High-efficiency sewage treatment system based on MBR (Membrane Bioreactor) membrane

A sewage treatment system, high-efficiency technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve the problem of low purification efficiency of MBR membrane filtration, high cost of sewage treatment, aeration effect Poor and other problems, to achieve the effect of improving equipment utilization, improving aeration effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

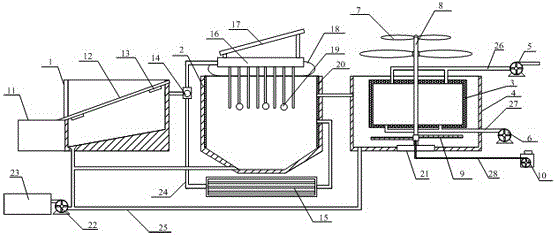

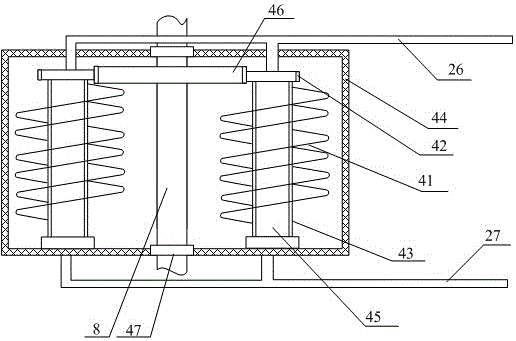

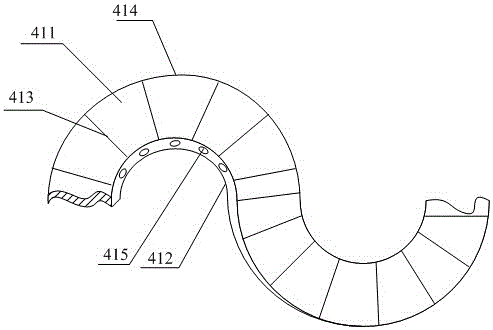

[0028] as attached figure 1 to attach Figure 5 shown

[0029]The present invention provides a high-efficiency sewage treatment system based on MBR membranes, including a regulating tank 1, an aerobic tank 2, an MBR tank 3, an MBR membrane module 4, an MBR membrane body 41, a driven gear 42, a support pipe 43, and a filter screen 44 , water outlet cavity 45, drive gear 46 and bearing 47 upper film layer 411, lower film layer 412, liner 413, reinforcement frame 414 and water outlet hole 415 water outlet pump 5, MBR membrane cleaning pump 6, wind impeller 7, wind drive rod 8 , aeration wheel 9, blower 10, filter residue tank 11, grid plate 12, vibrator 13, three-way solenoid valve 14, underground cooling pipe 15, heating water tank 16, photovoltaic panel 17, support air bag 18, temperature sensor 19, suction Heat layer 20, fixed seat 21, sewage pump 22, sludge tank 23, dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com