Preparation method of high-purity aluminum oxide ceramic

A high-purity alumina, alumina technology, applied in the field of ceramic materials, to avoid agglomeration, improve sintering effect, ensure the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

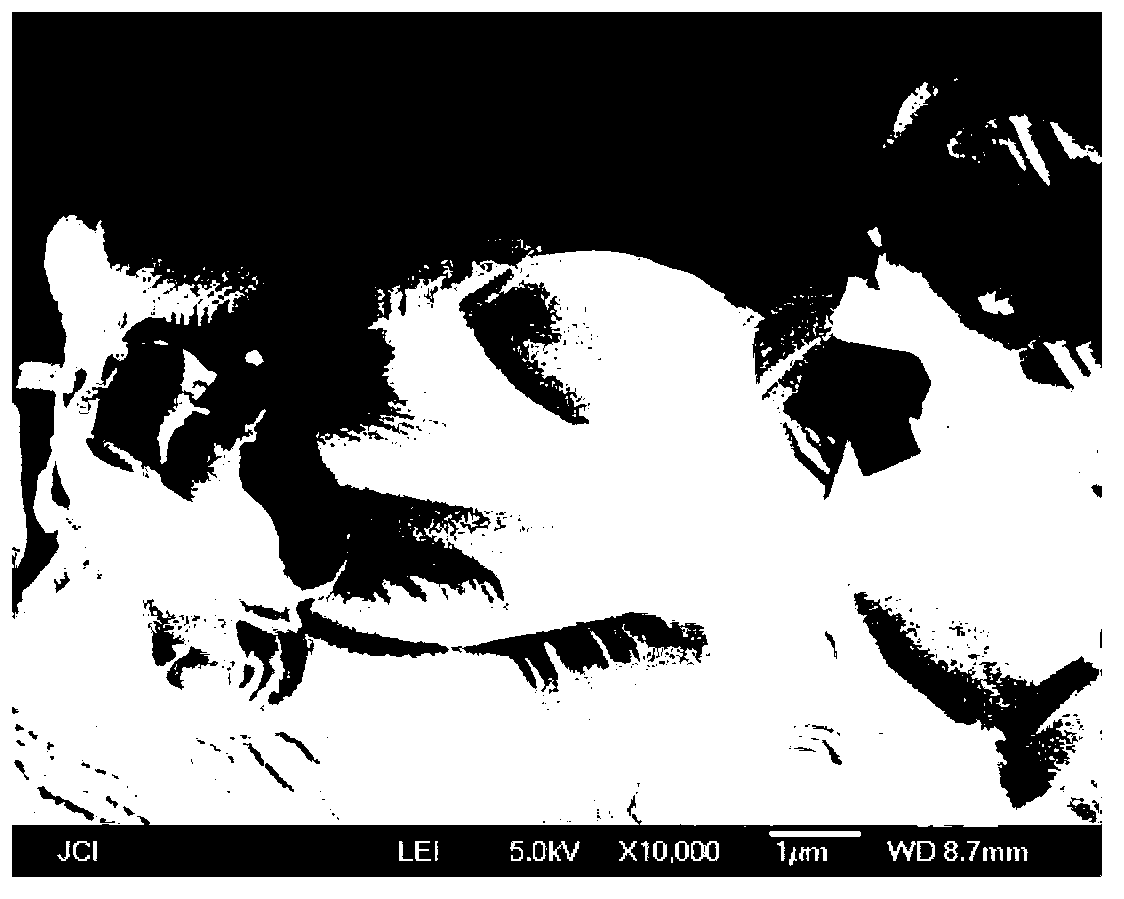

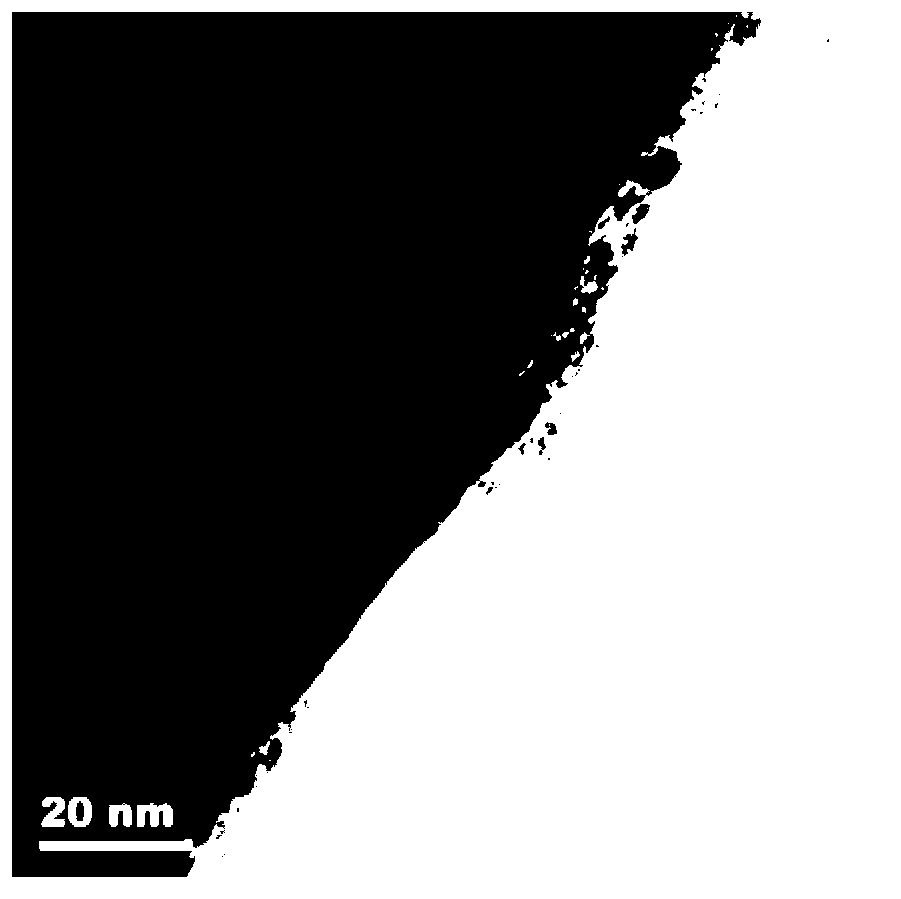

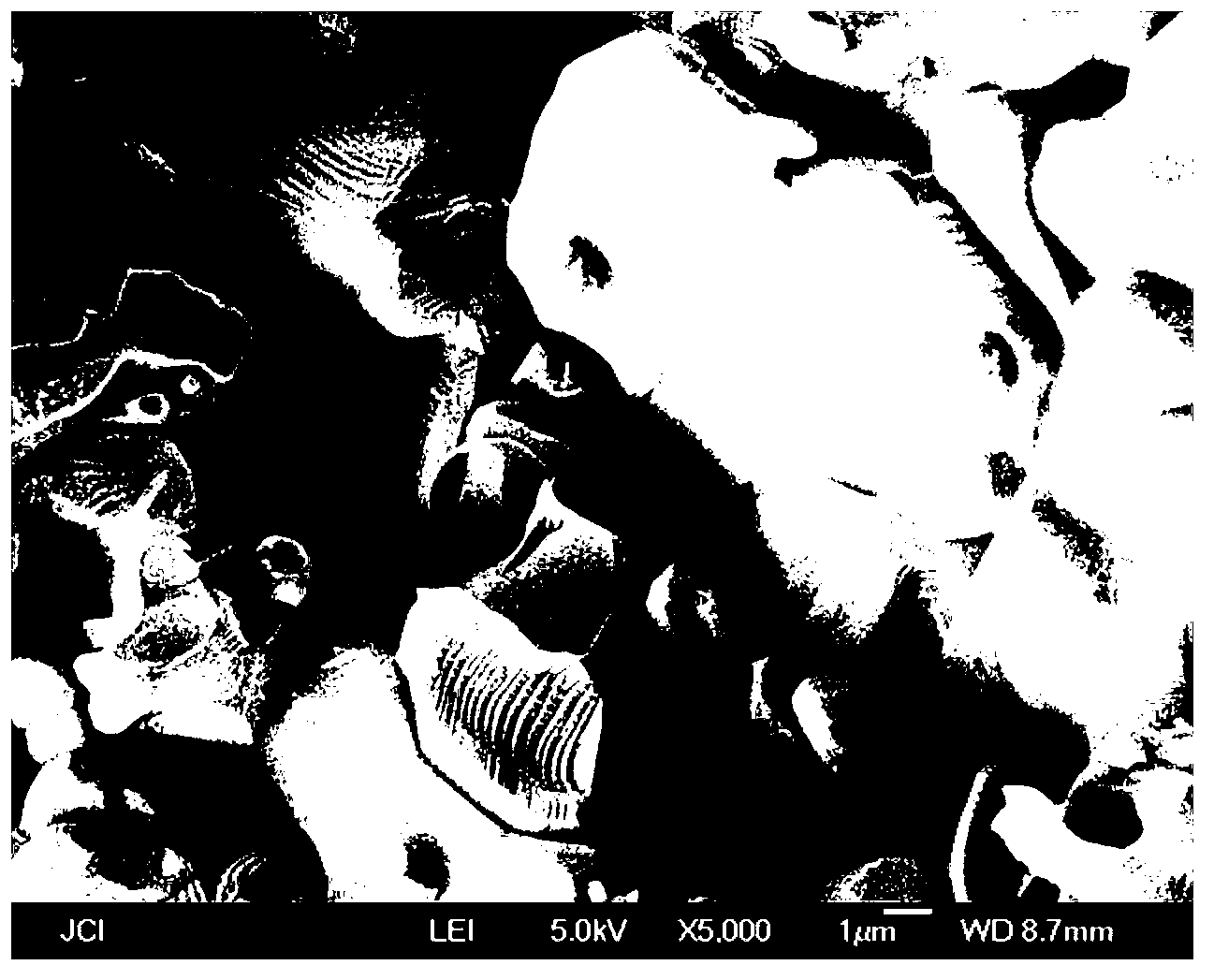

Image

Examples

Embodiment 1

[0028] A kind of preparation method of the present embodiment high-purity alumina ceramics, its steps are as follows:

[0029] (1) Get 20g aluminum isopropoxide and dissolve in 100ml xylene to form aluminum isopropoxide solution;

[0030] (2) Take 100g of alumina powder (W40, with an average particle size of 40 μm) and stir and mix with the above-mentioned aluminum isopropoxide solution to obtain a mixed suspension;

[0031] (3) Put the above mixed suspension in a hydrothermal reaction kettle, and treat it at 150° C. for 10 hours; then remove the upper layer solution of the mixed suspension to obtain the alumina slurry at the bottom;

