Finished vehicle thermal management system of pure electric automobile

A pure electric vehicle and management system technology, applied in the field of pure electric vehicle thermal management system, can solve the problems of unreasonable use of waste heat of the driving motor and lack of power battery cooling function, so as to avoid wasting battery energy and prolong the service life , Improve the effect of driving mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

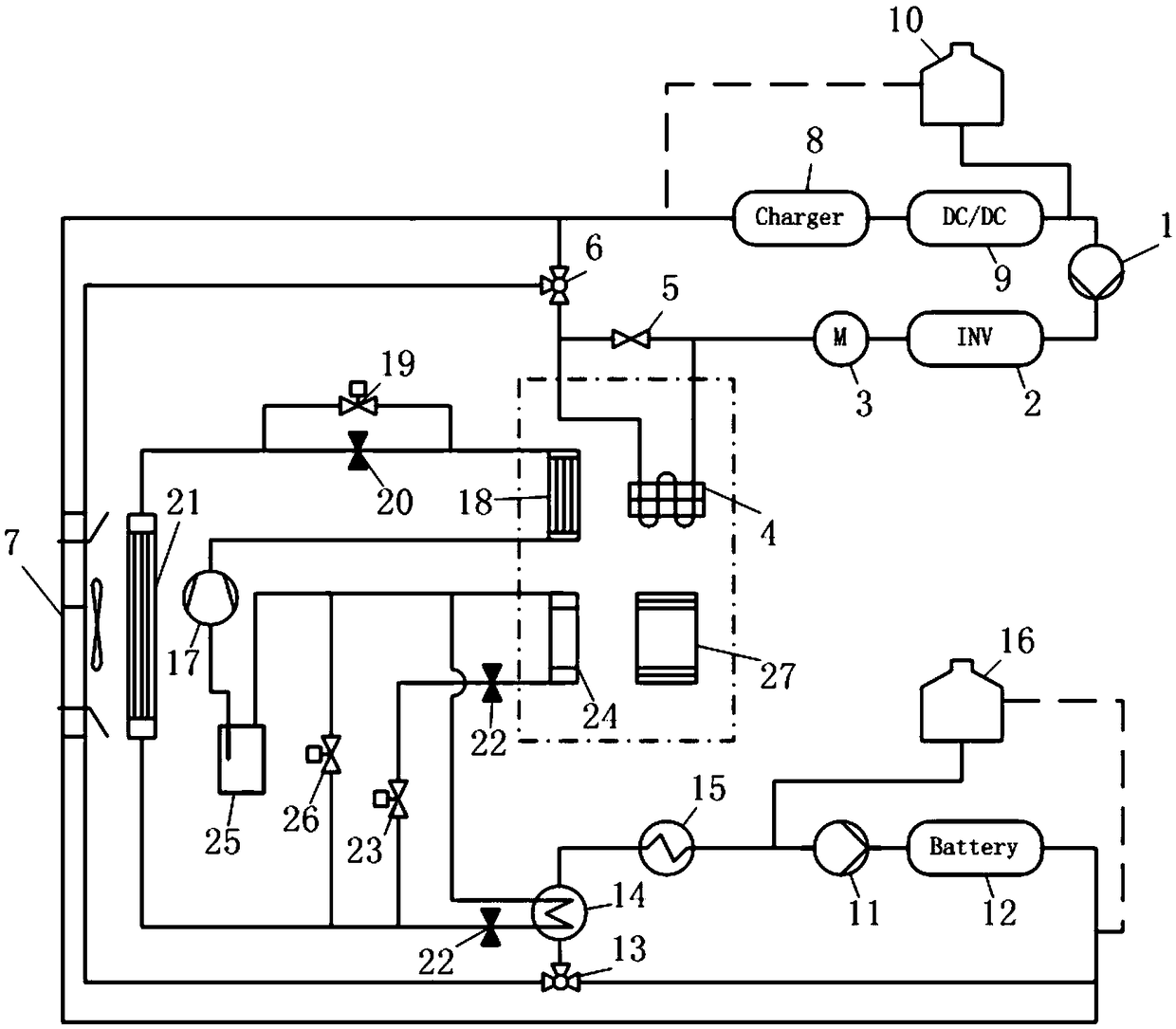

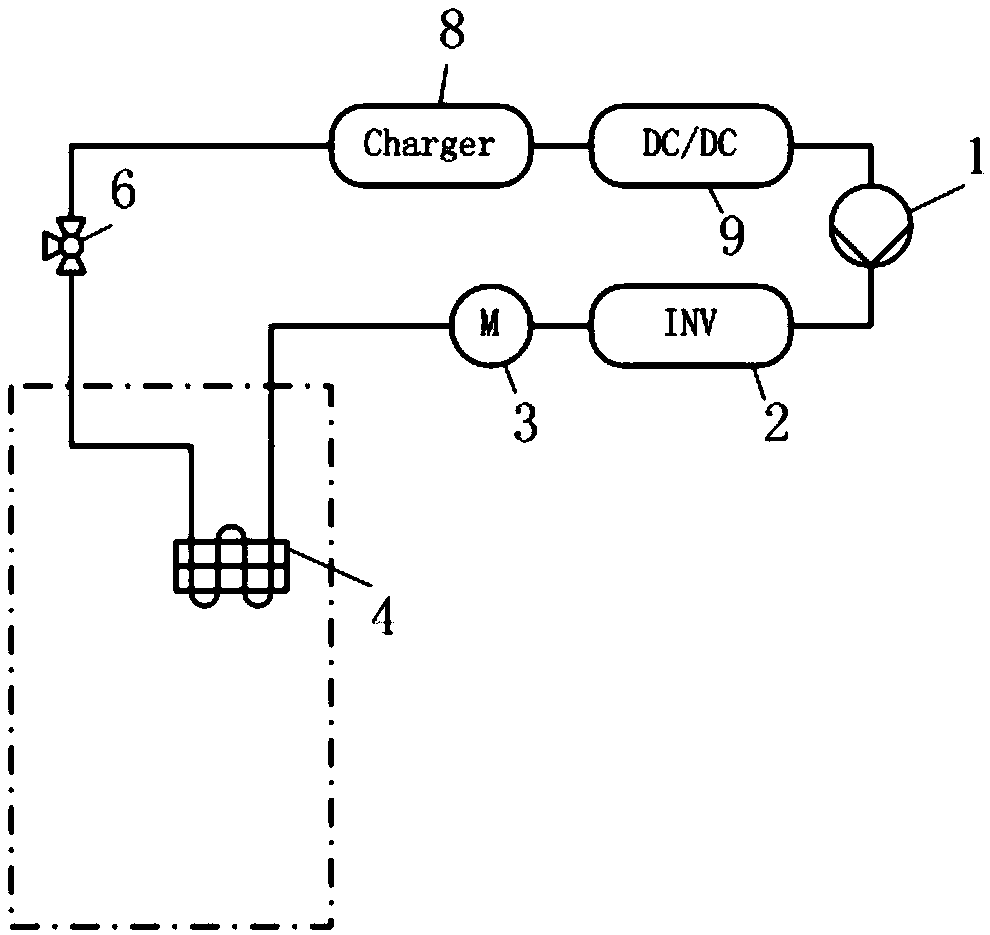

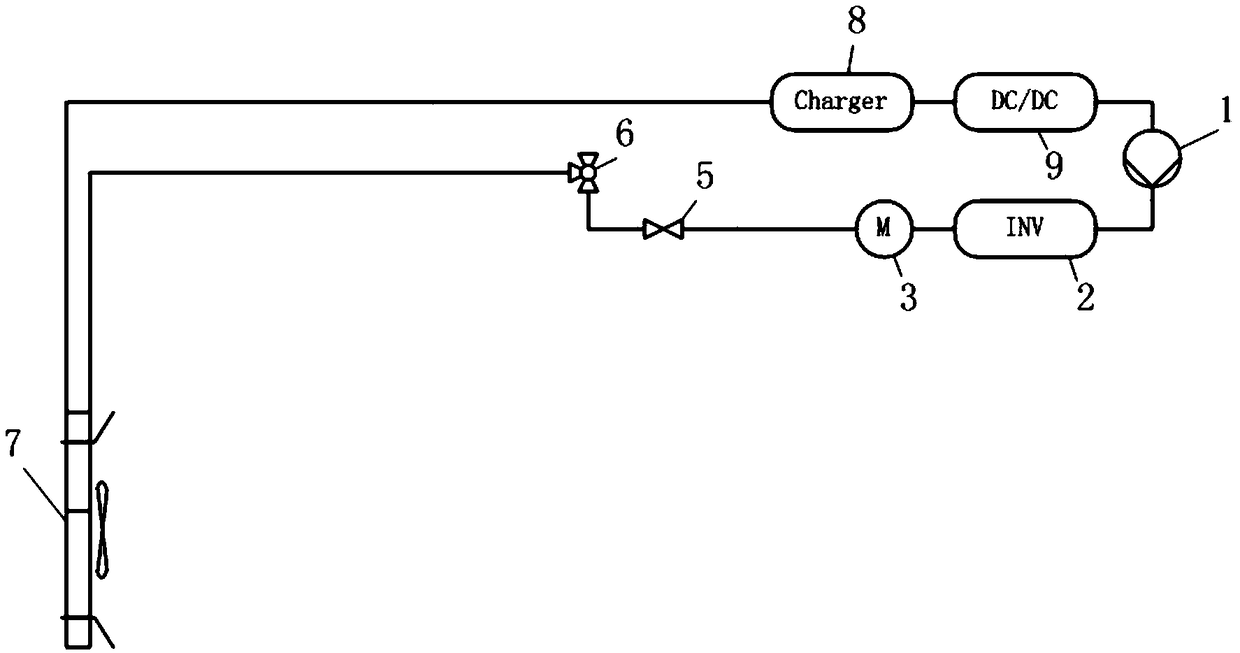

[0021] This embodiment provides a thermal management system for a pure electric vehicle, including a motor water pump 1, a motor controller 2, a drive motor 3, an indoor radiator 4, a two-way solenoid valve 5, a first three-way solenoid valve 6, two Cavity radiator 7, charger 8, DC / DC9, first expansion tank 10, battery water pump 11, power battery 12, second three-way solenoid valve 13, heat exchange device 14, plumbing PTC15, second expansion tank 16, electric Compressor 17, indoor condenser 18, first high-pressure solenoid valve 19, heating throttle pipe 20, outdoor condenser 21, thermal expansion valve 22, second high-pressure solenoid valve 23, evaporator 24, liquid storage drying tank 25, The third high voltage solenoid valve 26 and the high voltage PTC 27.

[0022] The first expansion tank 10 is connected to the inlet of the motor water pump 1, the outlet of the motor water pump 1 is connected to the inlet of the cooling pipeline of the motor controller 2, and the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com