Patents

Literature

45results about How to "Reduce external emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

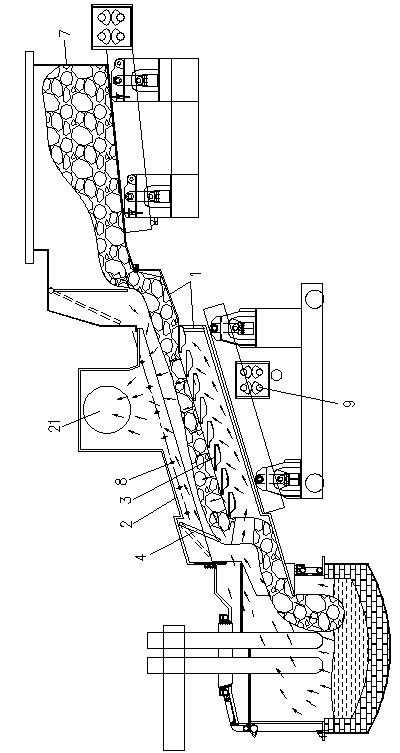

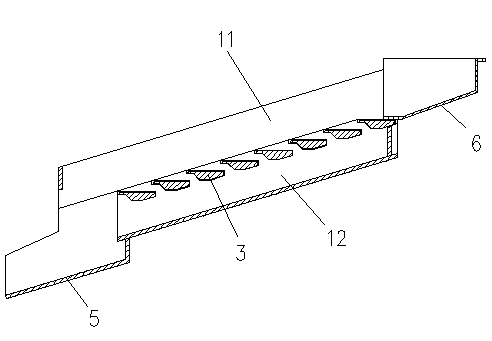

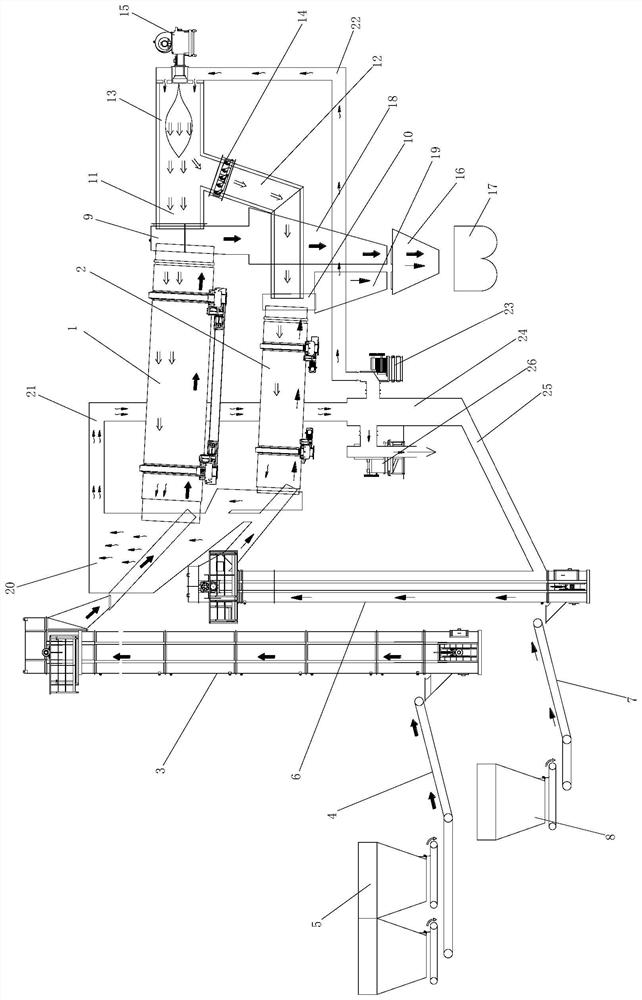

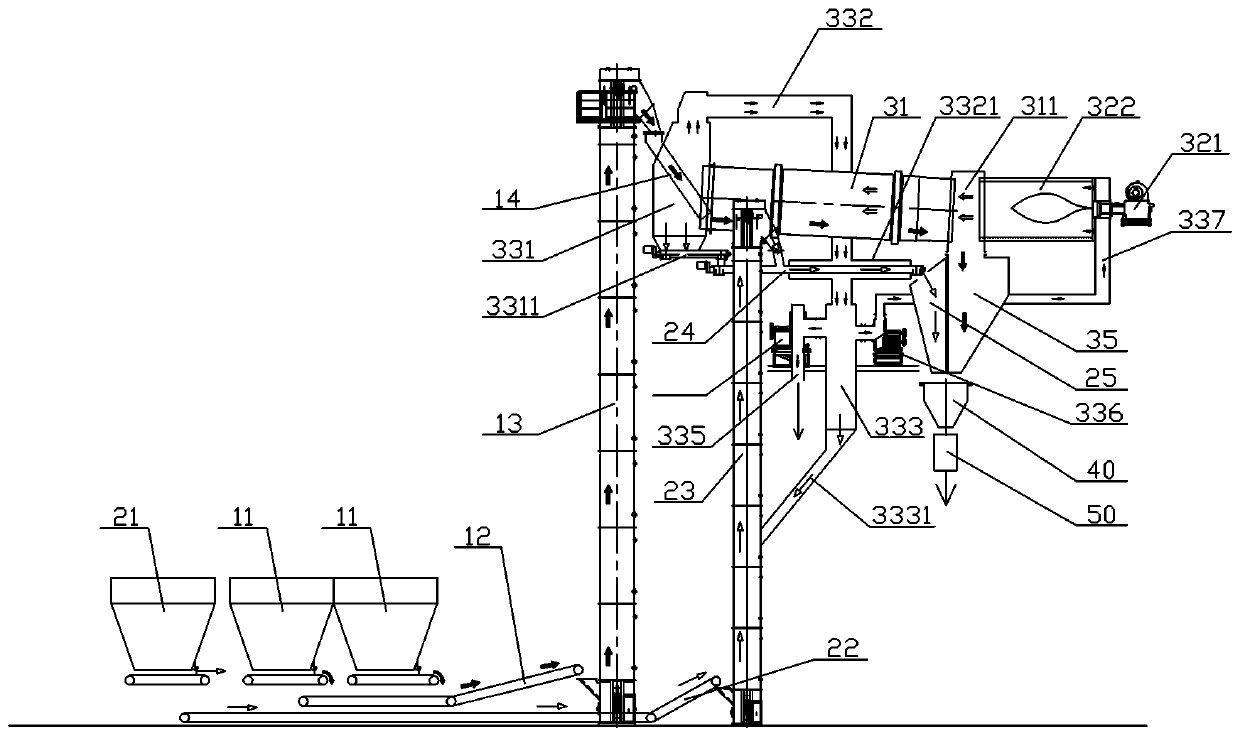

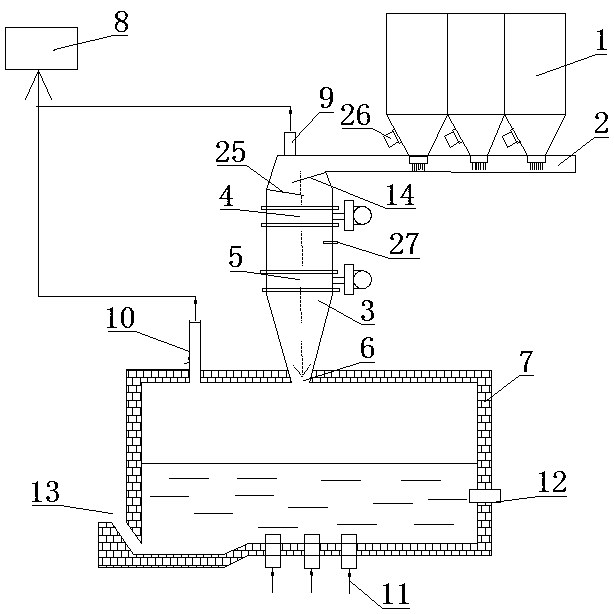

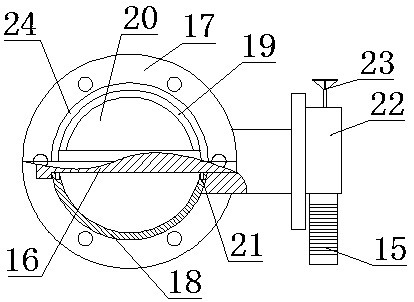

Continuous feeding device for electric arc furnace preheated by flue gases

InactiveCN103075881AImprove mechanical efficiencyIncrease contact areaLighting and heating apparatusFlueCold area

The invention discloses a continuous feeding device for an electric arc furnace preheated by flue gases. The device comprises a double-duct conveying trough and a flue gas guiding hood; a carrier plate with a flue gas channel is arranged in the middle part of the double-duct conveying trough; a material circulating duct is arranged above the carrier plate, and a flue gas circulating duct is arranged below the carrier plate; a seal gate matched with the upper opening of the lower end of the material circulating duct is arranged on the flue gas guiding hood; the double-duct conveying trough forms a flue gas diffusion heat exchanging mechanism from bottom to top, contact area between materials and high temperature flue gas is enlarged, the stay time of the flue gas is long, and the material preheating effect is greatly improved; as the double-duct conveying trough is arranged in an inclined way, the feeding point is raised, the trough bevel is large, the waste steel material blanking point can easily close to the center high temperature area of the furnace, so that the cold area phenomenon is eliminated; as the diffusion and heat exchange designs are realized, the powder dust in the exhausted flue gases is greatly reduced, the flue gas flowing is more in line with the natural rules, and the problems of exhaust pipe blockage and the like are solved.

