Fine iron powder pre-pressing-roller grinding system and method

A technology of iron fine powder and high-pressure roller mill, which is applied in the field of iron fine powder pre-pressing-roller mill system, which can solve the problem of material blockage and material collapse in the feed channel, affecting the pretreatment application of high-pressure roller mill, and the operation of high-pressure roller mill. Stability and other issues, to achieve the effect of improving the index of rolling products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

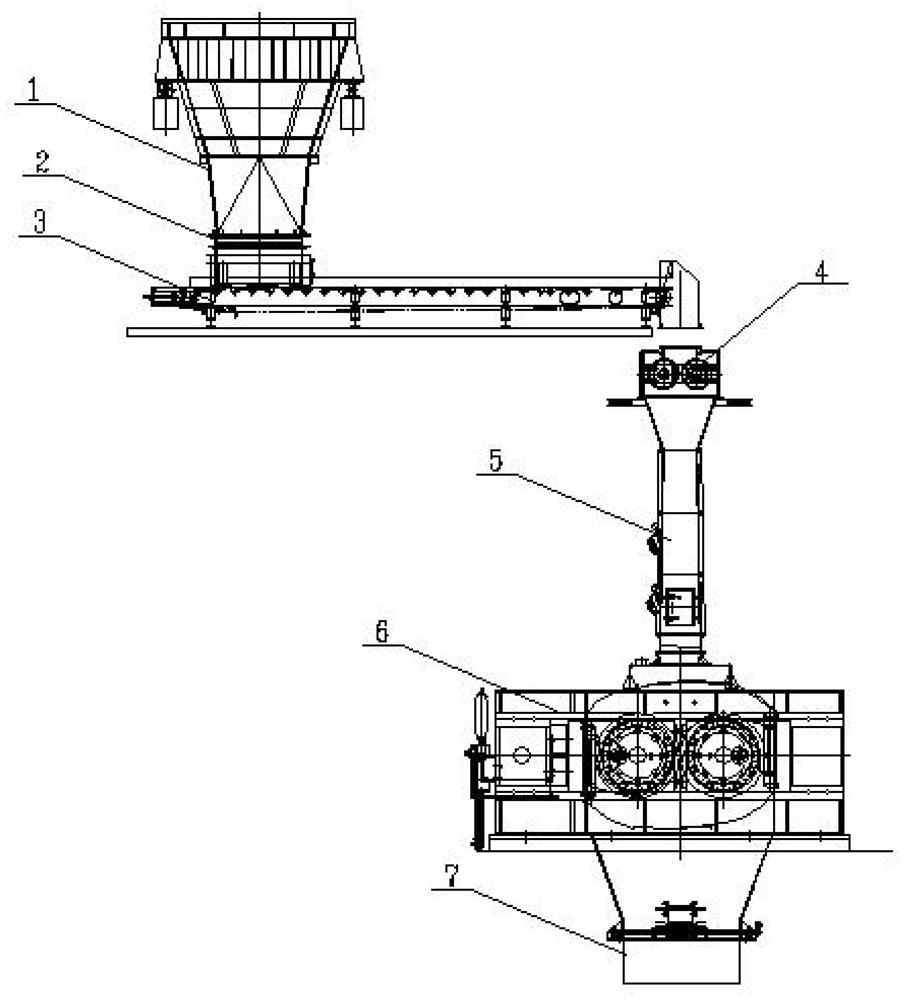

[0046] A kind of iron fine powder pre-pressing-roller milling system, such as Figure 1-4As shown, it includes a feeding system, a pre-press 4 and a high-pressure roller mill 6, and the high-pressure roller mill 6 is connected to the pre-press 4 for pre-compressing the material; the feed port of the pre-press 4 is connected to the material system, and the material supply between the material system and the pre-press 4 is linked with each other.

