Digital type refrigerant quantitative charging-discharging machine

A digital, liquid-filling technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of refrigerant waste, complicated operation, high labor intensity, etc., and achieve easy portability, simple maintenance equipment, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

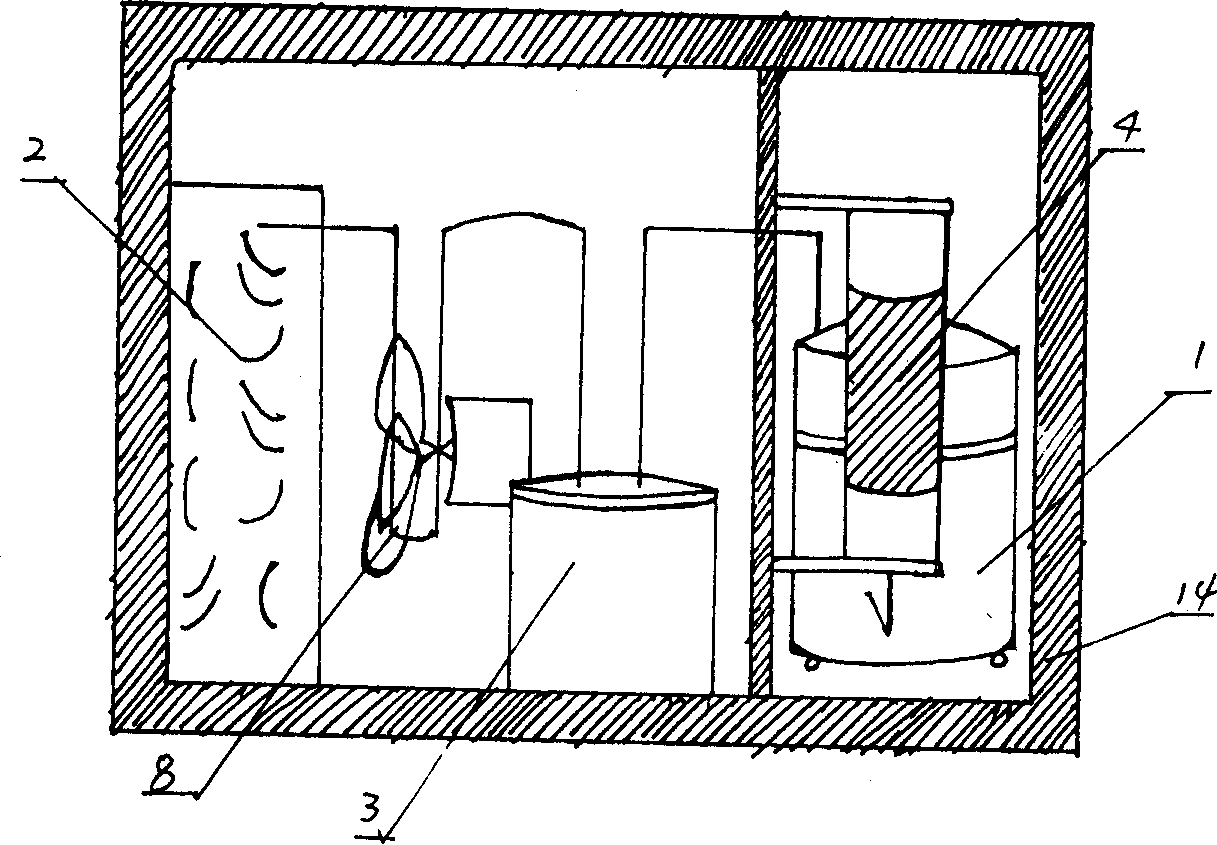

[0037] according to Figure 1-Figure 3 Shown, electric fan 8 is housed in the shell 14, pumping gas device and accurate quantitative pumping liquid device.