Owner:CISDI ENG CO LTD

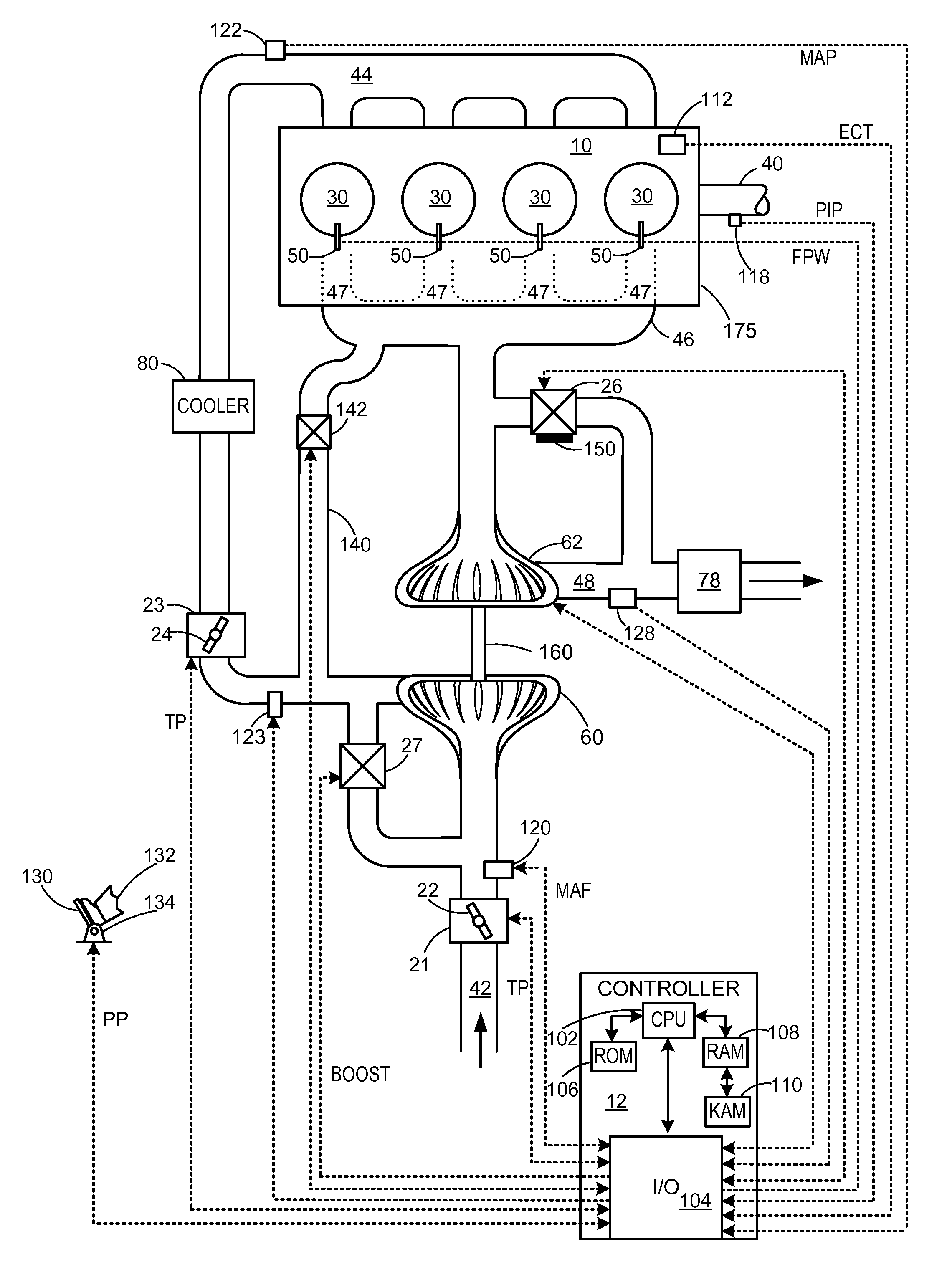

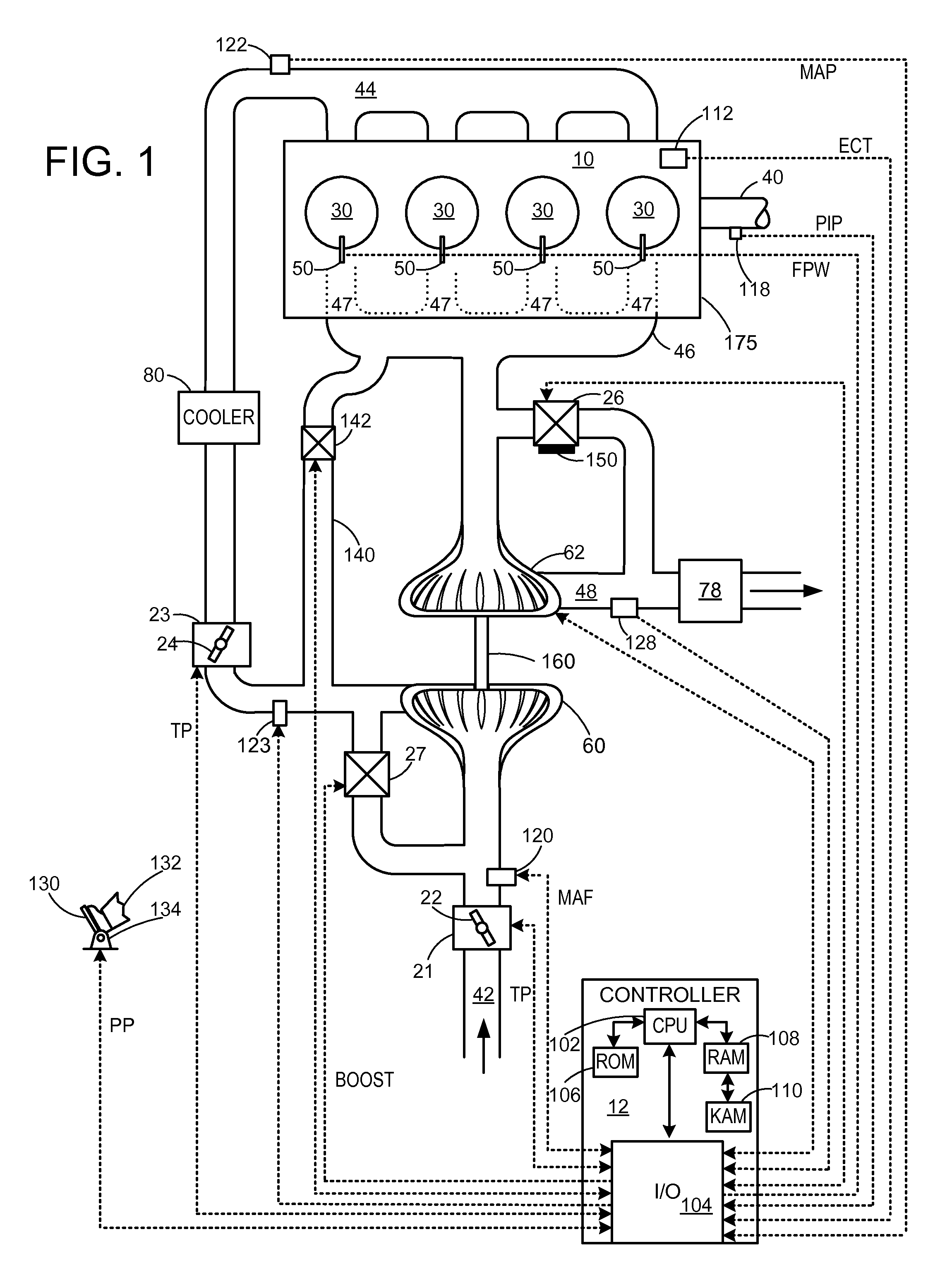

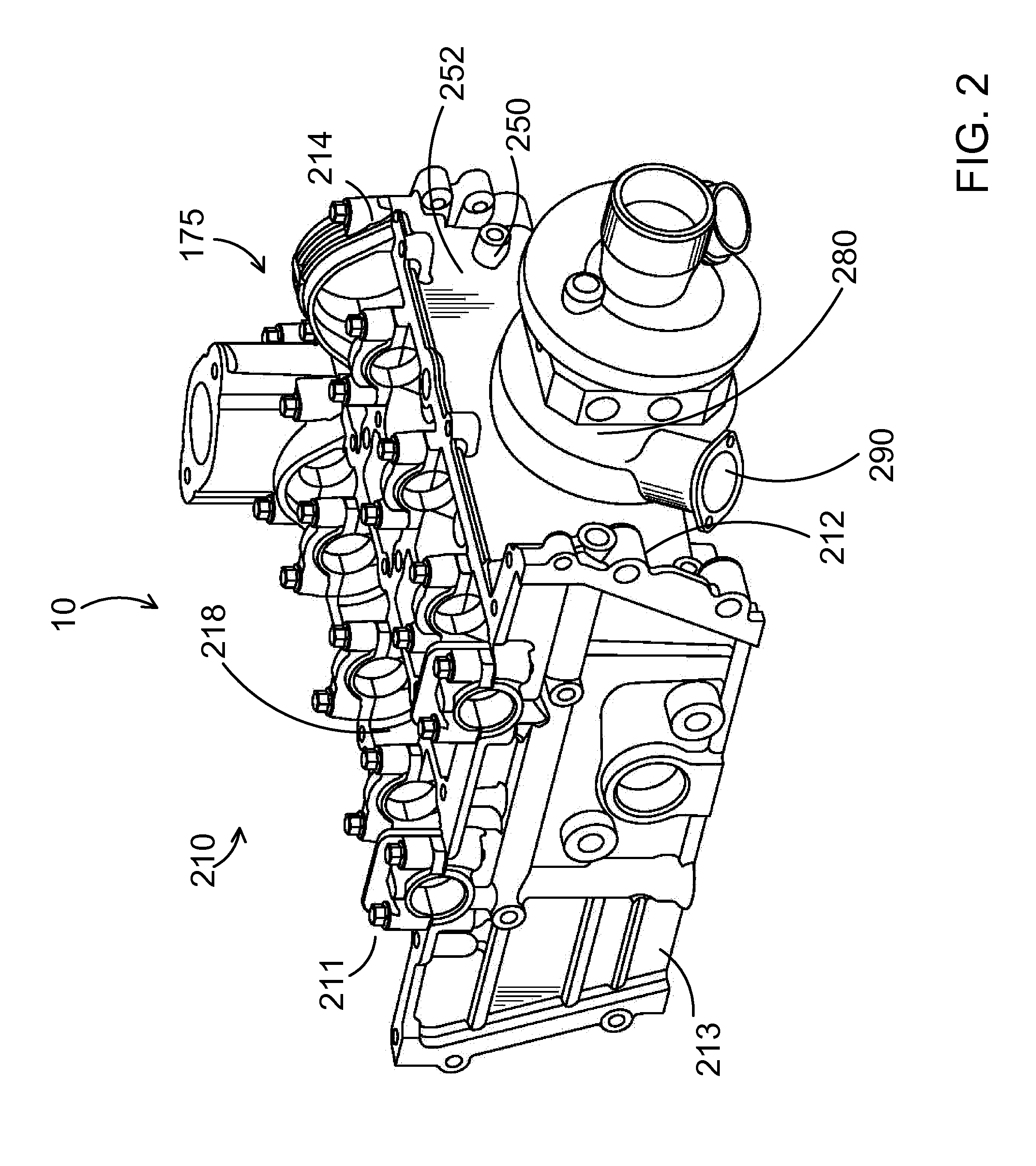

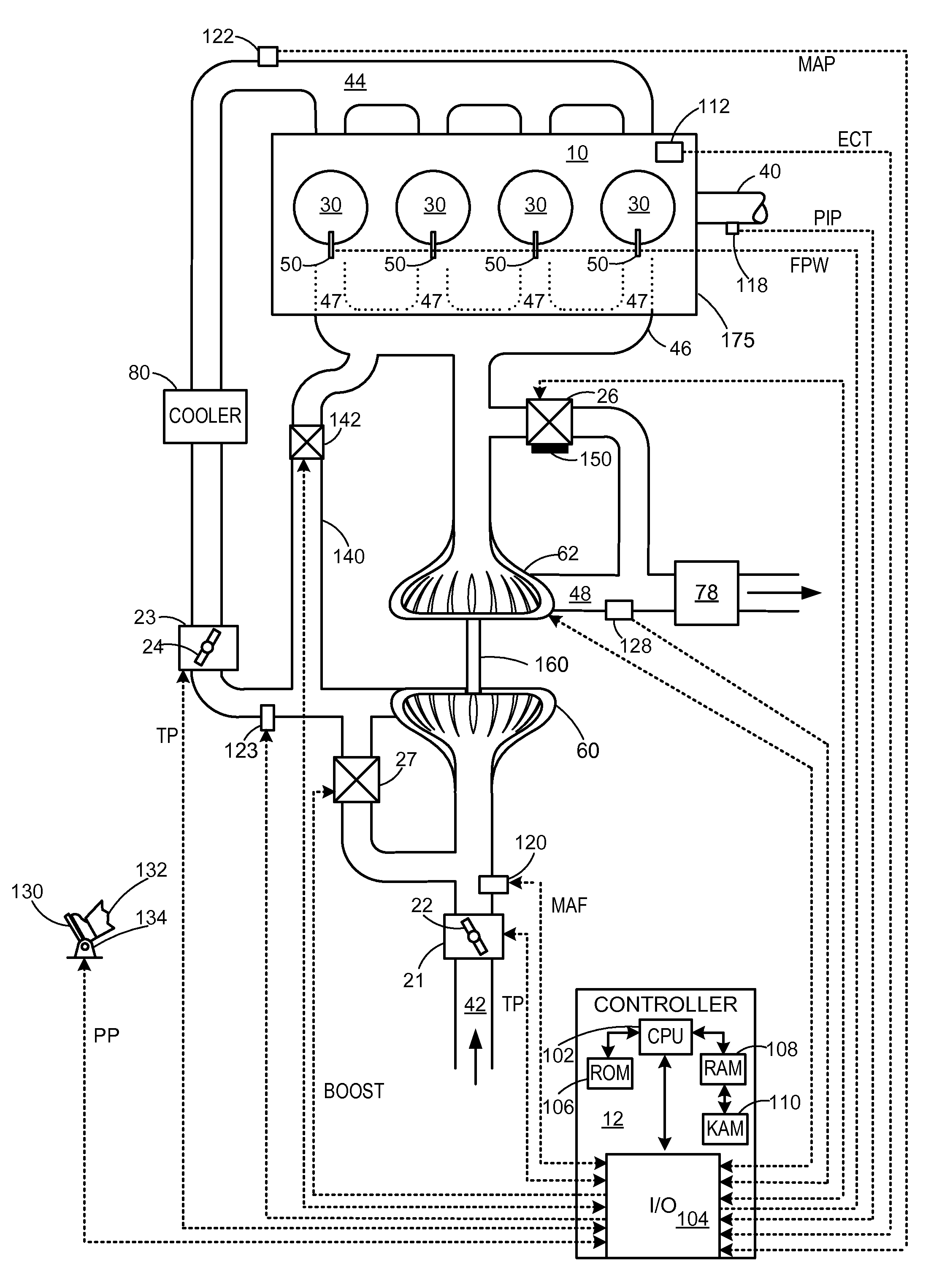

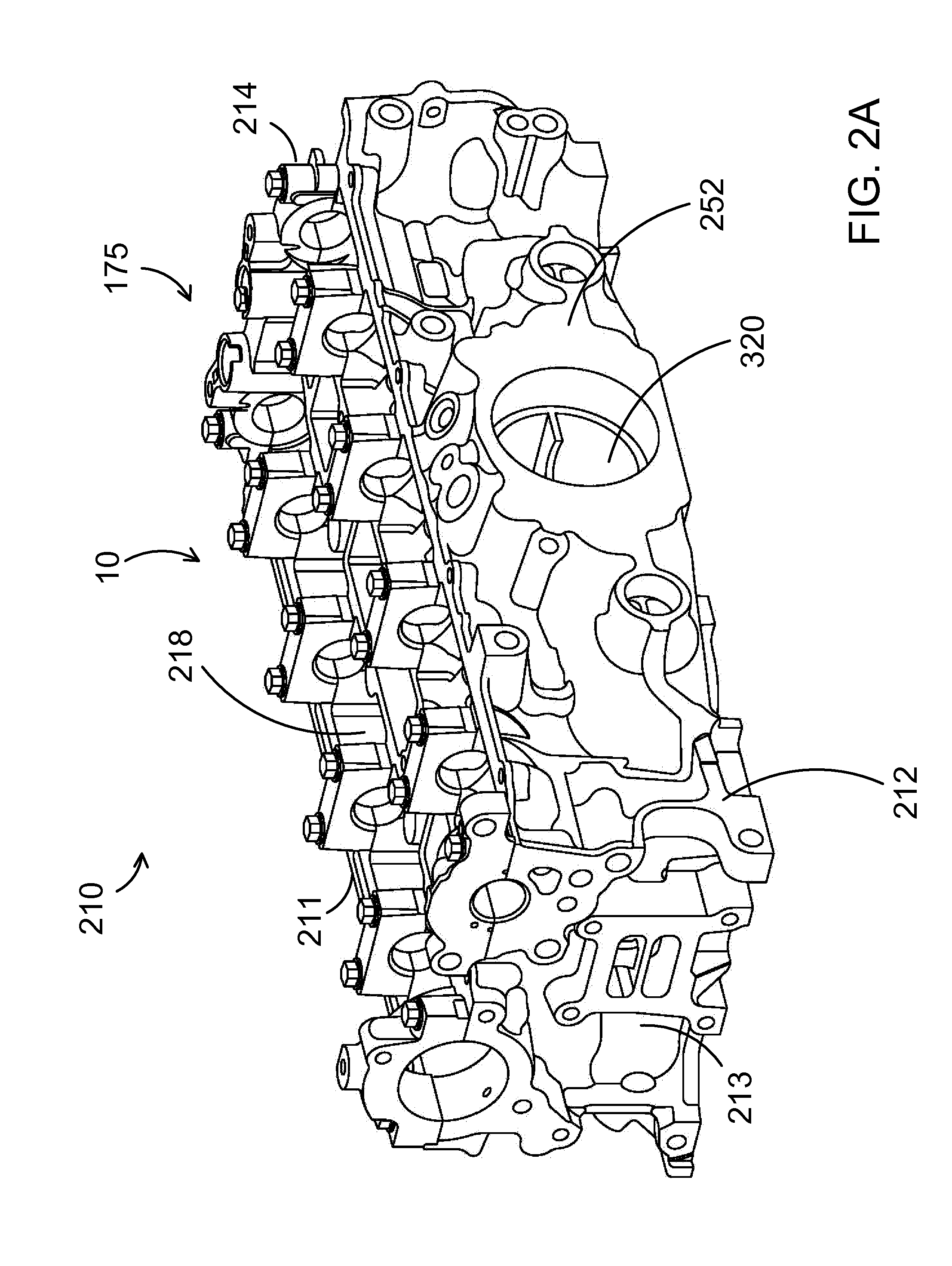

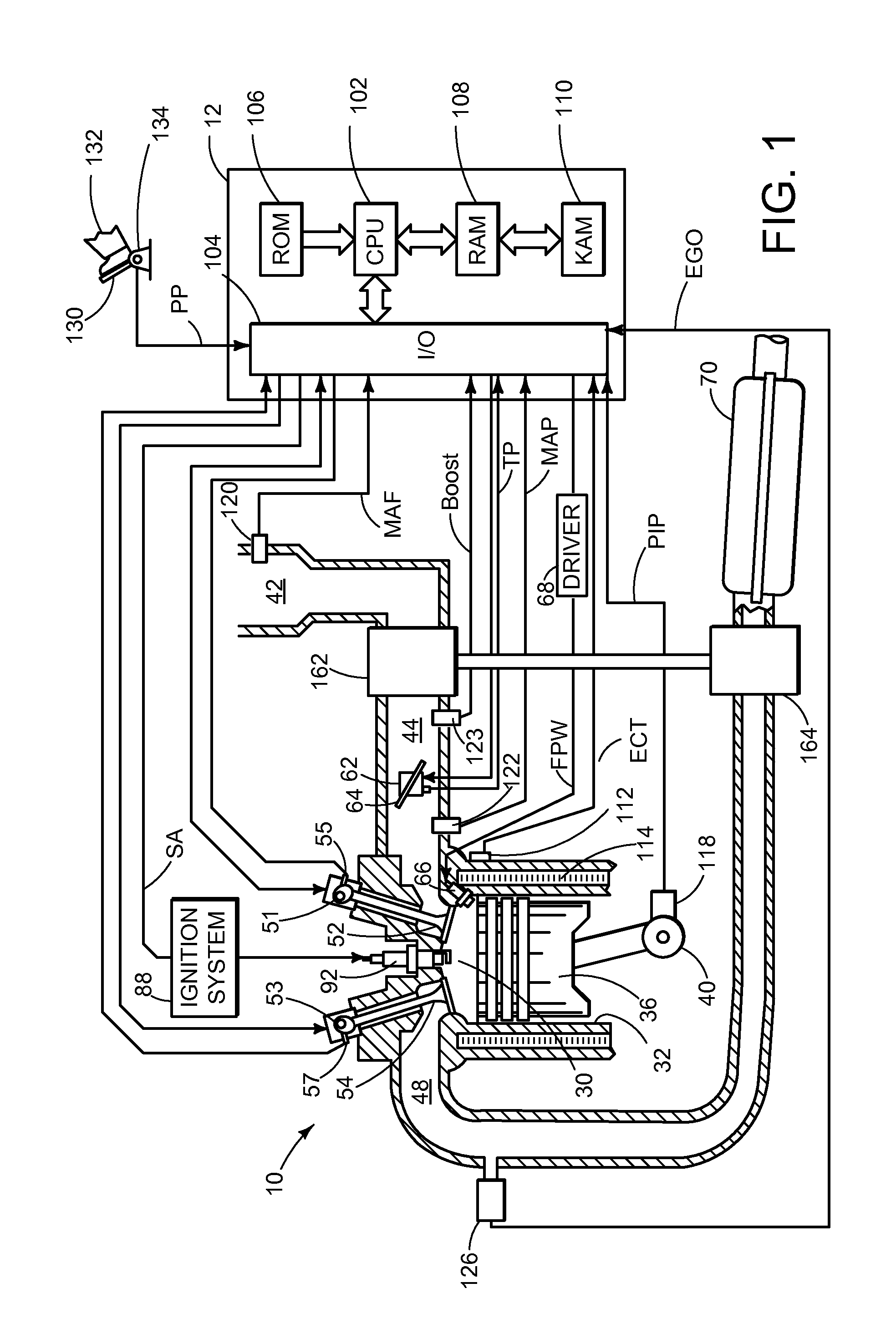

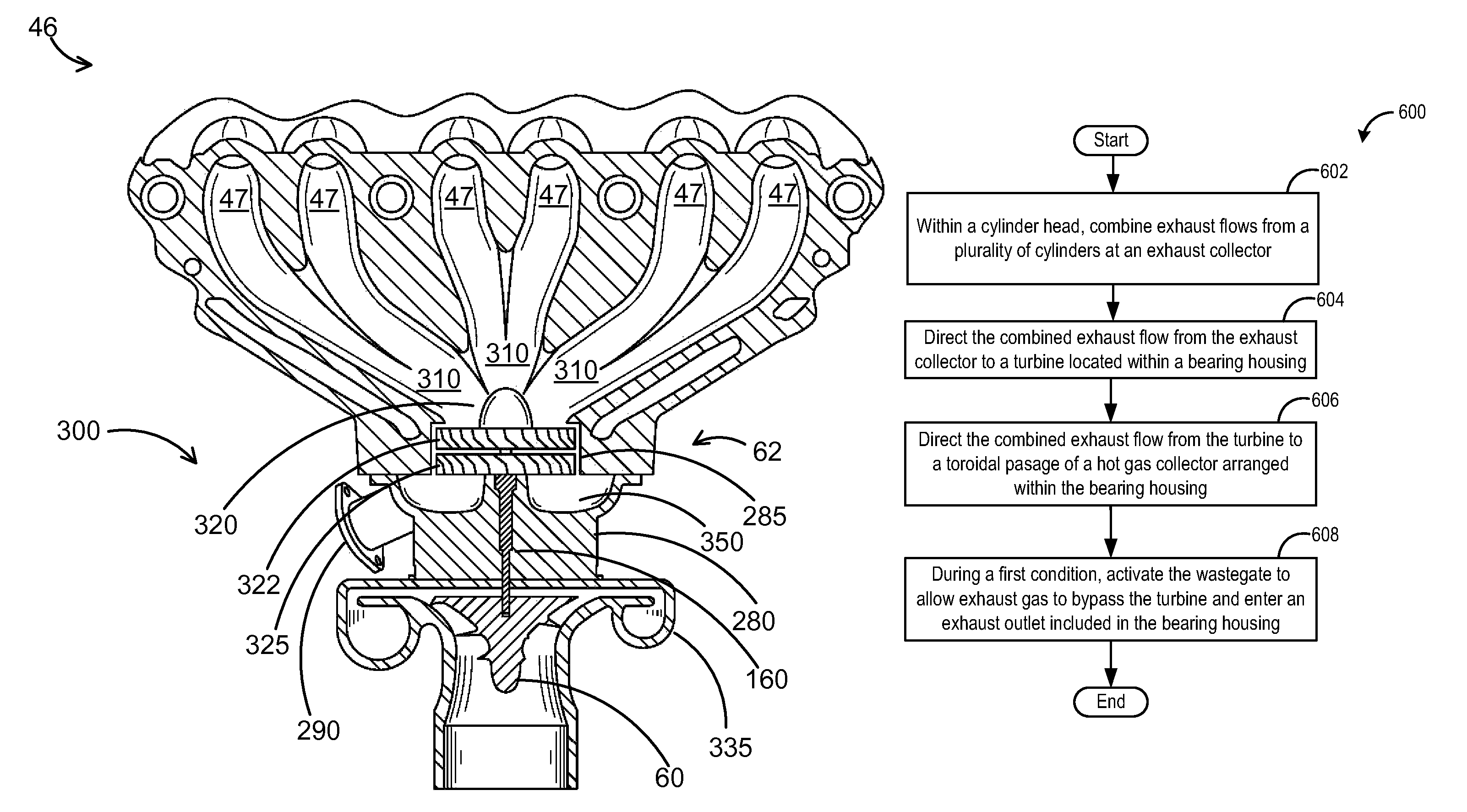

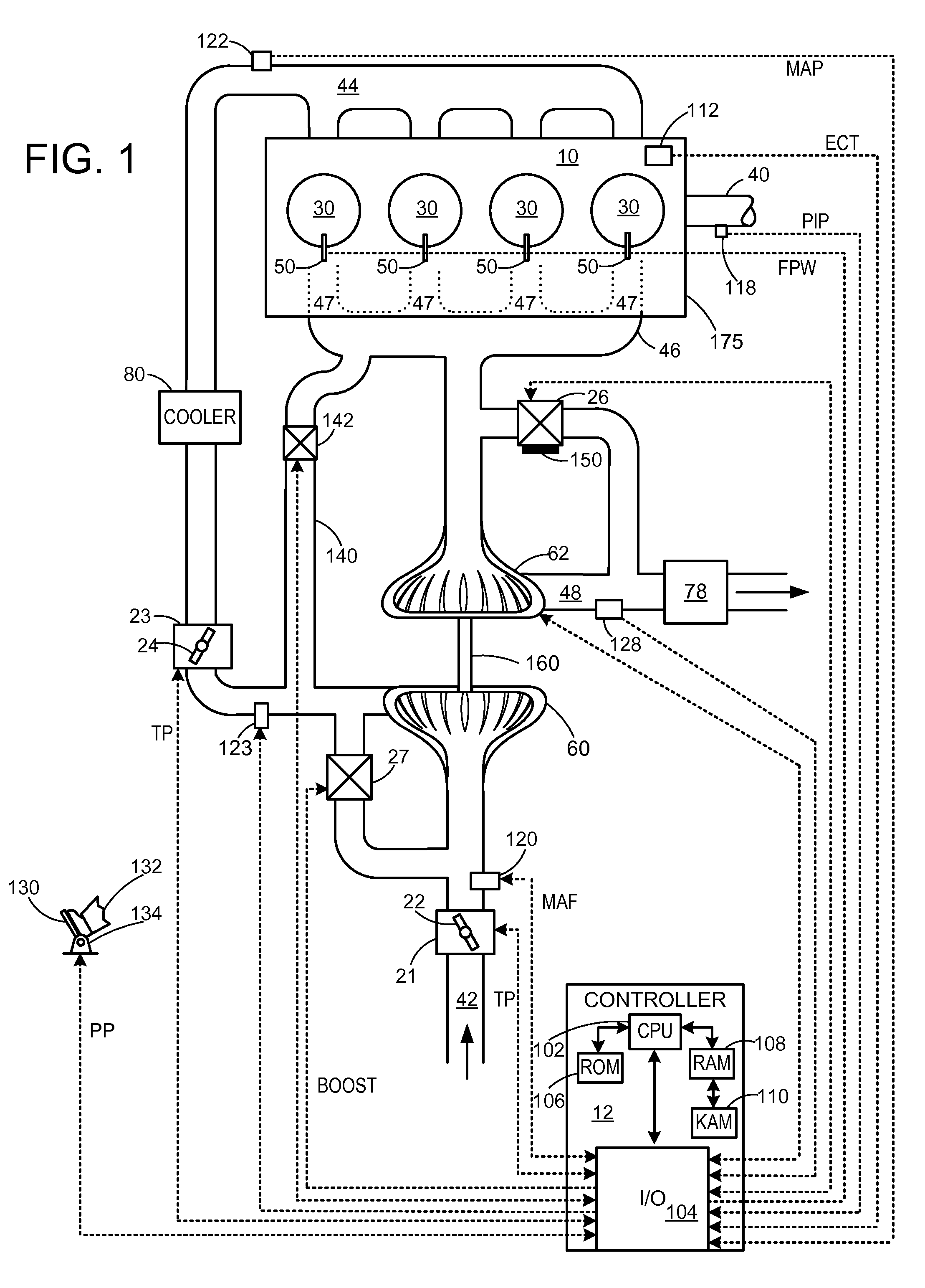

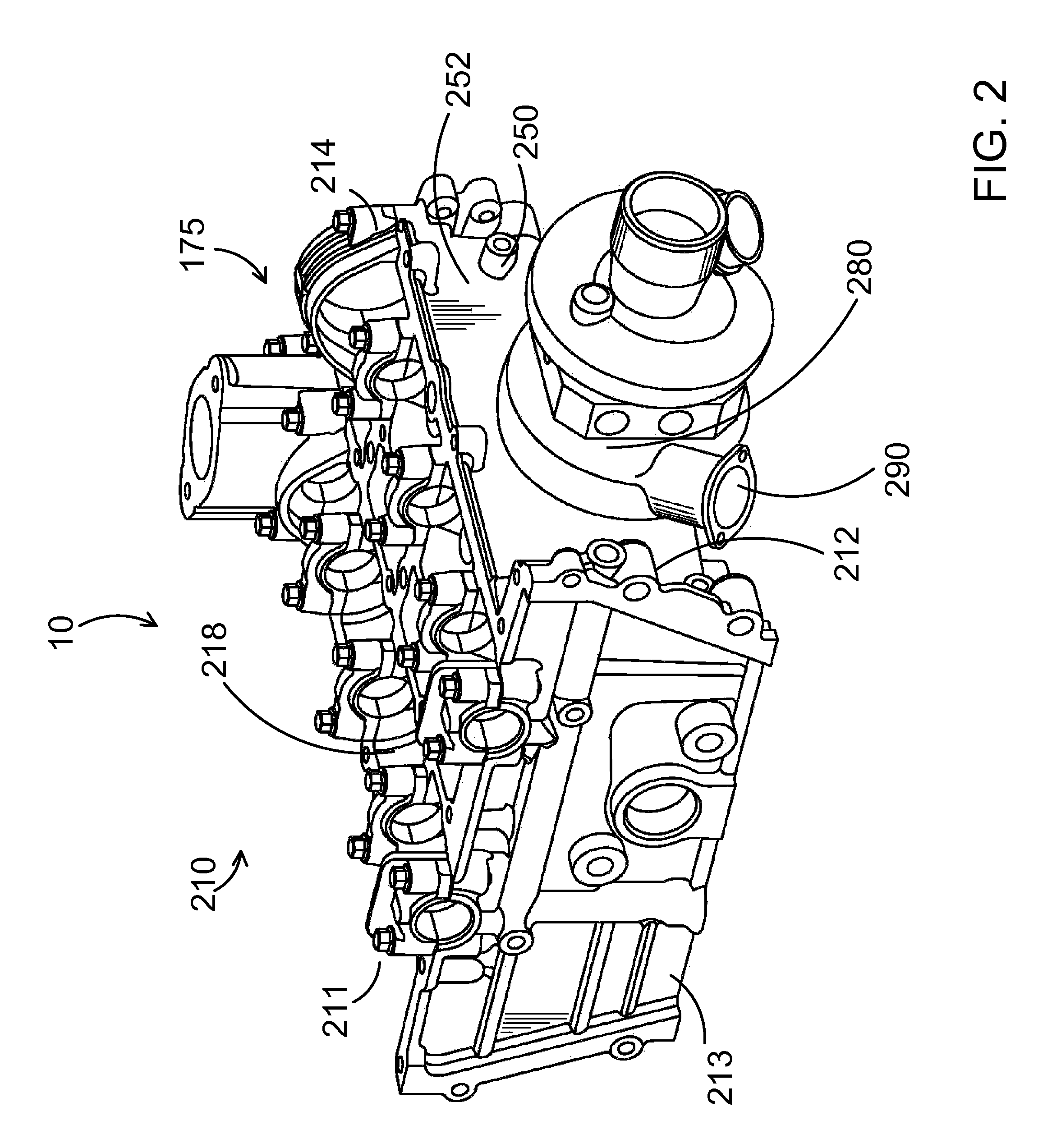

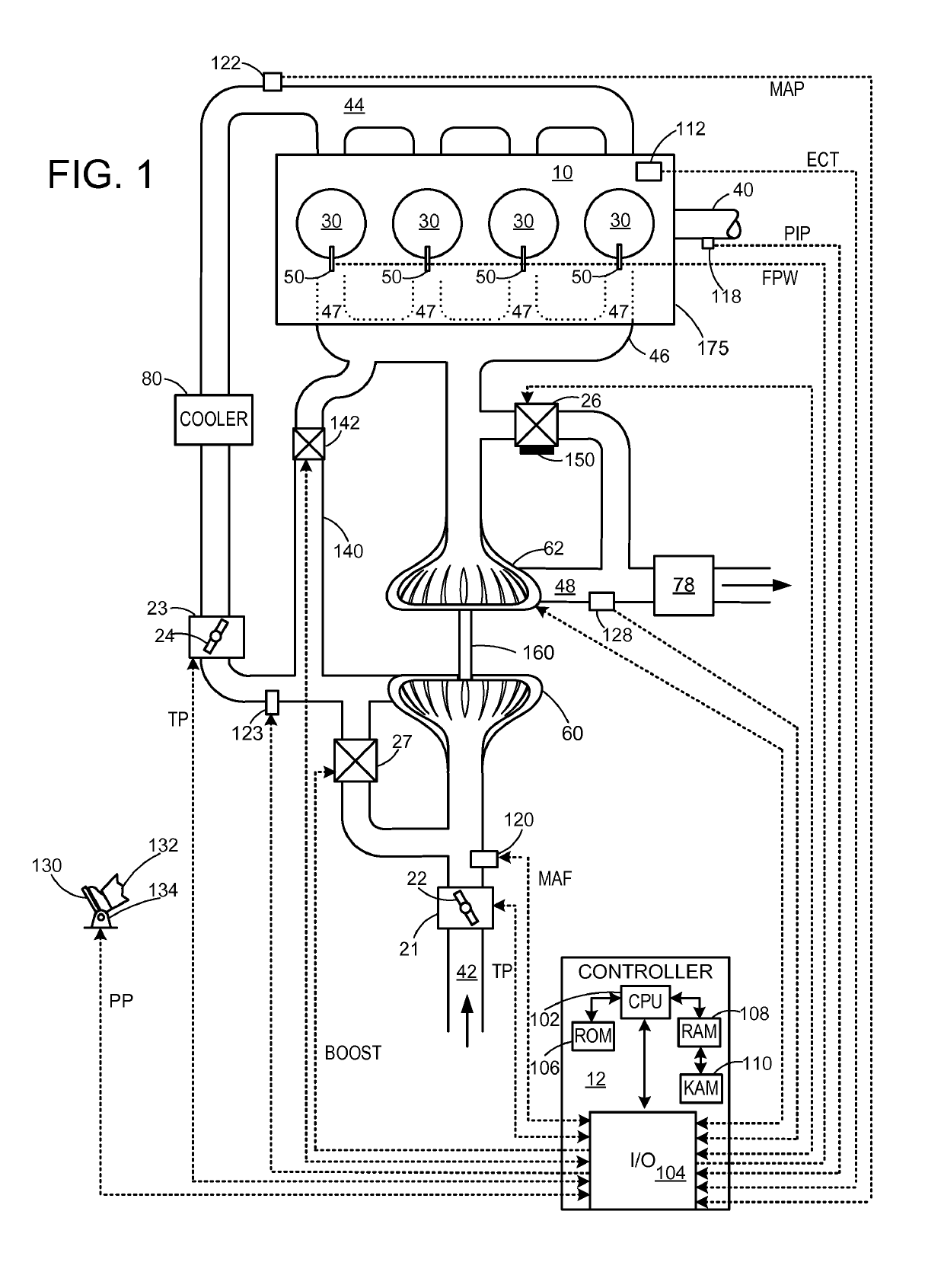

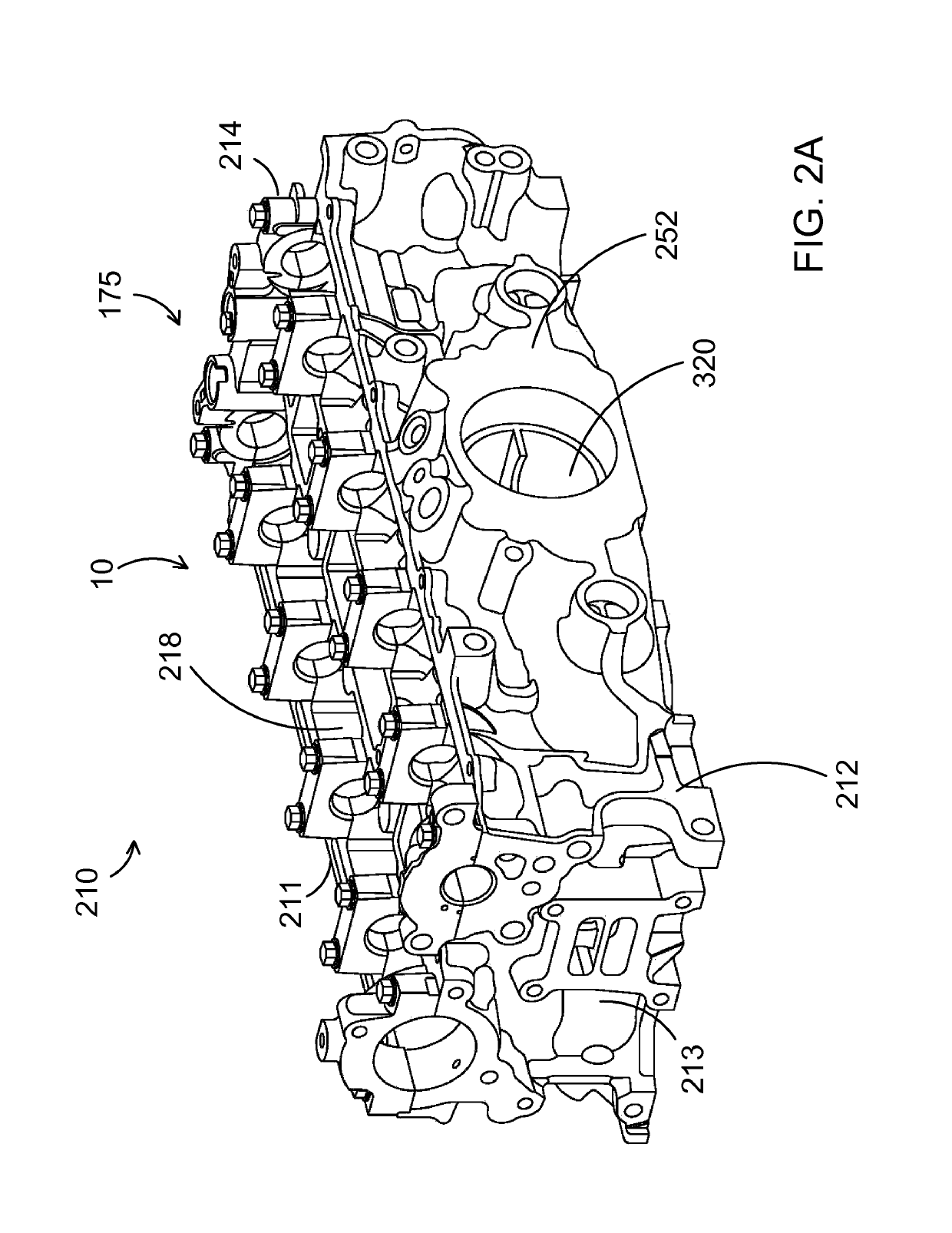

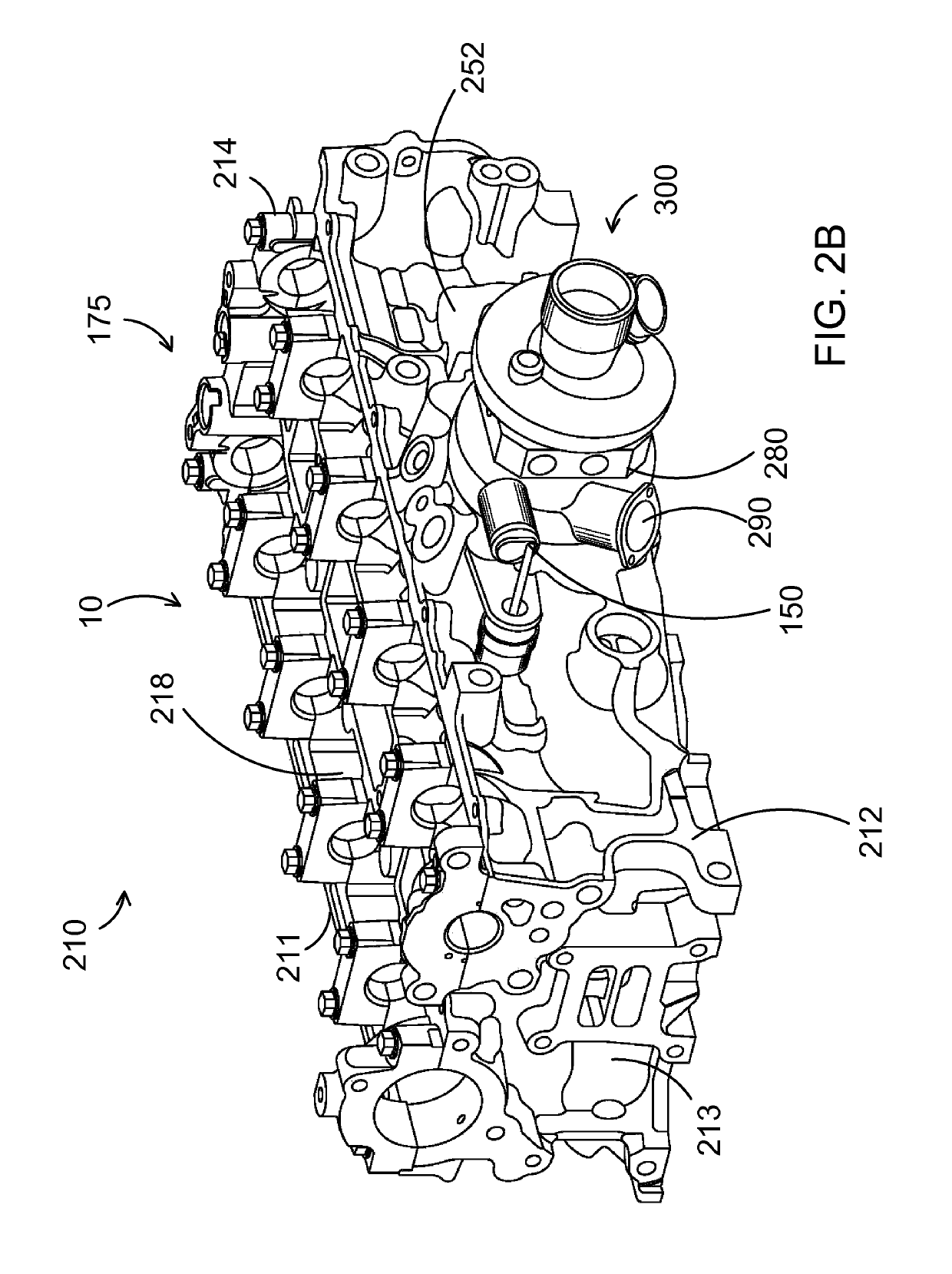

Direct inlet axial automotive turbine

ActiveUS20150007563A1Increase specific power outputReduce external emissionsInternal combustion piston enginesPump componentsCylinder headTurbocharger

Systems and methods for operating a turbocharged engine are described. In one example, a turbocharger system, comprising: a bearing housing including a turbine and at least one compressor coupled to the turbine via a shaft; and wherein the turbine comprises a stator stage and a rotor stage mounted to the cylinder head by the bearing housing and positioned in an exhaust passage of a cylinder head. In this way, a more compact design is achieved which eliminates the cost and complexity of a turbine housing and improves turbine efficiency by positioning the turbine closer to the exhaust pulses.

Owner:FORD GLOBAL TECH LLC

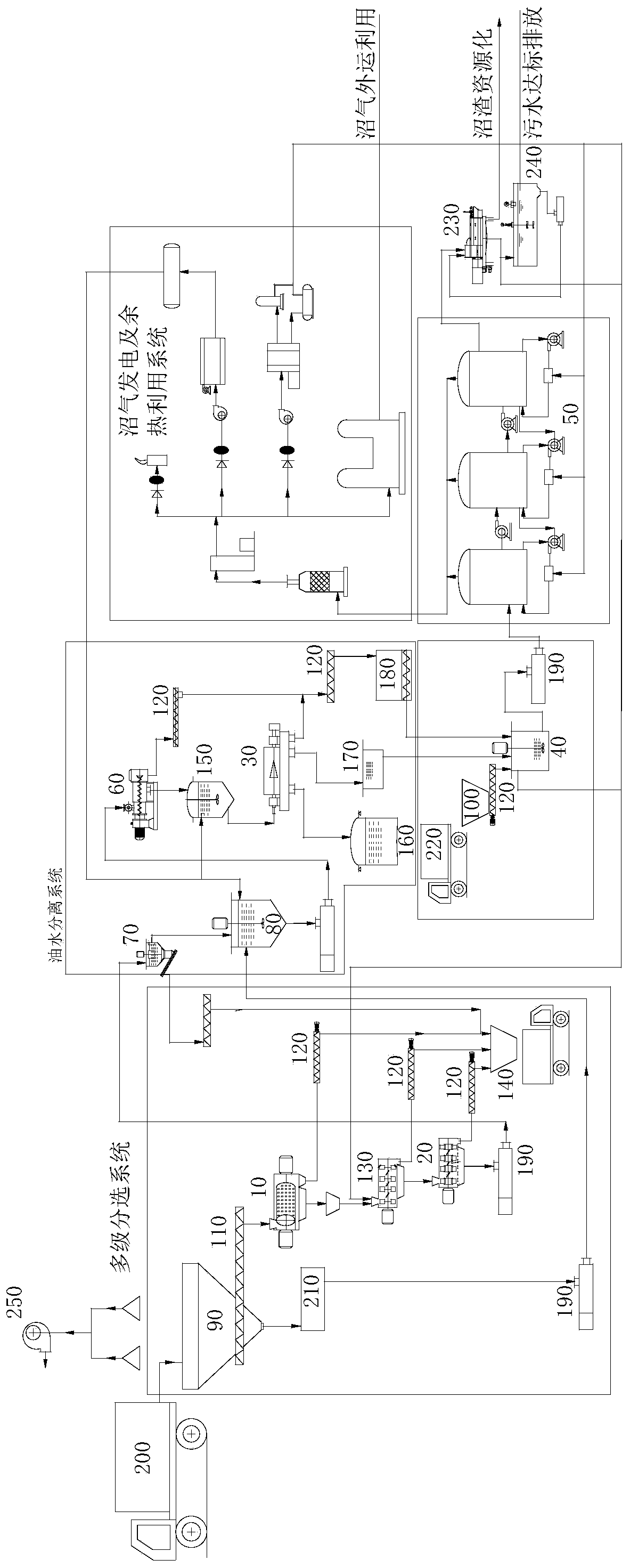

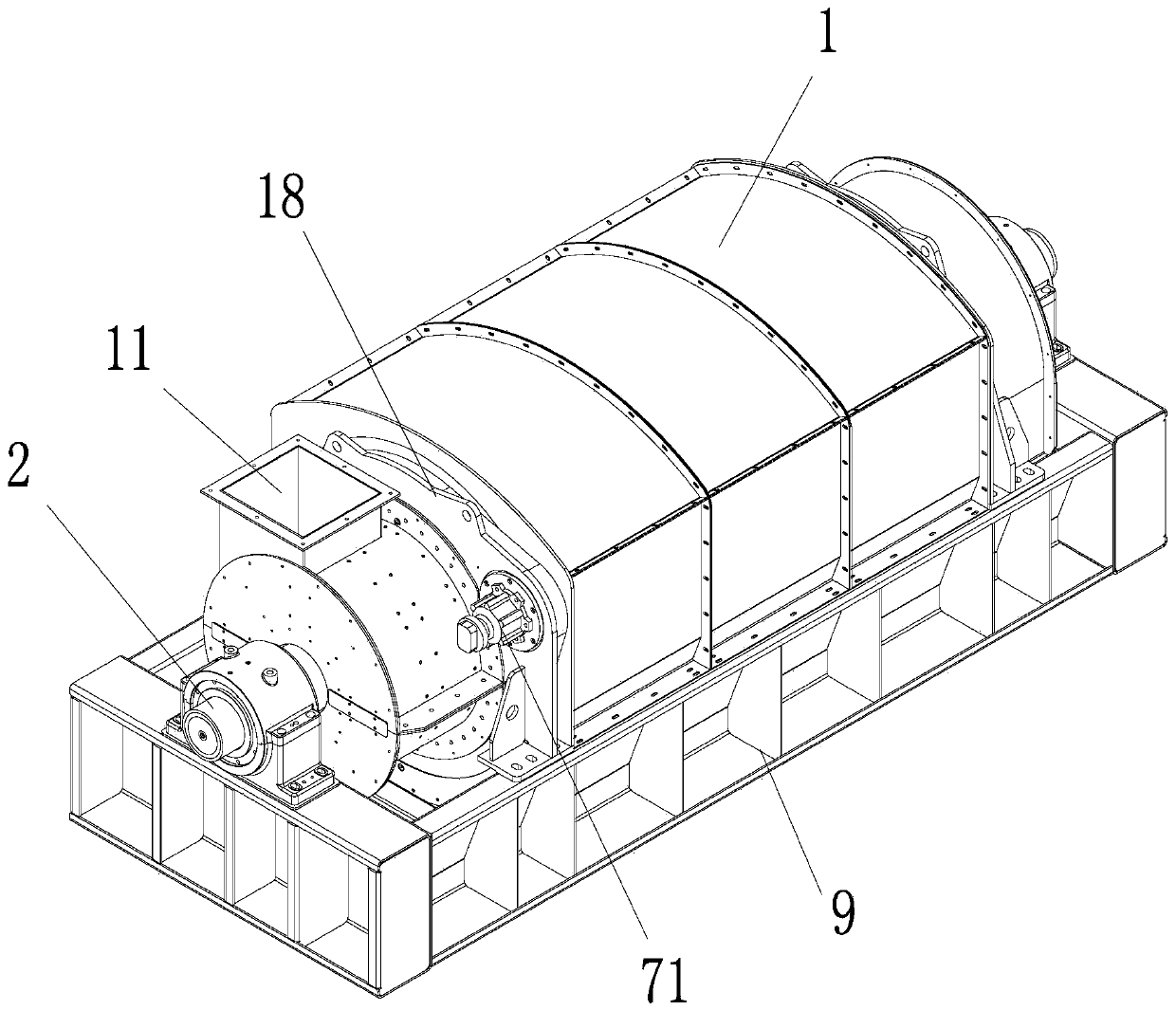

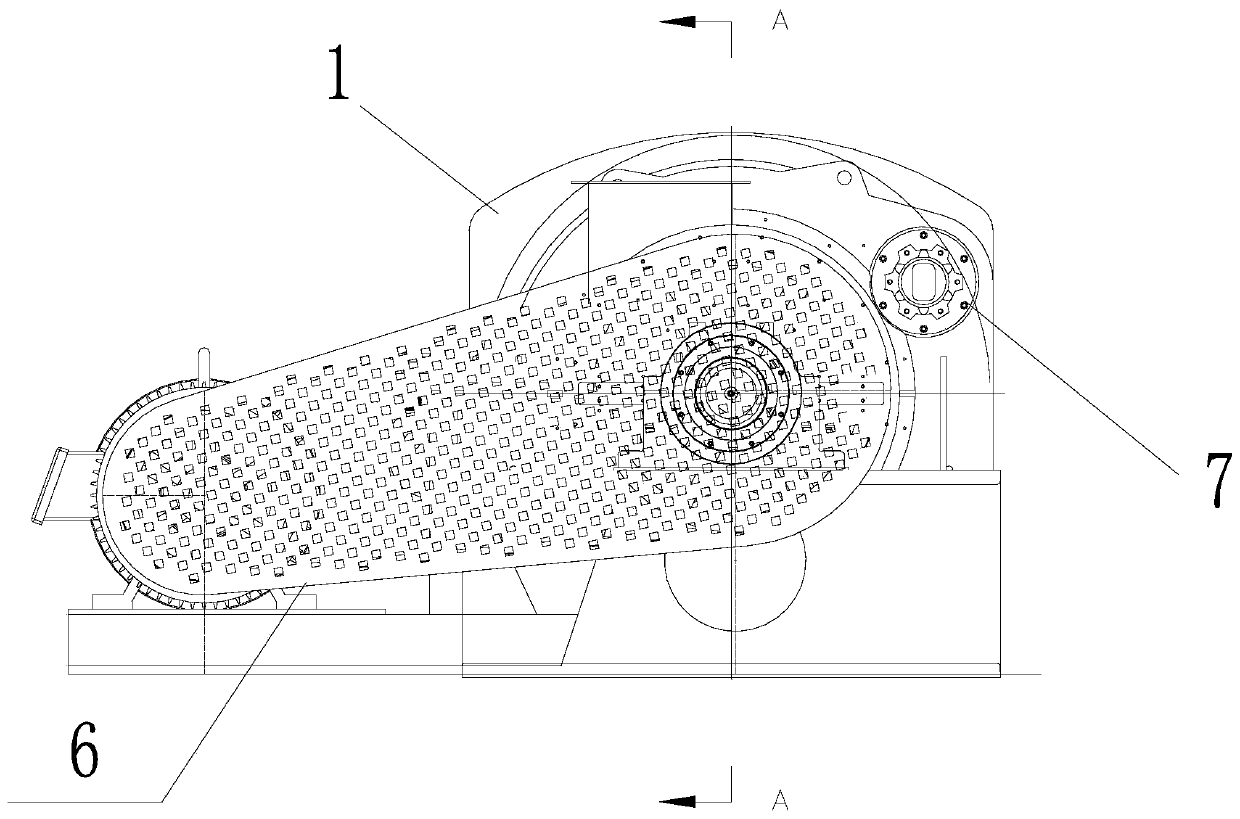

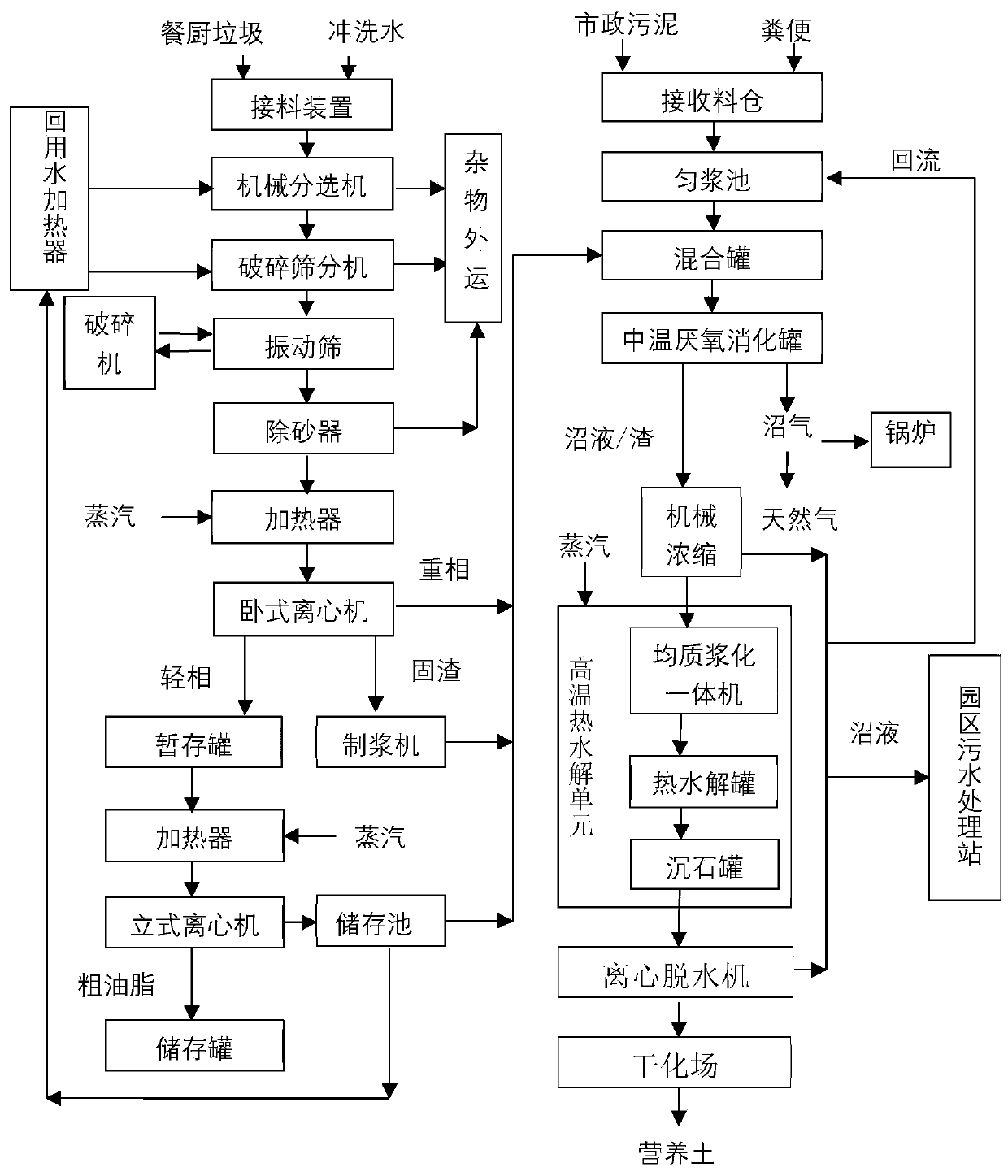

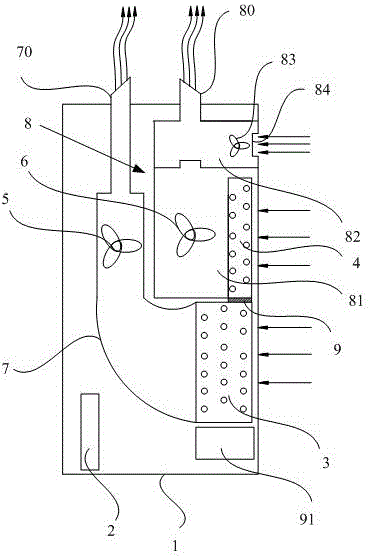

Kitchen waste and sludge collaborative treatment system and method

PendingCN110538861AIncrease profitSmall footprintBioreactor/fermenter combinationsBio-organic fraction processingOil and greaseBiodiesel

The invention discloses a kitchen waste and sludge collaborative treatment system and method. The system comprises screen type separation equipment for screening kitchen waste, crushing and separationequipment for crushing and separating the small kitchen materials obtained after screening, oil-water separation equipment for carrying out oil removal treatment on the kitchen slurry separated out by the crushing and separation equipment, collaborative pulping equipment for mixing the sludge and the kitchen slurry after oil removal treatment and anaerobic digestion equipment for carrying out anaerobic digestion on the mixed slurry prepared by the collaborative pulping equipment. After the kitchen waste is subjected to classification and separation and slag removal, the content of inorganic matter can be reduced, and the anaerobic fermentation efficiency is improved. Meanwhile, the internal abrasion of a tank body is reduced. On one hand, the oil removal treatment can collect the waste oil for reutilization (such as preparing of biodiesel), so that the project benefit is increased; and on the other hand, the grease content and the specific adhesion and isolation characteristics of grease in the slurry can be reduced, and the anaerobic reaction effect is increased after the grease is removed.

