Antibiotic residue treatment and utilization technological method

A technology of antibiotic bacteria residues and bacteria residues, applied in the direction of combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of poor biodegradability, high energy consumption, high cost, etc., and achieve a high degree of reduction and reduction The effect of reducing the chemical cost and improving the utilization rate of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

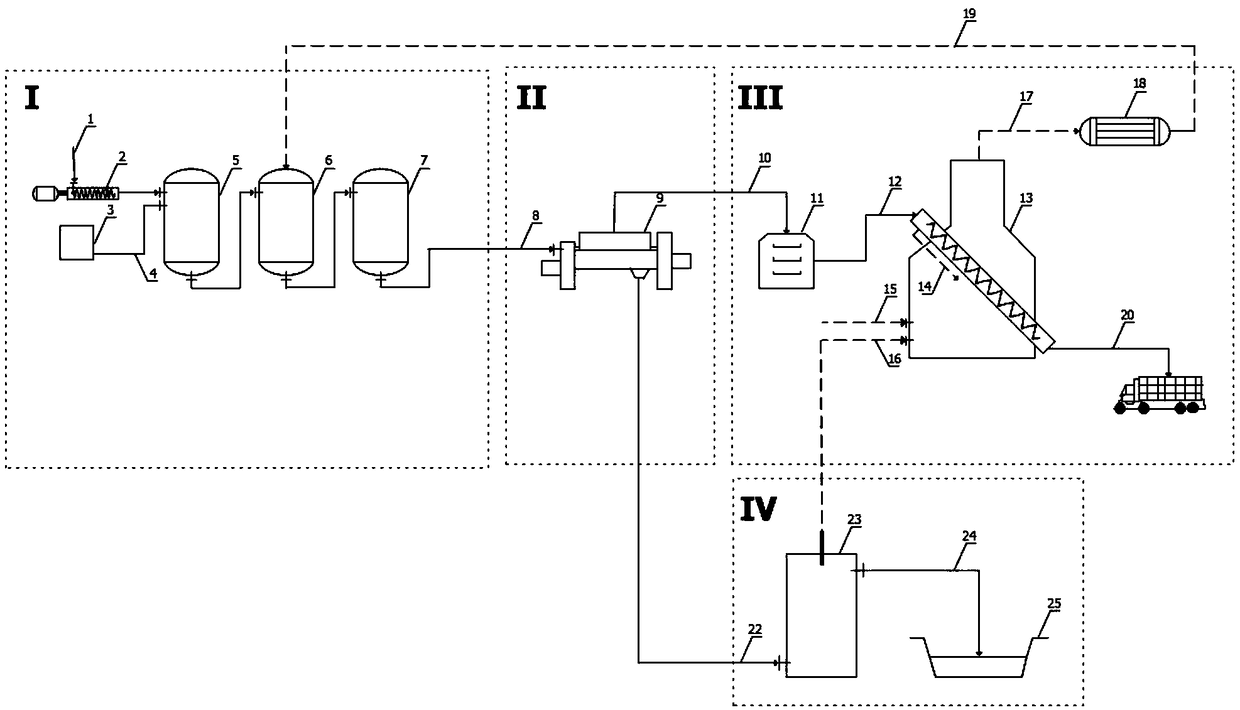

Method used

Image

Examples

Embodiment 1

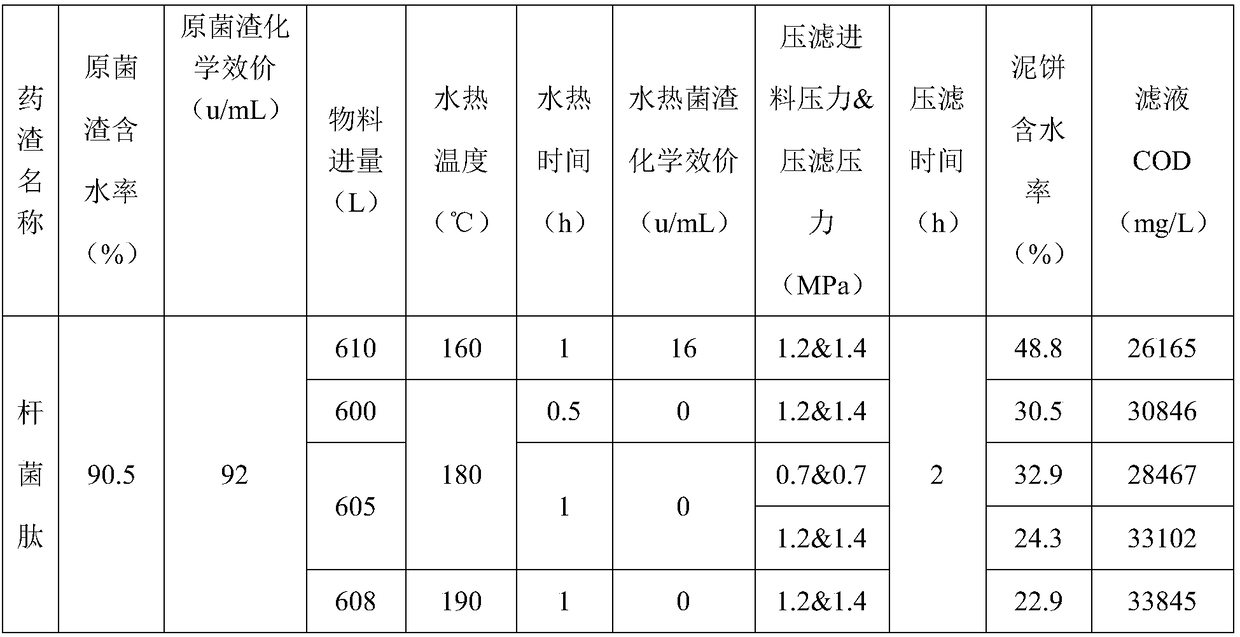

[0045] Coordinated with reference to the following table 1, the following table 1 is the comparison of the detection test data of bacitracin. .

