Improved deep-water semi-submersible laying pipe floating crane

A semi-submersible and lifting vessel technology, applied in the direction of pipe-laying ships, hulls, hull decks, etc., can solve the problems of reducing the deck loading capacity in sailing conditions, the distance between the center of gravity and the center of buoyancy, and uneven thrust distribution. Achieve the effects of improving the variable load of the deck, facilitating equipment maintenance and purchasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

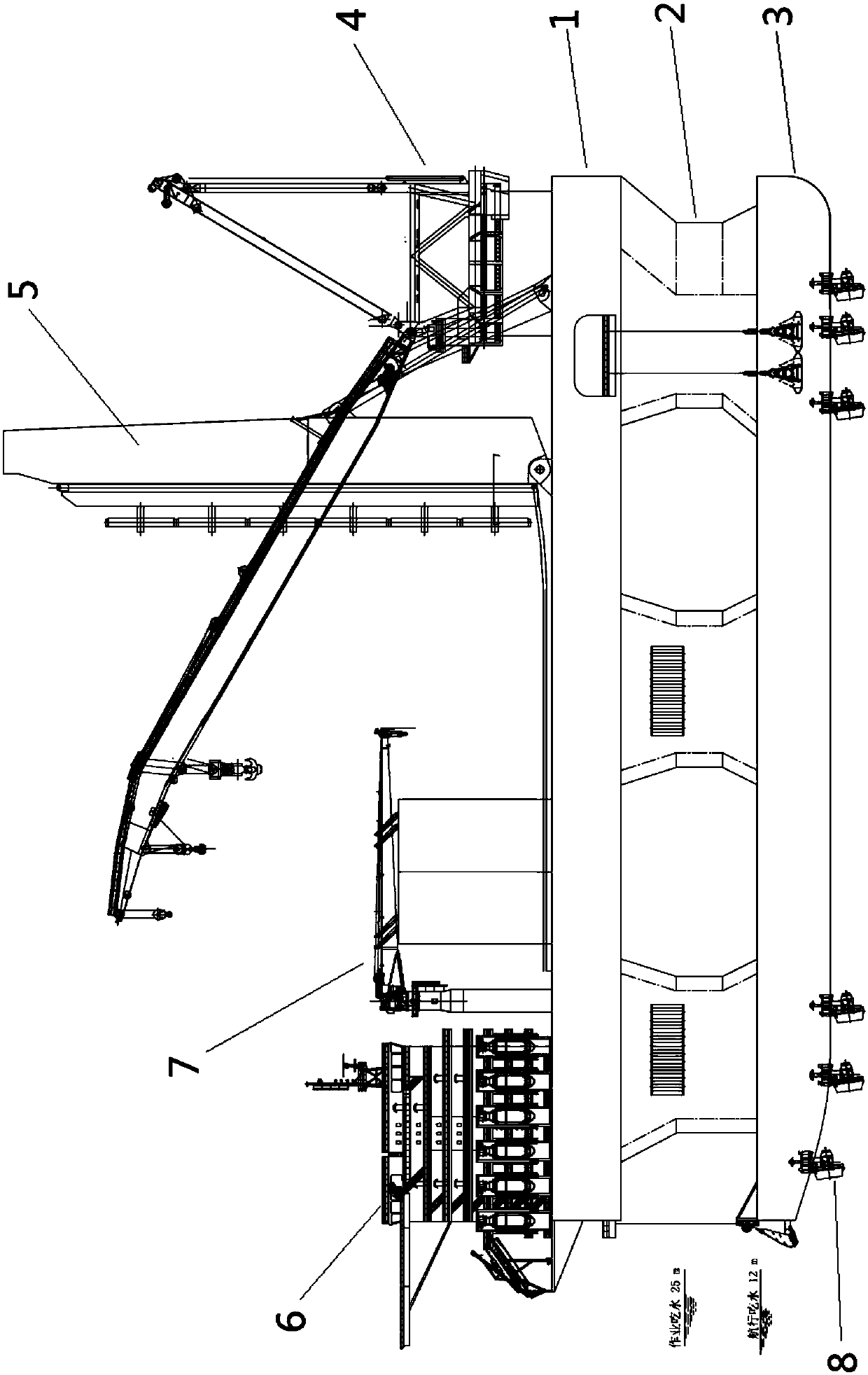