Owner:中铁环境科技工程有限公司

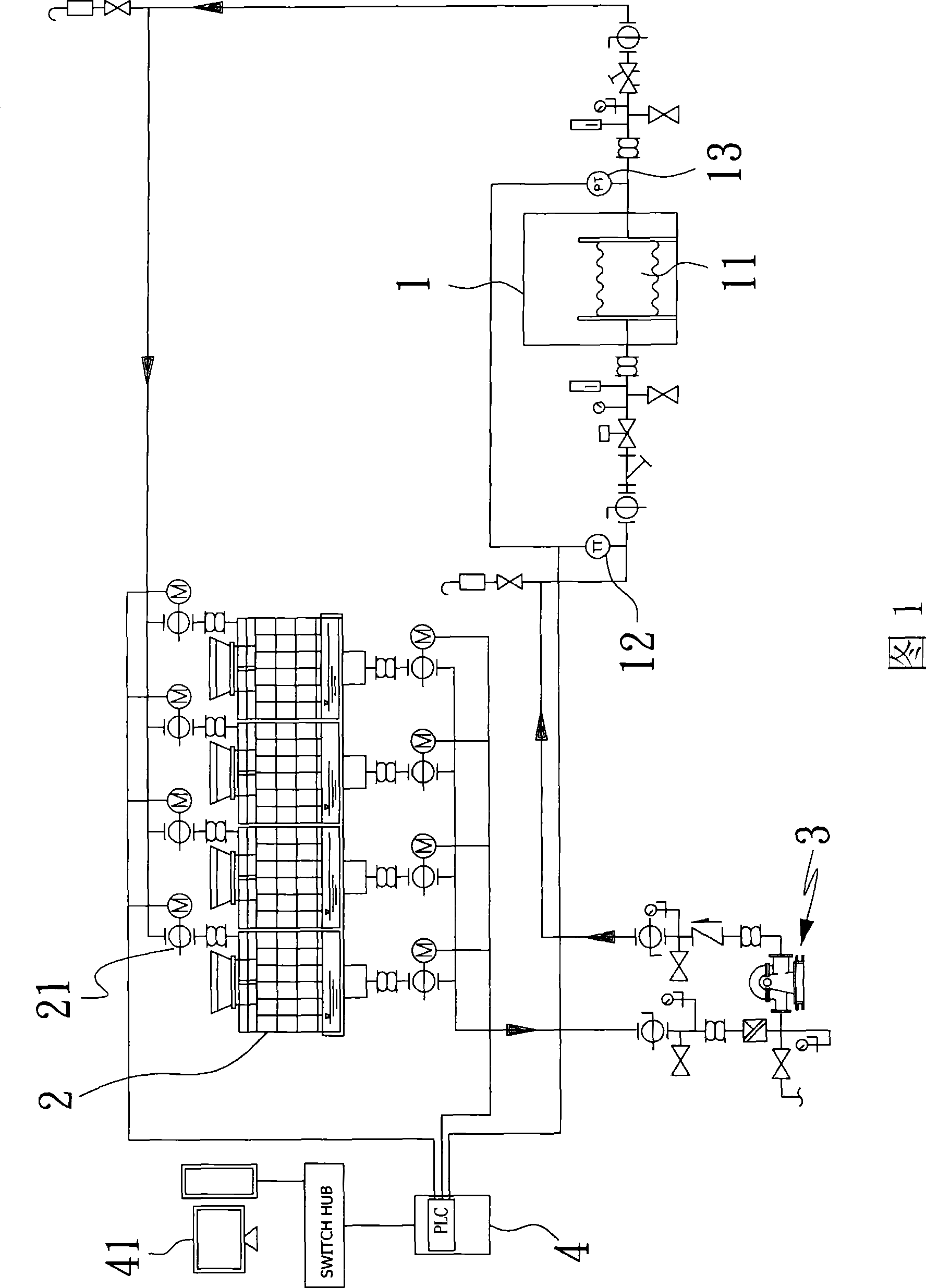

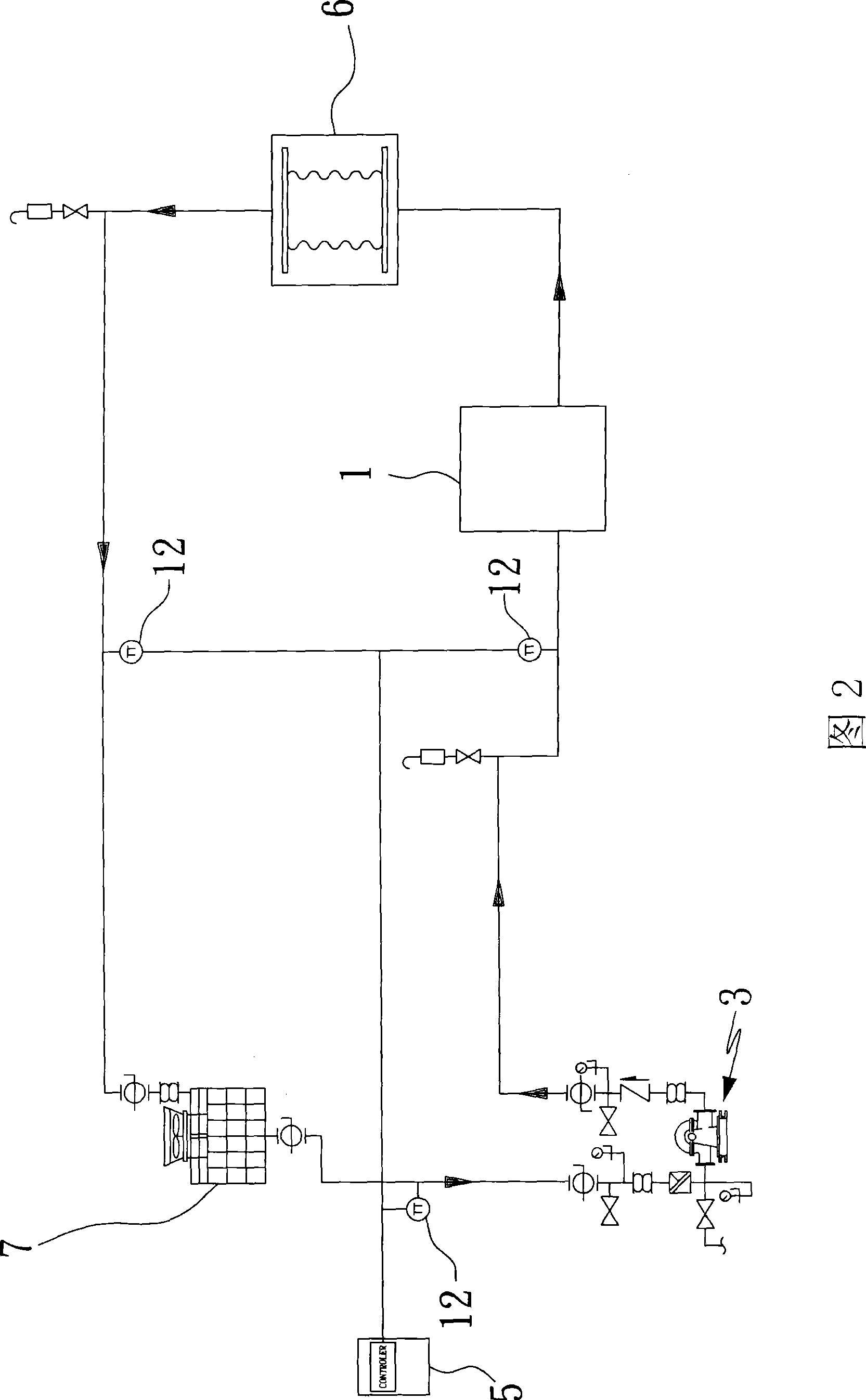

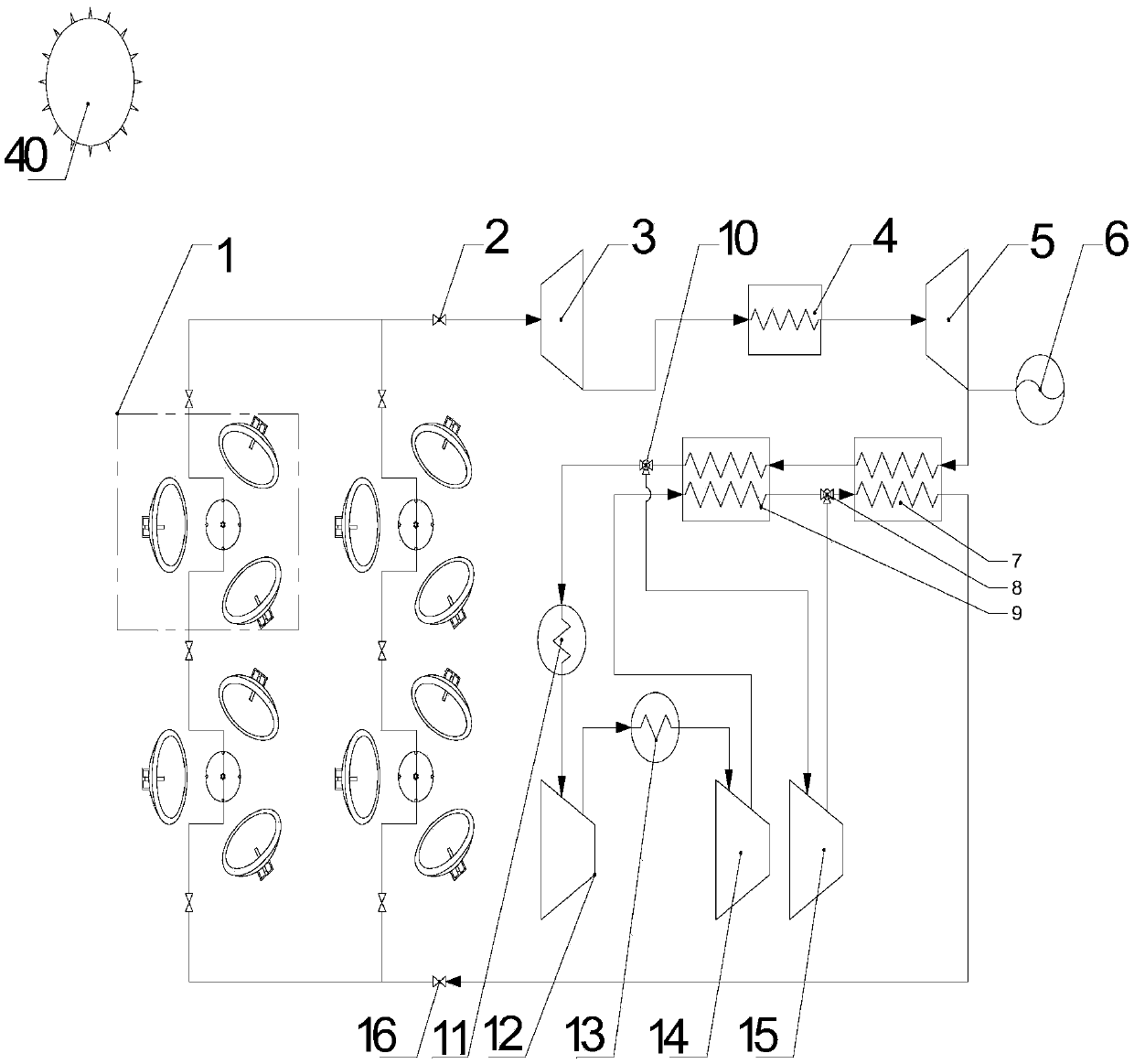

Thermal recovery circulating system of air compressor

InactiveCN101435420AReduce consumptionAvoid damagePositive displacement pump componentsPositive-displacement liquid enginesThermal energyControl signal

The invention provides a heat recovery and circulating system of an air compressor. Typically, a heat-transferring device is arranged between the air compressor and a cooler. The system can recycle the heat energy produced by the air compressor effectively, and converts the heat into heat resources for other purposes, uses a pump to pressurize cooling water to make the cooling water to pass through the air compressor, the heat transferring device and the cooler respectively, uses a controller to monitor the temperature of the cooling water flowing through the air compressor and the cooler, and then outputs a control signal after calculation according to the preset condition so as to control the acceleration-deceleration or operation stop of the cooler so that the cooling water can flow back to the pump via the cooler after passing through the air compressor and the heat transferring device to form the heat recovery and circulating system. With control of the temperature of the cooling water at control positions, the heat recovery and circulating system can achieve the optimum recovery and heat dissipating efficiency.

Owner:曾德勋

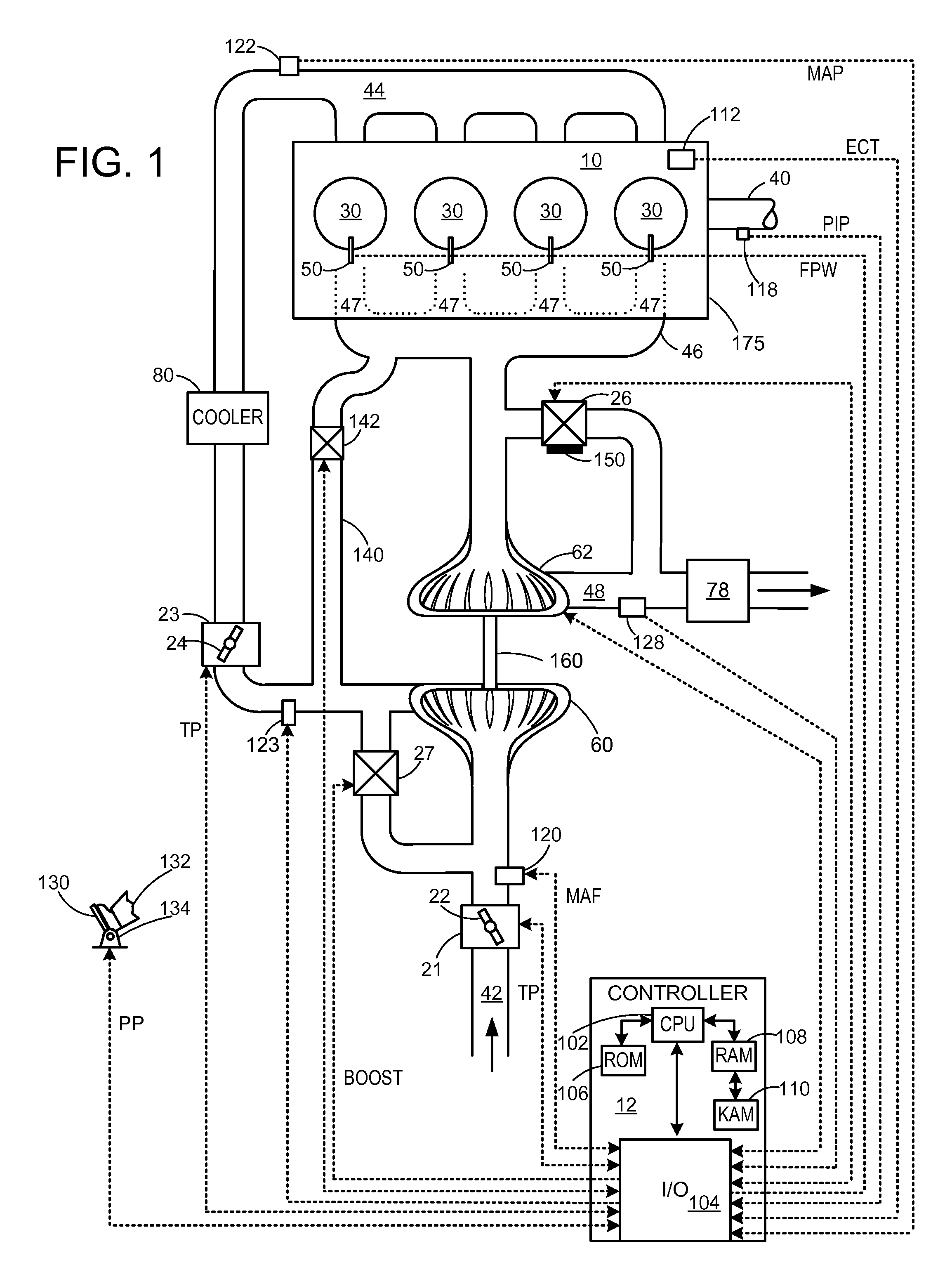

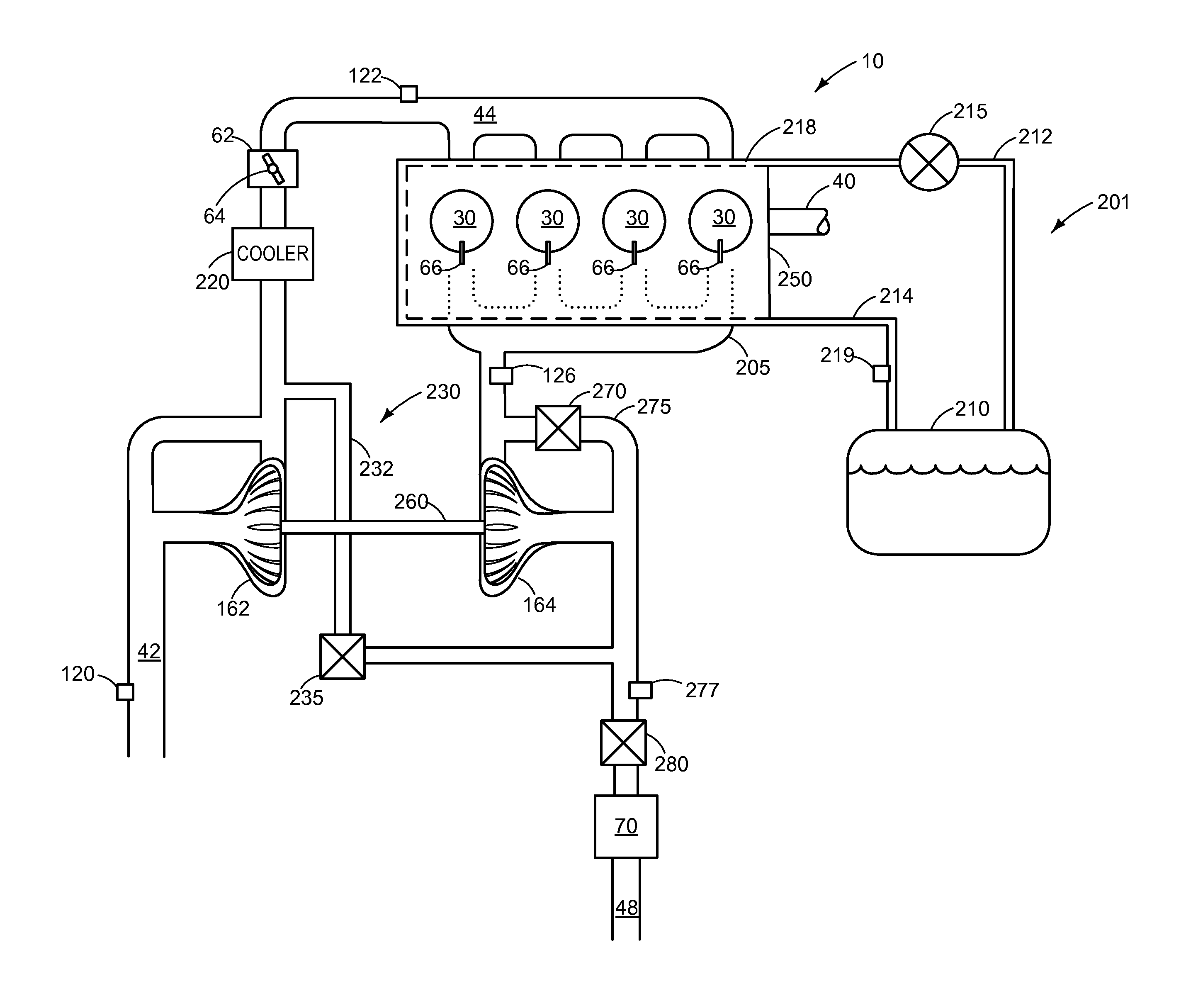

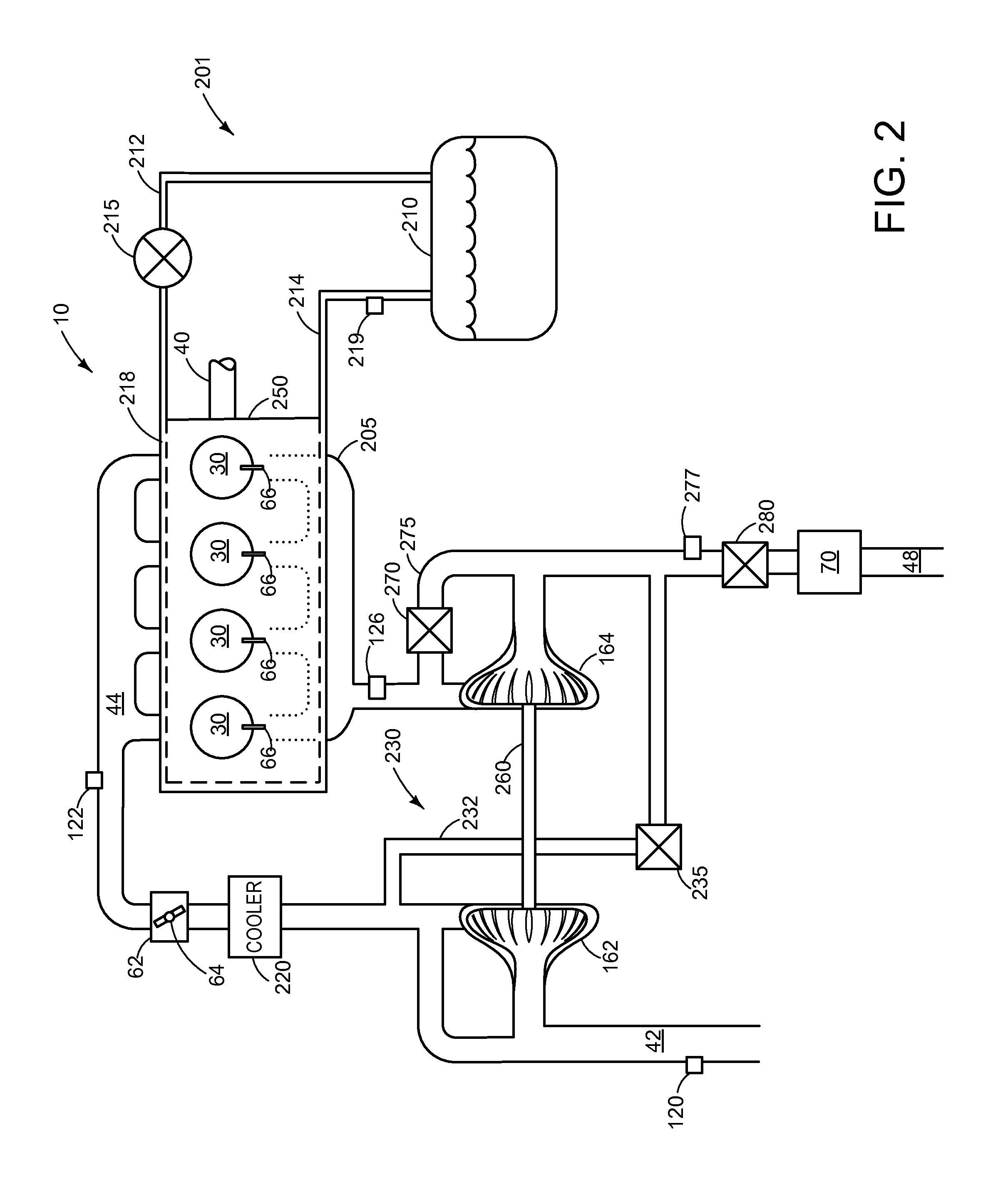

Pulse separated direct inlet axial automotive turbine

ActiveUS20150007800A1Reduce external emissionIncrease specific power outputInternal combustion piston enginesNon-fuel substance addition to fuelTurbineCylinder head

Systems and methods for operating a turbocharged engine are described. In one example, a system comprises a cylinder head having a first and second exhaust duct separately coupled to first and second groups of cylinders, each of the first and second exhaust ducts leading to an exhaust driven turbine mounted inside the cylinder head on a bearing, the bearing located within a bearing housing supported by the cylinder head. In this way, exhaust pulses remain separate up to the turbine mounted inside the cylinder head.

