Patents

Literature

35results about How to "Meet the needs of green environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

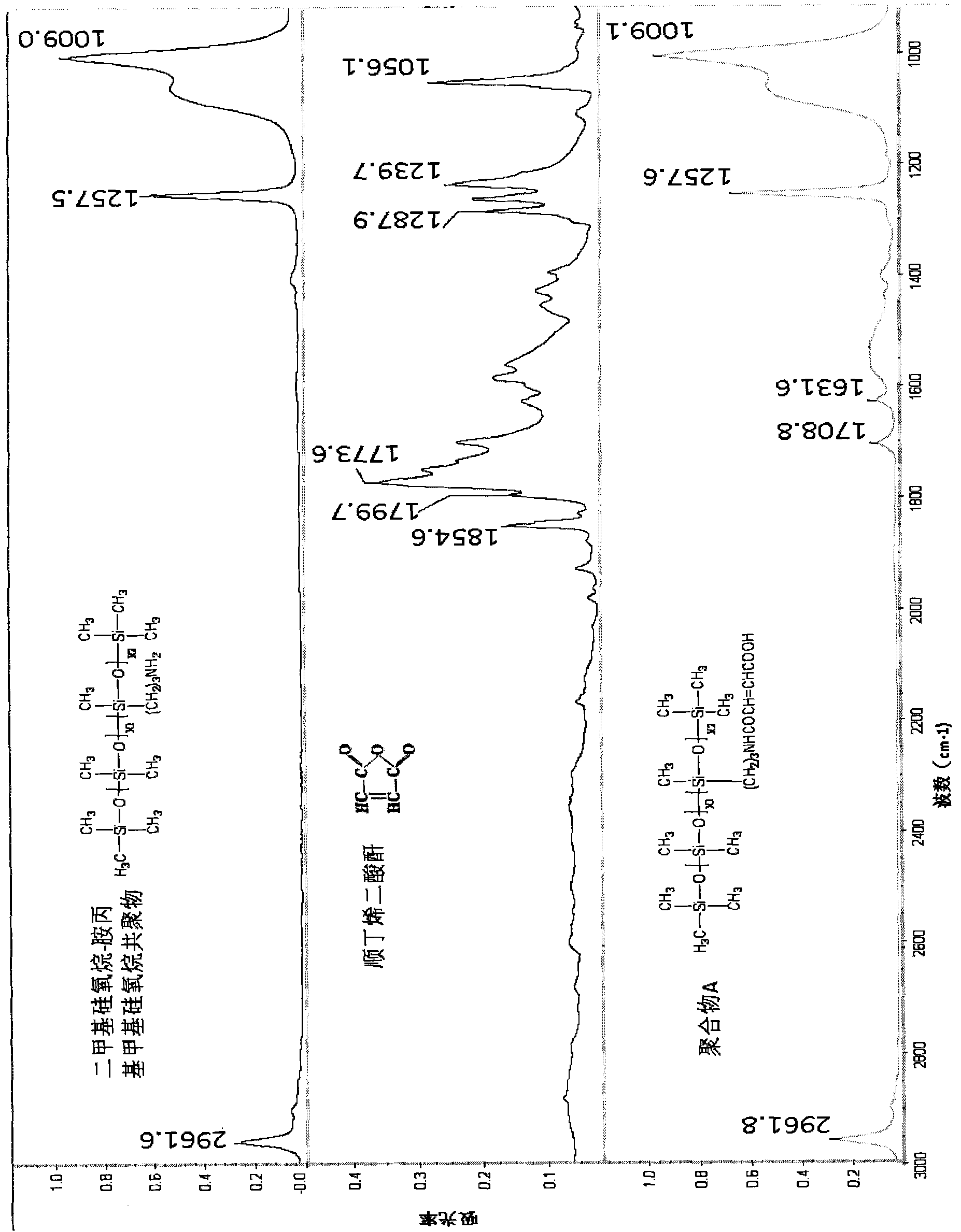

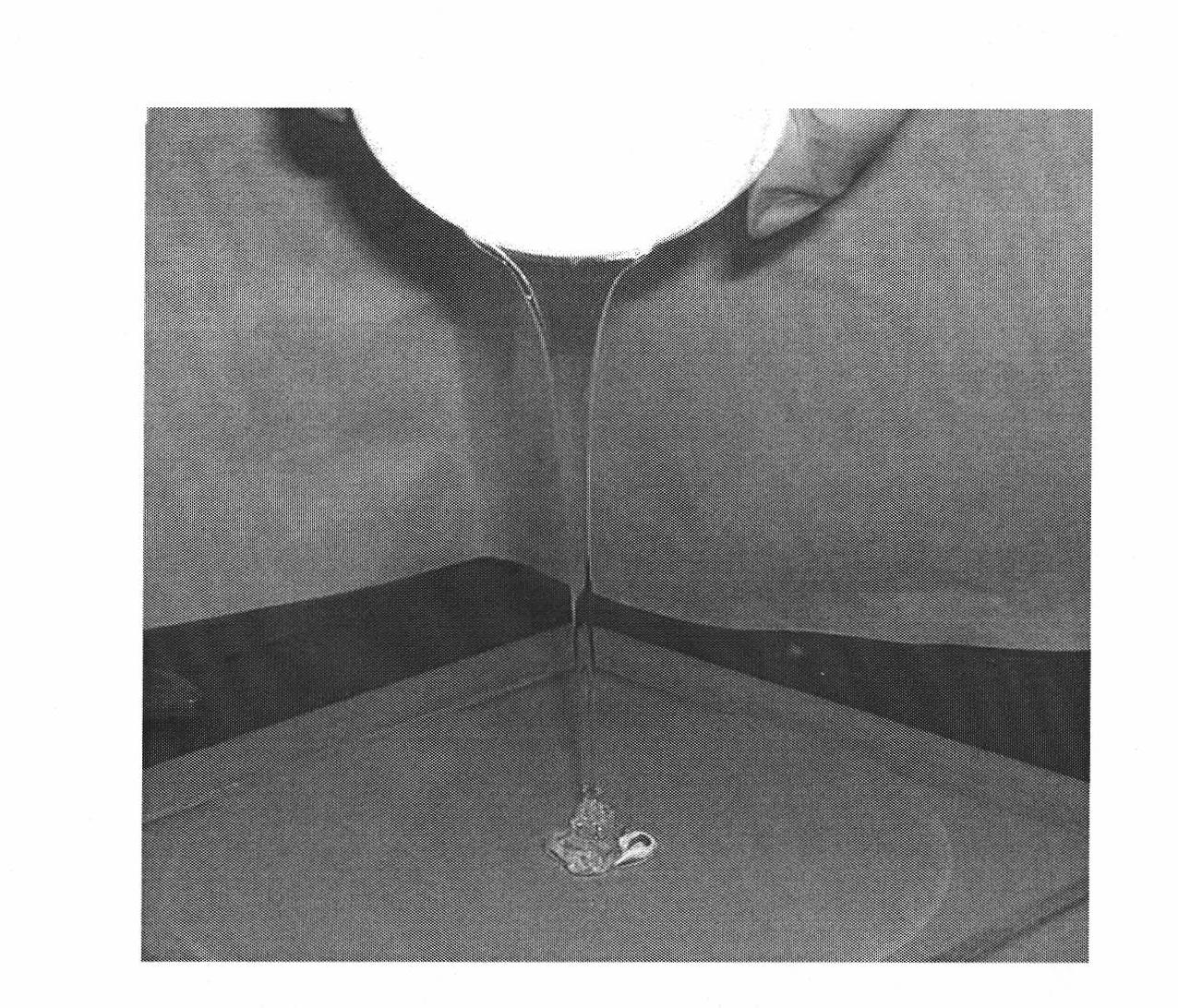

Composition for preparing organic silicon elastomer, organic silicon elastomer and preparation method and application thereof

