Calcined clinker prepared by replacing part of clay with municipal solid waste incineration bottom slag and preparation method of calcined clinker

A technology of municipal solid waste and bottom slag incineration, which is applied in the cement field to achieve the effect of realizing resource recycling, reducing stacking and external discharge, and broadening utilization channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0150] The present invention also provides a method for preparing the above municipal solid waste incineration bottom slag replacing part of the clay calcined cement clinker, the method comprising the following steps:

[0151] (1) Raw material crushing: crush large pieces of limestone and clay separately, and the particle size of the material below 30mm should not be less than 85%. After the crushed limestone and clay are mixed with municipal solid waste incineration bottom slag and non-ferrous metal ash, etc., they will pass through the conveying equipment. Transport to respective homogenization warehouses for storage and homogenization; further, the conveying equipment is conventional equipment, such as a belt conveyor;

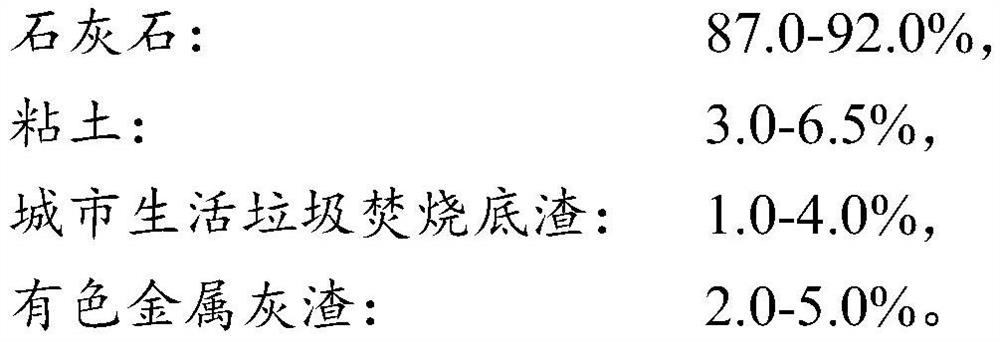

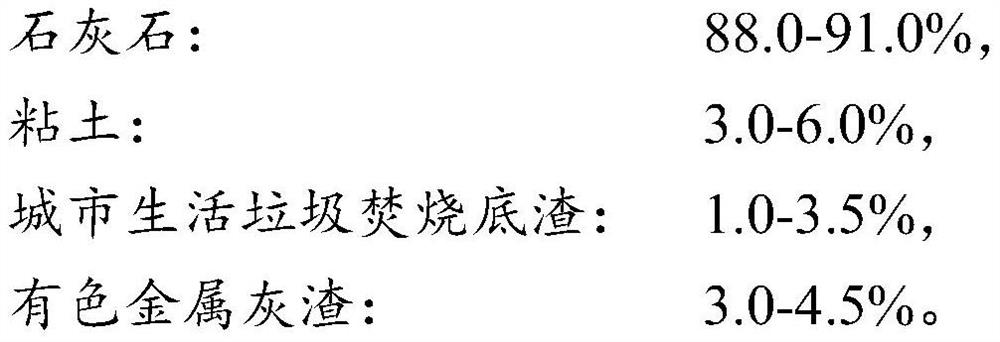

[0152](2) Raw meal batching: limestone, clay, municipal solid waste incineration bottom slag, and non-ferrous metal ash are batched according to the composition of the above-mentioned raw material mass fractions (ie mass percentages) through metering equipme...

Embodiment 1

[0171] A kind of cement clinker is calcined by substituting part of the clay with the incineration bottom slag of municipal solid waste. What is used is to prepare the raw meal by replacing part of the clay with the bottom slag of the municipal solid waste incineration and then calcining to obtain the cement clinker. The raw meal corresponding to the clinker is as follows Each component of mass fraction (i.e. mass percentage):

[0172] Limestone: 89.0%,

[0173] Clay: 6.2%,

[0174] Municipal solid waste incineration bottom slag: 1.5%,

[0175] Non-ferrous metal ash: 3.3%,

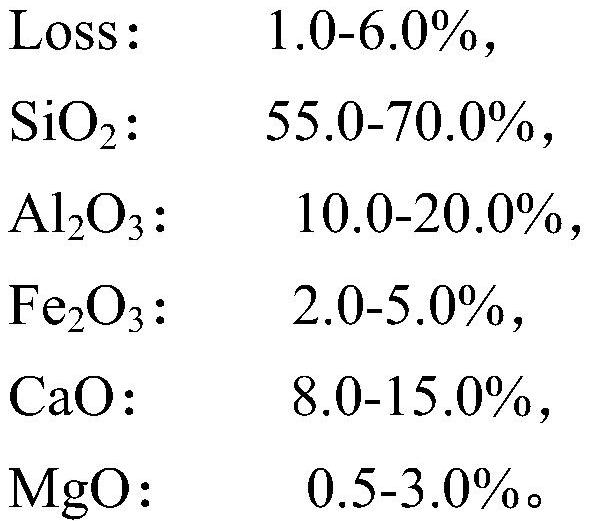

[0176] The concrete mass situation of each component is as follows (by mass percentage), and some trace components are not listed:

[0177]

[0178] The concrete quality situation of described clinker is as follows (by mass percentage), and part trace component is not listed, and wherein, the pulverized coal mixing amount is 9.54% of raw meal quality:

[0179]

[0180] The clinker quality control...

Embodiment 2

[0193] A kind of substituting part of the clay-calcined cement clinker with municipal solid waste incineration bottom slag, what adopt is to replace part of the clay-calcined cement clinker with municipal solid waste incineration bottom slag, wherein, the corresponding raw material of clinker is composed of the following mass fraction (i.e. mass The composition of each component of percentage):

[0194] Limestone: 88.8%,

[0195] Clay: 5.7%,

[0196] Municipal solid waste incineration bottom slag: 2.0%,

[0197] Non-ferrous metal ash: 3.5%,

[0198] The concrete mass situation of each component is as follows (by mass percentage), and some trace components are not listed:

[0199]

[0200] The specific quality of the clinker is as follows (by mass percentage), and some trace components are not listed. Wherein, the amount of coal added is 9.54% of the mass of the raw material:

[0201]

[0202]

[0203] The clinker quality control index values are: KH: 1.040±0.02,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com