Owner:FORD GLOBAL TECH LLC

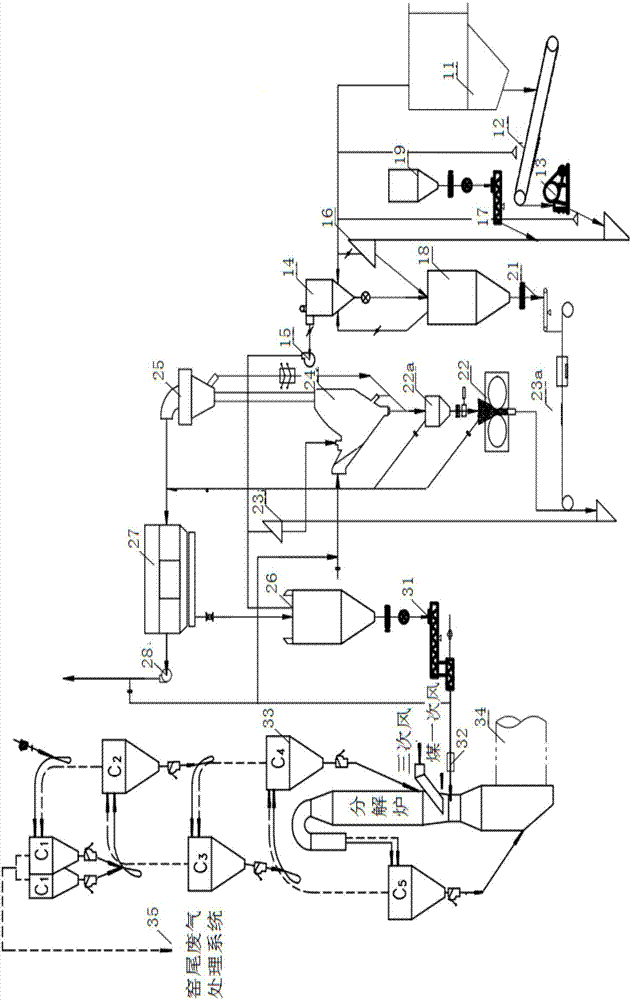

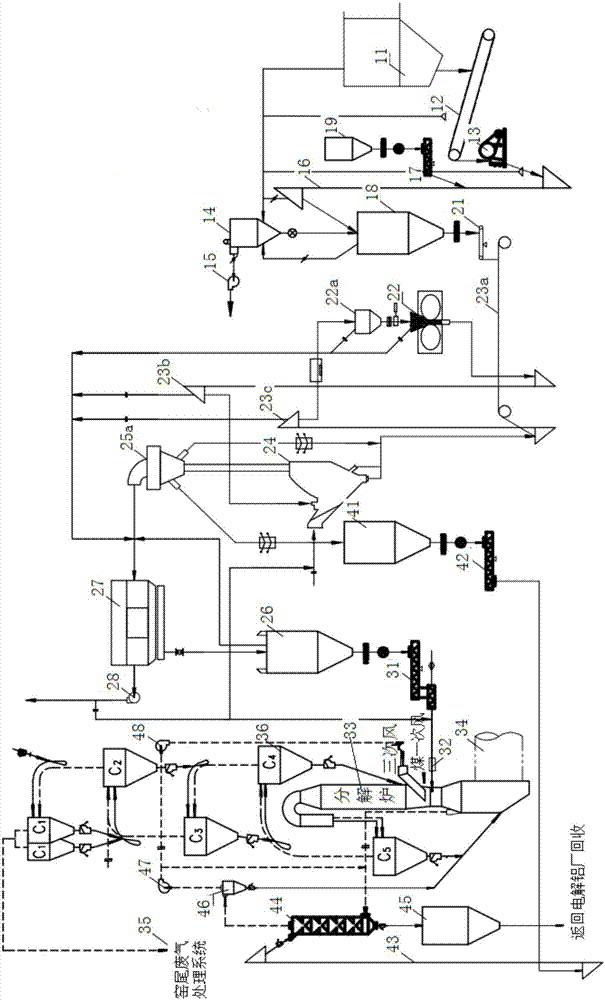

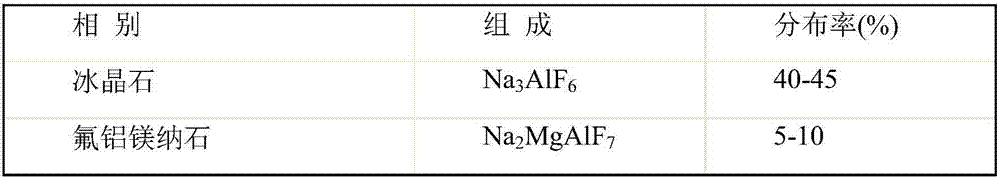

Treatment device and method for slag obtained after overhauling aluminum electrolysis cell

ActiveCN107401746ALose toxicityEliminate hazardsClinker productionIncinerator apparatusElectrolysisSlag

The invention provides a treatment device and method for slag obtained after overhauling an aluminum electrolysis cell. The treatment method comprises the following steps: crushing the slag obtained after overhauling the aluminum electrolysis cell, mixing the crushed slag with a lime fluoride retention additive, grinding the mixture, performing powder selection circulation to obtain powder, and combusting the powder in a cement kiln, so as to completely eliminate hazards and enable the aluminum electrolysis cell to completely lose toxicity. According to the treatment device and method for slag obtained after overhauling the aluminum electrolysis cell, the overall treatment process is carried out in a sealing environment, exhaust gas generated is basically dry gas and finally discharged after being combusted, so that the clean emission is realized, and the secondary atmospheric pollution is avoided; besides, residue generated is used as a cement clinker and can be effectively reutilized, the risk of secondary pollution is completely eliminated, and the environment and production safety is also realized.

Owner:长沙中硅环保科技有限公司

Sludge, excrement and kitchen waste synergistic anaerobic digestion process

InactiveCN109942161AImprove dehydration effectInhibition of killingWater contaminantsSludge treatment by pyrolysisFecesSlurry

The invention discloses a sludge, excrement and kitchen waste synergistic anaerobic digestion process. The process comprises the following steps: uniformly mixing pretreated kitchen waste with sludgeand excrement, regulating the water content to 90 percent, cooling to 38 DEG C, and performing an anaerobic digestion reaction in a medium-temperature anaerobic digestion tank for 20 days, using the generated methane part in a steam boiler, preparing natural gas from the rest part, and pretreating kitchen waste and heating in pyrohydrolysis with steam; concentrating biogas residues and biogas slurry to enable the sold content to be 15 percent, performing homogeneous pulping and pyrohydrolysis reaction, cooling the reacted material to 80 DEG C, dehydrating and drying until the water content islower than 40 percent to prepare nutrient soil; recycling part of biogas slurry generated in the dehydrating process, and draining the rest part into a sewage treatment plant for treatment. The process can be used for comprehensively treating sludge, excrement and kitchen waste to generate natural gas and nutrient soil, biogas slurry in the process flow can be refluxed and utilized to reduce external emission, resource, emission reduction and innocent treatment of sludge, excrement and kitchen waste can be realized.

Owner:GUANGXI TEACHERS EDUCATION UNIV

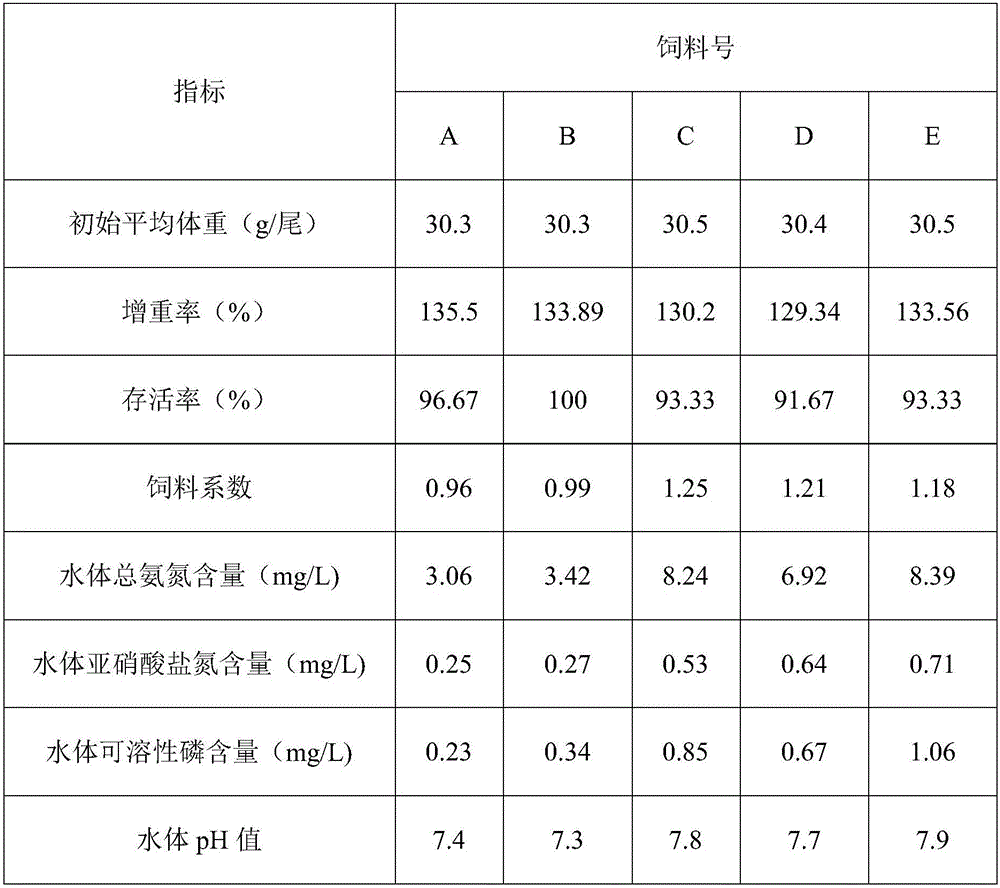

Environmentally protective raw fish puffed feed with low emissions of nitrogen and phosphorus and preparation method thereof

InactiveCN105767588ADoes not affect growth performanceReduce dosageFood processingClimate change adaptationVitamin CAntioxidant

The invention provides an environmentally protective raw fish puffed feed with low emissions of nitrogen and phosphorus. The puffed feed comprises fish meal, defatted soybean meal, corn protein powder, wheat gluten powder, spray dried blood meal, squid small peptides, fish oil, soybean oil, phosphatide oil, choline chloride, flour, tapioca flour, L-lysine hydrochloride, DL-methionine, threonine, tyrosine, taurine, mannan oligosaccharide, vitamin C, trace element premix, vitamin premix, an antioxidant. The prepared raw fish feed can significantly reduce nitrogen and phosphorus emissions, has a strong stability in water, is low in dissolve-loss ratio, and has a high-quality environmentally protective effect.

Owner:珠海海龙生物科技有限公司

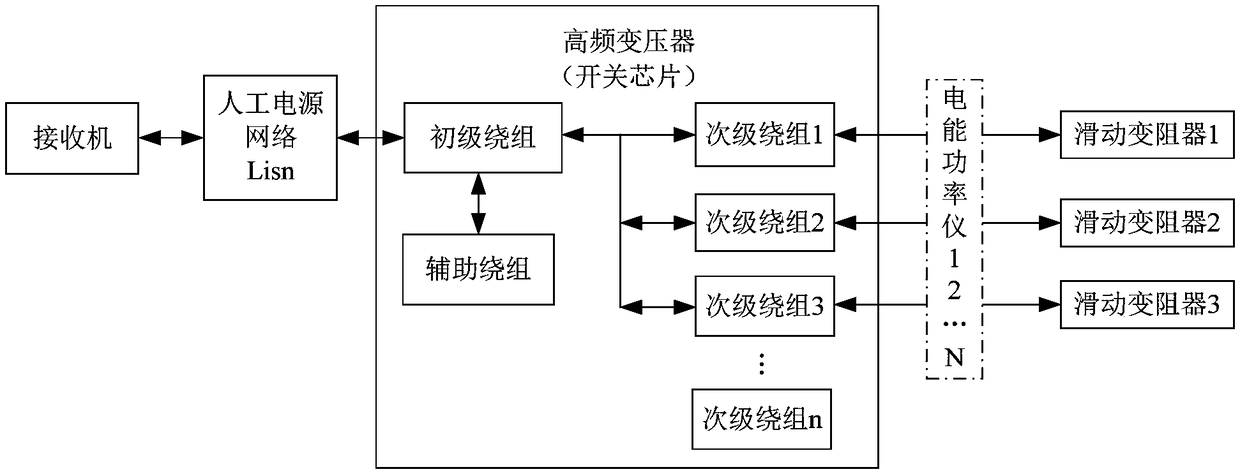

Switching power supply EMI test device and method

ActiveCN108872880AImprove stabilityImprove consistencyBase element modificationsPower supply testingTransformerSecondary loop

The present invention discloses a switching power supply EMI test device and method. The device comprises a high-frequency transformer, a receiver, an artificial mains network, an electric energy power instrument and a sliding slide rheostat, the high-frequency transformer comprises a primary winding and a plurality of secondary windings, the receiver, the artificial mains network, the primary winding and the secondary windings are connected in order, and the secondary windings is connected with the sliding slide rheostat through the electric energy power instrument. The switching power supplyEMI test device and method employ the secondary windings to connect with the sliding slide rheostat to replace a circuit, the sliding slide rheostat is a pure impedance device so as not to generate high-frequency components or have no interference or inhibition effect on the high-frequency components; the stability and the consistency of the performances of the switching power supply EMI are improved; the influences of the high-frequency transformer secondary loop electronic circuits in the switching power supply test on the EMI test are effectively solved so as to separately evaluate the performances of the EMI of the circuit of the switching power supply itself; and moreover, the external emission amount of the whole air conditioner is reduced to better improve the performances of the whole machine and save the rectification time and development cost.

Owner:GREE ELECTRIC APPLIANCES INC

High-reference plant-mixed heat regeneration equipment

InactiveCN111851207ARealize separate heatingAchieve high referenceDispersed particle separationRoads maintainenceHot air ovenFrequency conversion

The invention relates to high-reference plant-mixed heat regeneration equipment which comprises a first regeneration drying drum and a second regeneration drying drum which are arranged at intervals,and a first discharge box and a second discharge box on the first regeneration drying drum and the second regeneration drying drum are respectively communicated with a first air outlet pipe and a second air outlet pipe of a hot air hearth. The high-reference plant-mixed heat regeneration equipment is simple in structure, coarse and fine materials can be separately heated; coarse and fine materialsare respectively dried and heated through independent regeneration drying rollers; the temperature of coarse and fine materials is easier to control; particularly, fine materials are controlled; therotating speed of the regeneration drying drum is controlled through frequency conversion, so that the adding amount of the fine aggregate can be controlled by selecting different rotating speeds; thedischarging temperature of the fine aggregate can be effectively guaranteed by adjusting the size of the adjusting air door in a matched mode, coarse materials and fine materials are heated separately through the two rollers, the discharging temperature of the recycled coarse materials and the discharging temperature of the recycled fine materials can be effectively controlled, the yield of the recycled materials is effectively increased, and the high reference ratio of the recycled materials is achieved.

Owner:FUJIAN TIETUO MACHINERY

Strategy for engine cold start emission reduction

ActiveUS20140238318A1Reduce external emissionsIncrease specific power outputLiquid coolingCylinder headsEngineeringCoolant

A method for operating an engine having a cylinder head, comprising: following light-off of an exhaust catalyst from a cold-start condition, circulating liquid coolant through a cooling jacket of the cylinder head, and at a subsequent engine-off condition, draining at least some of the liquid coolant from the cooling jacket. In this way, at a cold start condition, the cooling jacket of the cylinder head may be filled with air, thus decreasing the amount of time needed for the exhaust catalyst to reach a light-off temperature.

Owner:FORD GLOBAL TECH LLC

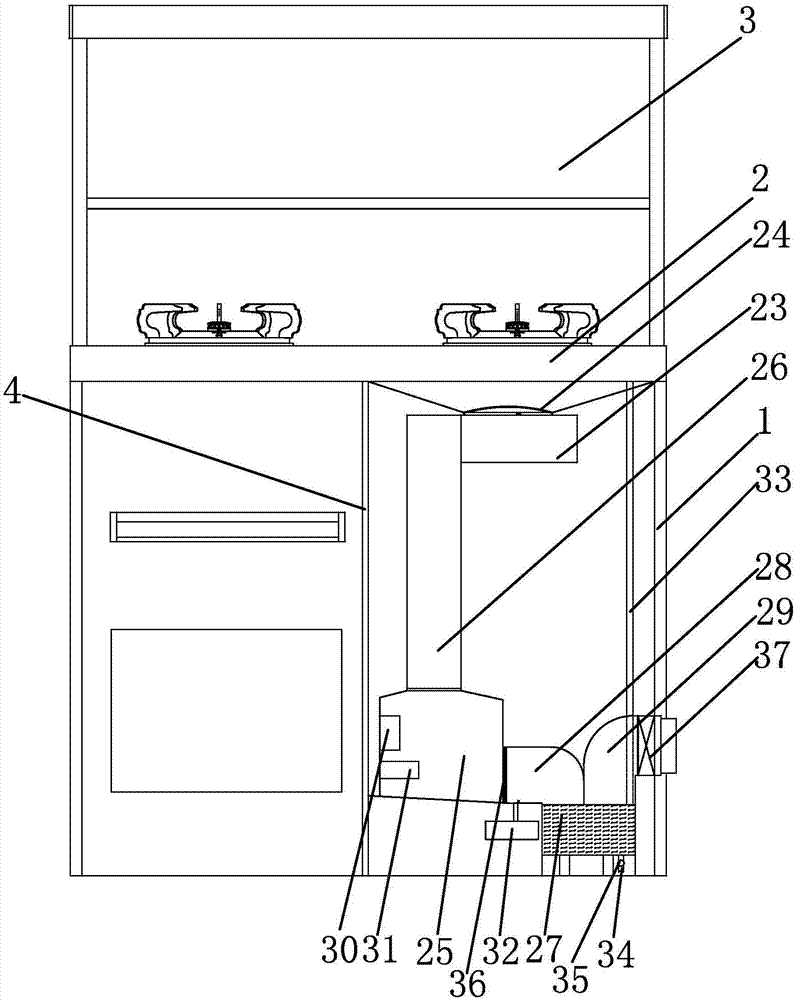

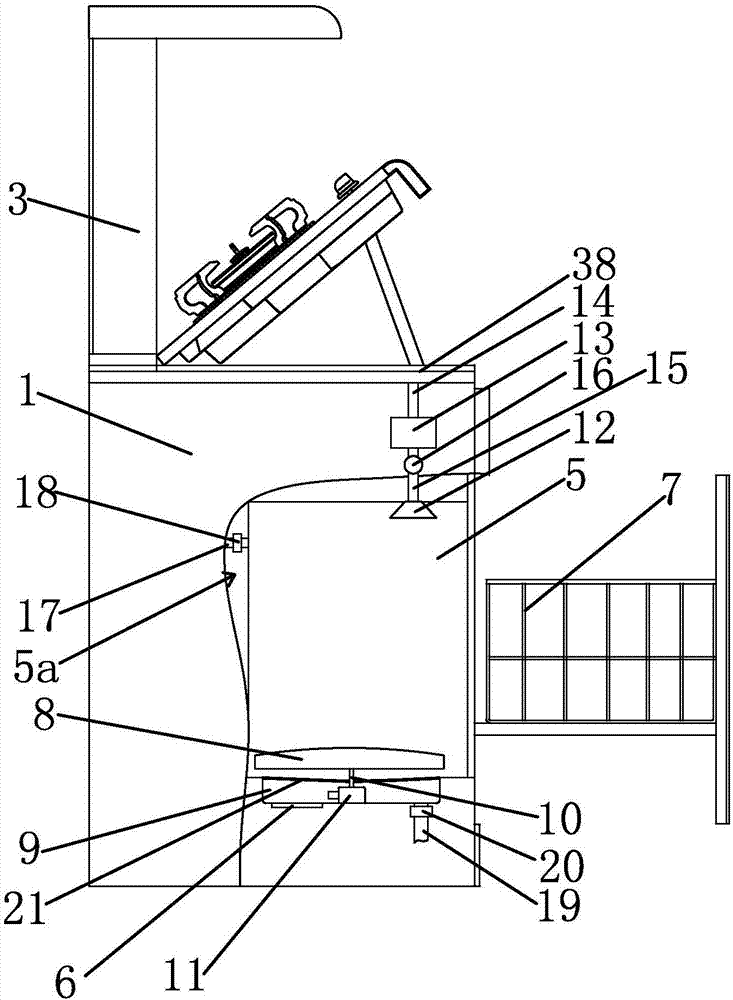

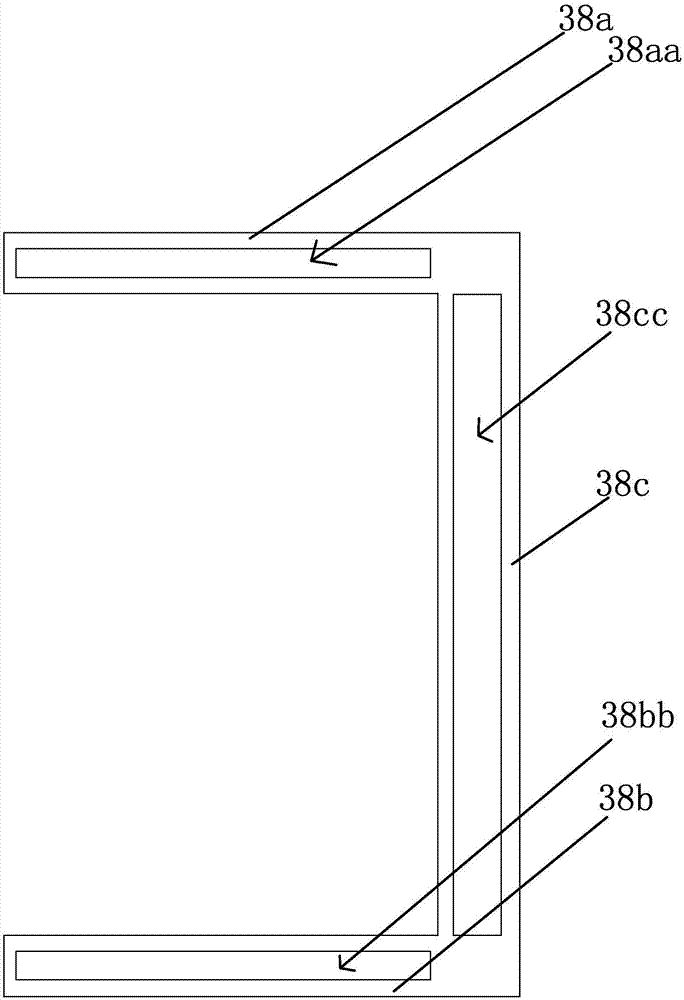

Improved multifunctional integrated cooker

InactiveCN107131532AImprove space utilizationReduce external emissionsCombination devicesDomestic stoves or rangesCookerEngineering

The invention provides an improved multifunctional integrated stove, which belongs to the technical field of integrated stoves. It solves the problem of the single function of the integrated stove in the prior art. The improved multifunctional integrated cooker comprises a cooker body, a cooker top and a smoke baffle, the cooker is located above the cooker body, the smoke baffle is connected to the cooker body and is located above the back of the cooker, and a fixed plate is vertically fixed in the cooker body , the fixing plate divides the stove body into cavity one and cavity two, cavity one is provided with a dishwasher mechanism capable of cleaning tableware, cavity two is provided with a purifying mechanism capable of purifying oil fumes, and the stove body is also provided with There is a turning mechanism capable of turning the stove top up. The invention has the advantages of washing dishes and purifying lampblack.

