Modified organosilicone defoaming agent, defoaming agent composition and preparation method thereof

A technology of silicone defoamer and composition, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of large consumption, low foam breaking rate, low foam suppressing ability, etc. The effect of long-lasting foam suppression, rapid defoaming, suitable viscosity and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

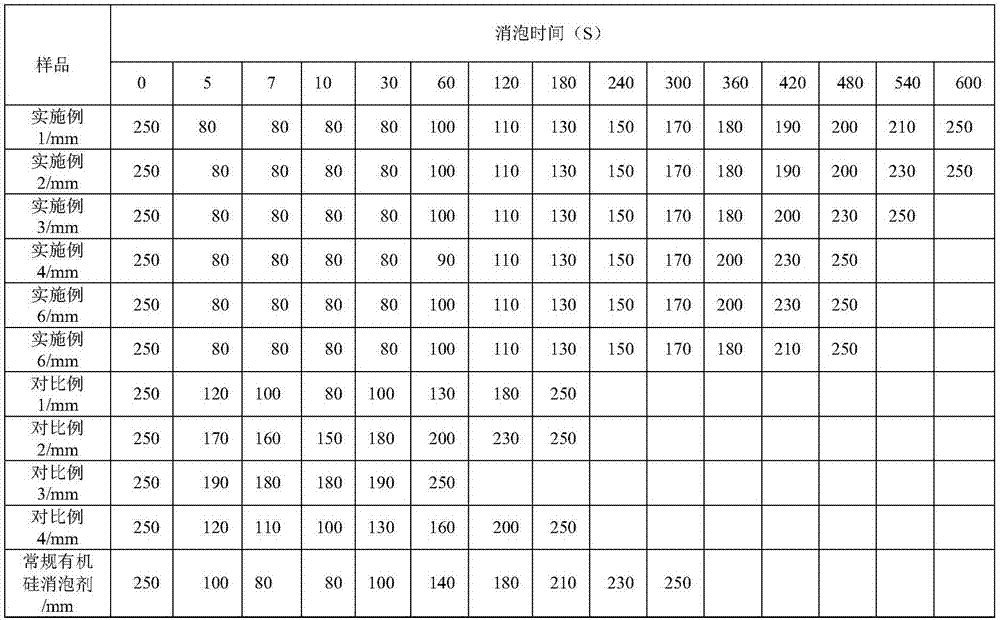

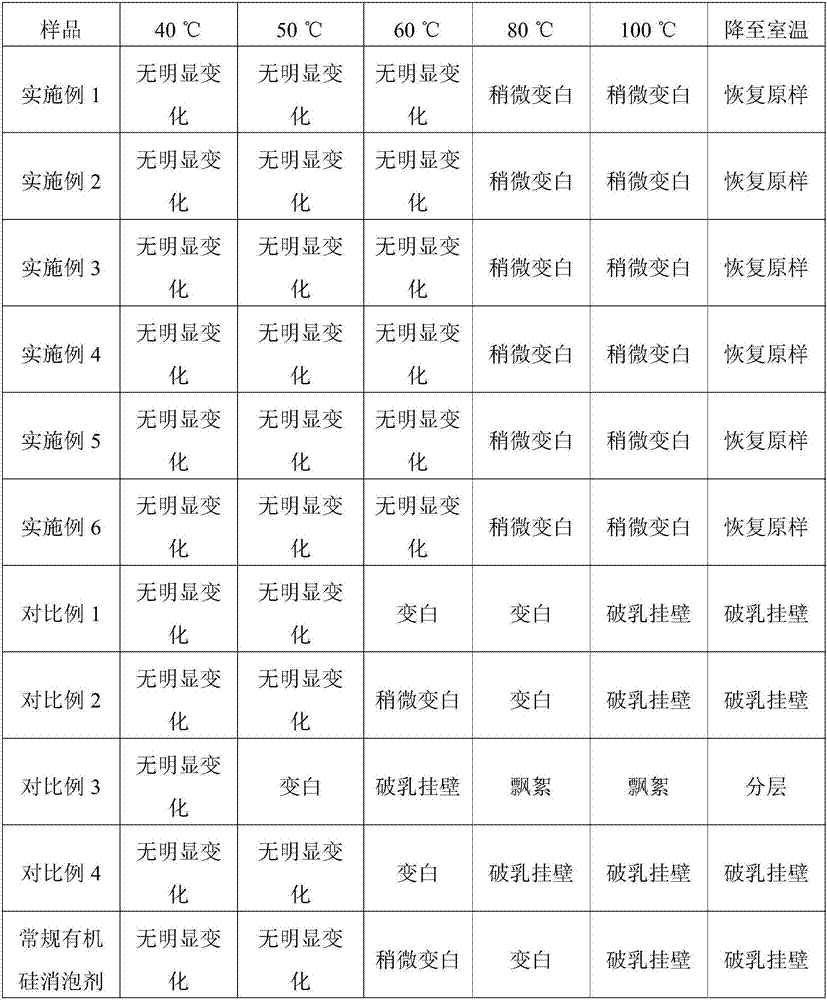

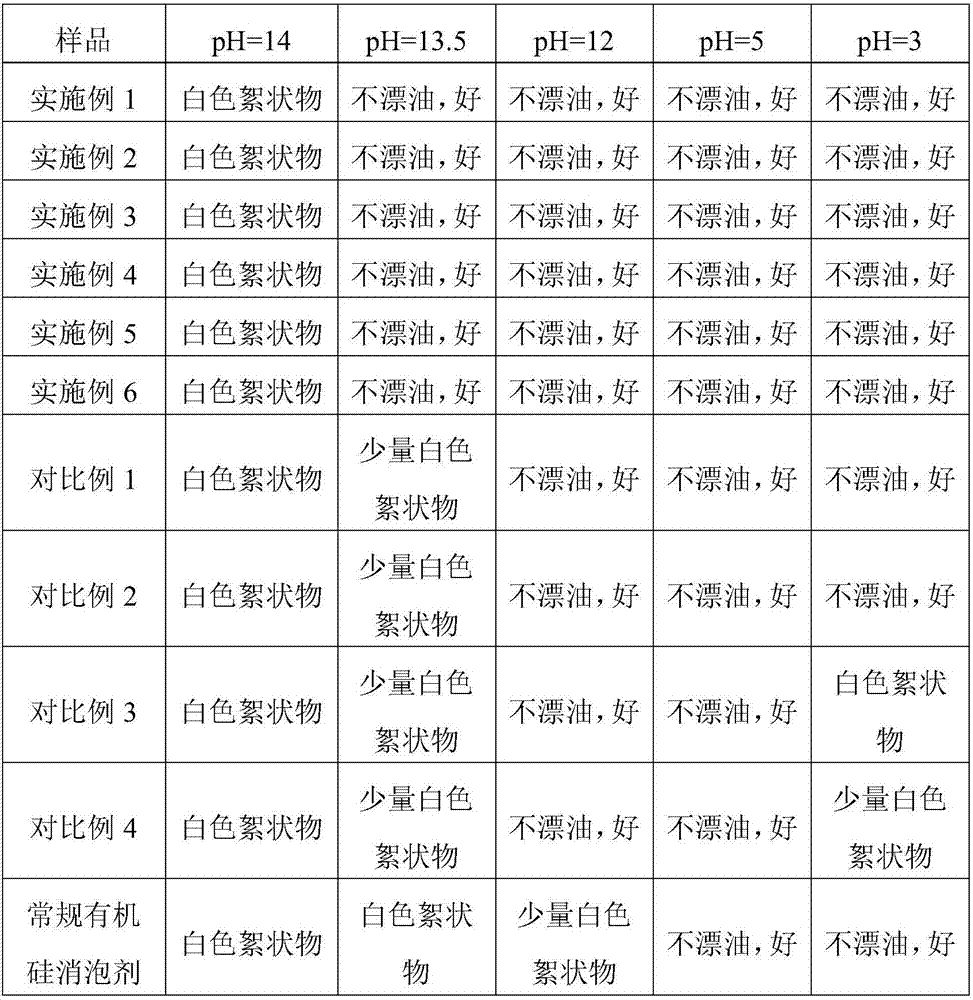

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a modified silicone defoamer, wherein the modified silicone defoamer is the above-mentioned modified silicone defoamer; the preparation method comprises:

[0041] First add the surfactant and the first thickener into the water, mix evenly at 60-80°C; then add silicone paste, EO / PO block copolymer, mix at 60-80°C; then cool down to 40-50°C ℃, add the remaining water and fungicide and mix well.

[0042] The present invention also provides a defoamer composition, comprising the following raw materials in parts by weight:

[0043] 90-100 parts of modified silicone defoamer, such as 90 parts, 92 parts, 95 parts, 98 parts or 100 parts;

[0044] 10-20 parts of leveling agent, such as 10 parts, 12 parts, 15 parts, 18 parts or 20 parts, etc.;

[0045] 0.2-0.3 parts of the second thickener such as 0.2 parts, 0.22 parts, 0.25 parts, 0.28 parts or 0.3 parts, etc.;

[0046] 0.01-0.05 parts of preservatives such as 0.01 pa...

Embodiment 1