[0046]

[0047] The moisture content of bacitracin residue is 90.5% (TS=95060mg / L, VS=82540mg / L, VS / TS=86.8%, SS=72373mg / L, VSS=59942mg / L, COD=115596mg / L, pH=4.0, Chemical potency = 92u / mL), without dilution during the slurry reaction period, it is directly passed into the hydrothermal reactor after being stirred evenly, and the slag is heated to 180°C by passing in 200°C, 1.6MPa saturated steam, and the reaction time is After 60 minutes, the colloid and cell structure in the bacteria residue were destroyed, and the water-heated bacteria residue was leaked into the flash tank, the colloid and cell structure in the bacteria residue were further destroyed, and the hydrothermal bacteria residue in the flash reactor was sampled for detection (TS =73444mg / L, VS=60519mg / L, VS / TS=82.4%, SS=48870mg / L, VSS=36740mg / L, COD=96740mg / L, pH=4.4...

Embodiment 2

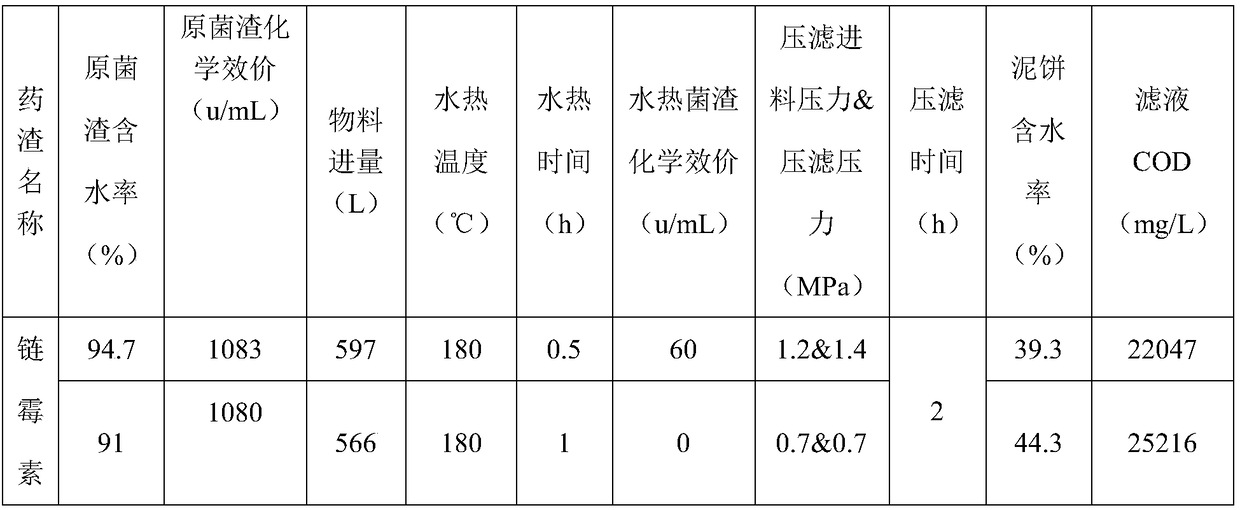

[0053] Referring to the following table 2, the following table 2 is a comparison of the detection test data for streptomycin.

[0054]

[0055] The moisture content of streptomycin residue is 94.7% (TS=53021mg / L, VS=43583mg / L, VS / TS=82.2%, SS=33164mg / L, VSS=24273mg / L, COD=58472mg / L, pH=3.75 , chemical potency = 1083u / mL), there is no need to dilute during the slurry reaction period, after stirring evenly, it is directly passed into the hydrothermal reactor, and the saturated steam of about 200°C and 1.6MPa is passed through to heat the bacterial residue to 180°C, and the reaction The time is 60 minutes, the colloid and cell structure in the bacteria residue are destroyed, and the water-heated bacteria residue is leaked into the flash tank, the colloid and cell structure in the bacteria residue are further destroyed, and the hydrothermal bacteria residue in the flash reactor is sampled for detection (water content=96.5%, TS=34776mg / L, VS=26531mg / L, VS / TS=76.3%, SS=20227mg / L,...

Embodiment 3

[0061] The moisture content of gentamicin bacteria residue is 96.9% (TS=31333mg / L, VS=25882mg / L, VS / TS=82.6%, SS=16227mg / L, VSS=14068mg / L, COD=44563mg / L, pH= 6. Chemical potency = 31u / mL), no need to dilute during the slurry reaction period, after stirring evenly, it is directly passed into the hydrothermal reactor, and the saturated steam of about 200°C and 1.6MPa is passed through to heat the bacterial residue to 180°C, The reaction time is 30 minutes, the colloid and cell structure in the bacteria residue are destroyed, and the water-heated bacteria residue is leaked into the flash tank, the colloid and cell structure in the bacteria residue are further destroyed, and the hydrothermal bacteria residue in the flash reactor is sampled Detection (moisture content=97.4%, TS=25820mg / L, VS=22060mg / L, VS / TS=85.4%, SS=13380mg / L, VSS=11621mg / L, COD=33088mg / L, pH=5.76, chemical Titer = 0 u / mL).

[0062] Pass the bacitracin slag at 105°C in the flash reactor into a small plate-and-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com