Method for treating surplus sludge, compost product and application

A technology for excess sludge and composting, applied in the direction of sewage/sludge fertilizer, application, special treatment targets, etc., can solve the problems of limited earthworm function, unsatisfactory compost stabilization effect, and long-term and efficient earthworm composting. Achieve the effect of improving the stabilization effect, improving the degree of humification, and facilitating the treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

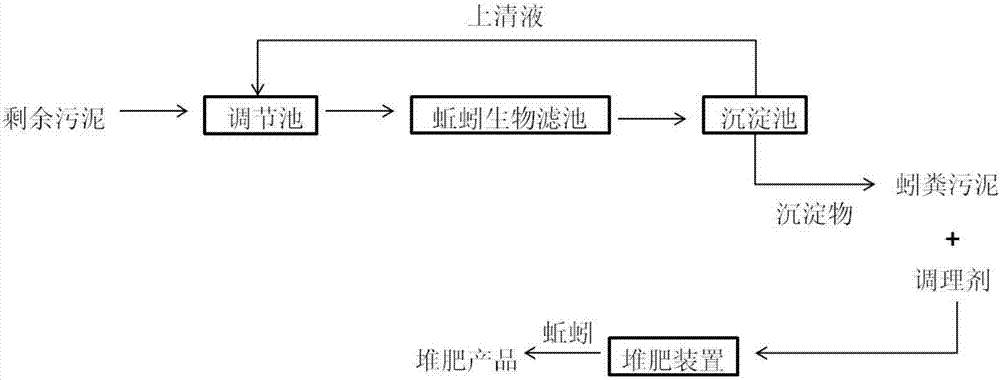

[0085] Example 1: A method for treating excess sludge

[0086] The method for treating excess sludge in this embodiment includes the following steps:

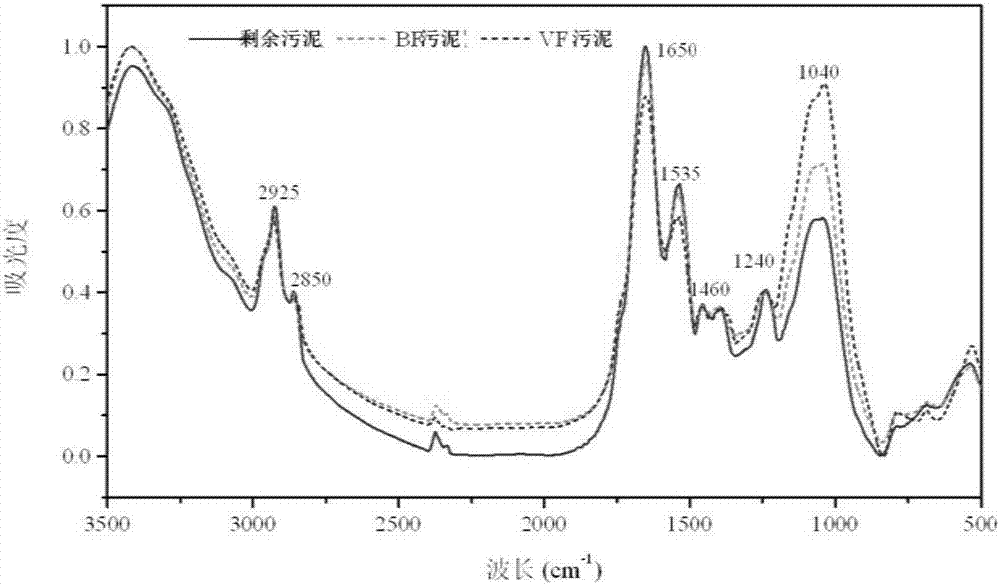

[0087] (1) After adjusting the concentration of the remaining sludge through the adjustment tank, the concentration of the remaining sludge is 395mg / L, and the hydraulic load is 4.0m 3 / (m 2 ·D), the organic load is 1.19kg·VSS / (m 3 ·D), pump into the earthworm biological filter tank, after treatment, drip filter into the sedimentation tank, the supernatant in the sedimentation tank is returned to the adjustment tank, the sediment is concentrated, filtered and left to get the earthworm sludge, its moisture content 90%, organic matter content (TOC) is 268g / kg, pH is 6.83, conductivity (EC) is 2150us / cm, and C / N is 7.5;

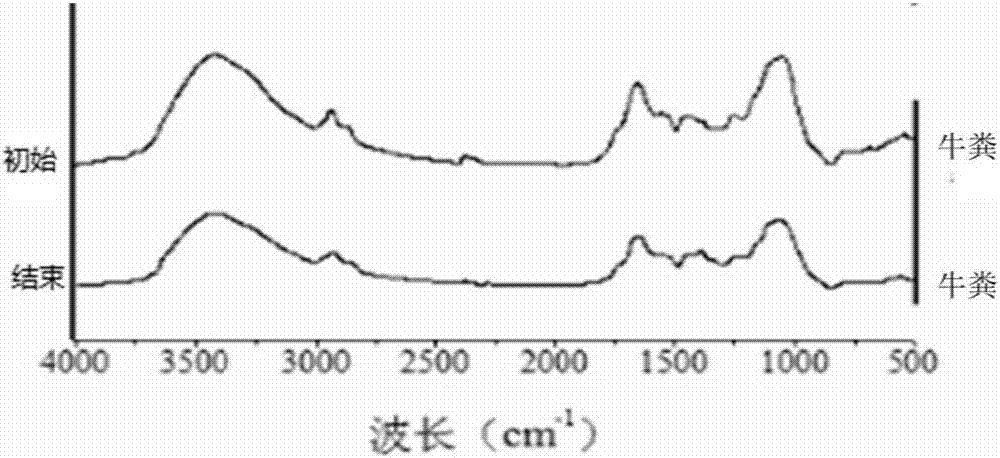

[0088] (2) After mixing the worm manure sludge with the conditioner cow manure in the composting device for 14 days, the moisture content of the cow manure is 21%, the organic matter content (TOC) is 347g / kg, the pH val...

Embodiment 2

[0093] Example 2: Composting device

[0094] The composting device of this embodiment includes: a lid and an open container which are sequentially arranged from top to bottom, and the lid and the open container are detachably connected. Among them, the open container is a round cone-shaped container made of polyethylene plastic, with an upper mouth diameter of 20cm, a lower mouth diameter of 15cm, and a height of 15cm; the lid is evenly distributed with 6 through holes, and the bottom of the open container is evenly distributed with 4 Through holes, the density of through holes is 1.67 pcs / cm 2 , The hole diameter is 6 mesh; in addition, a layer of gauze is laid on the bottom of the open container after perforation.

[0095] In fact, the diameter of the upper mouth of the open container is within 20±3cm, the diameter of the lower mouth is within 15±1cm, the height is within 15±5cm, and the density of the through holes is 1.67±0.3 pcs / cm 2 Within the range, the aperture is within 6-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com