InactiveCN101798464AMeet the needs of green environmental protectionQuick responseOther chemical processesCoatingsElastomerAziridine

The invention discloses a composition for preparing organic silicon elastomer, which contains polymer A and compound B, wherein the polymer A is silicones polymer containing at least two carboxyl groups, the compound B contains at least two aziridine rings, and the mol ratio of the carboxyl groups of the polymer A to the aziridine rings of the compound B is 1:0.2-10. The invention further discloses a method for preparing organic silicon elastomers by using the composition, and an organic silicon elastomer and application thereof.

Owner:HENKELCHINAINVESTMENT

Cheese dyeing posttreatment process

The invention provides a cheese dyeing posttreatment process including sequential first cold water washing, acid pickling, second cold water washing, soaping and low-temperature soaping, the soaping is as follows: in the conditions of pH of 6-7, temperature of 80-96 DEG C, adding a soaping enzyme of 0.2-0.4g / L and a reducing agent of 0.2-0.4g / L for soaping for 10-20 minutes, and the low temperature soaping is as follows: at the temperature of 50-70 DEG C, adding a soaping agent of 0.4-0.8g / L for soaping for 8-10 minutes. According to the cheese dyeing posttreatment process, the soaping enzyme is used for soaping treatment of dyed yarn, the soaping enzyme plays decomposition and decolorization effects on a hydrolysis dye and a color-unfixed dye, but does not play effects on a bonded dye, does not change shade, and can shorten the posttreatment process as soon as possible to improve the color fastness and reduce the production cost, so that the posttreatment process is more economic and more environmentally friendly, greatly alleviates the cost pressure on sewage treatment, and is in line with the green environmental protection requirements.

Owner:WUHU FUCHUN DYEING & WEAVING

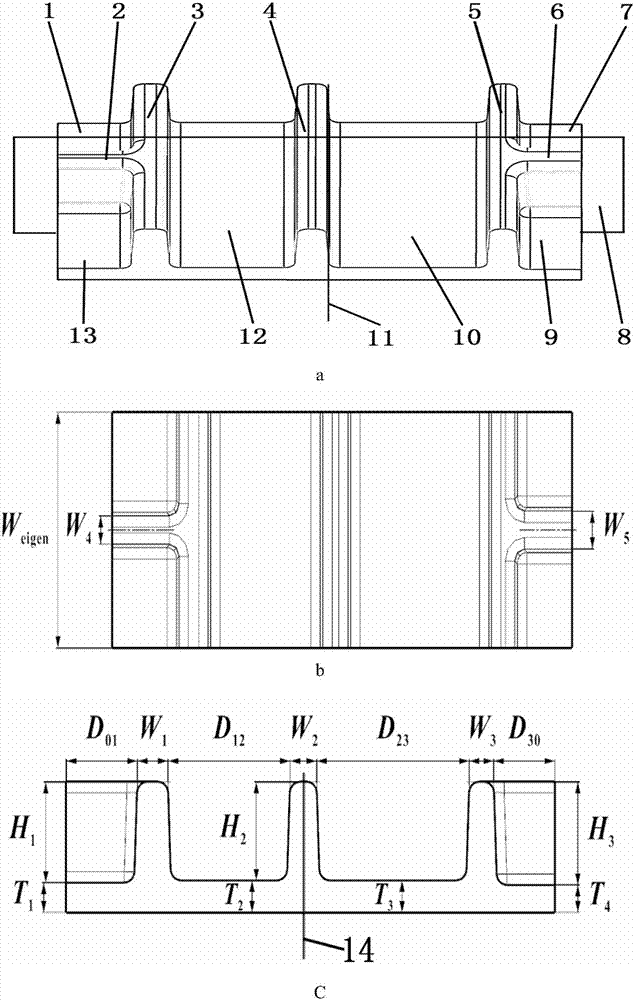

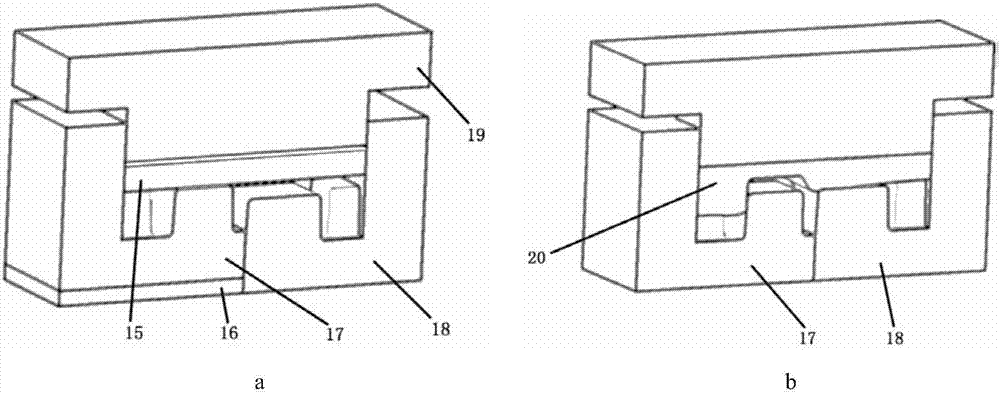

Local loading forming-based optimization method for preformed blank of rib plate part

ActiveCN106971029AImprove carrying capacityAvoid Folding DefectsGeometric CADDesign optimisation/simulationTransitional RegionEngineering

The invention discloses a local loading forming-based optimization method for a preformed blank of a rib plate part. Isothermal local loading forming is realized by controlling material flow and macroscopic defects of a transitional region. The preformed blank subjected to optimization design can effectively improve the uniformity of the material flow, reduce transverse material flow of a cross rib in the transitional region, and improve the filling capability of a rib type cavity. In engineering application, the usage performance of members is improved, the production cost is reduced, and a foundation is laid for forming and integrated manufacturing of large complex members made of titanium alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

