Novel production technology for producing sodium fluoride and white carbon black in co-production mode by using fluorosilicic acid

A production process, the technology of fluosilicic acid, is applied in the production process field of producing sodium fluoride and co-producing white carbon black with fluosilicic acid, which can solve the problems of high cost of raw materials and high pressure of wastewater treatment, and achieve control of reaction concentration, reduction of Sewage discharge, the effect of reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

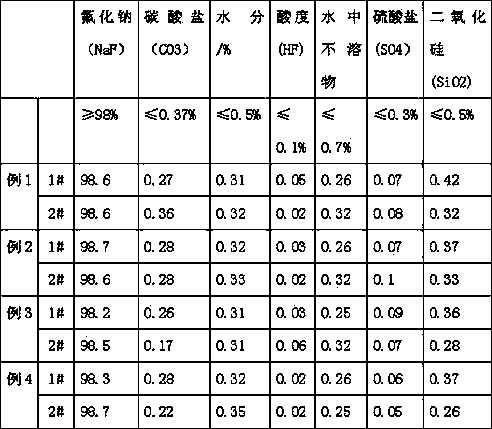

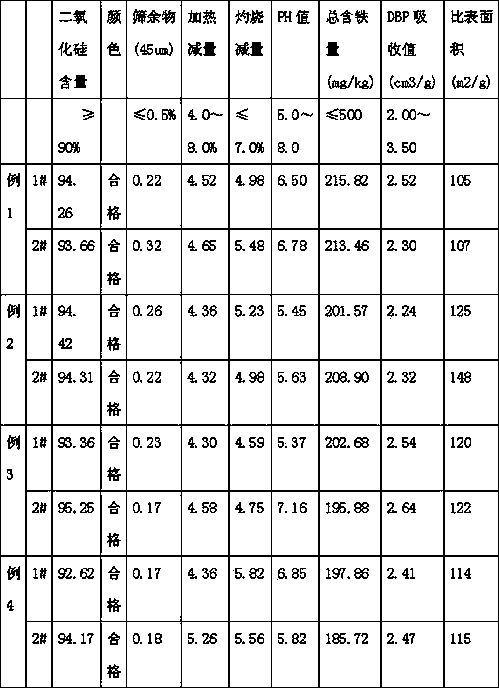

Embodiment 1

[0031] 1. Dissolve sodium carbonate with water or sodium fluoride mother liquor, content 15-16%.

[0032] 2. Dilute 32-34% water glass to 15-16% water glass content;

[0033] 3. Dilute 40% fluosilicic acid to 15%;

[0034] 4. Put the diluted water glass solution and fluosilicic acid into the reaction kettle at the same time in proportion, and heat up to 80°C with steam during the reaction process, and control the pH value to 4-5;

[0035] 5. After the reaction between water glass and fluosilicic acid is completed, slowly add soda ash solution according to the reaction ratio, and heat up to 80°C with steam during the reaction process, and control the pH value to 9-10;

[0036] 6. After the reaction in the reactor is complete, use the specific gravity difference reaction liquid to carry out solid-solid separation after flotation, and the solid-solid separation is sodium fluoride and silicon dioxide. Silica can be sold as white carbon black after pressure filtration and drying....

Embodiment 2

[0038] 1. Dissolve sodium carbonate with water or sodium fluoride mother liquor, content 20-21%.

[0039] 2. Dilute 32-34% water glass to 20-21% water glass content;

[0040] 3. Dilute 40% fluosilicic acid to 20-21%;

[0041] 4. Put the diluted water glass solution and fluosilicic acid into the reaction kettle at the same time in proportion, and heat up to 80°C with steam during the reaction process, and control the pH value to 4-5;

[0042] 5. After the reaction between water glass and fluosilicic acid is completed, slowly add soda ash solution according to the reaction ratio, and heat up to 80°C with steam during the reaction process, and control the pH value to 9-10;

[0043] 6. After the reaction in the reactor is complete, use the specific gravity difference reaction liquid to carry out solid-solid separation after flotation, and the solid-solid separation is sodium fluoride and silicon dioxide. Silica can be sold as white carbon black after pressure filtration and dryi...

Embodiment 3

[0045] 1. Dissolve sodium carbonate with water or sodium fluoride mother liquor, content 15-16%.

[0046] 2. Dilute 32-34% water glass to 15-16% water glass content;

[0047] 3. Dilute 40% fluosilicic acid to 20-21%;

[0048] 4. Put the diluted water glass solution and fluosilicic acid in the ratio of 1:1.05 into the reactor at the same time, heat up to 80°C with steam during the reaction process, and control the pH value to 4-5;

[0049] 5. After the reaction between water glass and fluosilicic acid is completed, slowly put into the soda ash solution according to the reaction ratio of 1.05, and heat up to 80°C with steam during the reaction process, and control the pH value to 9-10;

[0050] 6. After the reaction in the reactor is complete, use the specific gravity difference reaction liquid to carry out solid-solid separation after flotation, and the solid-solid separation is sodium fluoride and silicon dioxide. Silica can be sold as white carbon black after pressure filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com