Device and method for measuring solid circulation flow rate

A circulating flow rate and measuring device technology, which is applied in the direction of mass flow measuring device, etc., can solve problems such as difficult to meet the measurement requirements of high solid circulating flow rate and high solid circulating flow rate, and achieve the effect of simple structure, large land occupation and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

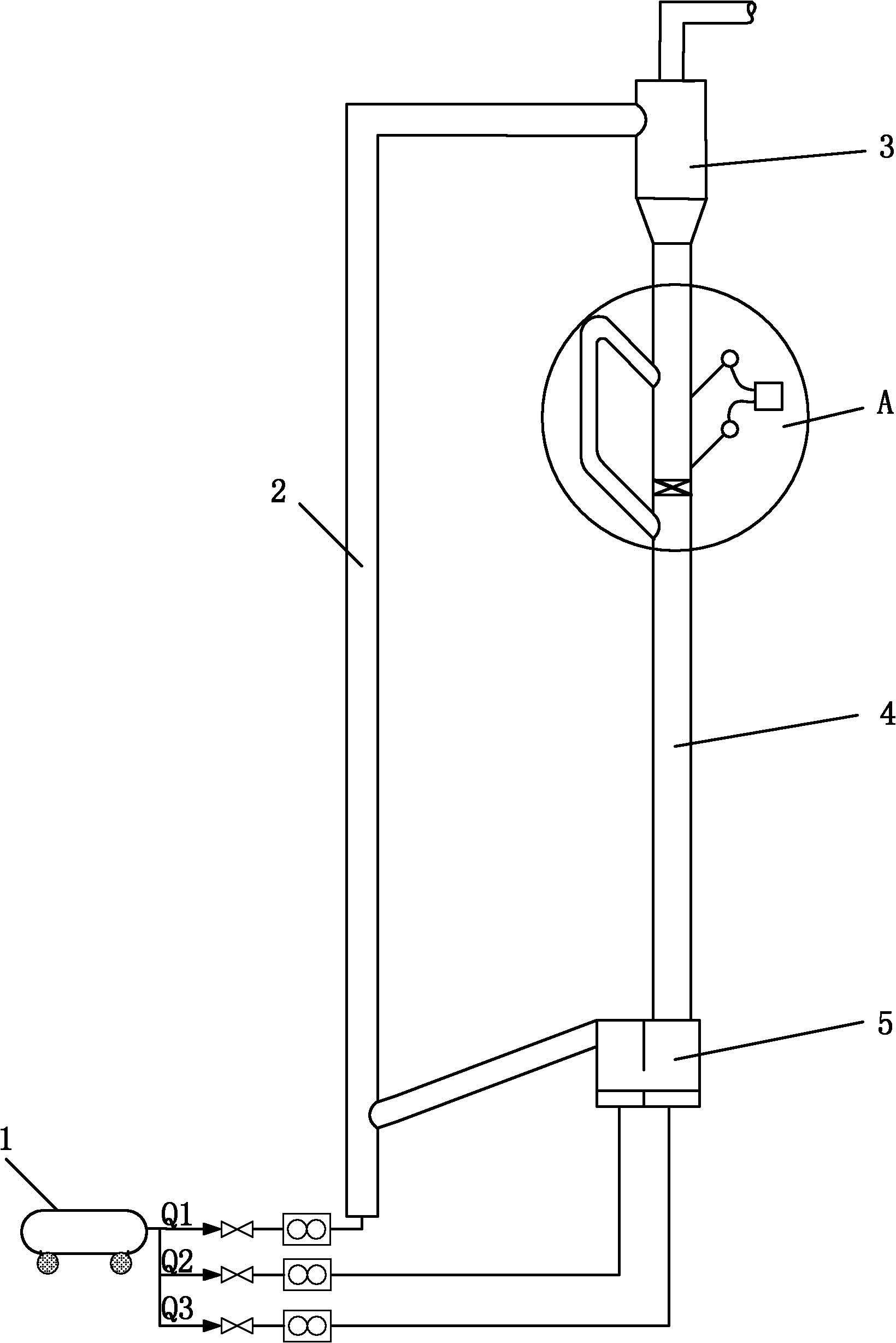

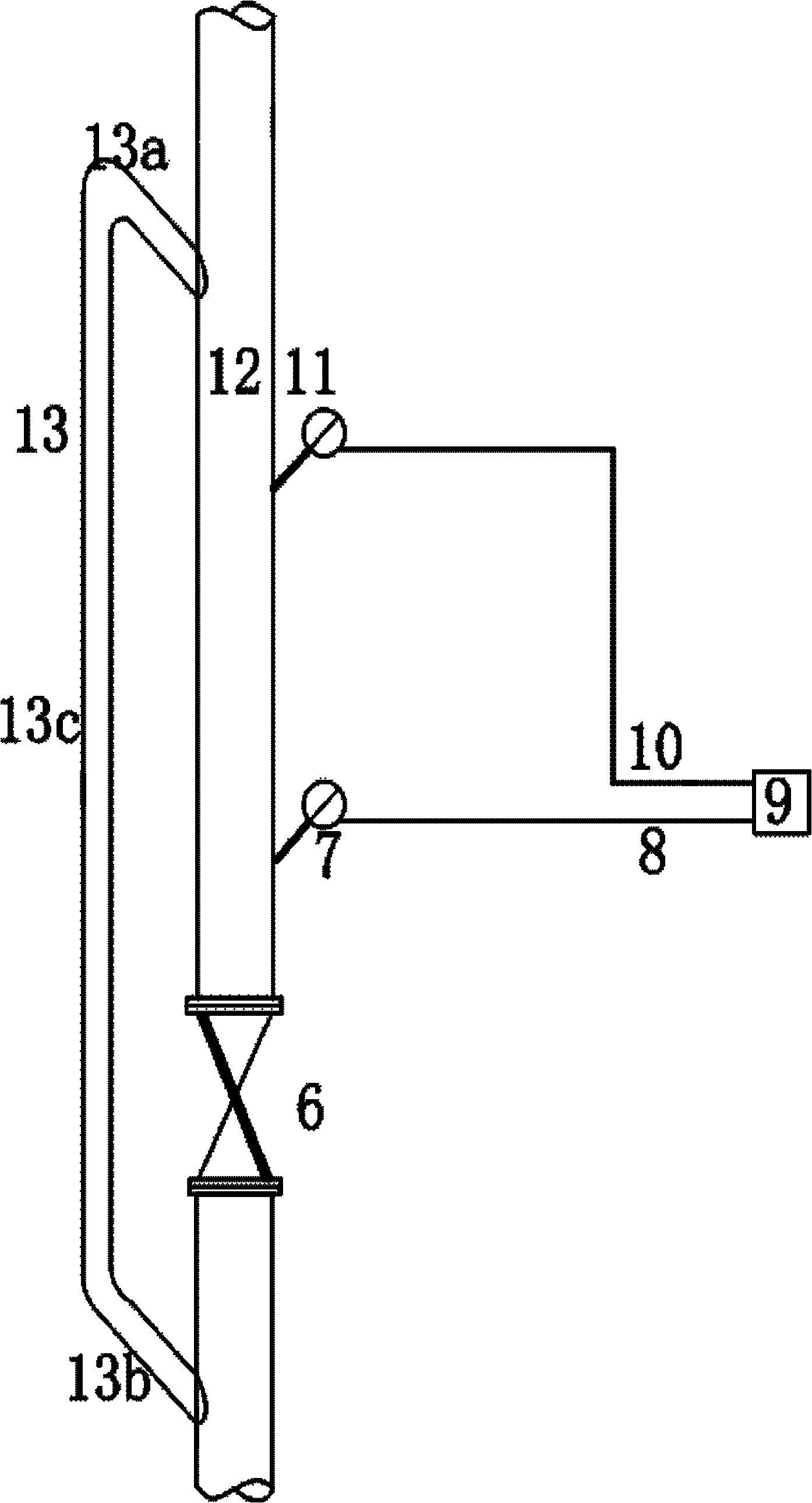

[0046] figure 1 It is a structural schematic diagram of a solid circulating flow rate measuring device of the present invention. A circulating fluidized bed is mainly composed of an air compressor 1, a riser 2, a cyclone separator 3, a material leg 4 and a feeder 5. Air compressor 1 is used as an air source, mainly providing three parts of air: Q1, Q2 and Q3. Q1 is used as the fluidizing medium of the riser 2, and Q2 and Q3 are used as the fluidizing gas and loosening gas of the feeder 5 respectively. Q1 fluidizes the solid particles in the riser and carries the solid particles through the cyclone separator 3. Through the gas-solid separation of the cyclone separator 3, the solid particles are discharged from the lower ash hopper into the dipleg 4, and the gas is discharged from the cyclone center tube. Q2 and Q3 make the solid particles enter the riser 2 from the dipleg 4 through the feeder 5 for circulation. The inner diameter of the riser 2 is Dr, and the accumulation an...

