Offshore Oilfield Natural Gas Compression Processing Jack-up Platform

A self-elevating platform and compression treatment technology, applied in water conservancy projects, artificial islands, floating buildings, etc., can solve the problems of small space area, large weight, and small variable load of the triangular main deck, so as to improve production efficiency and improve production efficiency. Product quality, large crew working space, and the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

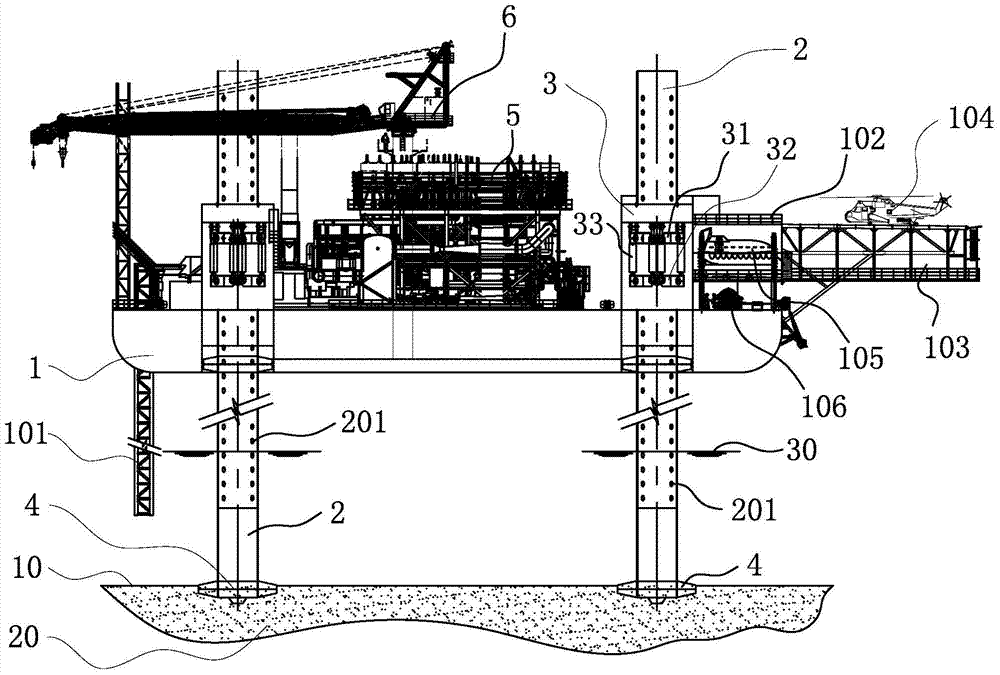

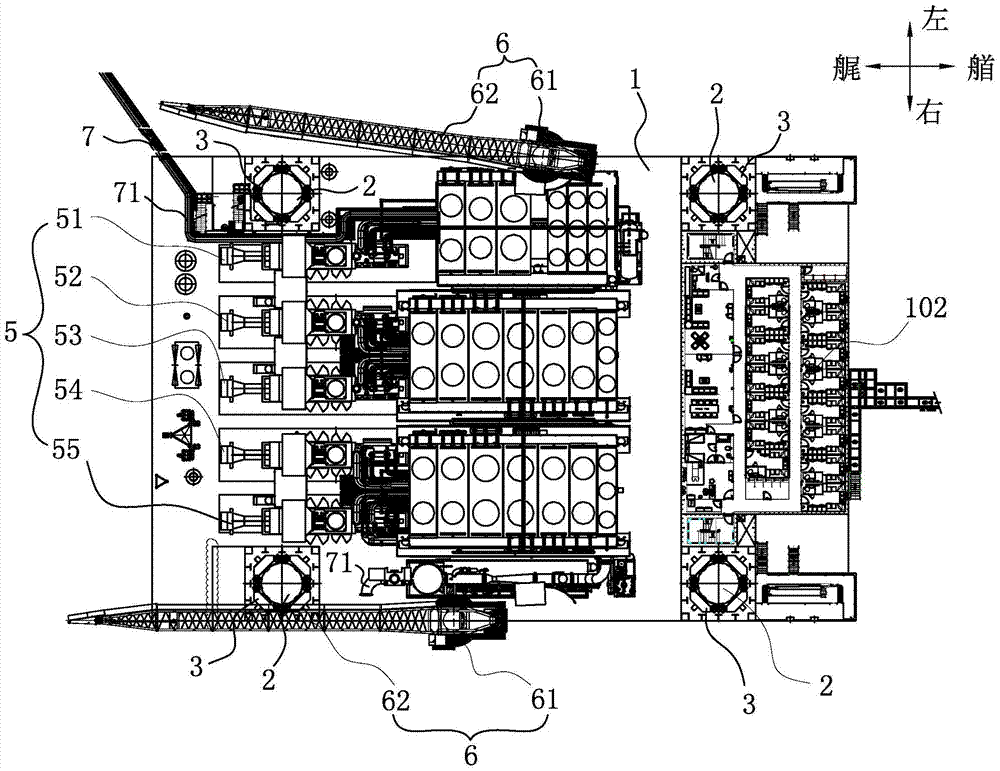

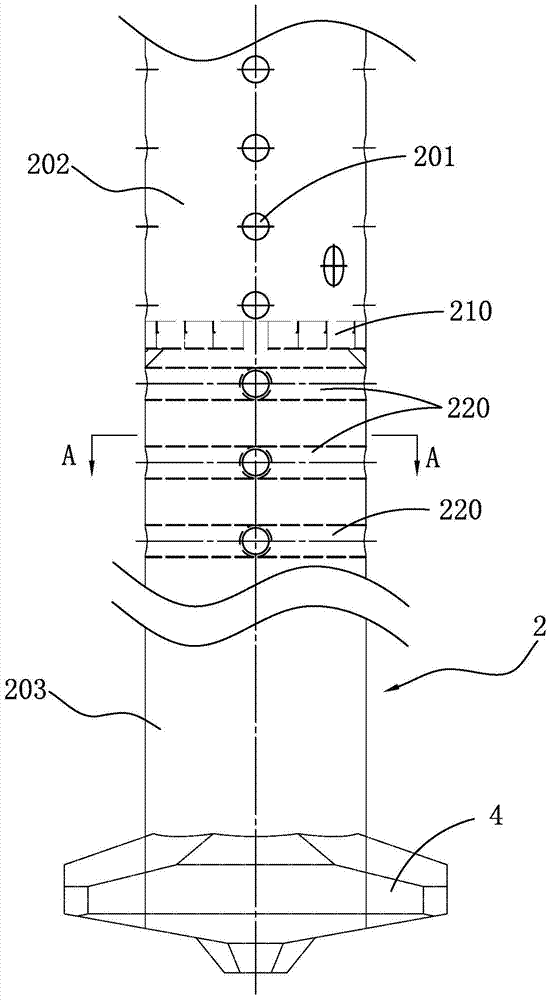

[0033] The invention provides a self-elevating platform for natural gas compression processing in offshore oilfields. The self-elevating platform belongs to mobile oil and gas production and processing equipment, and is used as an auxiliary platform for oil and gas processing and production to process oil and gas mixtures with an oil production platform. The jack-up platform is mainly used to compress and separate the natural gas in the oil-gas mixture, condense and store it, and then re-inject it into the subsea oil well after being pressurized by a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com