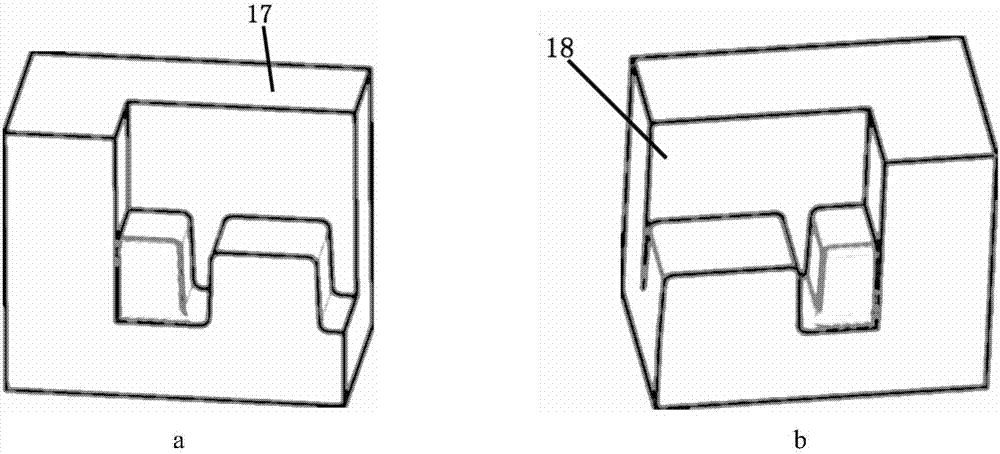

Air purifying agent and preparation method thereof

InactiveCN107174941AEfficient decompositionReductiveGas treatmentDispersed particle separationReduced propertiesCarbonate

The invention discloses an air purifying agent and a preparation method thereof. The air purifying agent is prepared from the following raw materials in parts by weight: 25 to 30 parts of sepiolite, 15 to 35 parts of attapulgite, 10 to 15 parts of active carbon, 8 to 12 parts of diatom ooze, 25 to 35 parts of urea, 8 to 10 parts of propylene glycol carbonate, 15 to 20 parts of an oxidant, 11 to 18 parts of itaconic acid, 15 to 20 parts of a plant extracting solution, 2 to 6 parts of a surfactant and 15 to 28 parts of de-ionized water. The air purifying agent disclosed by the invention has the advantages of simple preparation method and low cost, is used for efficiently decomposing various harmful gas in the air and has a relatively good effect of purifying air; the plant extracting solution has a reducing property and can be subjected to oxidation-reduction reaction with formaldehyde with oxidizability and the concentration of the formaldehyde is reduced.

Owner:NINGBO JUNCHUAN MUNICIPAL GARDEN ENG CO LTD

Air purifier

InactiveCN104815544AHigh reactivityReductiveDispersed particle separationDeodrantsMint extractAir purifiers

The invention discloses an air purifier. The air purifier is characterized by being prepared from the following materials in percentage by mass: 0.2-0.3 percent of cactus extract, 0.5-0.8 percent of lemon extract, 0.1-0.3 percent of aloe extract, 0.4-0.7 percent of mint extract, 0.2-0.6 percent of wormwood extract, 0.3-1 percent of sodium carboxymethylcellulose, 0.1-0.5 percent of surfactant and de-ionized water. The air purifier is nontoxic and harmless, and can purify air and remove peculiar smell.

Owner:上海中科昆虫生物技术开发有限公司

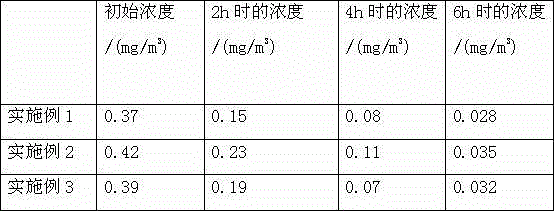

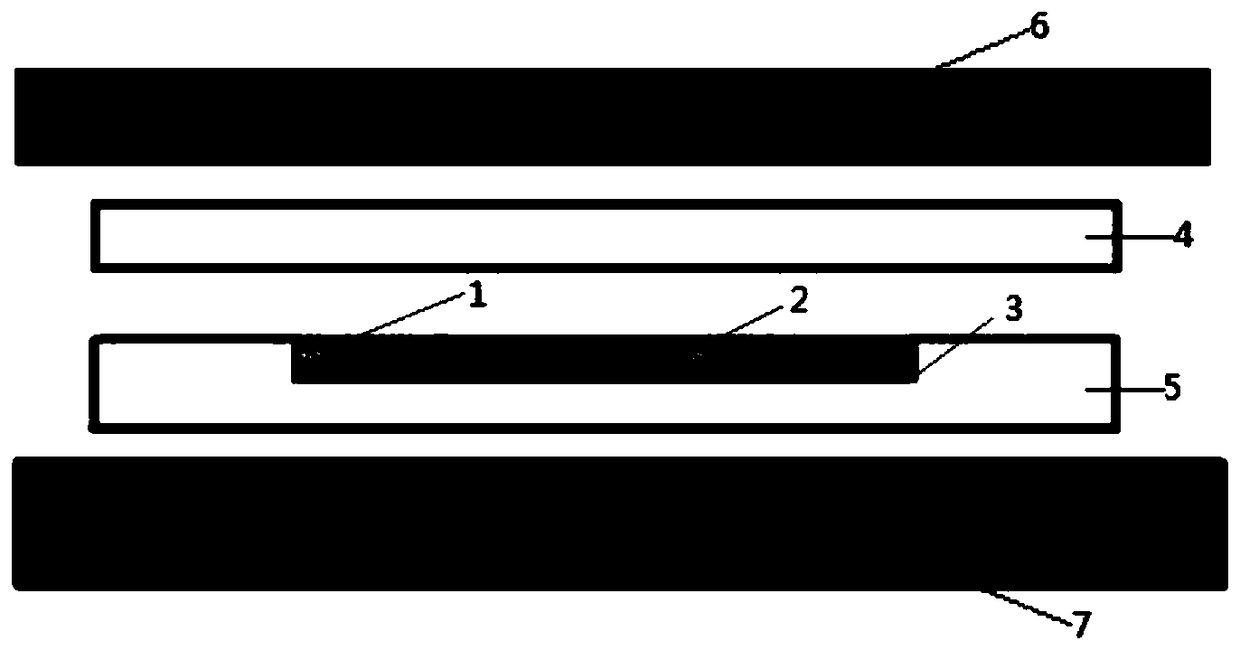

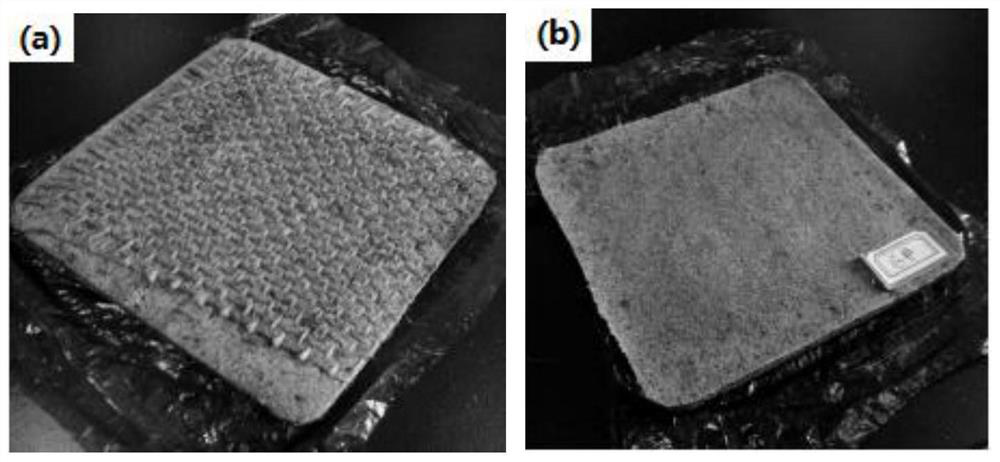

Parquet bamboo floor block formed by excess stock and manufacturing method thereof

