A cantilever beam moving and locking device

A locking device and cantilever beam technology, applied in floating buildings and other directions, can solve problems such as hidden safety hazards, large pushing force, metal adhesion, etc., achieve compact structure, reduce load bearing index, avoid damage and jamming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

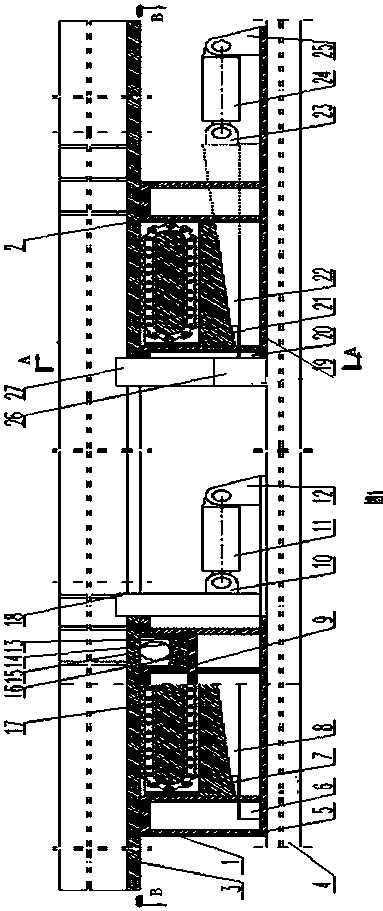

[0022] Now in conjunction with the accompanying drawings of the description, the present invention will be further described:

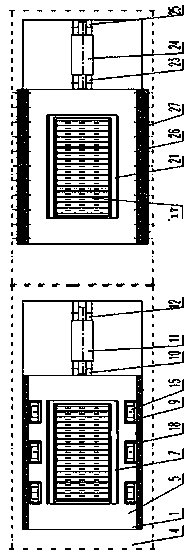

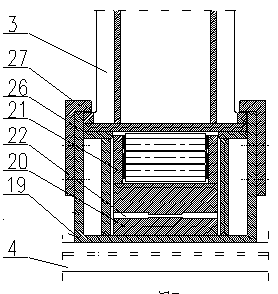

[0023] attached figure 1 with 2 , 3 provides a cantilever beam moving and locking device composed of two sets of cantilever beam moving mechanism monomers (also called monomers) and a set of locking mechanisms. The two sets of monomers have the same structure and are arranged on the platform body 4, the locking mechanism is fixedly connected to one side of the cantilever beam moving mechanism on the left side of the figure.

[0024] The left unit is composed of support I1, fixed seat I5, slide rail I6, upper wedge I7, lower wedge I8, earring I10, hydraulic cylinder I11, hydraulic cylinder bracket I12, roller carrier and roller I17, guide plate I18 . The right side unit consists of support II2, fixed seat II19, slide rail II20, upper wedge II21, lower wedge II22, earring II23, hydraulic cylinder II24, hydraulic cylinder bracket II25, roller carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com