Owner:ZHEJIANG CHOOSITON KITCHEN ELECTRIC APPLIANCE CO LTD

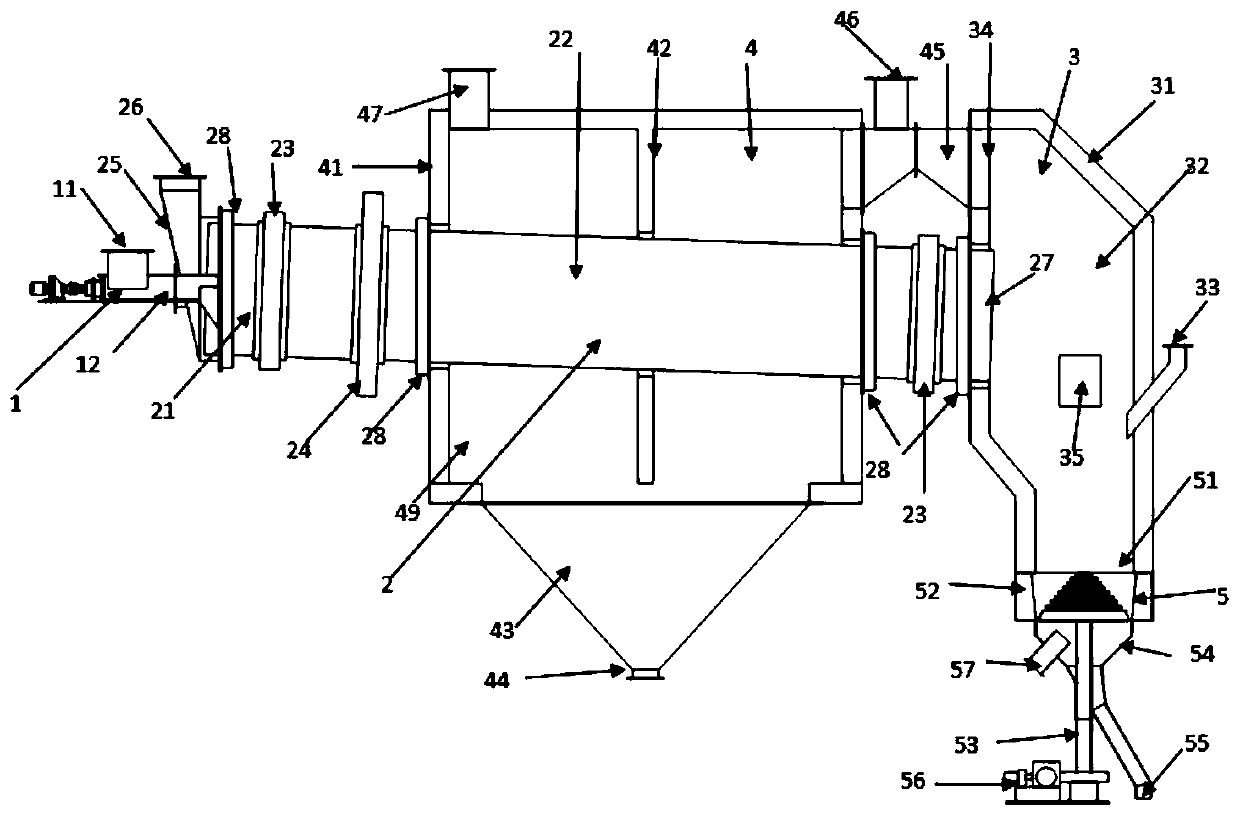

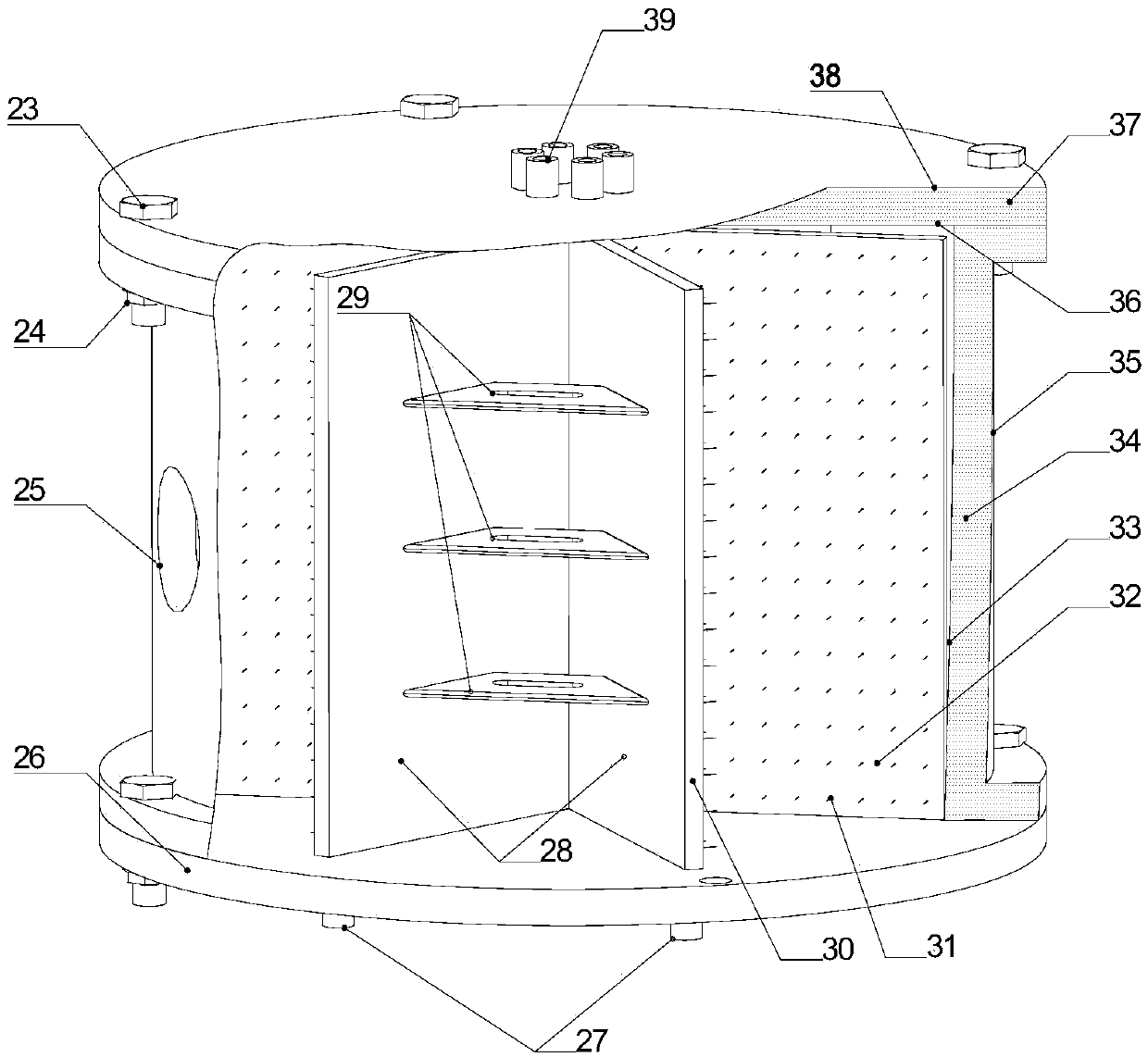

Combination melting furnace for treatment of arsenicsoda slag and low-melting-pointheavy-metal containing waste residue

PendingCN109708125ARealize thermal desorption methodImprove adaptabilityIncinerator apparatusMetals industrySlag

The invention discloses a combination melting furnace for treatment of arsenic soda slag and low-melting-point heavy-metal containing waste residue. The combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue comprises an air-lock feeder, a rotary kiln, a vertical incinerator, a high-temperature flue gas chamber and a crushing discharging mechanism, the air-lock feeder is connected with the rotary kiln, the rotary kiln is connected with the vertical incinerator, the vertical incinerator is connected with the crushingdischarging mechanism, the high-temperature flue gas chamber covers the outer part of the rotary kiln, the cylindrical shell of the rotary kiln is connected with the two ends of the high-temperatureflue gas chamber and the machine shell of the vertical incinerator through sealing rings, after two stages of combustion process are conducted on materials through the rotary kiln and the vertical incinerator, high-temperature flue gas is discharged through the rotary kiln and an flue gas outlet of the high-temperature flue gas chamber, and complete combustion of the combusted slag is thoroughly achieved after through the action of the crushing discharging mechanism. The combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue serves as combustion equipment, the equipment structure is simple and unique, the operation is convenient, the cost is low, waste residue smelting is conducted on industrial waste residue containing low-melting-point heavy-metal such as the arsenic soda slag and sludge containing arsenic, mercury, lead, zinc, cadmium through the unique technology of two stages combination combustion, andthe combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue is also suitable for pyrolytic incineration of waste materialcontaining organics.

Owner:长沙中硅环保科技有限公司

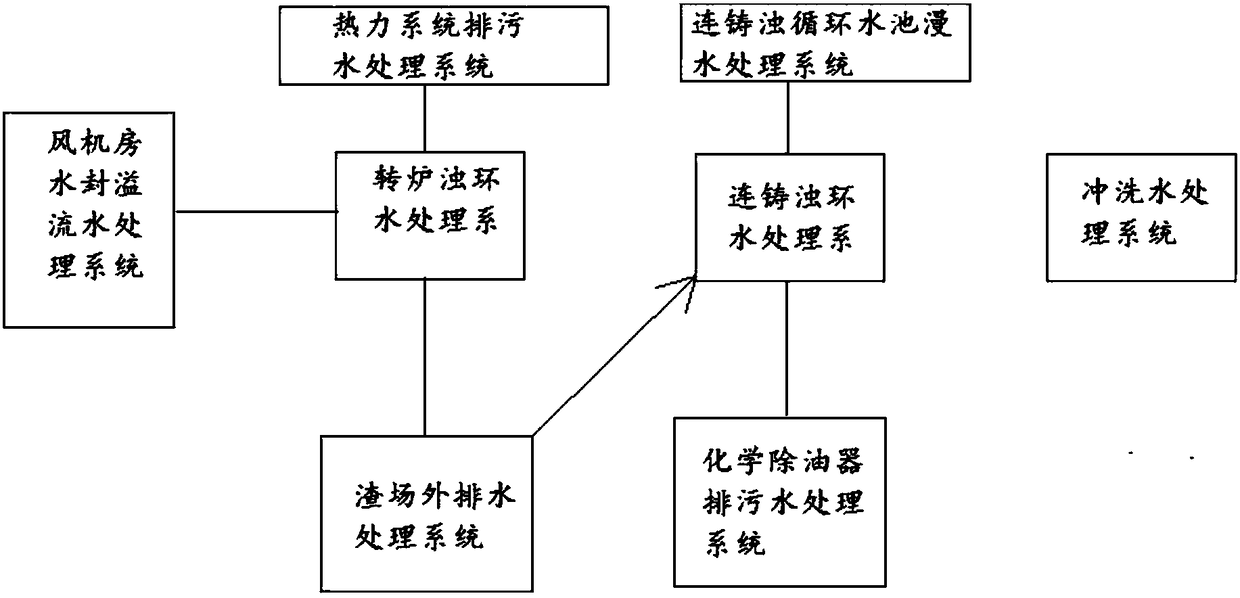

Sewage treatment system

InactiveCN108395049AReduce external emissionsReduce pollutionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWater treatment systemSewage

The invention discloses a sewage treatment system. The sewage treatment system comprises a converter turbid circulating water treatment system, a continuous casting turbid circulating water treatmentsystem and a washing water treatment system. The sewage treatment system with the structure is suitable for treating production sewage of a steel rolling factory, a large part of the sewage is recycled after being treated, drainage of the sewage to the outside is greatly reduced, and the pollution to the environment is relieved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

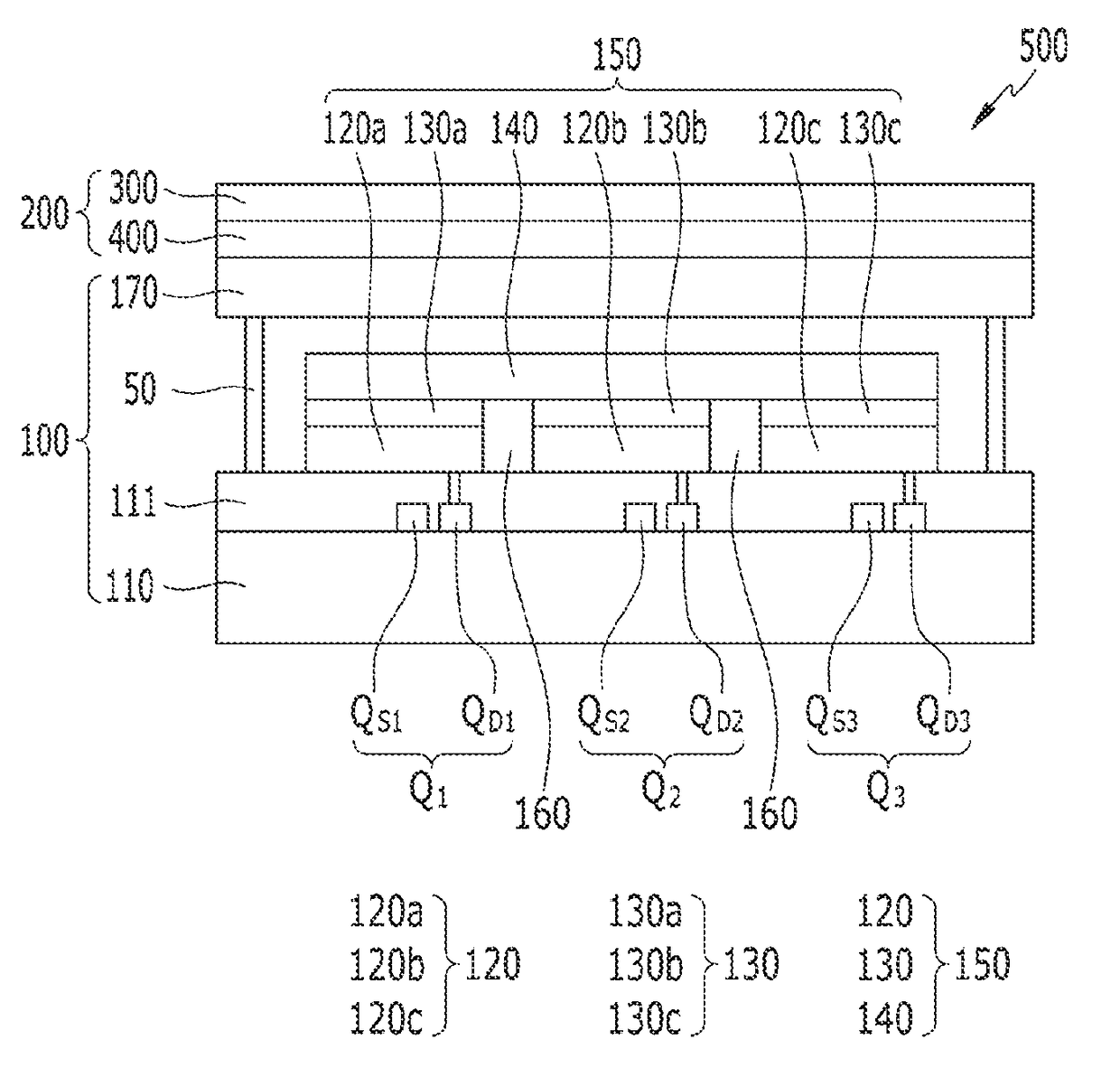

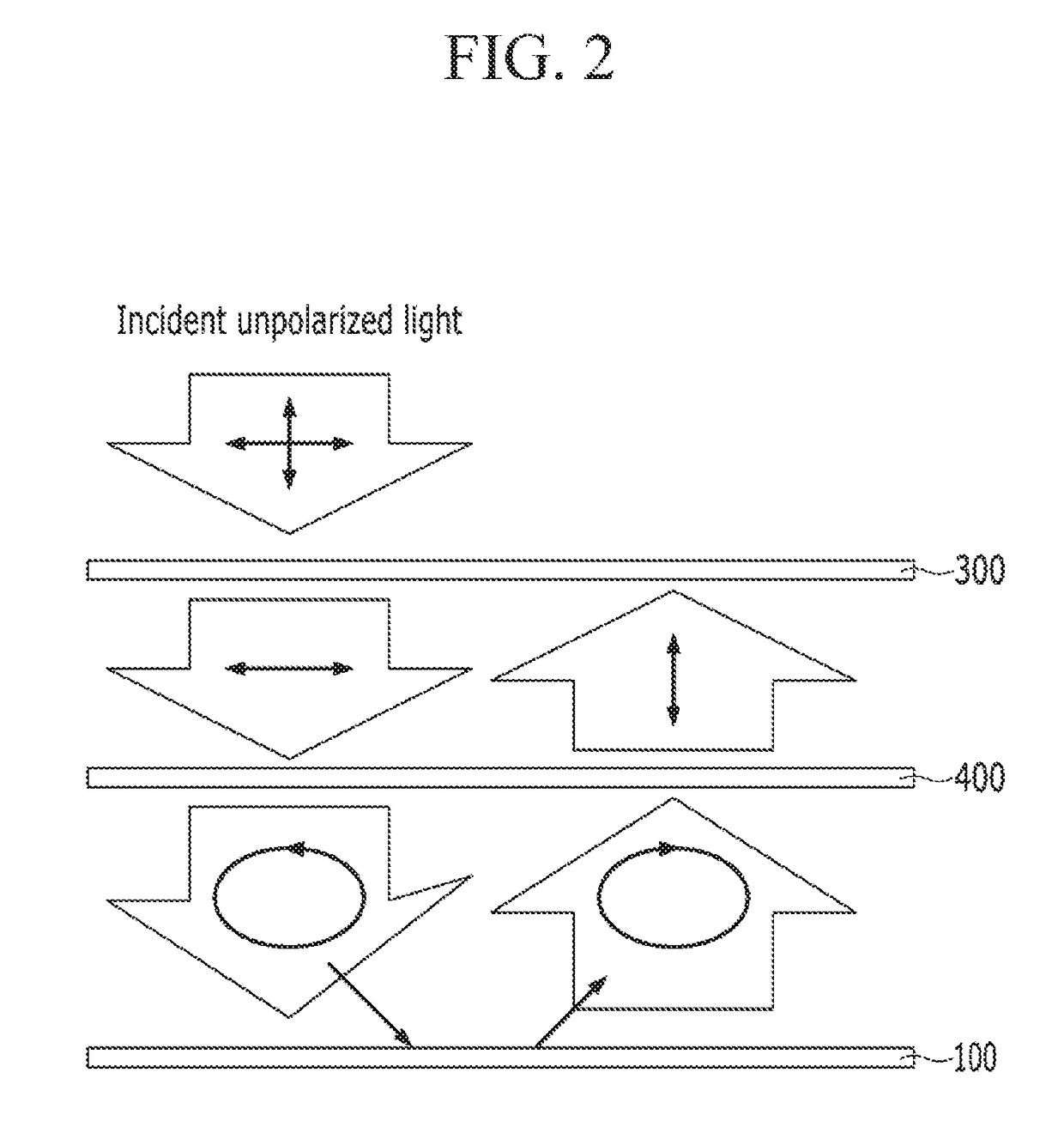

Organic light emitting diode device

ActiveUS20170285234A1Reduce reflectionReduce external emissionsSolid-state devicesPolarising elementsPolarizerLight-emitting diode

An organic light emitting diode device includes an organic light emitting display panel and a circular polarizing plate disposed on the organic light emitting display panel and including a polarizer and a compensation film, where a retardation of the compensation film in a first direction is determined based on a retardation of the organic light emitting display panel in the first direction.

Owner:SAMSUNG ELECTRONICS CO LTD

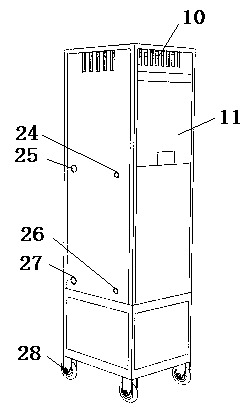

Movable air conditioner and air mixing method

InactiveCN106225096AReduce external emissionsImprove operational efficiencyCondensate preventionLighting and heating apparatusEvaporationEngineering

The invention discloses a movable air conditioner and an air mixing method. The movable air conditioner comprises a shell, a compressor, a condenser, an evaporator, a condensation fan and an evaporation fan. An evaporation air flue is arranged in the shell. An evaporation cavity and an air mixing cavity which communicate with each other are formed in the evaporation air flue. The evaporator and the evaporation fan are arranged in the evaporation cavity. An auxiliary air inlet is formed in the air mixing cavity. The air mixing fan is arranged at the position of the auxiliary air inlet. The evaporator is located above the condenser. A condensate water conveying part for flowing of condensate water is further arranged between the evaporator and the condenser and provided with a water channel.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

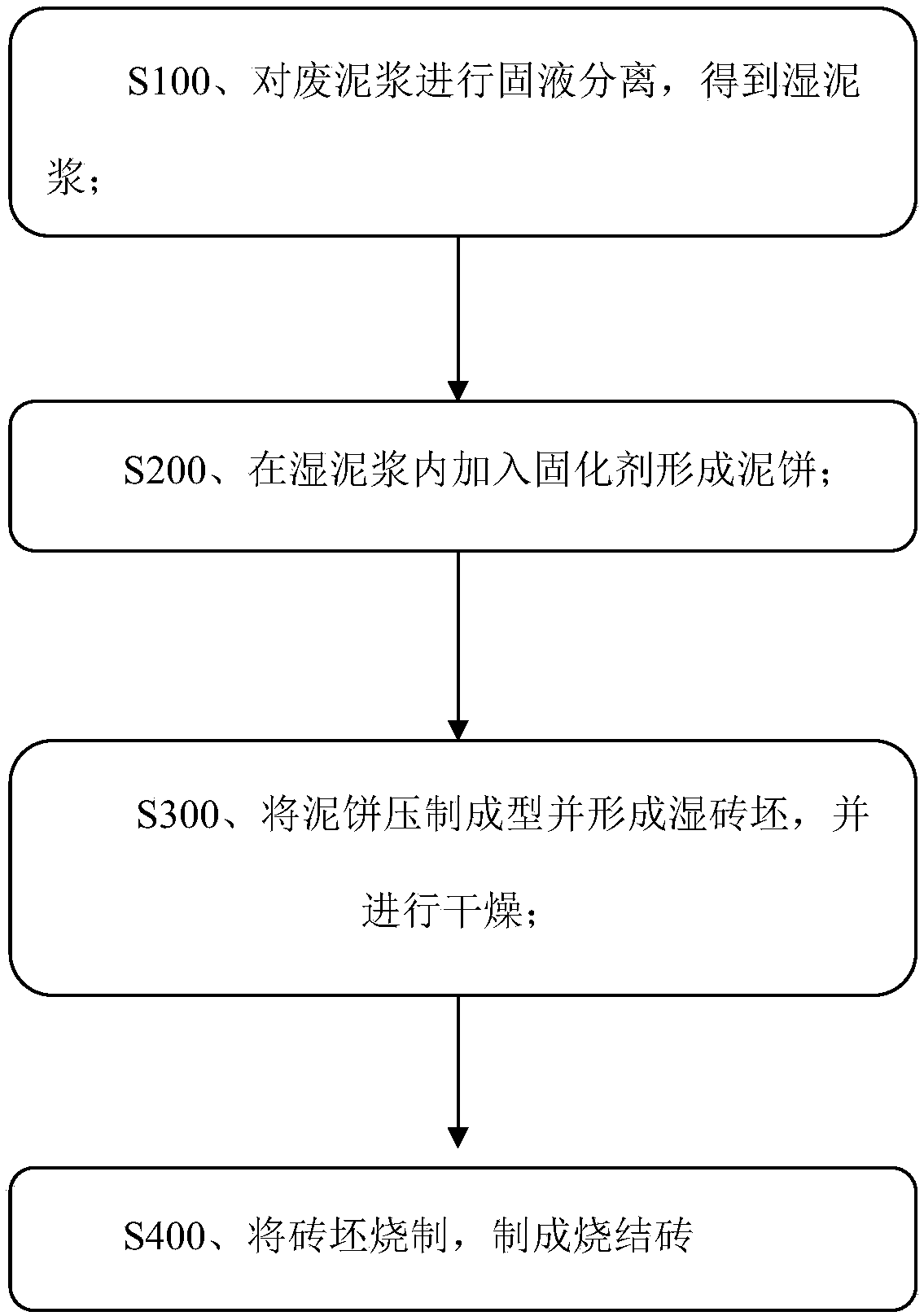

Production method for manufacturing sintered brick by using water-base mud

InactiveCN108329013AReduce alkaline corrosionReduce external emissionsSludge treatment by de-watering/drying/thickeningCeramic materials productionSolid phasesCorrosion

The invention discloses a production method for manufacturing a sintered brick by using water-base mud. The method comprises the following steps that firstly, waste mud is subjected to solid and liquid separation; supernate is pumped out; solid phase wet mud is obtained; secondly, a curing agent is added into the solid phase wet mud; the solid phase wet mud is cured to form mud cake; then, the mudcake is pressed and shaped to form a wed brick blank; drying is performed; finally, the dried brick blank is fired to form a sintered brick; the abandoned water-base mud is subjected to consolidationtreatment through a dehydrating agent and a flocculating agent; the alkaline corrosion of the mud is reduced; the supernate and the solid phase wet mud of the waste mud can be separated, and are respectively recovered and utilized; liquid is cyclically utilized without outward discharging; the curing agent is added into the solid phase wet mud, so that the character of the solid phase wet mud canbe changed; a sintered brick material with cement characteristics is formed; the outward discharging quantity of the waste mud is reduced; harmful substances in the waste mud are prevented from polluting and destroying environment.