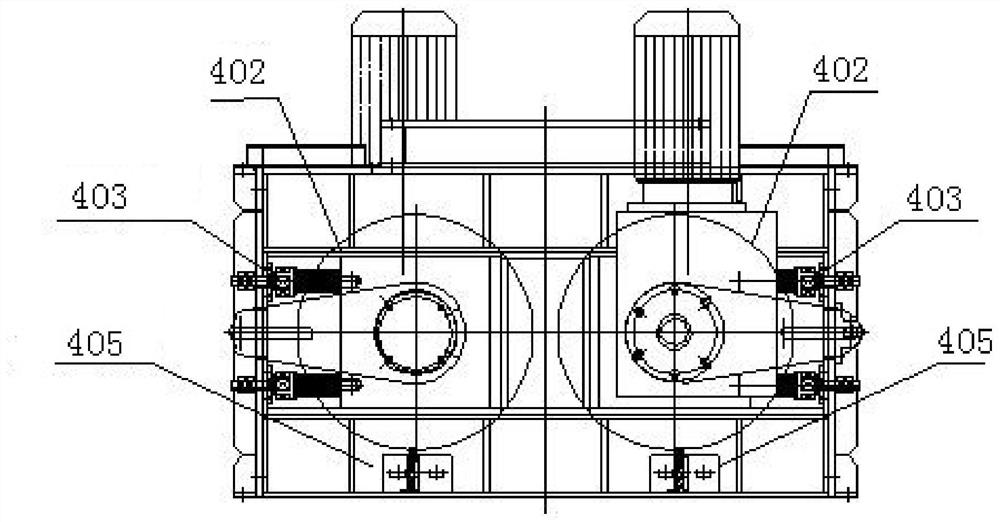

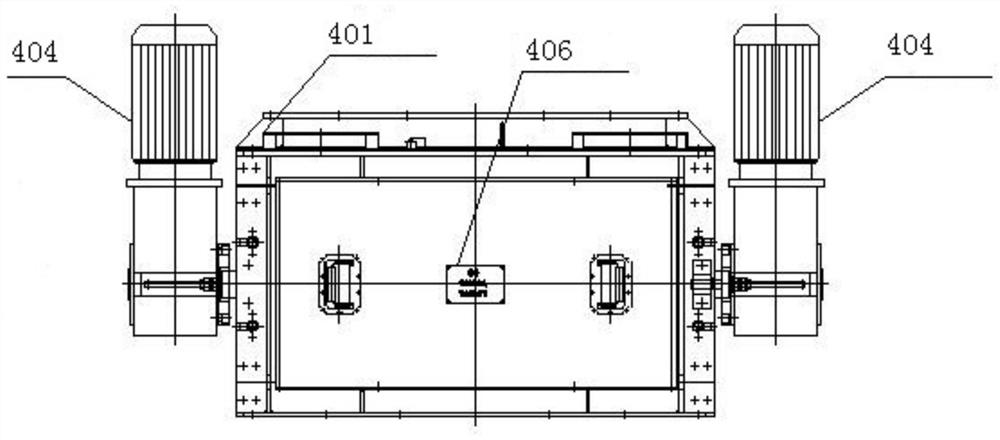

[0047] Described pre-pressing machine 4 comprises frame 401, cylinder 402, locking mechanism 403 and driving mechanism 404, and described cylinder 402 is horizontally arranged in the frame 401 in pairs, and forms roll gap between the cylinder 402 of pair; The roller 402 is provided with a locking mechanism 403 to prevent the displacement of the roller 402 , and the main shaft of the roller 402 is connected with a driving mechanism 404 for driving the roller 402 to rotate.

[0048] Frame 401 is processed by welding steel plates, and t...

Embodiment 2

[0066] A pelletizing plant in Panzhihua used the high-pressure roller mill process to frequently cause material blockage and material collapse, and the system operation was very unstable. After adopting the pre-pressing-roller milling process after modification, the overall operating efficiency is high; the product index is significantly improved, the -200 mesh content is only increased by 4-6%, and the specific surface area is increased by 300-600cm 2 .g -1 , The ball forming rate has increased by 3.30%.

Embodiment 3

[0068] A domestic pelletizing factory adopted the wet grinding process in the early stage, with high installed power and high power consumption; the process is long and the operating efficiency is low, the product index has not improved significantly, and the -200 mesh content has only increased by 1-2%. ;Using this pre-pressing-roller milling process to pretreat the raw materials of the pellets, and replace the wet mill. The installed power is reduced by more than half, the power consumption is significantly reduced, the process flow is shortened, and the overall operating efficiency is high. When the moisture content is 6.0%-7.0%, the particle size content of -0.074mm in the iron concentrate is lower than that after rolling. Increased by 4.53%, the specific surface area increased by an average of 402cm 2 .g -1 , The amount of bentonite is reduced by about 40%, which greatly improves the pelletizing performance of iron concentrate and improves the quality of green pellets. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com