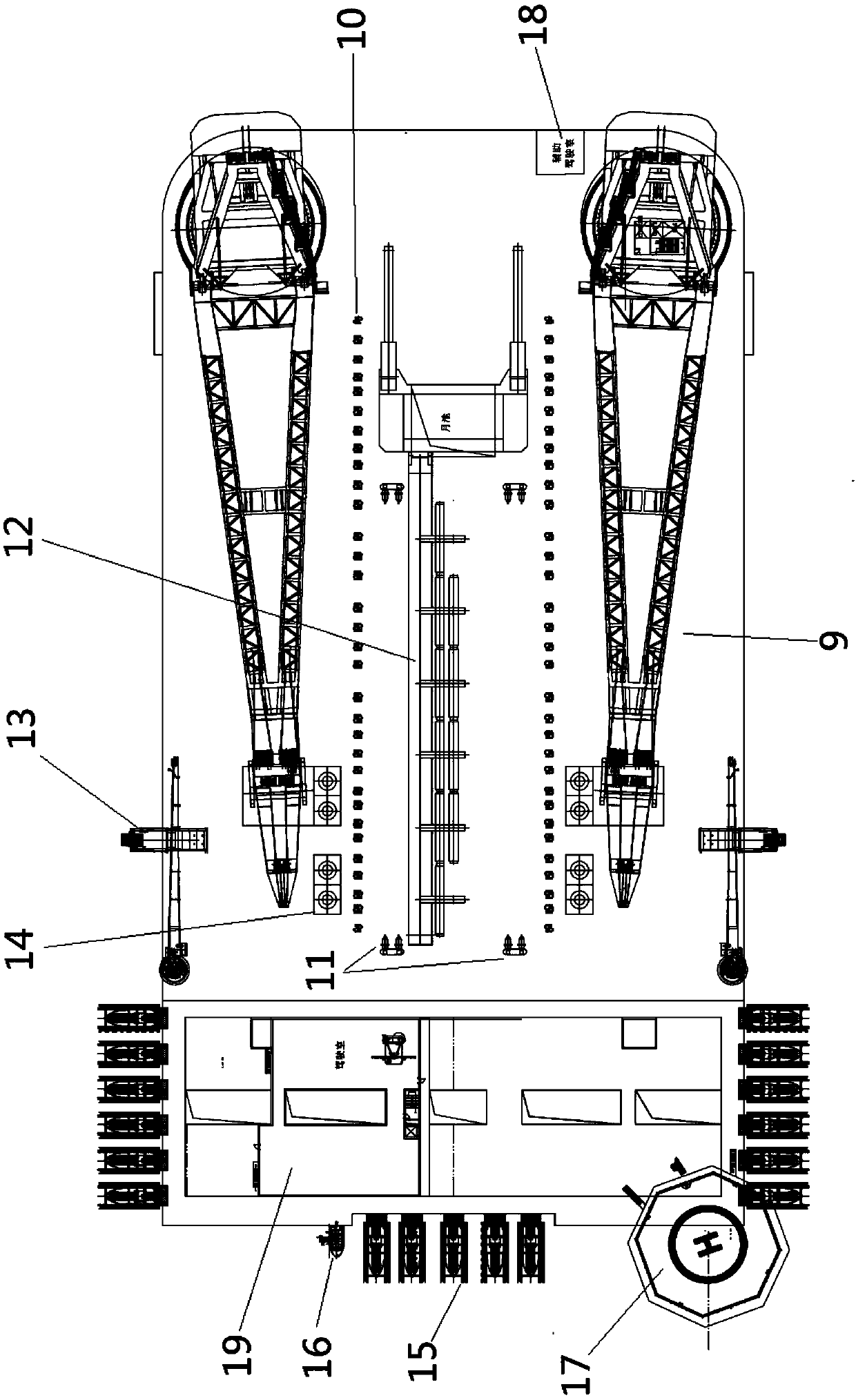

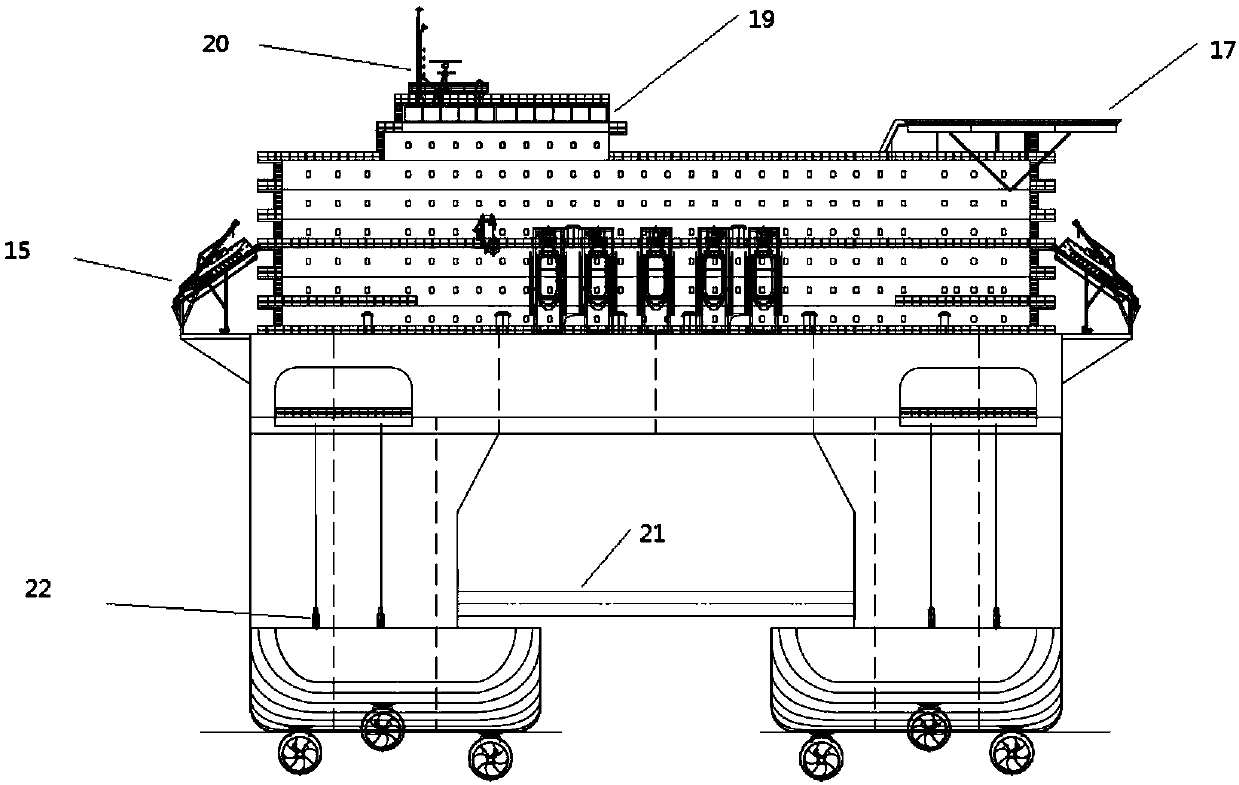

[0016] Such as Figure 1 to Figure 4 As shown, the improved deep-water semi-submersible pipe-laying crane ship of the present invention includes a main hull, which is composed of an upper floating body 1, a lower floating body 3, and a lower floating body and an upper floating body. It is composed of several columns 2 between them; it is characterized in that two main cranes 4 are arranged on the bow main deck of the upper floating body, a living building 6 is arranged at the stern of the upper floating body 1, and a J-shaped pipe laying tower 5 is arranged on the upper floating body 1 Near the middle of the bow, and the auxiliary cab 18 is set on the main deck of the bow of the floating body 1 .

[0017] Such as Figure 1 to Figure 4 As shown, the improved deep-water semi-submersible pipe-laying crane ship of the present invention, wherein: two main cranes 4 are arranged on the bow main deck of the floating body 1, and pipe stacking areas are respectively arranged under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com