Liquid-phase sugar nano tellurium and preparation method thereof as well as method for storing nano tellurium in liquid phase

A nano and liquid-phase technology, applied in the field of preparation and preservation of nano-materials, can solve the unsolved problems of liquid-phase elemental tellurium, elemental tellurium cannot be quantitatively controlled, and biological activity research has not yet been carried out in large quantities, achieving convenient control and simple preparation methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

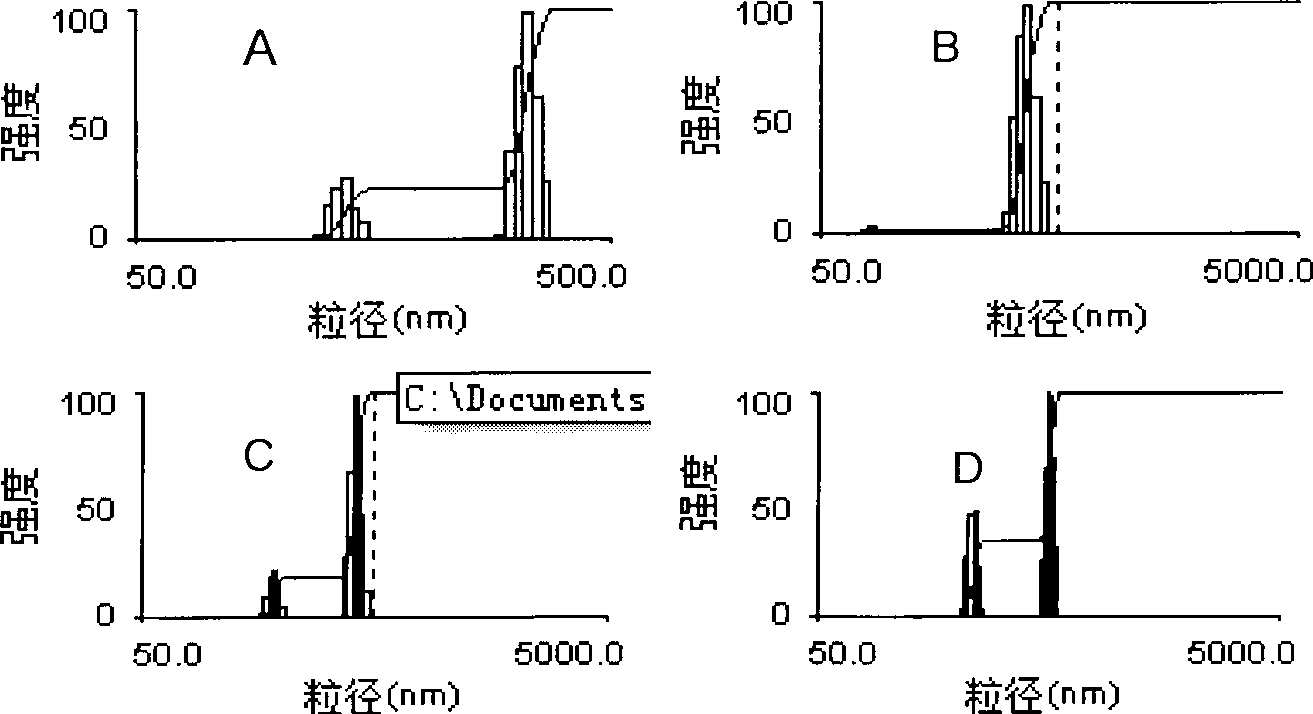

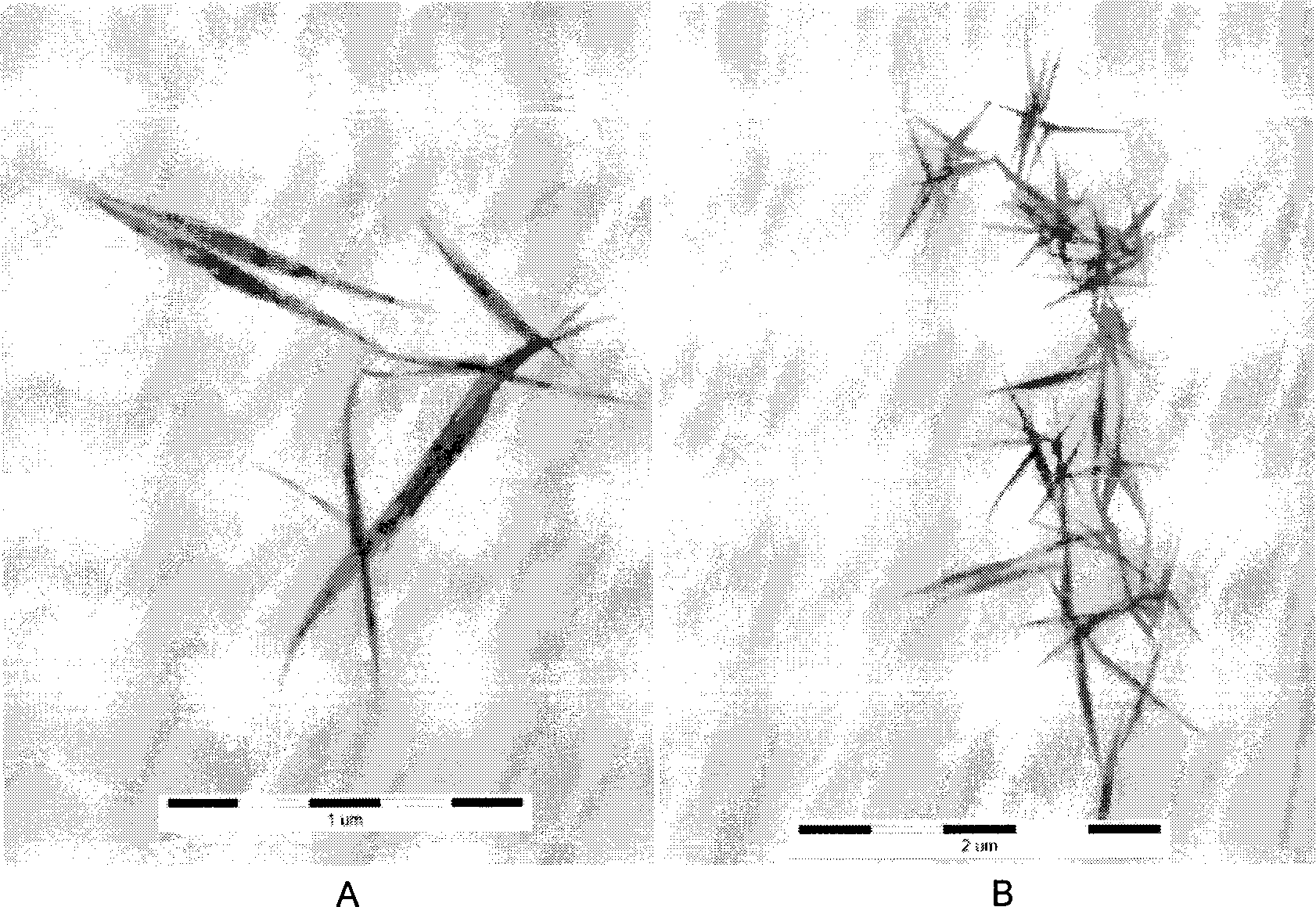

Embodiment 1

[0036] At normal temperature and pressure, take 1mL (the amount added can be adjusted in proportion according to actual needs) Na with Te of 4.62mmol / L 2 TeO 3 Aqueous solution (i.e. composed of solid Na 2 TeO 3 Be prepared as an aqueous solution with a concentration of 4.62mmol / L), add sucrose and ascorbic acid (Vc) in the aqueous solution under stirring, and adjust the volume to 50mL with double distilled water (depending on the actual production requirements), the final reaction system obtained is (5% sucrose+0.01mol / L Vc+93.2μmol / L Na 2 TeO 3 ). Heating and reacting at 60°C for 6 hours (the length of time can control the growth of nano-tellurium, which can be adjusted according to the situation), the product is obtained, and the volume of the final sample can be prepared into different volumes according to different needs.

[0037] The mass fraction of the above-mentioned sucrose is based on the mass fraction of the final reaction solution, and 5% ie 5g of sucrose nee...

Embodiment 2

[0039] At normal temperature and pressure, take 1mL (the amount added can be adjusted in proportion according to actual needs) Na with Te of 4.62mmol / L 2TeO 3 Aqueous solution (i.e. composed of solid Na 2 TeO 3 Be prepared into the aqueous solution that concentration is 4.62mmol / L), in the aqueous solution of the glucose that adds under stirring and ascorbic acid, use secondary distilled water to adjust volume to 50mL (depending on demand in actual production), the reaction system that finally obtains is (mass Fraction 2% glucose+0.01mol / L Vc+93.2μmol / L Na 2 TeO 3 ). Heating at 60° C. for 6 hours (the length of time can control the growth of nano-tellurium, which can be adjusted according to the situation), the product is obtained, and the volume of the final sample can be prepared into different volumes according to different needs.