Embodiment 2

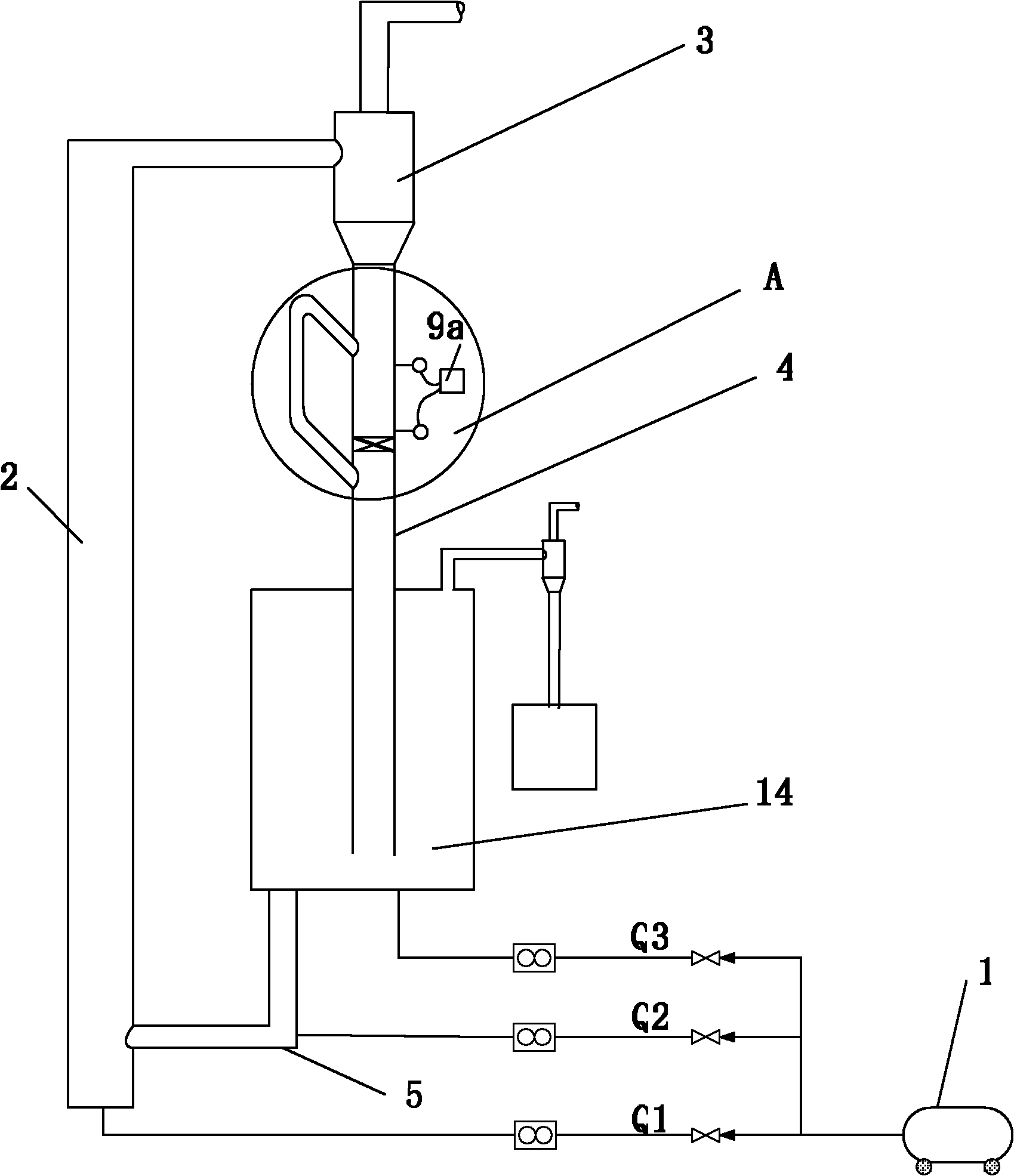

[0059] figure 2 It is another structural schematic diagram of a solid circulating flow rate measuring device of the present invention. A circulating fluidized bed is mainly composed of an air compressor 1, a riser 2, a cyclone separator 3, a material leg 4, a feeder 5 and a bubbling bed or a turbulent bed 14. The air compressor 1 is used as an air source, and mainly provides three parts of air, namely Q1, Q2 and Q3. Q1 serves as the fluidizing medium of the riser 2, and Q2 and Q3 serve as the return air of the feeder 5 and the fluidization air of the bubbling bed or turbulent bed 14, respectively. Q1 fluidizes the solid particles in the riser and carries the solid particles through the cyclone separator 3, through the gas-solid separation of the cyclone separator 3, the solid particles enter the bubbling bed or turbulent bed 14 from the lower end material leg 4 of the cyclone separator 3, Gas is discharged from the cyclone center cylinder. Q2 and Q3 make the solid particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com