Nanometer titanium dioxide cotton fiber modifying method with improved dyeing property and attachment firmness

A technology of nano-titanium dioxide and adhesion fastness, which is applied in fiber treatment, plant fiber, ultrasonic/sonic fiber treatment, etc. It can solve the problem of low bonding fastness between nano-titanium dioxide and cotton fiber and poor dyeing performance of nano-titanium dioxide-coated cotton fiber And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

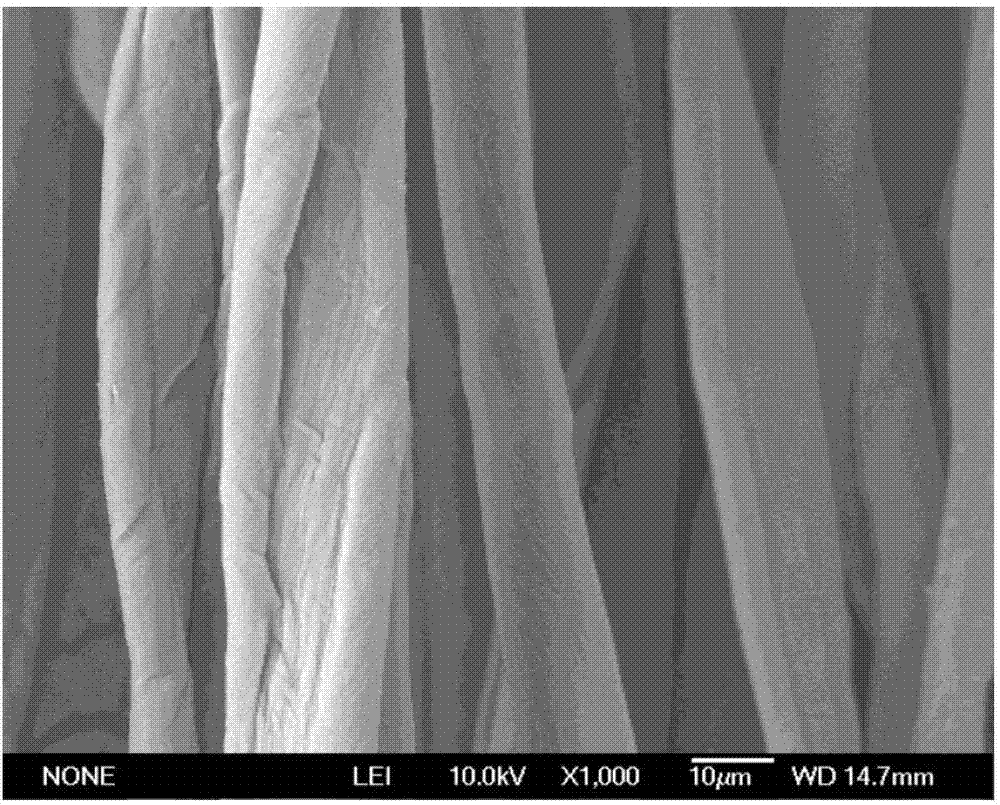

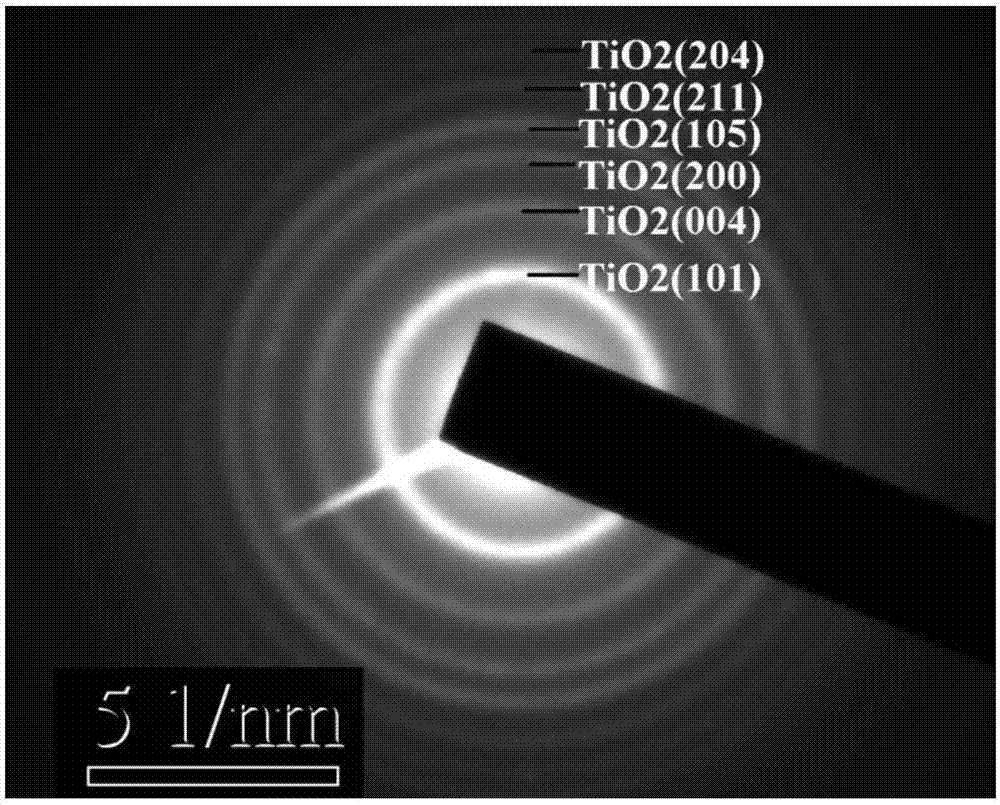

Embodiment 1

[0062] Soak 0.72g of cotton fibers in 80% volume concentration of acetone, absolute ethanol and deionized water respectively, ultrasonically wash at 50°C for 10min, and then dry at 70°C; dissolve 0.96g of titanium sulfate in 19.2 1 g of deionized water is prepared into a titanium sulfate solution, and then 2.4 g of urea is added to the titanium sulfate solution and vigorously stirred to obtain a mixed solution, and then 0.036 g of a shell with a deacetylation degree of 86% and a molecular weight of less than 2000 is added to the mixed solution. Polysaccharide, 0.028g cetyltrimethylammonium bromide, the configuration is called modified solution; soak the cleaned cotton fiber in the modified solution for 15min, put the cotton fiber soaked in the modified solution into a volume of 100mL In the high-temperature and high-pressure reactor, and pour the modified solution into the high-temperature and high-pressure reactor, fill with deionized water so that the volume of the modified s...

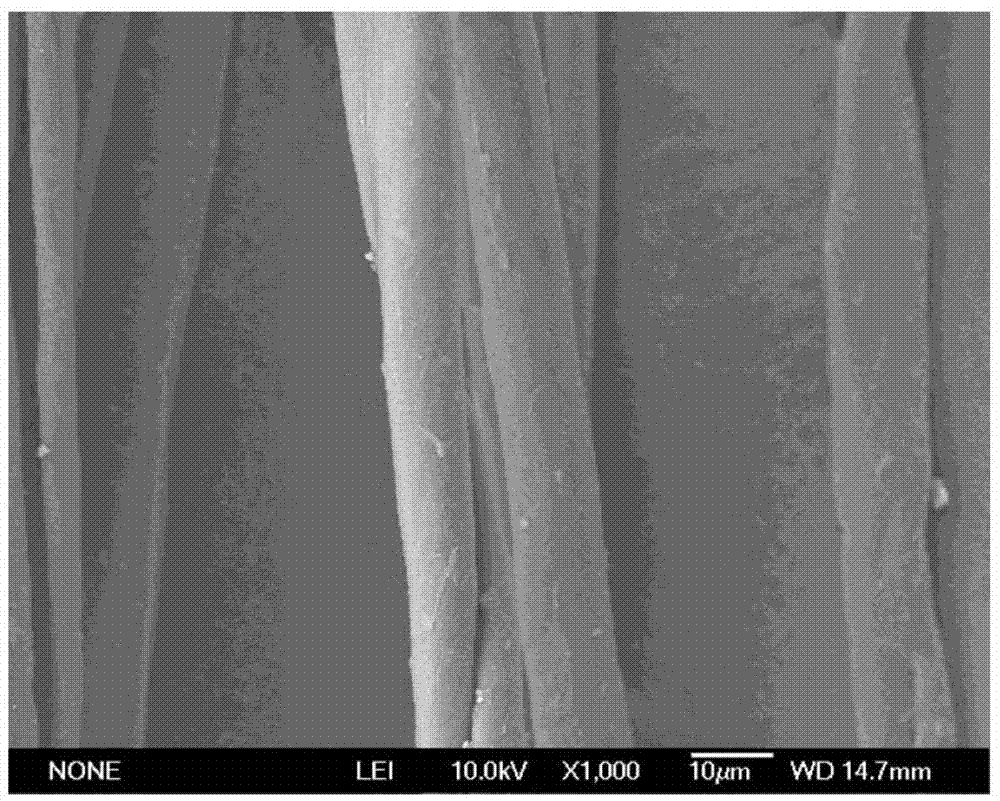

Embodiment 2