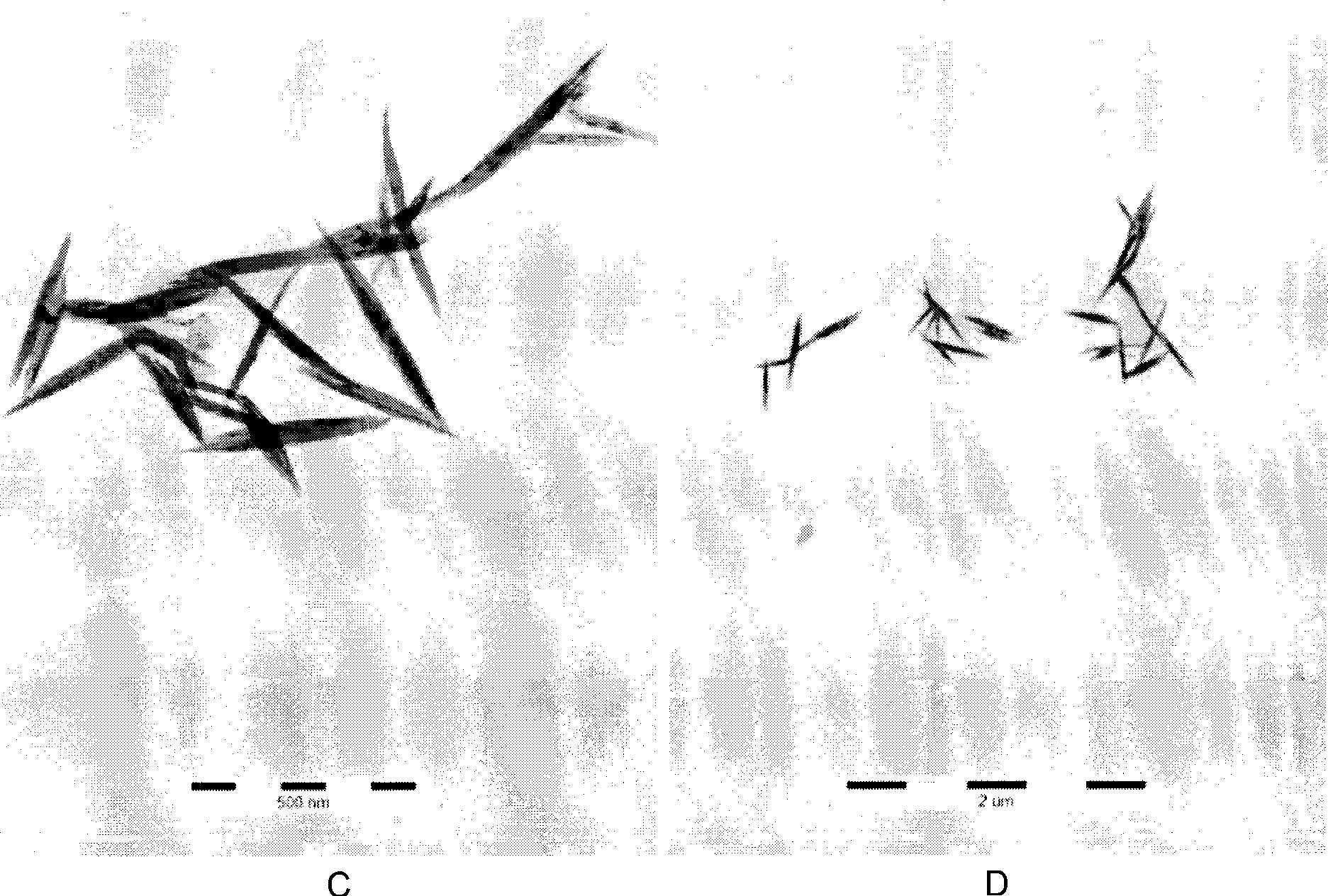

Embodiment 3

[0041] At normal temperature and pressure, take 1mL (the amount added can be adjusted in proportion according to actual needs) Na with Te of 4.62mmol / L 2 TeO 3 Aqueous solution (i.e. composed of solid Na 2 TeO 3 be prepared as an aqueous solution with a concentration of 4.62mmol / L), add glucose and ascorbic acid aqueous solution under stirring, and adjust the volume to 50mL with double distilled water (depending on the actual production requirements), the final reaction system is (mass fraction 1 %glucose+0.005mol / L Vc+93.2μmol / L Na 2 TeO 3 ). Heating at 60° C. for 6 hours (the length of time can control the growth of nano-tellurium, which can be adjusted according to the situation), the product is obtained, and the volume of the final sample can be prepared into different volumes according to different needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com