Light shield

A sensor and shelf technology, applied in the field of accurate inventory level prediction, can solve problems such as lack of cost, lack of complex electronic components and equipment, defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

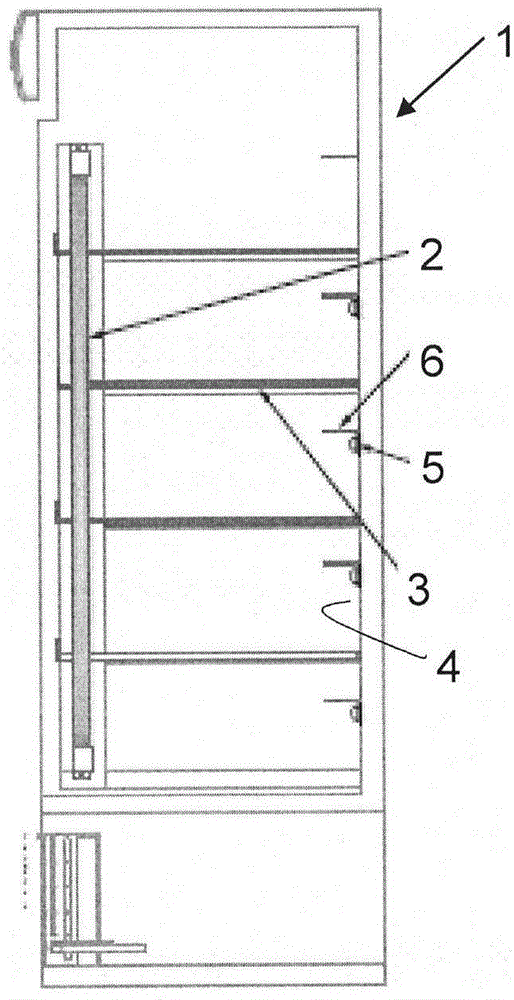

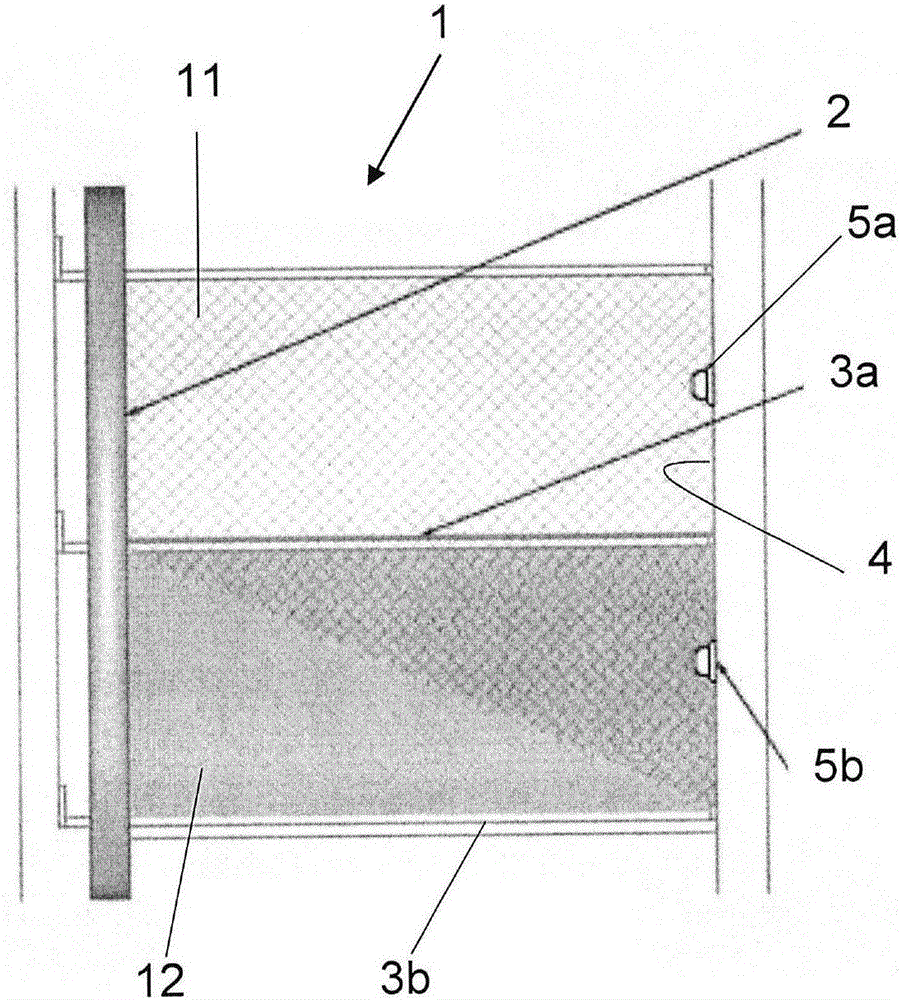

[0048] figure 1 A typical multi-shelf refrigerated beverage merchandising unit (RBMU) 1 is shown, comprising a light source 2 positioned at the front of the unit to illuminate a stack of four shelves 3 . Four photosensitive elements 5 are fixed to the rear wall 4 of the unit, with each sensor being located at an intermediate height between one shelf and the shelf