InactiveCN101591967AMeet the needs of green environmental protectionEasy to manufactureWood working apparatusFlooringEngineeringHome improvement

The invention relates to a parquet bamboo floor block formed by excess stock and a manufacturing method thereof, belonging to the technical field of decoration project of buildings. The bamboo floor block comprises a bamboo floor parquet and a frame; wherein, the bamboo floor parquet is embedded into the frame; the bamboo floor parquet consists of at least two cell blocks; each cell block is formed by laminating multilayer of bamboo-strand veneers; the bamboo texture directions of the adjacent two cell blocks are vertical; the frame is also formed by laminating multilayer of bamboo-strand veneers; the bamboo-strand veneers are formed by bamboo floor excess stock. The manufacturing method comprises the following steps: material preparing, cutting, polishing, laminating and forming by splicing. The method provided by the invention can reprocess and reuse the bamboo floor excess stock which originally serves as waste in the process of home decoration, and the whole manufacturing process is simple. At the same time, the newly prepared parquet bamboo floor block features skid and abrasion resistance and fine effect of parquet which can not be found in the current bamboo floor block.

Owner:TECSUN SUZHOU HOMES

Process for manufacturing health-care moxa

ActiveCN101606886AImprove performanceImprove antibacterial propertiesPharmaceutical product form changeMedicineHuman health

The invention provides a process for manufacturing health-care moxa. The process has steps of drying fresh folium artemisiae argyi in shade, crashing and processing dried folium artemisiae argyi into moxa so as to further develop and utilize the wild folium artemisiae argyi, widely apply folium artemisiae argyi to fields of life articles, disease prevention and health care, medicine and the health, and the like, and lead the moxa to better server for human health. The process for manufacturing health-care moxa has an extremely wide application prospect.

Owner:WUHAN KANGZHONG BAOAI CASHMERE PRODS

Bacteriostatic and degradable food packaging film and preparation method thereof

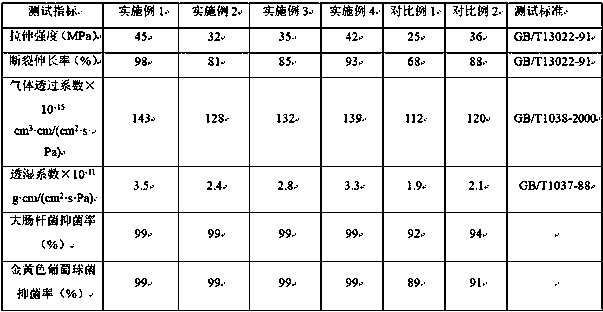

InactiveCN109337397AImprove mechanical propertiesImprove antibacterial propertiesFlexible coversWrappersFood packagingOxide

The invention provides a bacteriostatic and degradable food packaging film and a preparation method thereof. The bacteriostatic and degradable food packaging film is prepared from the following raw materials in parts by weight: 50-80 parts of crop straw, 10-20 parts of succinic glycoside, 10-20 parts of polybutylene succinate, 12-22 parts of polylactic acid, 8-16 parts of polyvinyl alcohol, 6-12 parts of sepiolite, 5-10 parts of zinc oxide, 8-15 parts of silicon dioxide, 4-8 parts of gamma-aminopropyltriethoxysilane, 3-8 parts of a dispersing agent, 8-16 parts of tea polyphenol, 10-16 parts ofchitosan, 9-15 parts of sodium benzoate, 15-30 parts of N methylmorpholine-N-oxide NMMO / water, 4-9 parts of dodecyl trimethyl ammonium chloride, 2-7 parts of 1-ethyl-3-methylimidazolium tetrafluoroborate, 8-14 parts of isopropanol and 10-20 parts of water. The bacteriostatic and degradable food packaging film has excellent antibacterial performance, mechanical properties, moisture and gas permeability and degradability and has a broad application prospect in the field of food packaging.

Owner:SUZHOU INST OF TRADE & COMMERCE

Waterborne polyurethane emulsion as well as preparation method and application thereof

PendingCN110724239ASmall particle sizeReduce consumptionPolyurea/polyurethane coatingsCarboxyl radicalPtru catalyst

The invention provides a waterborne polyurethane emulsion as well as a preparation method and application thereof. The waterborne polyurethane emulsion is prepared from the following raw materials: abio-based emulsifier, diisocyanate, a first chain extender, a second chain extender, a salt-forming agent, a viscosity reducer and deionized water. The bio-based emulsifier is used as a preparation raw material for the first time, and the bio-based emulsifier not only contains hydroxyl capable of reacting with isocyanate radicals, but also contains carboxyl capable of generating salt forming reaction, therefore, requirements of a traditional waterborne polyurethane emulsion preparation process on catalysts and organic solvents are avoided, and consumption of hydrophilic chain extenders can bereduced, besides, the bio-based emulsifier is used as a soft segment in polyurethane molecular chains, and the molecular structure of the bio-based emulsifier contains carboxyl, so that the particle size of the waterborne polyurethane emulsion is reduced, and the dispersity and stability of particles are improved. The preparation method is simple and easy to operate, no solvent or catalyst is usedin the whole preparation process, and the preparation method is more environmentally friendly.

