Low-noise sound insulation sleeve for double-ended ball mill

A steel ball coal mill, double-in and double-out technology, applied in the field of mechanical noise reduction, can solve problems such as noise pollution, and achieve the effects of easy accident hidden danger, low cost, and easy removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

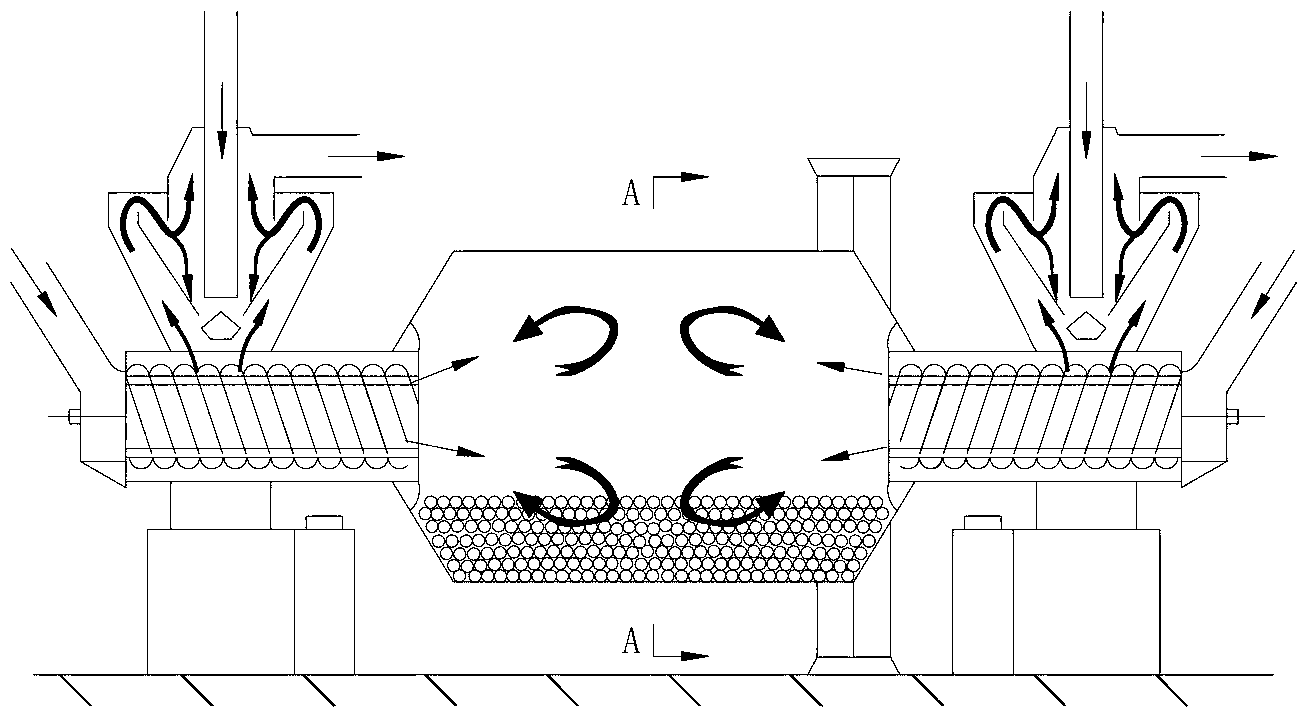

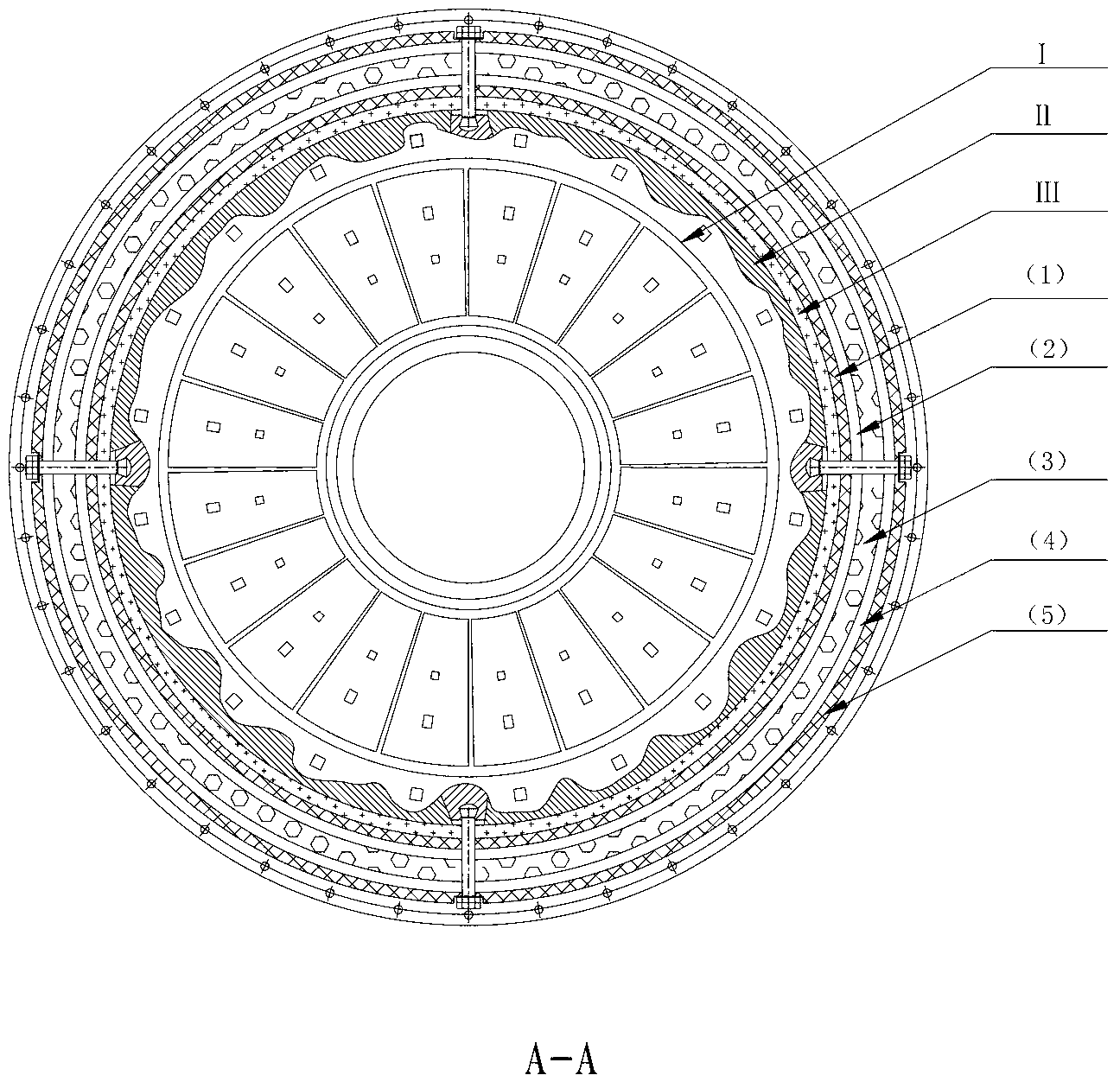

[0019] Select a measuring point in a double-inlet and double-outlet steel ball coal mill for noise monitoring. The noise of the original ball mill model is about 118dB (A). figure 1 Shown is a schematic diagram of the overall structure of a low-noise double-inlet and double-outlet steel ball coal mill; figure 2 Shown is a cross-sectional view of the sound insulation sleeve of the cylinder body of the low-noise double-inlet and double-outlet steel ball coal mill;