Owner:四川同步油田技术服务有限公司

Plant-mixed heat regeneration equipment with cold adding function and production method thereof

PendingCN111218880AReduce adhesionReduce the risk of downtimeRoads maintainenceProcess engineeringHeating system

The utility model discloses plant-mixed heat regeneration equipment with a cold adding function. The plant-mixed heat regeneration equipment comprises a coarse aggregate conveying system, a coarse aggregate drying and heating system, a fine aggregate conveying system and a reclaimed material conveying device, the coarse aggregate drying and heating system comprises a regeneration drying roller, acombustion device and a tail gas treatment device, the regeneration drying roller is obliquely arranged, the tail end of the coarse aggregate conveying system is connected to the high position of theregeneration drying roller, a discharging box is arranged at the low position of the regeneration drying roller, and a coarse aggregate temporary storage bin is connected to the lower portion of the discharging box; the fine aggregate conveying system comprises a fine aggregate bin, a fine aggregate belt conveyor, a fine aggregate elevator and a fine aggregate conveying device, a fine aggregate temporary storage bin is arranged at the discharging end of the fine aggregate conveying device, a measuring scale is arranged below the fine aggregate temporary storage bin and the coarse aggregate temporary storage bin, and a reclaimed material conveying device is arranged below the measuring scale. Separate conveying and heating of coarse aggregate and fine aggregate can be achieved, the adhesiondegree of a regeneration drying roller and the like is reduced, the equipment shutdown risk is reduced, and the use performance of equipment is guaranteed.

Owner:FUJIAN TIETUO MACHINERY

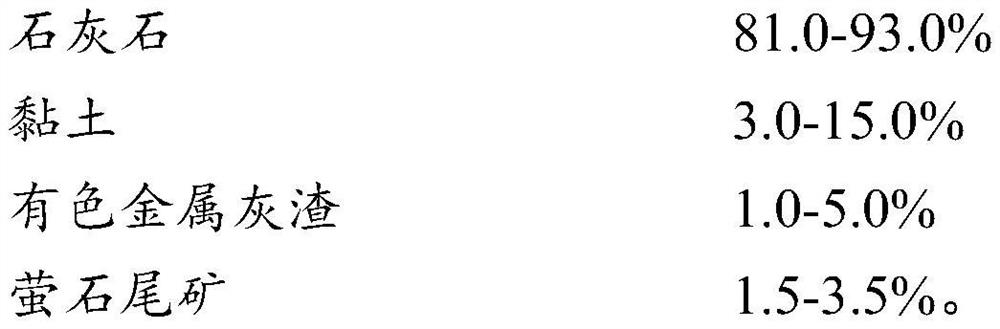

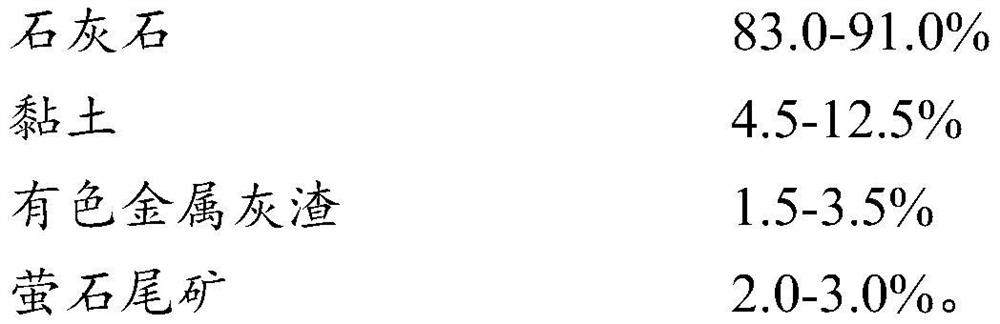

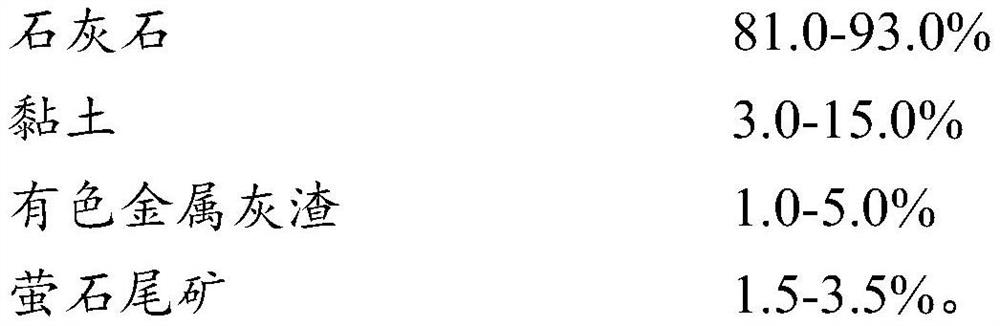

Retarding clinker and preparation method thereof

ActiveCN112341014AProlonged initial settingExtension of timeSolid fuelsCement productionClinker (waste)Nonferrous metal

The invention belongs to the field of cement, and particularly relates to a retarding clinker and a preparation method thereof. The retarding clinker comprises the following raw materials in percentage by mass: 81.0-93.0% of limestone, 3.0-15% of clay, 1.0-5.0% of non-ferrous metal ash residues, and 1.5-3.5% of fluorite tailings, wherein the content of calcium fluoride in the fluorite tailings is15-30%. By adding a certain amount of fluorite tailings, the initial setting time and the final setting time of the clinker are prolonged, and the production of the delayed coagulation clinker is realized, so the requirements of special engineering on the performance of retarding cement can be met; in addition, the mechanical property of the clinker is still maintained, so concrete quality can beensured while the requirements on cement retarding characteristics are met; and meanwhile, the fluorite tailings are effectively utilized, the utilization way of the fluorite tailings is broadened, stacking and external emission of waste production enterprises are reduced, and the demands of environmental protection are met.

Owner:兰溪南方水泥有限公司 +1

Direct inlet axial automotive turbine

ActiveUS9587588B2Increase specific power outputReduce external emissionsInternal combustion piston enginesExhaust apparatusCylinder headTurbocharger

Owner:FORD GLOBAL TECH LLC

A water-soluble fertilizer synergist

The invention discloses a water-soluble fertilizer synergist which contains 3,4-dimethylpyrazole phosphate, polyglutamic acid, polyacrylamide, bacillus subtilis and bacillus mucilaginosus. The water-soluble fertilizer synergist has the effects of holding water and enhancing the fertilizer efficiency, is capable of reserving effective ingredients and moisture in soil at a plough layer, further improving the nitrogen, phosphorus and kalium utilization ratio, conditioning soil, prolonging the fertilizer efficiency period and finally realizing the efficacies of fertilizer conservation, water conservation, labor conservation and environmental friendliness, and is simple in production process, convenient to use and beneficial to large-scale popularization.

Owner:张彬

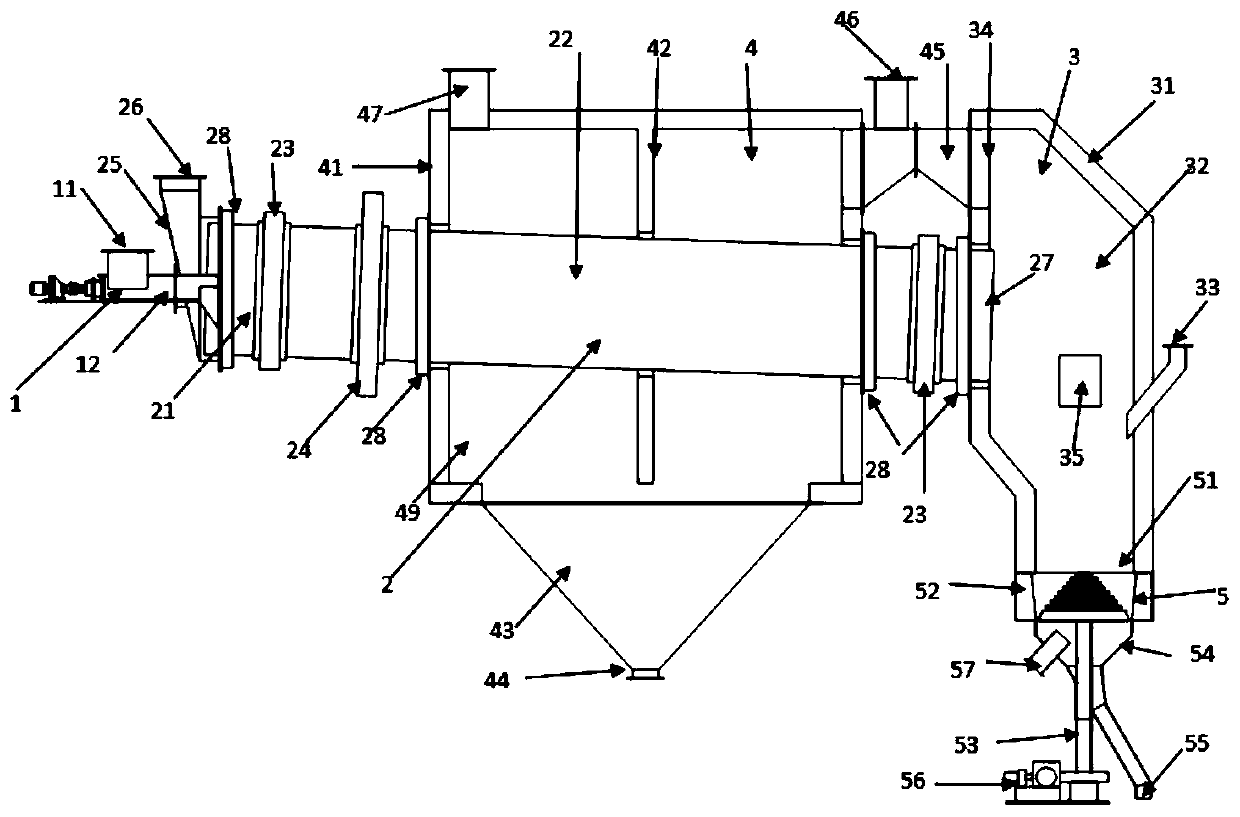

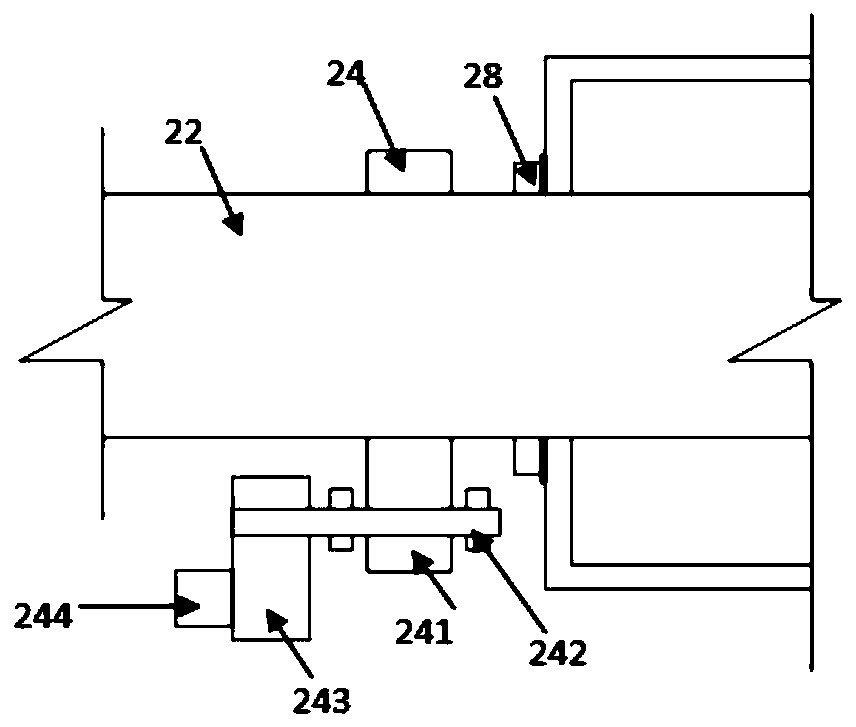

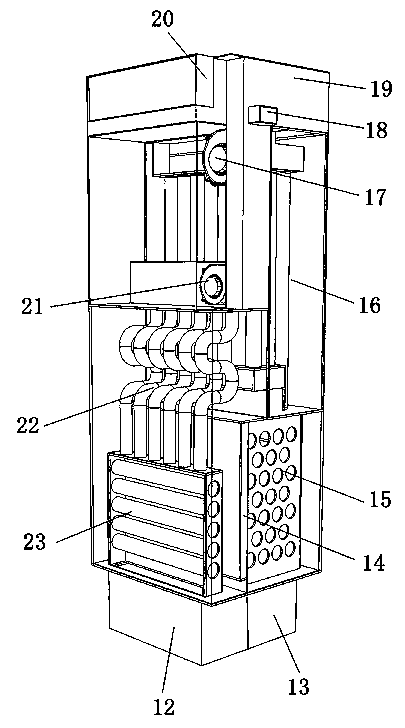

Environment-friendly type continuous feeding device and method of smelting furnace

PendingCN108362129AReduce high temperatureImprove working environmentCrucible furnacesWaste heat treatmentEngineeringFlange

The invention belongs to the field of smelting furnace equipment and particularly relates to an environment-friendly type continuous feeding device of a smelting furnace. The environment-friendly typecontinuous feeding device of the smelting furnace comprises a steady flow bin, an airtight conveying belt, a feeder and the smelting furnace which are connected in sequence. A bottom outlet of the steady flow bin is arranged above the head end of the airtight conveying belt. The feeder comprises a feeder pipeline, and a first baffle structure and a second baffle structure are sequentially connected in the feeder pipeline through flanges from top to bottom. The feeder is provided with a feeder inlet, the feeder inlet is arranged below the tail end of the airtight conveying belt and provided with a flow guide plate matched with the airtight conveying belt, and a buffer plate is arranged below the flow guide plate in a staggered mode. The upper side of the smelting furnace is provided with afeeding inlet matched with an outlet of the feeder. The invention further relates to an environment-friendly type continuous feeding method of the smelting furnace. According to the environment-friendly type continuous feeding device and method of the smelting furnace, the structure is simple and continuous feeding can be achieved.

Owner:河南省冶金研究所有限责任公司

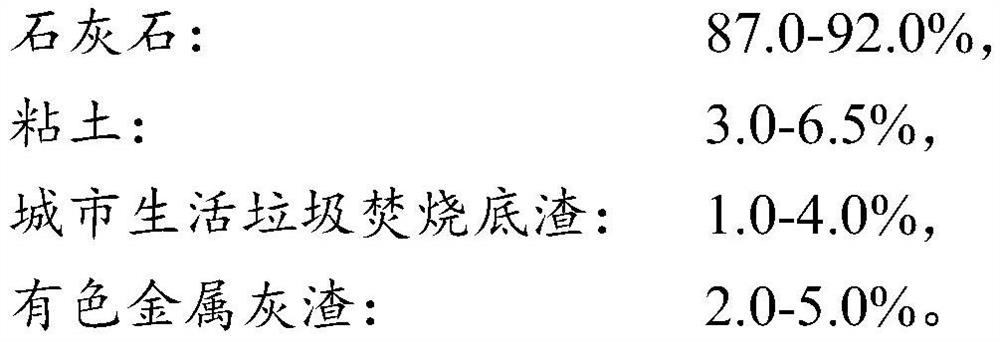

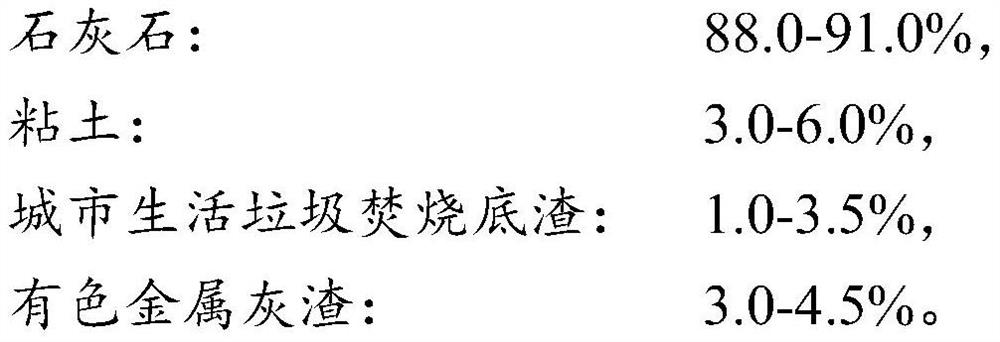

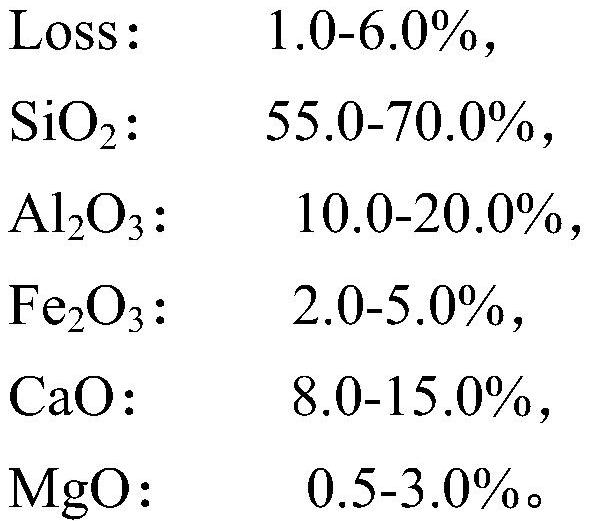

Calcined clinker prepared by replacing part of clay with municipal solid waste incineration bottom slag and preparation method of calcined clinker

The invention belongs to the field of cement, and particularly relates to a calcined cement clinker prepared by replacing part of clay with municipal solid waste incineration bottom slag and a preparation method of the calcined cement clinker. The raw material of the cement clinker is prepared by replacing part of clay with municipal solid waste incineration bottom slag, and the raw material of the cement clinker comprises the following components in percentage by mass: 87.0-92.0% of limestone, 3.0-6.5% of clay, 1.0-4.0% of municipal solid waste incineration bottom slag and 2.0-5.0% of non-ferrous metal ash. According to the clinker ingredients, the production cost of the clinker is effectively reduced, the use of clay resources can be reduced, a new path is opened up for comprehensive utilization of municipal solid waste incineration bottom slag resources, meanwhile, the quality of the cement clinker is kept unchanged, and the production requirements are met.

Owner:兰溪南方水泥有限公司

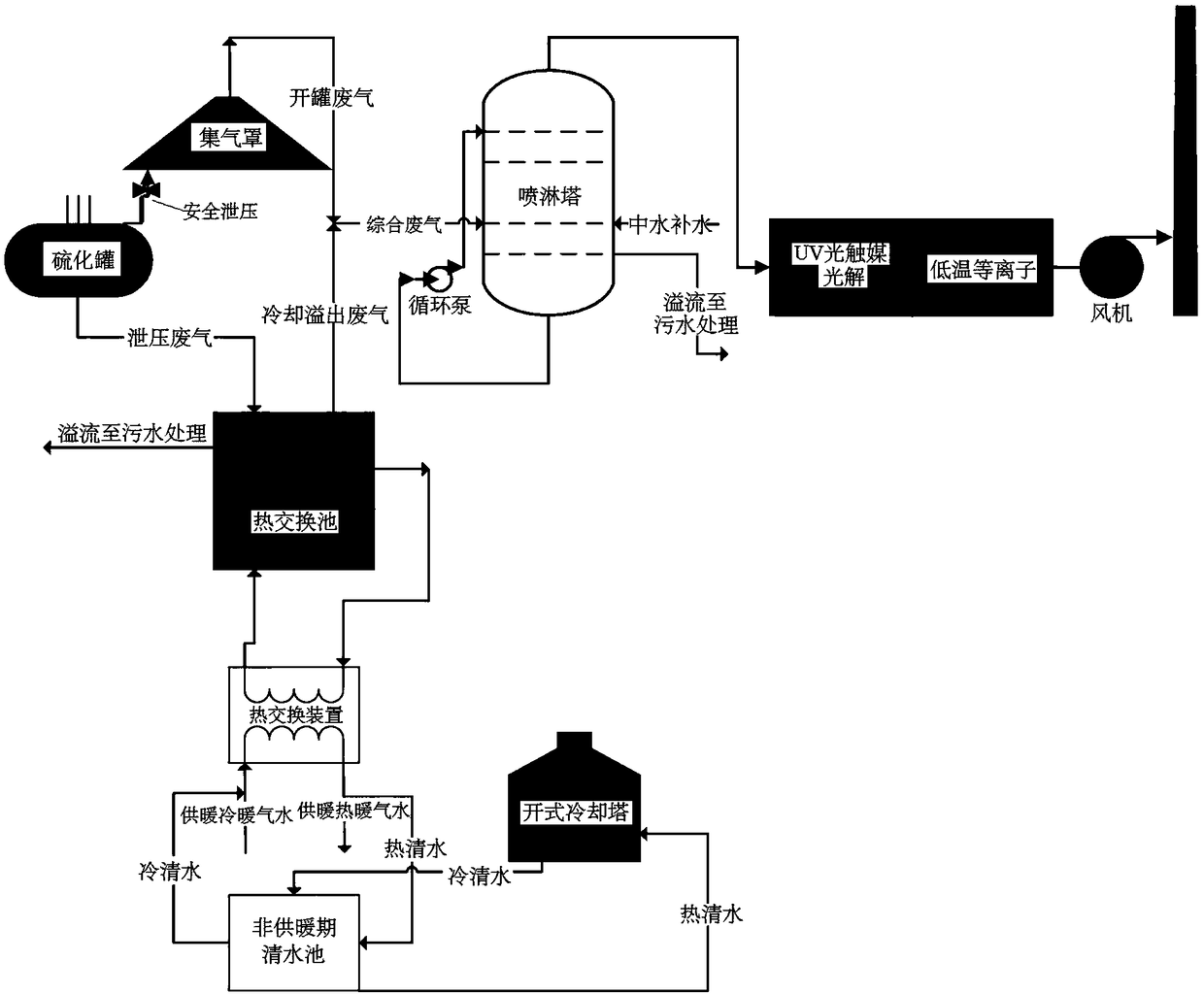

Rubber vulcanizing waste gas treatment process

InactiveCN108744920ALow running costReduce energy consumptionGas treatmentDispersed particle separationWater vaporHigh energy

The invention discloses a rubber vulcanizing waste gas treatment process. The process specifically includes following steps: step 1, spraying, cooling and drying waste gas generated by tank opening, and performing triple ultraviolet catalytic oxidation to obtain a first product; step 2, sequentially performing low-temperature plasma treatment, low-temperature high-energy plasma treatment and activated carbon absorbing treatment on the first product, and then discharging; step 3, feeding waste gas generated in the process when a vulcanizing tank releases pressure into a heat exchange tank connected with a heat exchange device until temperature of the waste gas is cooled to below 60 DEG C, and repeating the step 1 and the step 2 on the waste gas after being cooled. Comprehensive utilizationof heat and comprehensive utilization of reclaimed water are taken into consideration, so that boiler running cost in heating seasons is saved greatly, and comprehensive energy consumption of a factory in the heating seasons is lowered; sewage is recycled partly, so that outward discharge is reduced, consumption of underground water is reduced, and water vapor content in the process of waste gas emission is lowered.