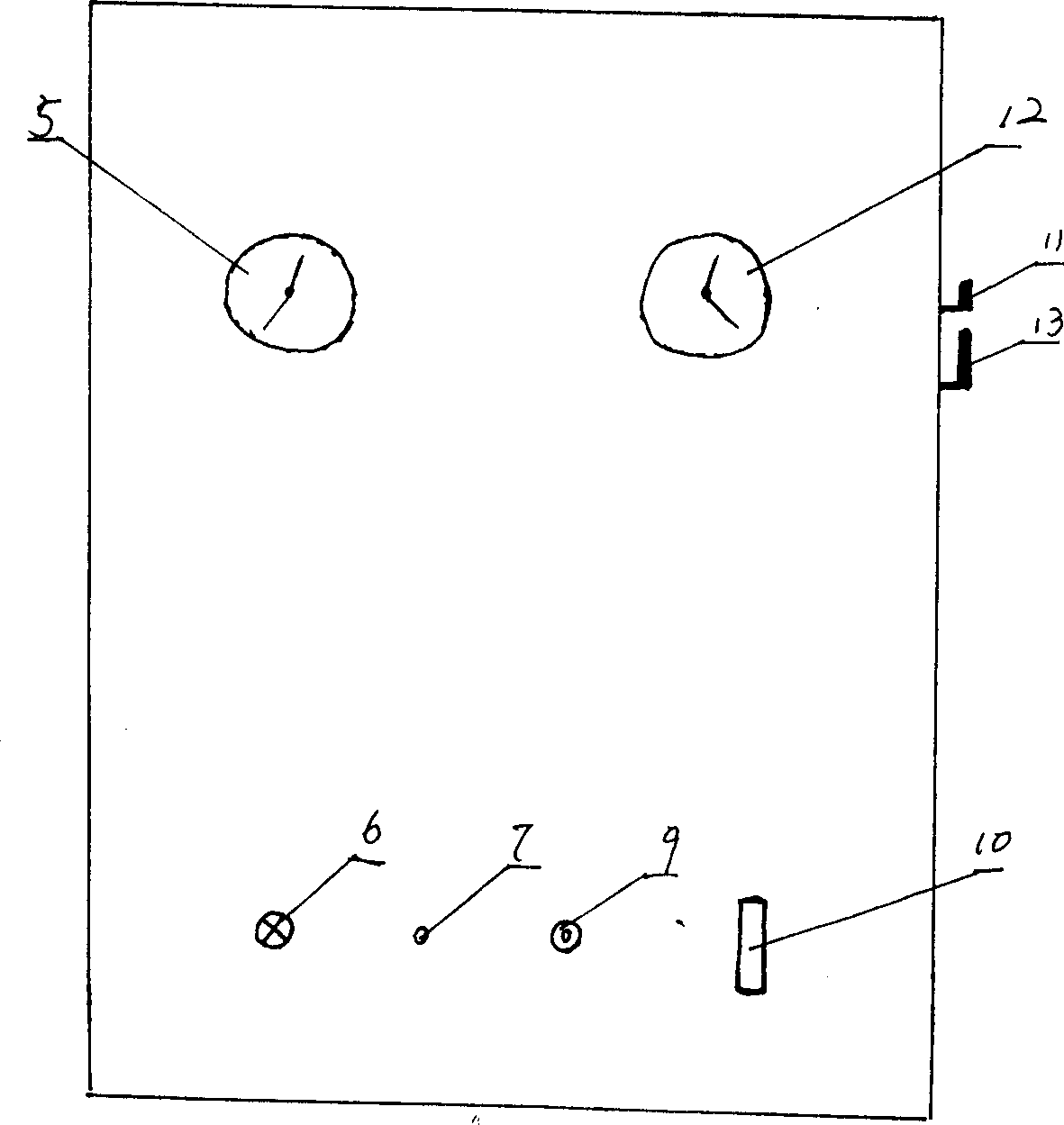

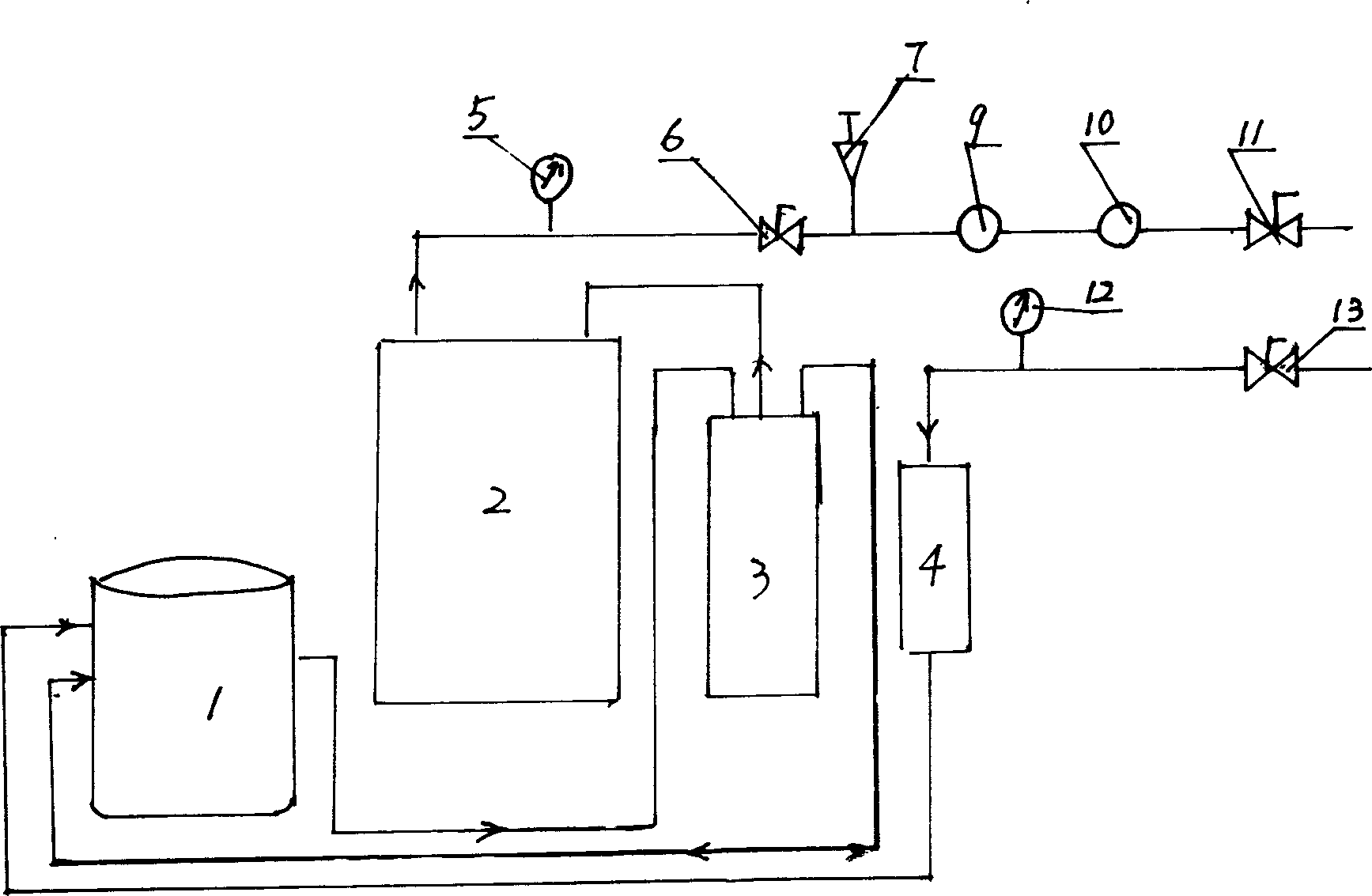

[0038] The pumping gas device includes: the inlet pipe of the compressor 1 is connected to the dry filter 4, the oil return pipe is connected to the oil-gas separator 3, the gas outlet pipe is connected to the oil-gas separator 3, the gas outlet pipe of the oil-gas separator 3 is connected to the gaseous state of the condenser 2 The pipes are connected, the liquid pipe of the condenser 2 is connected in series with the high pressure gauge 5 and the manual valve 6, and the dry filter 4 is connected with the low pressure pipeline, and the low pressure pipeline includes: the low pressure gauge 12 is connected with the low pressure valve 13.

[0039] The device for accurately quantitatively pumping irrigation fluid includes: a fluorine-adding valve 7, a sight glass 9, a digital flowmeter assembly 10, and a high-pressure valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com