Owner:KUNSHAN JIALIPU PLATE MAKING TACKIFIER & INK

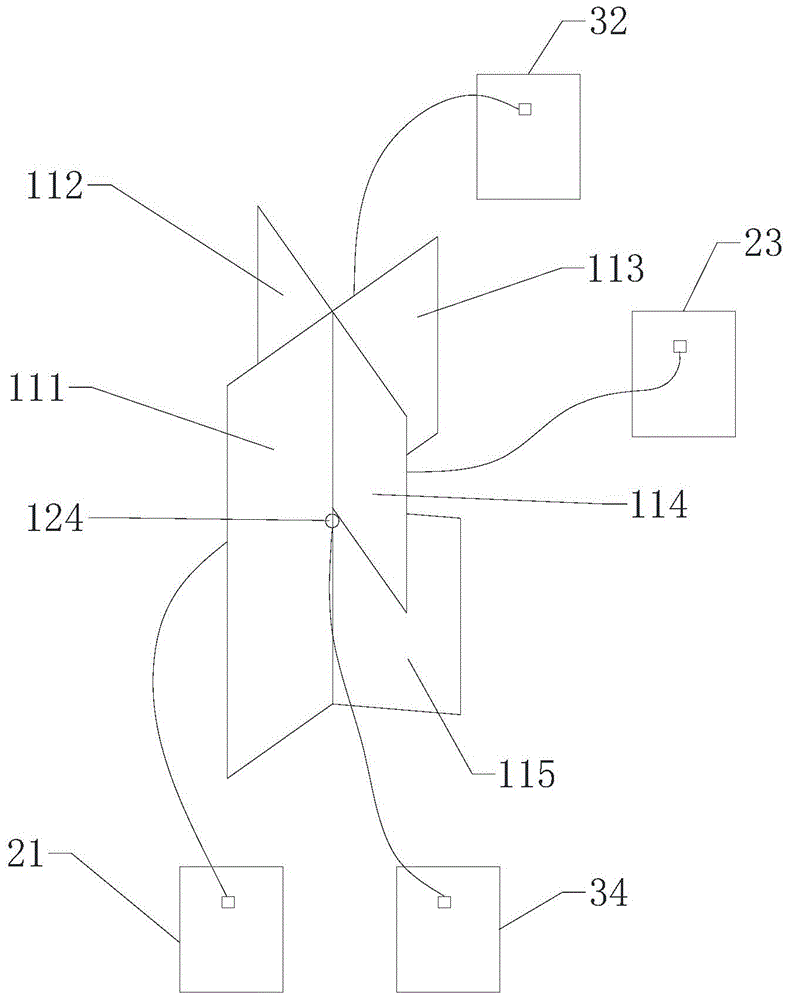

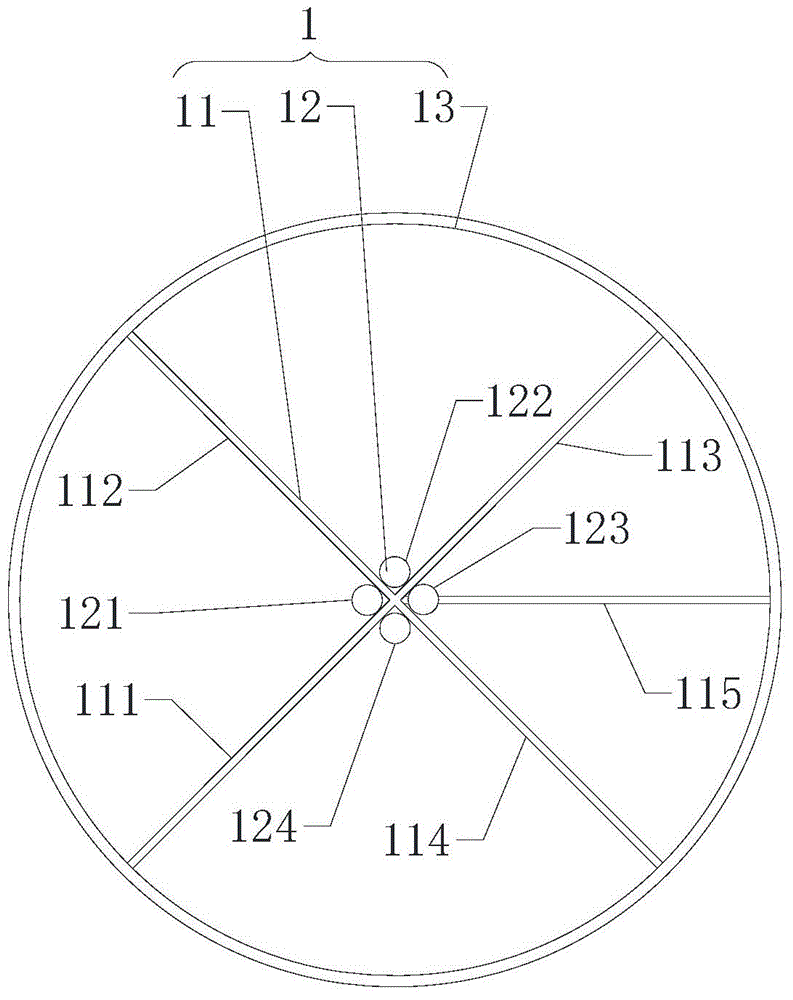

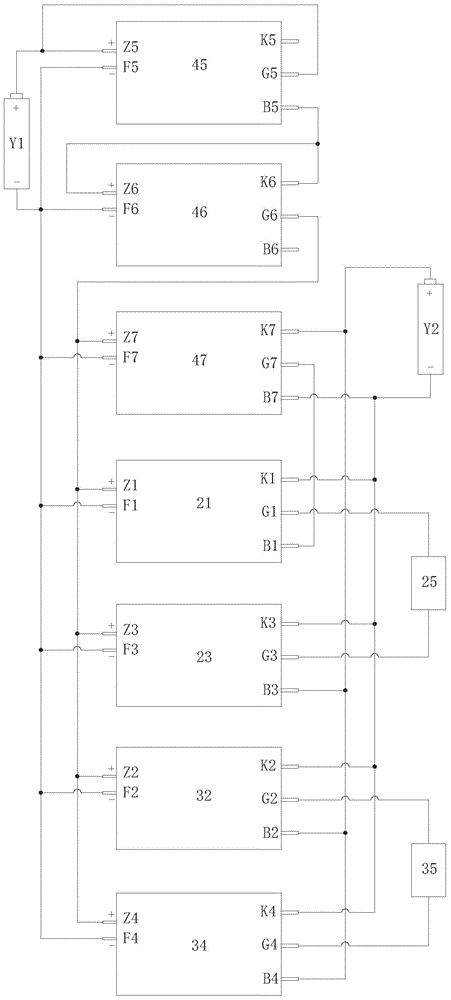

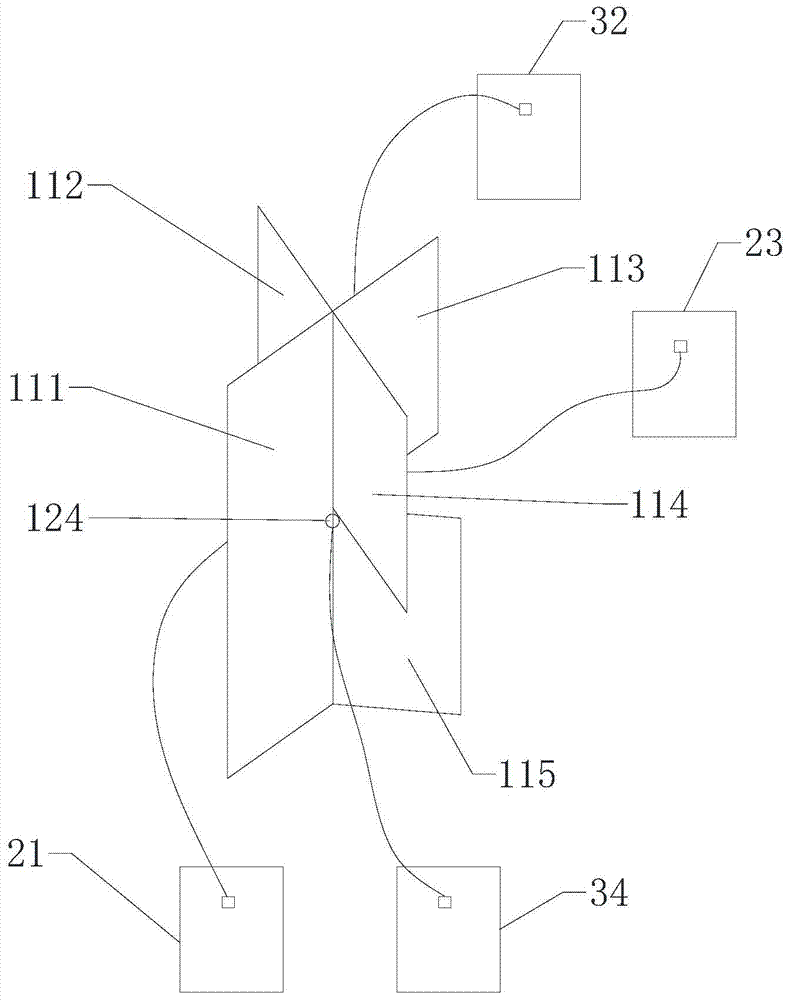

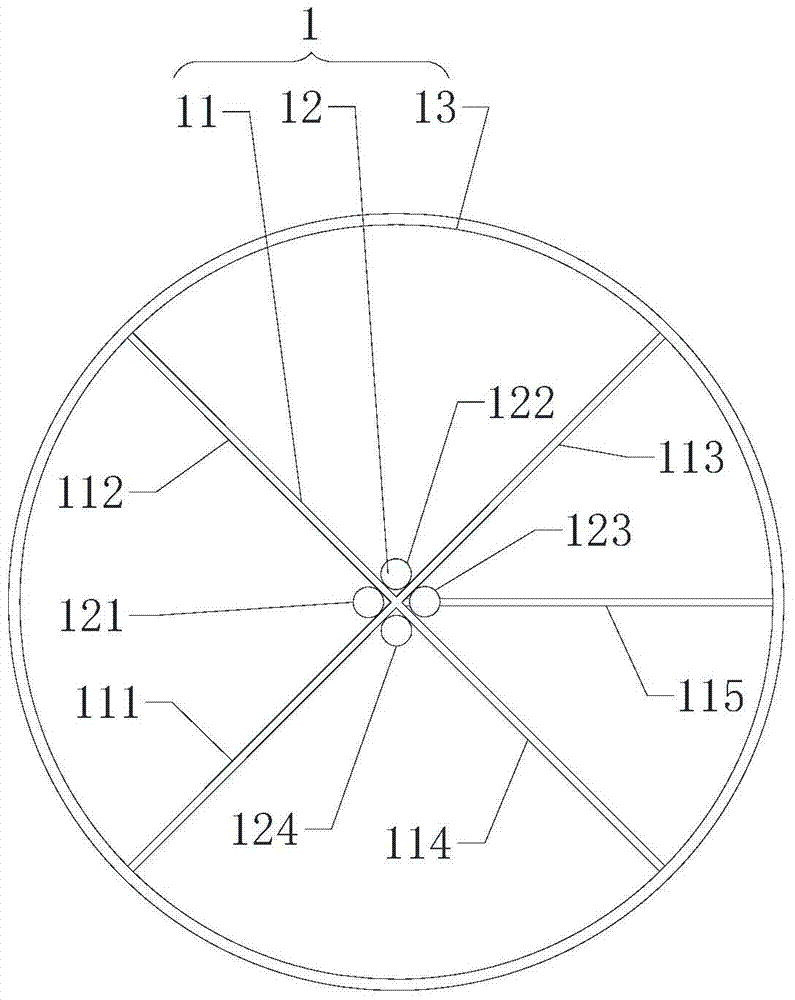

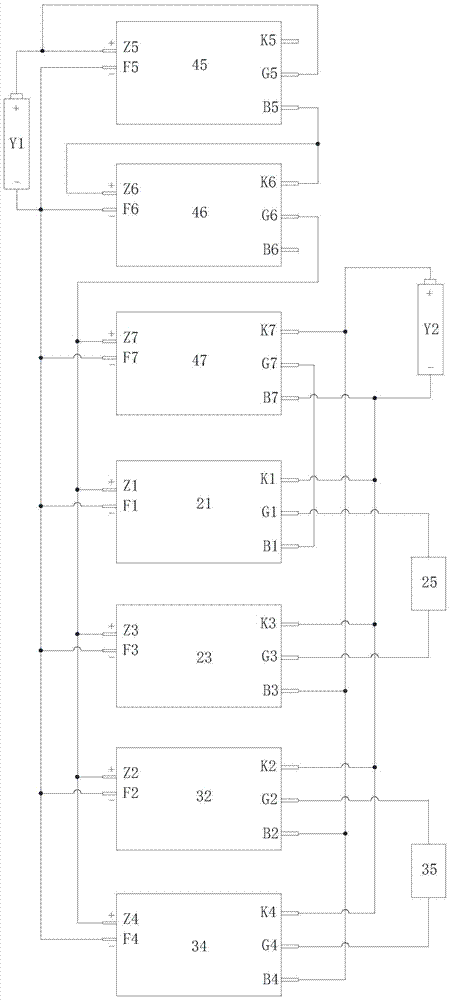

Phototropic controller for solar panel

The invention provides a phototropic controller for a solar panel. The phototropic controller is used for controlling the phototropic direction of the solar panel, and comprises a ray receiver, a vertical control circuit and a horizontal control circuit. The cross section of the upper part of a shading plate takes the shape of +; the cross section of the lower part of the shading plate is Y-shaped; when sunlight shines onto photosensitive sensors at different positions, the photosensitive sensors control the vertical control circuit or the horizontal control circuit according to received sunlight signals, so as to control a second control motor or a first control motor, and adjust the direction of the solar panel to ensure that the solar panel receives sunlight with a maximum angle and absorbs solar energy to the maximum extent all the while.