[0056] (1) Preparation of modified silicone defoamer: First, stir and mix 1.4 parts of polyoxyethylene monostearate, 1.6 parts of glycerin fatty acid ester and 1.5 parts of carboxymethyl cellulose, add them to 35 parts of water, and heat to Stir and mix evenly at 70°C; then add 10 parts of silicone paste and 10 parts of EO / PO block copolymer, stir at 70°C for 30 minutes, then cool down to 50°C, stir the above mixture at 50°C for 30 minutes, and add 40 parts of water, and finally cooled to 30°C with stirring to obtain a modified silicone defoamer.

[0057] (2) Preparation of defoamer composition: Slowly add 0.2 parts of modified polyacrylic acid resin to 45 parts of deionized water (stir while adding), stir well, add 90 parts of modified silicone defoamer and stir evenly, then add 10 parts leveling agent α-[3-[1,3,3,3-tetramethyl-1-(trimethylsilyl-oxo)disiloxane]-propyl-ω-hydroxypolyoxyethylene ) and stir evenly, and finally add 0.01 part of Casson preservative, and it is read...

Embodiment 2

[0059] (1) Preparation of modified silicone defoamer: First, stir and mix 1 part of polyoxyethylene monostearate, 1 part of glycerin fatty acid ester and 1.8 parts of carboxymethyl cellulose, add to 30 parts of water, and heat to Stir and mix evenly at 60°C; then add 12 parts of silicone paste and 12 parts of EO / PO block copolymer, stir at 70°C for 30 minutes, then cool down to 40°C, stir the above mixture at 40°C for 30 minutes, and add 40 parts of water, and finally cooled to 30°C with stirring to obtain a modified silicone defoamer.

[0060] (2) Preparation of defoamer composition: Slowly add 0.22 parts of modified polyacrylic acid resin to 48 parts of deionized water (stir while adding), stir well, add 95 parts of modified silicone defoamer and stir evenly, then add 12 parts leveling agent α-[3-[1,3,3,3-tetramethyl-1-(trimethylsilyl-oxo)disiloxane]-propyl-ω-hydroxypolyoxyethylene ) and stir evenly, and finally add 0.03 parts of Kasone preservative, to get final product. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com