[0032] (4) Dry the above alumina powder slurry in an oven at 100°C, then heat it up to 800°C in a muffle furnace at a rate of 3°C / min for calcination, and keep it warm for 2 hours to obtain pretreated alumina powder body;

[0033] (5) Add 2wt%PVA to the above-mentioned pretreated alumina powder, dry press molding under a pressure of 6Mpa, and ...

Embodiment 2

[0036] A kind of preparation method of the present embodiment high-purity alumina ceramics, its steps are as follows:

[0037] (1) Get 20g aluminum isopropoxide and dissolve in 100ml xylene to form aluminum isopropoxide solution;

[0038] (2) Take 90g of alumina powder (W40, with an average particle size of 40μm) and 10g of alumina powder (W1, with an average particle size of 1μm) and mix them uniformly by ball milling to obtain a mixed alumina powder, and then mix it with the above-mentioned aluminum isopropoxide The solution is stirred and mixed to obtain a mixed suspension;

[0039] (3) Put the above mixed suspension in a hydrothermal reaction kettle, and treat it at 180° C. for 8 hours; then remove the upper layer solution of the mixed suspension to obtain the alumina slurry at the bottom;

[0040] (4) Dry the above alumina powder slurry in an oven at 100°C, then heat it up to 750°C in a muffle furnace at a rate of 3°C / min for calcination, and keep it warm for 2 hours to ...

Embodiment 3

[0044] The difference between the preparation method of a kind of high-purity alumina ceramics in this embodiment and the first embodiment is that:

[0045] In step (2), the alumina powder is 120g; in step (5), methyl cellulose, tung oil, glycerin, and water are added to the pretreated alumina powder, and a suitable The mud material is extruded to obtain a round tube (or cylindrical, multi-channel tube); then calcined at a temperature of 1650 ° C and kept for 2 hours to obtain a high-purity alumina rod (tube).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com