above. Four sensor covers 6 are connected to the rear wall 4 over each sensor 5 such that each cover 6 provides a cover over each sensor 5 .

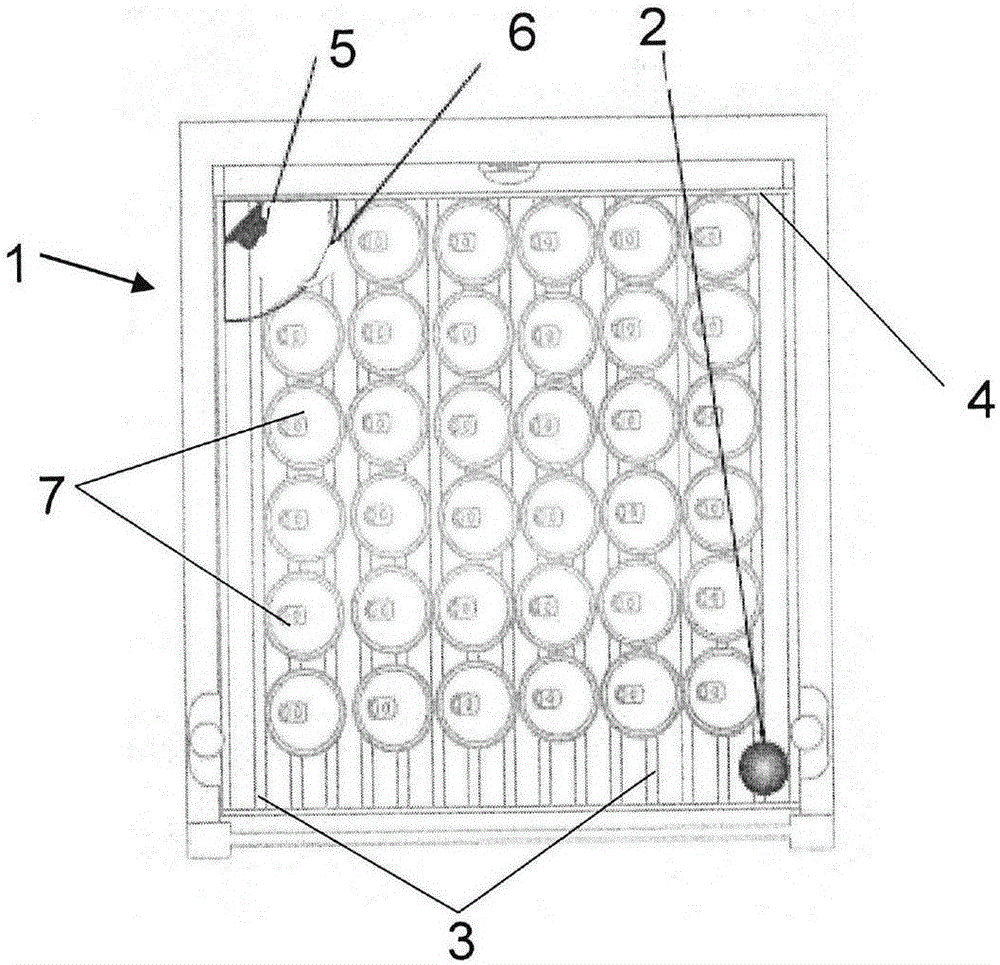

[0049] figure 2 The arrangement of sensors 5 and associated shrouds 6 on a fully stocked shelf 3 in RBMU1 is shown. Rack 3 is a slatted rack comprising a plurality of parallel bars running horizontally from the front of RBMU 1 to rear wall 4 . The shelf 3 is fully stocked with beverage cans 7 .

[0050] Light source 2 is located at the right front corner of RBMU1 and sensor 5 is located at the opposite corner. A shroud 6 , shown in outline and having a quarter circle, is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com