Tension force leg drill platform

A drilling platform and tension leg technology, which is applied to buildings, artificial islands, underwater structures, etc., can solve the problems of high construction cost, bulkiness, and huge deepwater tension leg drilling platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

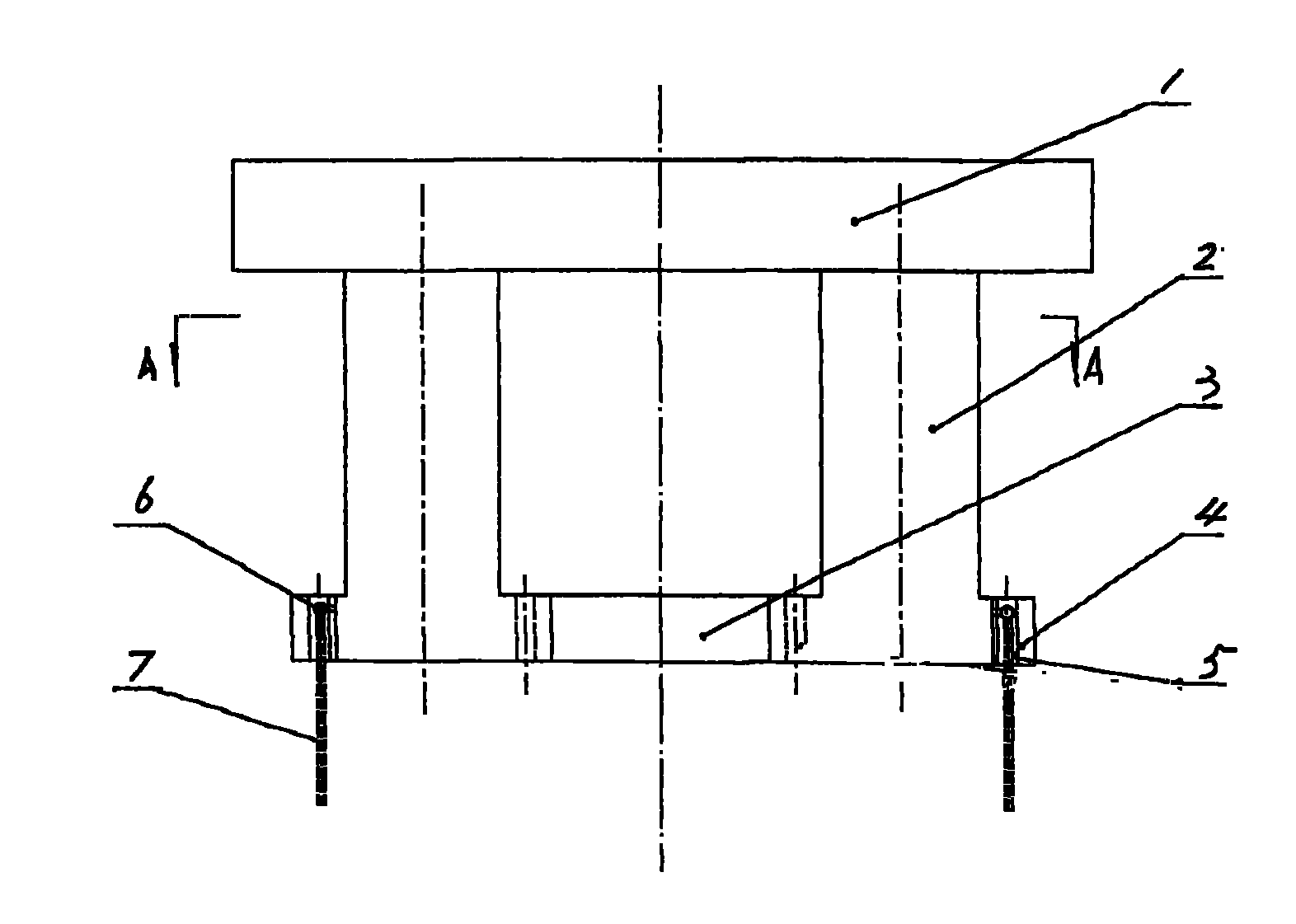

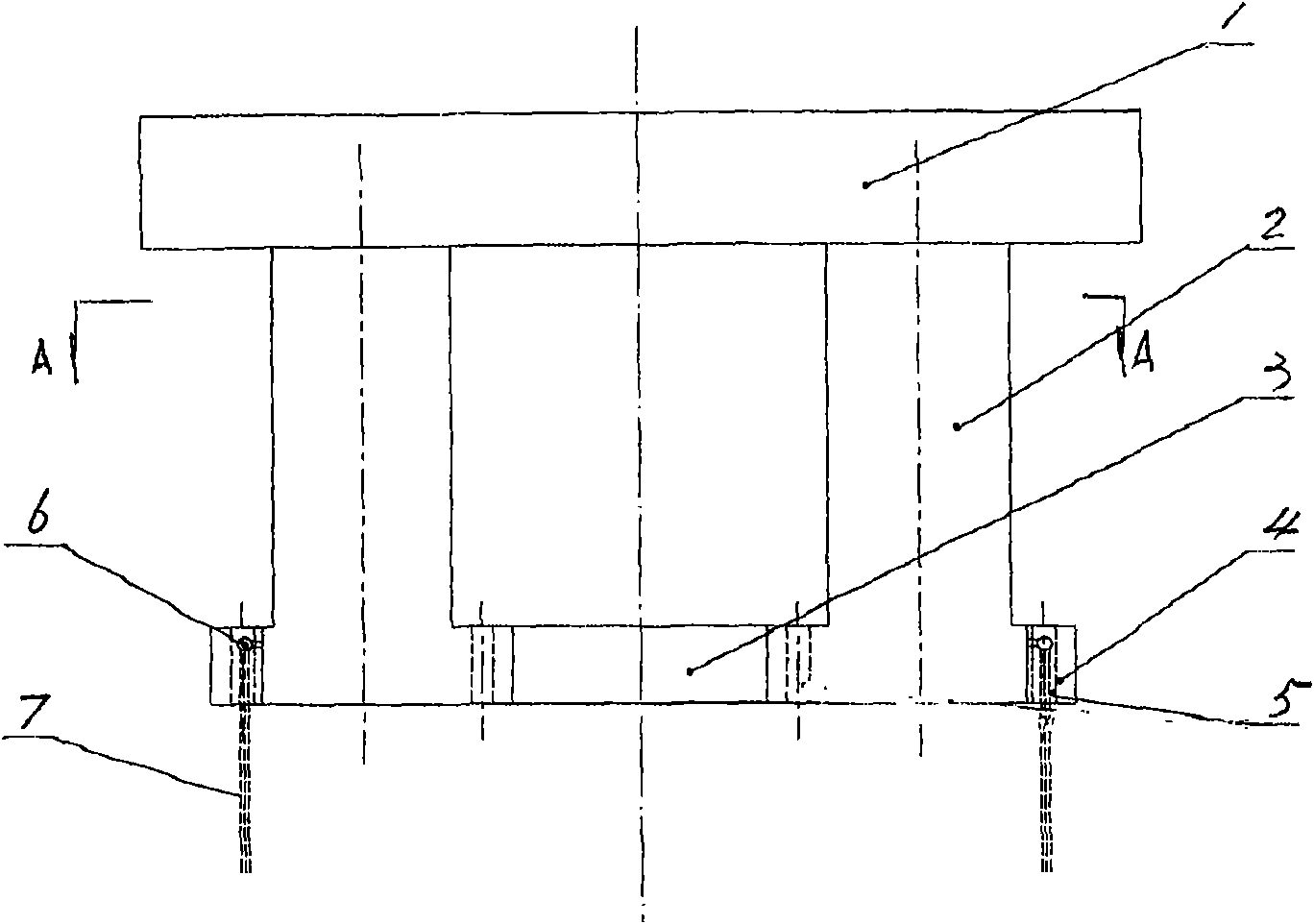

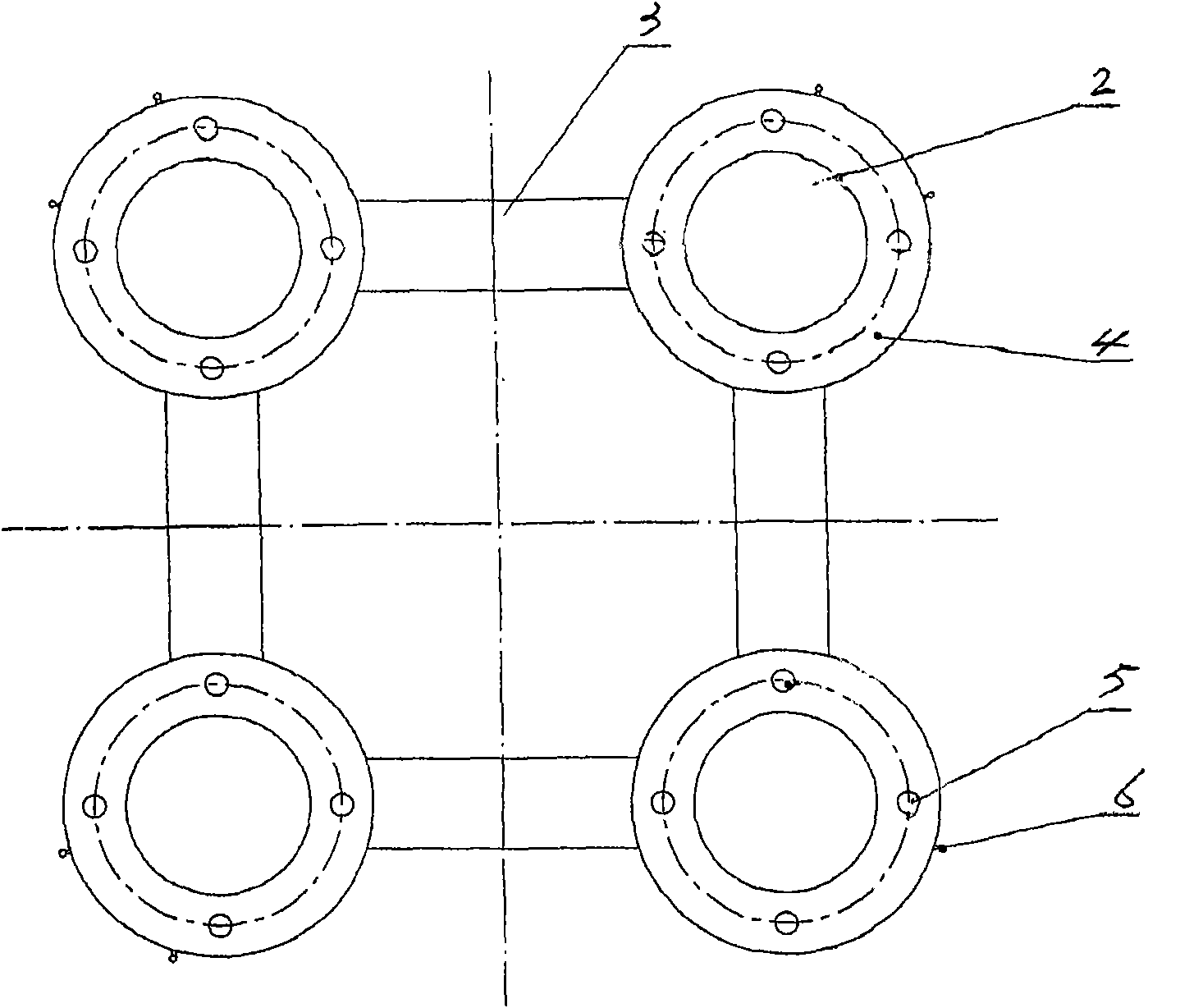

[0011] As shown in Fig. 1 and Fig. 2, the tension leg drilling platform of the present invention includes a superstructure 1, and the four corners of the superstructure 1 are all provided with pillars 2. The columns 2 are cylindrical, which are perpendicular to the upper and lower surfaces of the superstructure 1, and their upper ends are fixed to the four corners of the superstructure 1 respectively. A rectangular cross-section caisson 3 is provided between the lower ends of two adjacent upright columns 2, and a disc-type caisson 4 is installed between the lower end of each upright column 2 and the rectangular cross-section caisson 3 on both sides thereof. Connected with the rectangular cross-section caisson 3. Tension tendons 7 are arranged on the outer side of each upright column 2, and the upper and lower ends of the tension tendons 7 are respectively fixedly connected with the outer side of the lower end of the upright column 2 and the seabed base. Wherein, the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com