Light dydrocarbon preparation method and light dydrocarbon preparation system with methyl alcohol as raw materials

A methanol and raw material technology, applied in the field of light hydrocarbon preparation and light hydrocarbon preparation system using methanol as raw material, can solve the problems of insufficient recovery of reaction heat, high difficulty in process control, unstable product quality, etc., and achieve stable and suitable Reaction conditions, reduce control difficulty, reduce the effect of overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

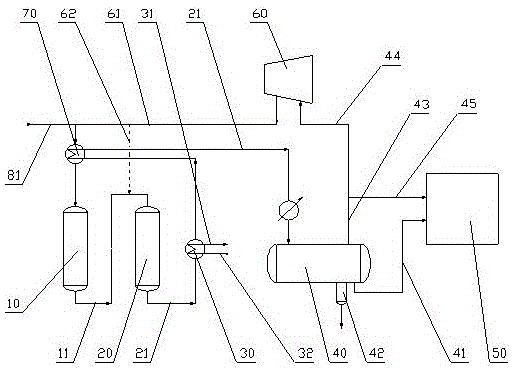

[0036] Example 1 (eg figure 1 Show):

[0037] The raw material methanol and the circulating gas are mixed to form a mixed feed, and after the heat exchange between the inlet and outlet heat exchangers and the output of the synthesis reactor, the temperature rises, and then enters the etherification reactor and the synthesis reactor to generate crude light hydrocarbons. A circulating gas cooling shock pipeline (indicated by a dotted line) can be arranged between the etherification reactor and the synthesis reactor. The output of the synthesis reactor is first sent to the medium-pressure steam generator to produce steam, and then the mixed feed is heated by the import and export heat exchangers, and the heat is further recovered. Finally, it is cooled (such as air cooler, water cooler) and then enters the three-phase Separation tank. Most of the separated gas phase is boosted by the compressor and returned to the reactor as a reaction cycle gas, and a small amount is discharge...

Embodiment 2

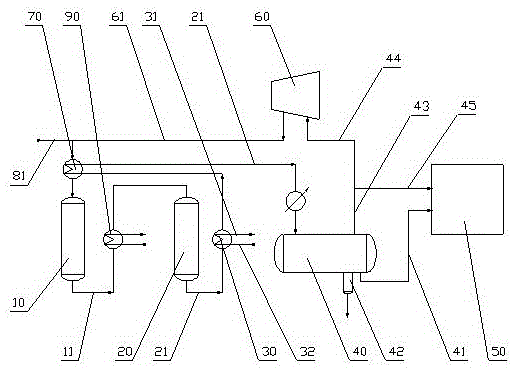

[0039] Example 2 (eg figure 2 Show):

[0040] The raw material methanol is mixed with the circulating gas to form a mixed feed, and after the heat exchange between the inlet and outlet heat exchangers and the output of the synthesis reactor, it enters the etherification reactor for reaction. The output from the etherification reactor is sent to the medium-pressure steam generator to produce by-product steam, and then enters the synthesis reactor to continue the reaction. The output from the reaction section is sent to the medium-pressure steam generator for by-product steam, then further heat recovery through the mixed feed heat exchanger, and finally cooled (such as air cooler, water cooler) and then enters the three-phase separation tank. Most of the separated gas phase is boosted by the compressor and returned to the reactor as a reaction cycle gas, and a small amount is discharged; the water phase is sent to the sewage treatment facility; the oil phase is sent to the pos...

Embodiment 3

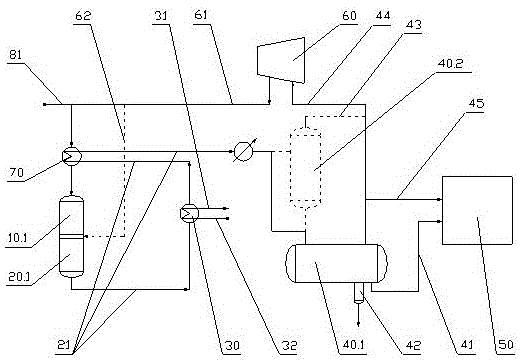

[0042] Example 3 (as image 3 Show):

[0043] The raw material methanol and the circulating gas are mixed to form a mixed feed, and after the heat exchange between the inlet and outlet heat exchangers and the output of the synthesis reactor, it enters the integrated reactor to generate crude and light hydrocarbons. The integrated reactor is divided into an etherification section and a synthesis section with upper and lower reaction beds, and a reaction cycle gas cooling shock pipeline (indicated by a dotted line) can be installed between the beds. The output from the synthesis reaction section is first sent to the medium-pressure steam generator to produce steam, then through the mixed feed heat exchanger for further heat recovery, and finally cooled (such as air cooler, water cooler) and then enters the three-phase separation system. The three-phase separation system can be a three-phase separator with a water bag, or a combination of a gas-liquid separator and an oil-water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com