Owner:韩志刚

Balanced macro-element water-soluble fertilizer

InactiveCN109438023AReduce productionReduce churnCalcareous fertilisersMagnesium fertilisersInorganic fertilizerFertilizer

The invention discloses a balanced macro-element water-soluble fertilizer which is characterized in that the water-soluble mineral additive comprises, by weight, 18-30 parts of inorganic fertilizers comprising N, P2O5 and K2O, 6-10 parts of medium trace element additives, 6-10 parts of sea algae extracts, 2-4 parts of functional additives, 2-4 parts of microbial additives, 1-3 parts of water-soluble initiators and 1-3 parts of water-soluble synergist. The medium trace element additives are EDTA (ethylene diamine tetraacetic acid) complexes.

Owner:内蒙古金地隆农业科技发展有限公司

Pulse separated direct inlet axial automotive turbine

ActiveUS10330053B2Increase specific power outputReduce external emissionsInternal combustion piston enginesExhaust apparatusCylinder headTurbine

Systems and methods for operating a turbocharged engine are described. In one example, a system comprises a cylinder head having a first and second exhaust duct separately coupled to first and second groups of cylinders, each of the first and second exhaust ducts leading to an exhaust driven turbine mounted inside the cylinder head on a bearing, the bearing located within a bearing housing supported by the cylinder head. In this way, exhaust pulses remain separate up to the turbine mounted inside the cylinder head.

Owner:FORD GLOBAL TECH LLC

Household appliance

ActiveCN111387034AImprove air qualityWon't releaseFluid heatersAgriculture gas emission reductionAgricultural scienceAgricultural engineering

The invention discloses a household appliance, and relates to the technical field of hydroponic planting machines and heating equipment. The household appliance includes a temperature raising module and a hydroponic planting module; the temperature raising module includes a drinking module, a heating module, an air purification module and a housing, and the drinking module, the heating module andthe air purification module are all arranged inside the housing; the hydroponic planting module includes a nutrient solution tank module, a hydroponic tank module and a bracket, and the nutrient solution tank module and the hydroponic tank module are both connected to the bracket; and the bracket is connected to the housing. The household appliance can be used for heating and purifying indoor air,and providing warm air to the hydroponic planting machines, so that energy is fully utilized; and the hydroponic planting machines can make full use of sunlight in a limited space, and the photosynthesis of plants is improved.

Owner:黄彦博

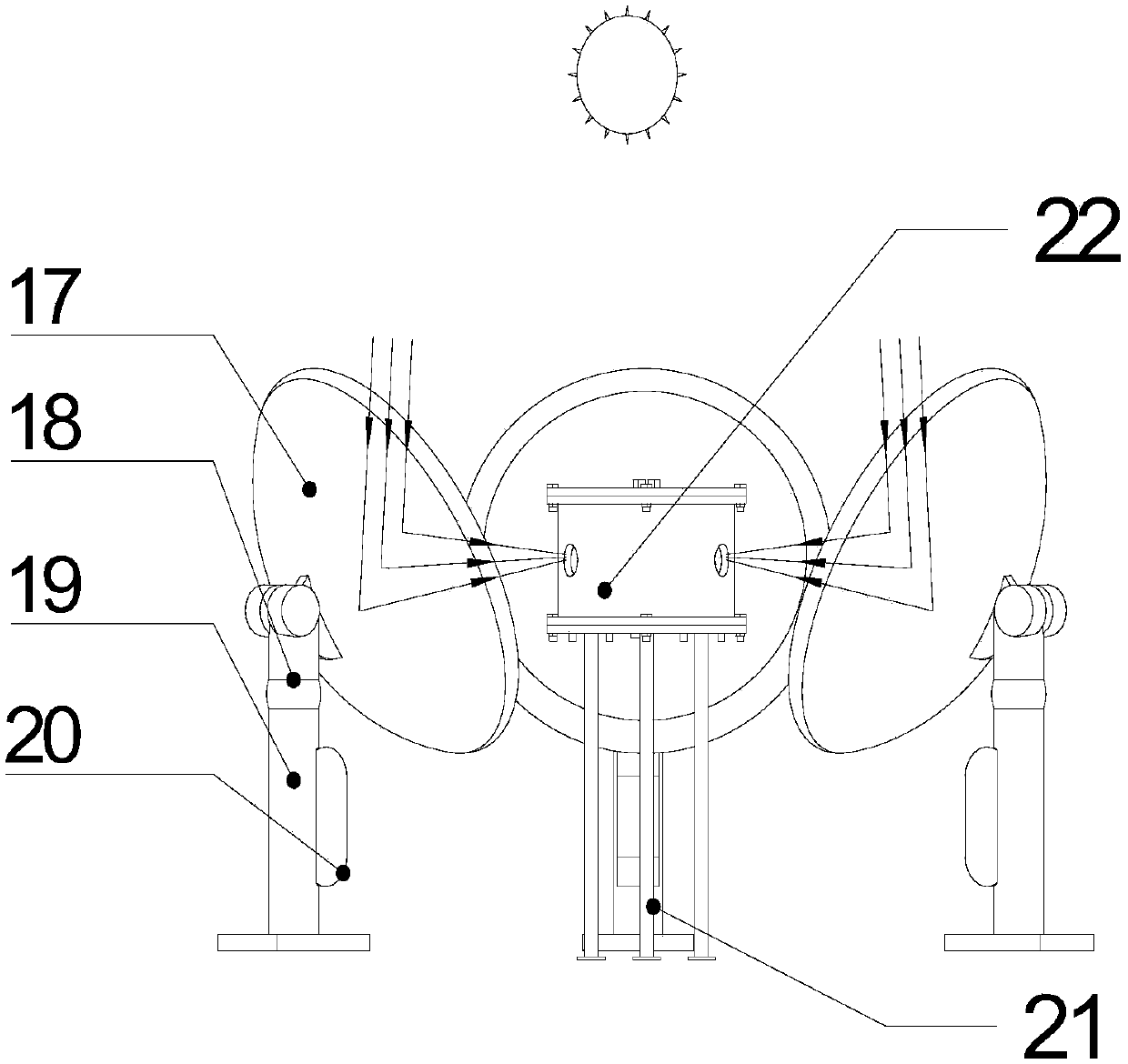

Disc type power generation device based on V-shaped heat absorption wall cavity type solar absorber

PendingCN109539583AGood for heat returnReduce absorptionSolar heating energyFrom solar energyBrayton cycleSolar disc

The invention discloses a disc type power generation device based on a V-shaped heat absorption wall cavity type solar absorber. The device comprises a light-heat conversion unit and a supercritical CO2 brayton cycle power generation system; the light-heat conversion unit comprises a V-shaped heat absorption wall cavity type solar absorber, collecting lenses and CO2 pipeline, wherein a plurality of collecting lenses are uniformly arranged on the periphery of the V-shaped heat absorption wall cavity type solar energy absorber, and the V-shaped heat absorption wall cavity type solar energy absorber is connected to the supercritical CO2 brayton cycle power generation system through the CO2 pipeline; the V-shaped heat absorption wall cavity type solar energy absorber is internally provided with a V-shaped heat absorption cavity assembly, wherein the V-shaped heat absorption cavity assembly comprises a plurality of heat exchange layers, an included angle alpha is formed between every two adjacent heat exchange layers, V-shaped closed spaces are arranged as heat preservation chambers or heat absorption cavities, the heat preservation chambers and the heat absorption chambers are alternately arranged, and an optical incident window directly faces the heat absorption chamber; and a heat exchange pipe is embedded into the heat exchange layers. The device has the advantages of being highin thermoelectric conversion efficiency, high in power generation efficiency, low in cost and the like. The invention belongs to the technical field of solar disc type power generation.

Owner:SOUTH CHINA UNIV OF TECH +1

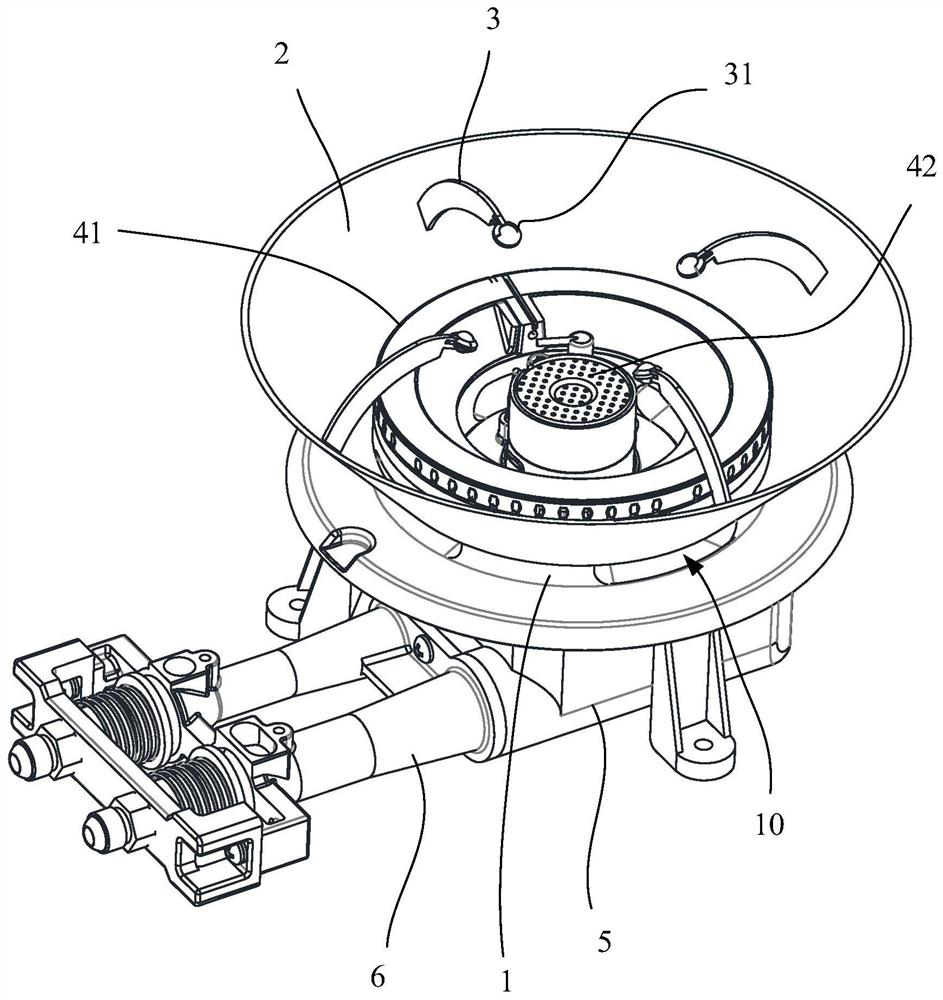

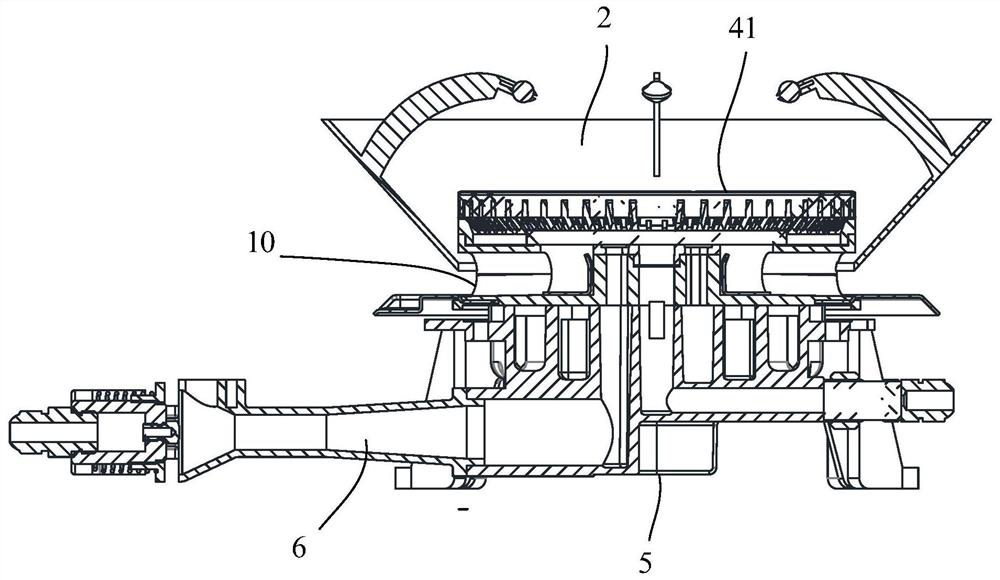

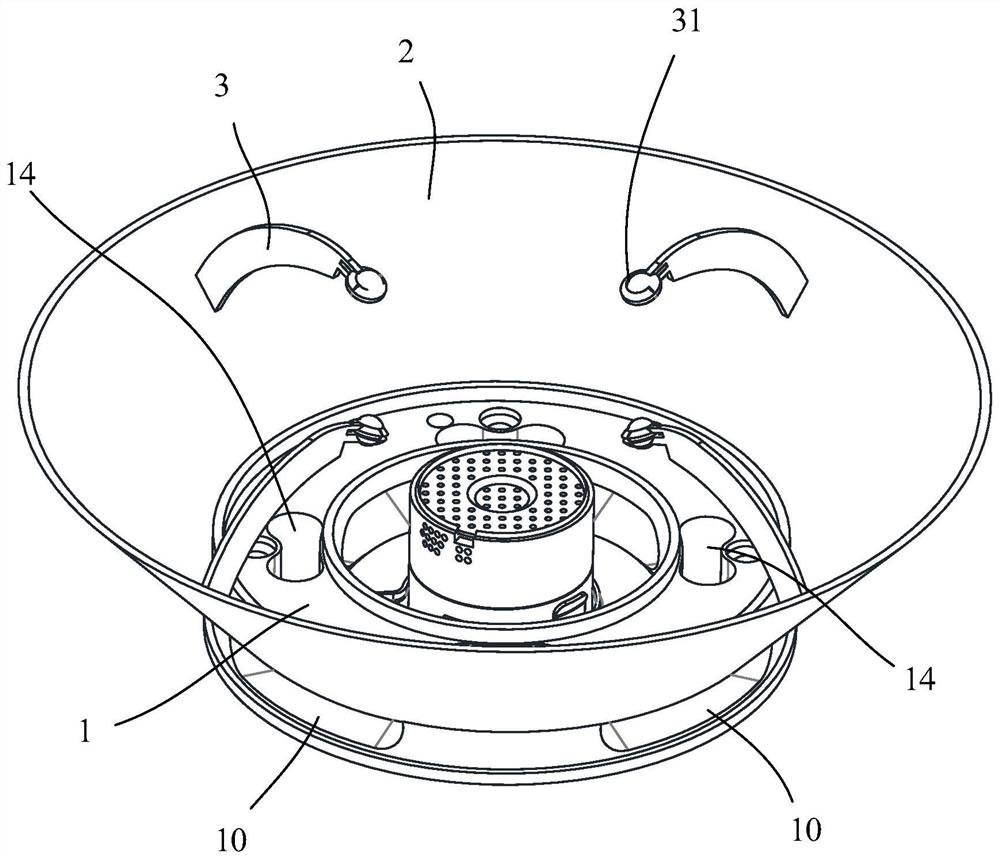

Integrated gas mixing structure, burner and cooker

ActiveCN112050217BSatisfy culinary skills needsReduce external emissionsDomestic stoves or rangesStoves/ranges topsCombustorFlue gas

The invention discloses an integrated gas mixing structure, a burner and a cooker. The integrated gas mixing structure includes: a gas mixing chamber, a secondary air inlet is provided on the outer ring surface of the gas mixing chamber, and the secondary air inlet connects the outer surface and the inside of the gas mixing chamber; Cover, the energy gathering cover is connected to the outer surface of the air mixing chamber, wherein the height of the lower end edge of the energy gathering cover is between the height of the upper edge and the lower edge of the inlet of the secondary air inlet , and form a smoke return area in the height direction of the secondary air inlet. The invention re-oxidizes the incompletely burned CO in the flue gas to CO 2 , to reduce the external emission of CO, and at the same time recover the heat in the flue gas to the bottom of the pot to improve the thermal efficiency of the burner.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

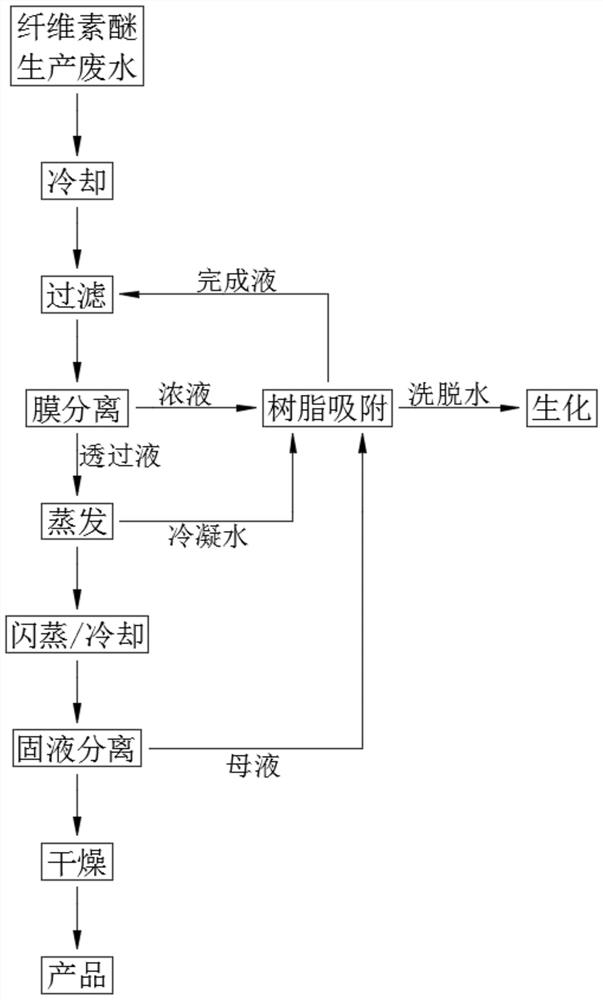

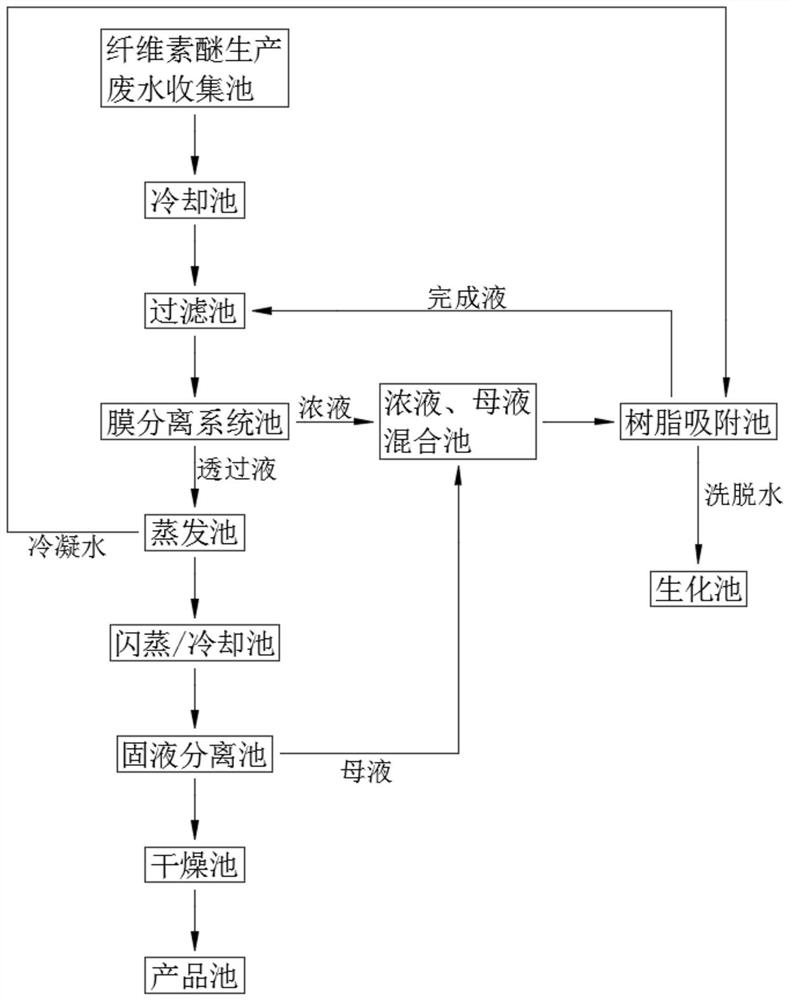

Recycling method of cellulose ether production wastewater

PendingCN113860669AReduce dependencyReduce processing costsSpecific water treatment objectivesTreatment involving filtrationCelluloseWater resources

The invention discloses a recycling method for cellulose ether production wastewater, relates to the technical field of production wastewater treatment, and provides the following scheme aiming at the problems that an existing recycling method for the production wastewater is relatively large in limitation, causes resource waste, increases the treatment cost of hazardous wastes and causes harm to the environment. The method comprises the following steps: S1, cooling the cellulose ether production wastewater resource, and filtering after cooling to remove visible particles; s2, feeding the filtered cellulose ether production wastewater resources to a membrane separation system to generate the concentrated liquid and filtrate through membrane separation; s3, performing evaporation, flash evaporation / cooling, solid-liquid separation and drying on permeate liquid after membrane separation to generate condensate water, crystal salt and mother liquor; s4, mixing the concentrated liquor and the mother liquor, treating the liquid by adsorptive resin, and returning the liquid to the membrane separation system after adsorption. The wastewater recycling method is low in treatment difficulty, and the additional value of resources is increased, so that the cost is reduced, and the discharge of mother liquor is reduced.

Owner:广州兰德环保资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com