[0065]Soak 0.72g of cotton fibers in 90% volume concentration of acetone, absolute ethanol and deionized water respectively, ultrasonically wash at 70°C for 20min, and then dry at 90°C; dissolve 1.92g of titanium sulfate in 2.56 1 g of deionized water is prepared into a titanium sulfate solution, and then 0.96 g of urea is added to the titanium sulfate solution and stirred vigorously to obtain a mixed solution, and then 0.07 g of a shell with a deacetylation degree of 86% and a molecular weight of less than 2000 is added to the mixed solution. Polysaccharide, 0.057g cetyltrimethylammonium bromide, the configuration is called modified solution; soak the cleaned cotton fiber in the modified solution for 30min, put the cotton fiber soaked in the modified solution into a volume of 100mL In the high-temperature and high-pressure reactor, and pour the modified solution into the high-temperature and high-pressure reactor, fill with deionized water so that the volume of the modified so...

Embodiment 3

[0068] Soak 0.72g of cotton fibers in 85% volume concentration of acetone, absolute ethanol and deionized water respectively, ultrasonically shake and clean at 60°C for 15min, and then dry at 80°C; dissolve 1.44g of titanium sulfate in 7.2 1 g of deionized water is prepared into a titanium sulfate solution, and then 1.2 g of urea is added to the titanium sulfate solution and stirred vigorously to obtain a mixed solution, and then 0.057 g of a shell with a deacetylation degree of 86% and a molecular weight of less than 2000 is added to the mixed solution. Polysaccharide, 0.043g cetyltrimethylammonium bromide, the configuration is called modified solution; soak the cleaned cotton fiber in the modified solution for 20min, put the cotton fiber soaked in the modified solution into a volume of 100mL In the high-temperature and high-pressure reactor, and pour the modified solution into the high-temperature and high-pressure reactor, fill with deionized water so that the volume of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com