Owner:李豹

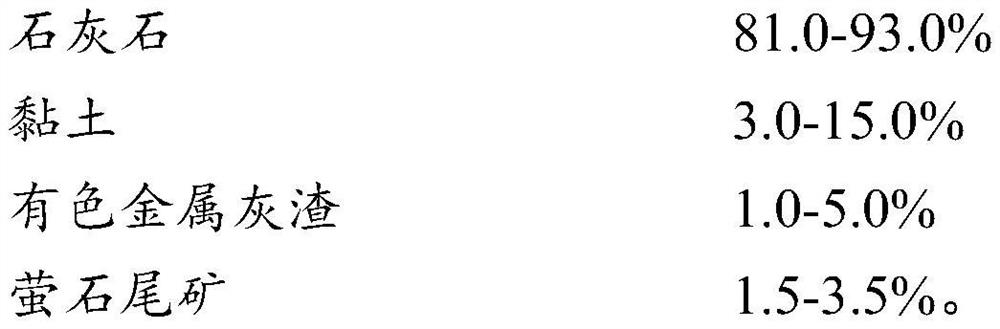

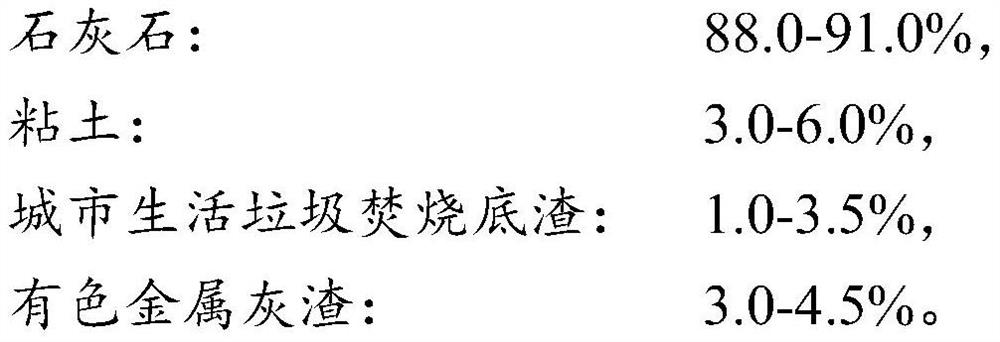

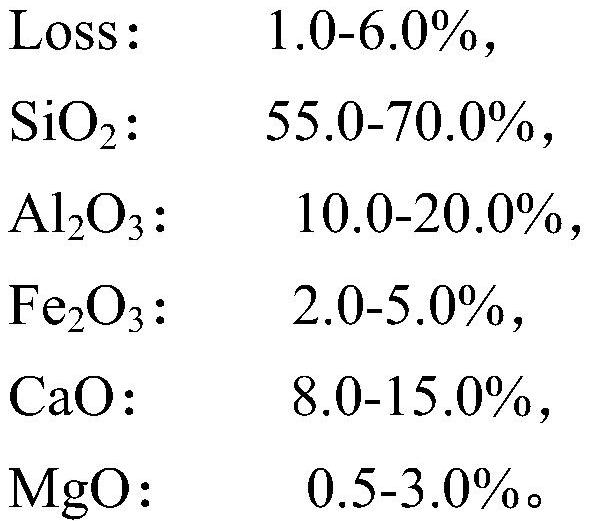

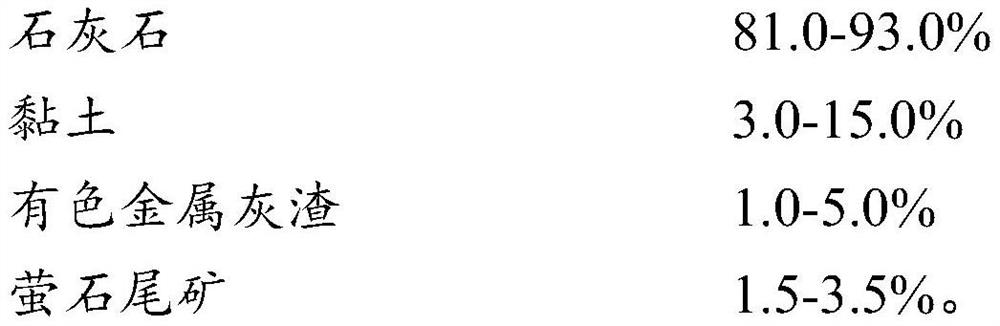

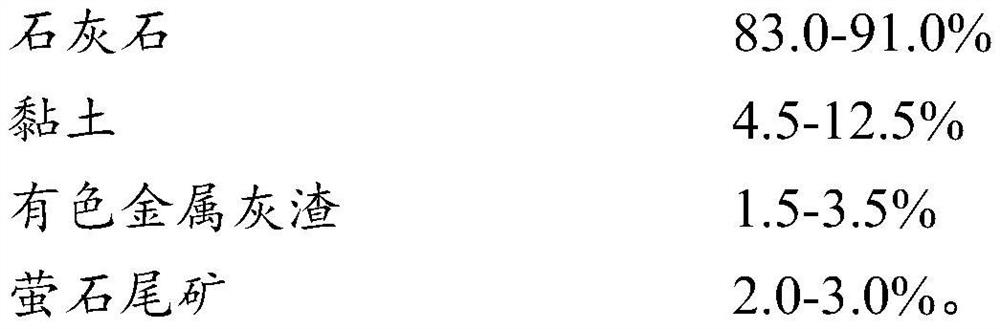

Retarding clinker and preparation method thereof

ActiveCN112341014AProlonged initial settingExtension of timeSolid fuelsCement productionClinker (waste)Nonferrous metal

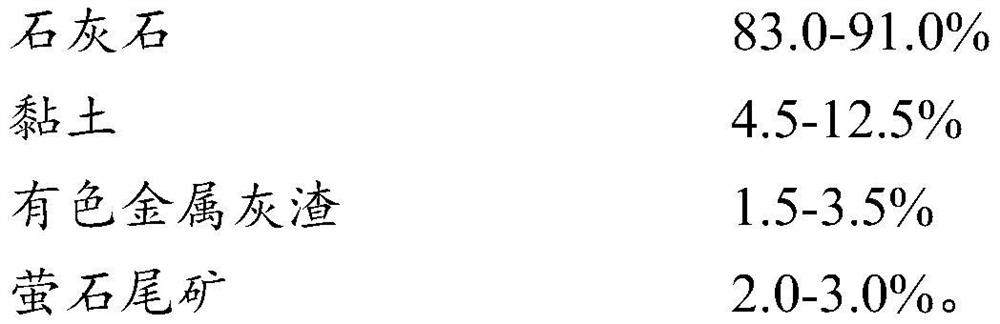

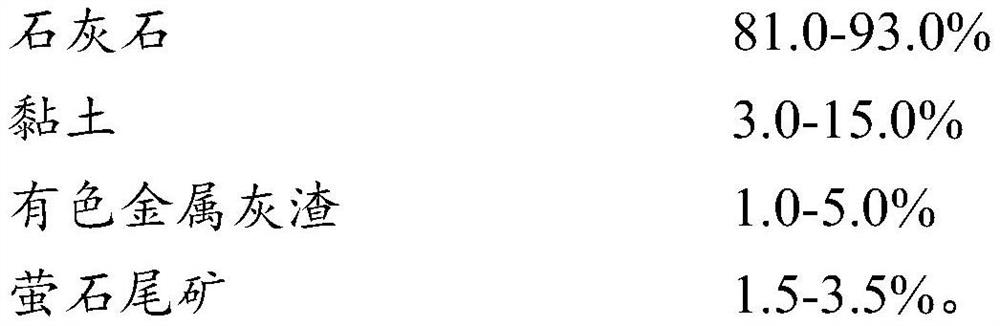

The invention belongs to the field of cement, and particularly relates to a retarding clinker and a preparation method thereof. The retarding clinker comprises the following raw materials in percentage by mass: 81.0-93.0% of limestone, 3.0-15% of clay, 1.0-5.0% of non-ferrous metal ash residues, and 1.5-3.5% of fluorite tailings, wherein the content of calcium fluoride in the fluorite tailings is15-30%. By adding a certain amount of fluorite tailings, the initial setting time and the final setting time of the clinker are prolonged, and the production of the delayed coagulation clinker is realized, so the requirements of special engineering on the performance of retarding cement can be met; in addition, the mechanical property of the clinker is still maintained, so concrete quality can beensured while the requirements on cement retarding characteristics are met; and meanwhile, the fluorite tailings are effectively utilized, the utilization way of the fluorite tailings is broadened, stacking and external emission of waste production enterprises are reduced, and the demands of environmental protection are met.