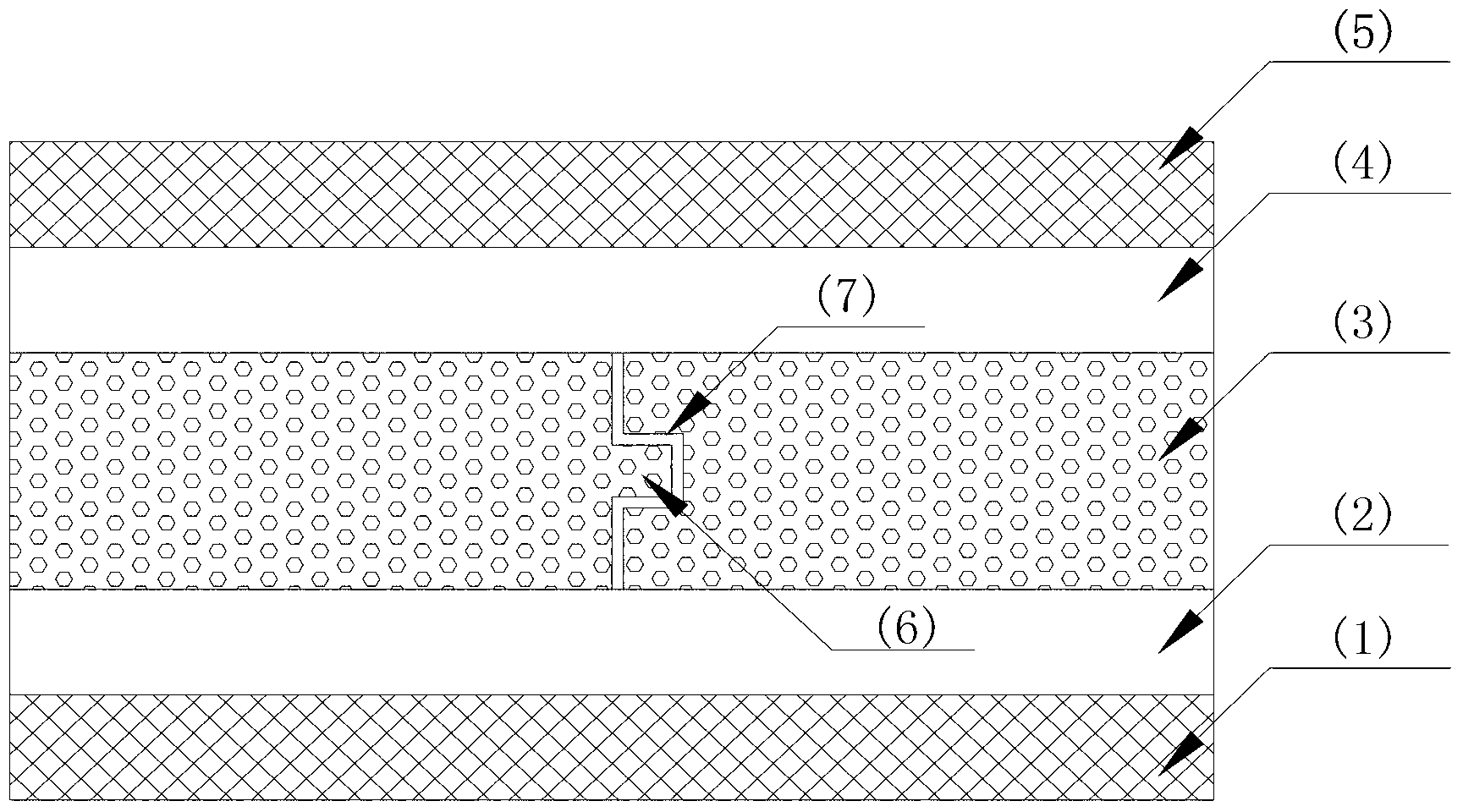

[0020] image 3 The low-noise double-inlet and double-outlet steel ball coal pulverizer shell shown in the partial structure of the sound insulation sleeve is shown. It can be seen that the sound insulation sleeve is composed of the following structures in sequence from the inner layer to the outer layer: the first layer is the inner layer 1 of the sound insulation sleeve, which is welded by 10mm thick stainless steel plate or steel plate 1, and laid on the asbestos pad III The upper layer is welded by steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com