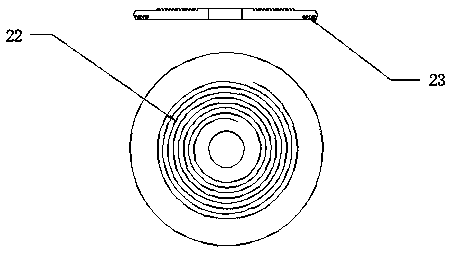

[0028] refer to figure 1 , an automatic cleaning device for the inner wall of a closed container, comprising a motor 1, the motor 1 is fixed on the motor support 2, and then fixed on the support plate 9 by screws, the output shaft of the motor is connected with the crank connecting rod shaft 4 through the belt 3, and the crank is connected The rod rotating shaft 4 drives the crank connecting rod 5 to rotate, one end of the crank connecting rod 5 is connected with the crank connecting rod support 8, and the other end is connected with the closed container fixing device 6, and a limit block 7 is fixed on the crank connecting rod support 8 , the limiting block 7 is located above the support, and when the crank connecting rod 5 reaches the horizontal position and contacts the limiting block 7, the crank connecting rod 5 cannot continue to rotate. The crank connecting rod type closed container inner wall cleaning device controls the forward and reverse rotation of the motor 1 The ...

Embodiment 2

[0033] As a further improvement of Embodiment 1, the device is provided with a component that realizes the shaking of the closed container above. For details of the component, see Figure 4 .

[0034] By using the cylinder group to do irregular telescopic movement, the shaking of the closed container above is realized, and the irregular movement of the working cylinder group 14 is realized through the controller's control of the air intake and exhaust of each cylinder of the cylinder group 14 .

[0035] Further, the group of working cylinders 14 also includes a controller, and the controller is electrically connected with the first cylinder 27, the second cylinder 29, the third cylinder 30, the fourth cylinder 31, the fifth cylinder 32, and the sixth cylinder 28. It is used to control the start and stop of the first cylinder 27, the second cylinder 29, the third cylinder 30, the fourth cylinder 31, the fifth cylinder 32, and the sixth cylinder 28; limit blocks are set on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com