Method for treating and preventing overcutting

A preventive method, the technology of springing the knife, applied in the field of mechanical processing, can solve the problems of unreasonable processing parameters, wear, and untimely discharge of iron slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

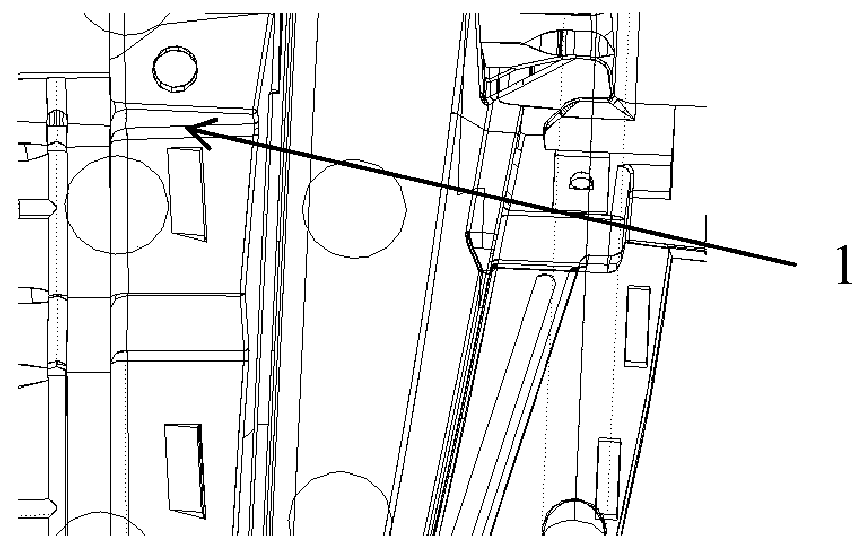

[0034] A method for treating and preventing knife snapping, comprising the following steps: the position where the knife snapping is likely to occur is the inner side of the boss shape, and the auxiliary surface is protected after roughening, so that the narrow area does not generate a tool track.

Embodiment 2

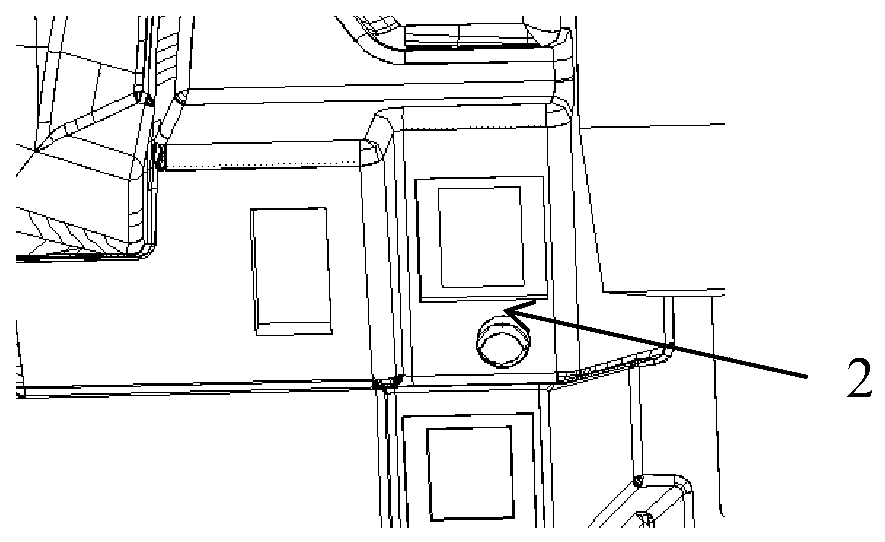

[0036] A method for treating and preventing the snapping of knives, comprising the following steps: the position where the snapping of knives is likely to occur is between the boss and the boss, the R between the boss and the boss is 0.5mm, and the middle light is cleared before the angle Use the R1 ball knife to make the thickness to a margin of 0.3mm, and then use the medium light to clear the corner to a margin of 0.1mm.

Embodiment 3

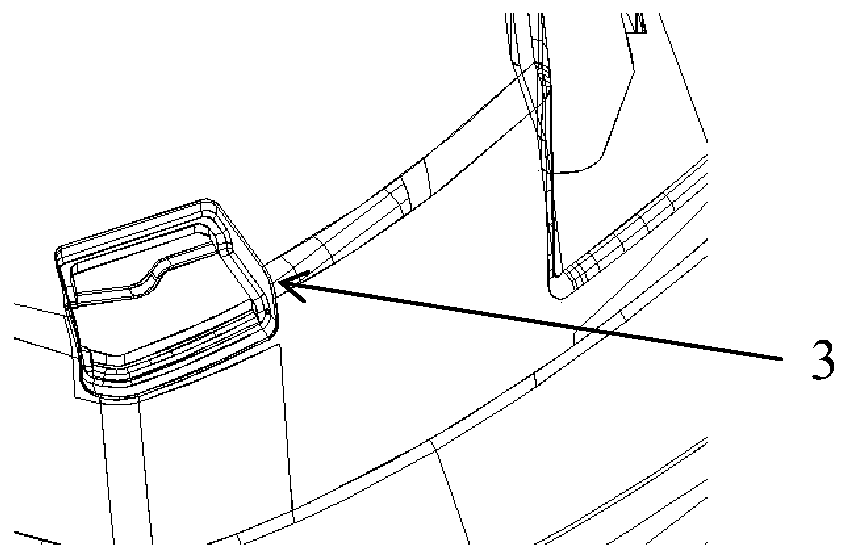

[0038] A treatment and preventive method for snapping knives, including the following steps: the position where the snapping knives are prone to occur is the side of the V-shaped groove, the auxiliary surface is protected first, and then EDM processing is performed. Coarse to a margin of 0.3mm, and then clear the corners to a margin of 0.1mm to keep the trimming range of the tool path consistent. After generating the tool path, delete the tool path on the side of the V-groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com