Owner:兰溪南方水泥有限公司 +1

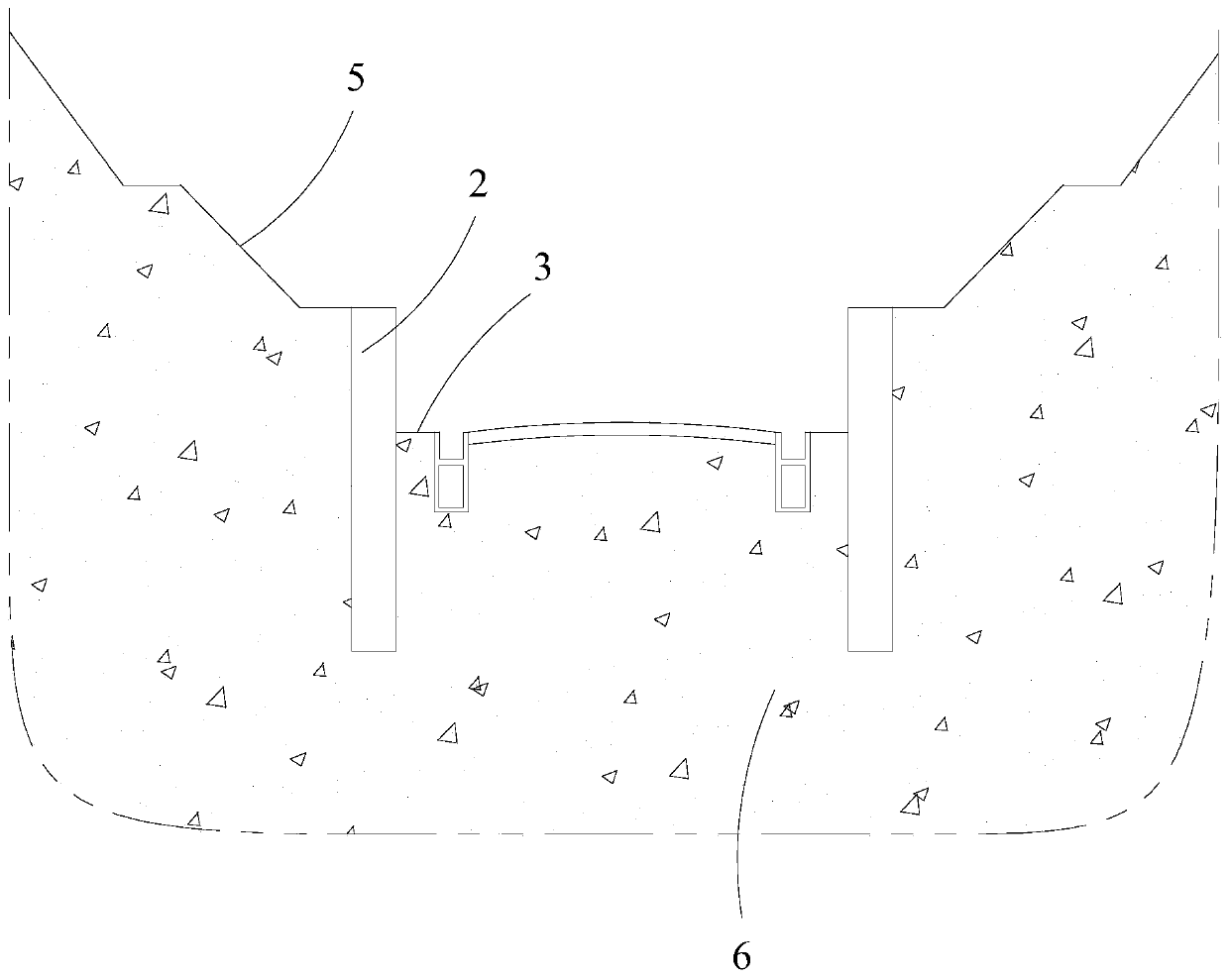

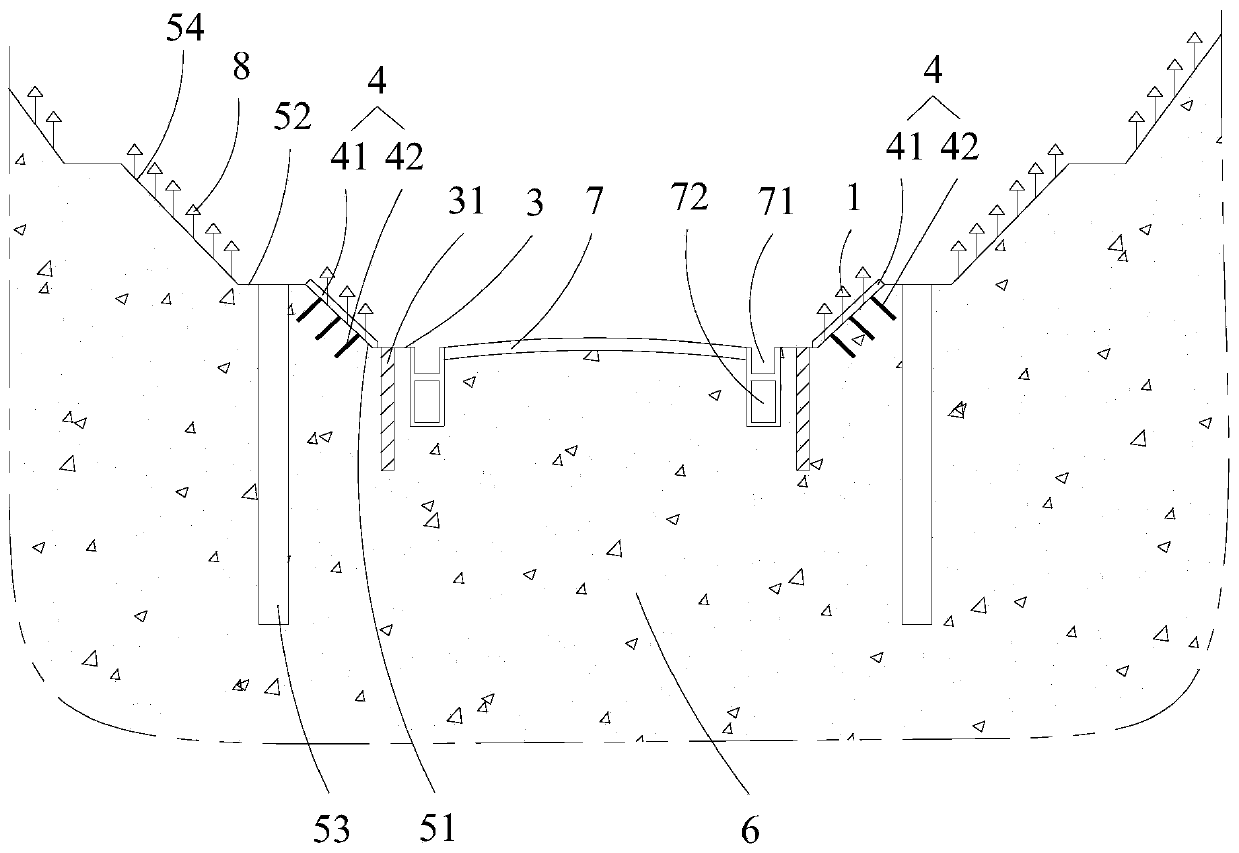

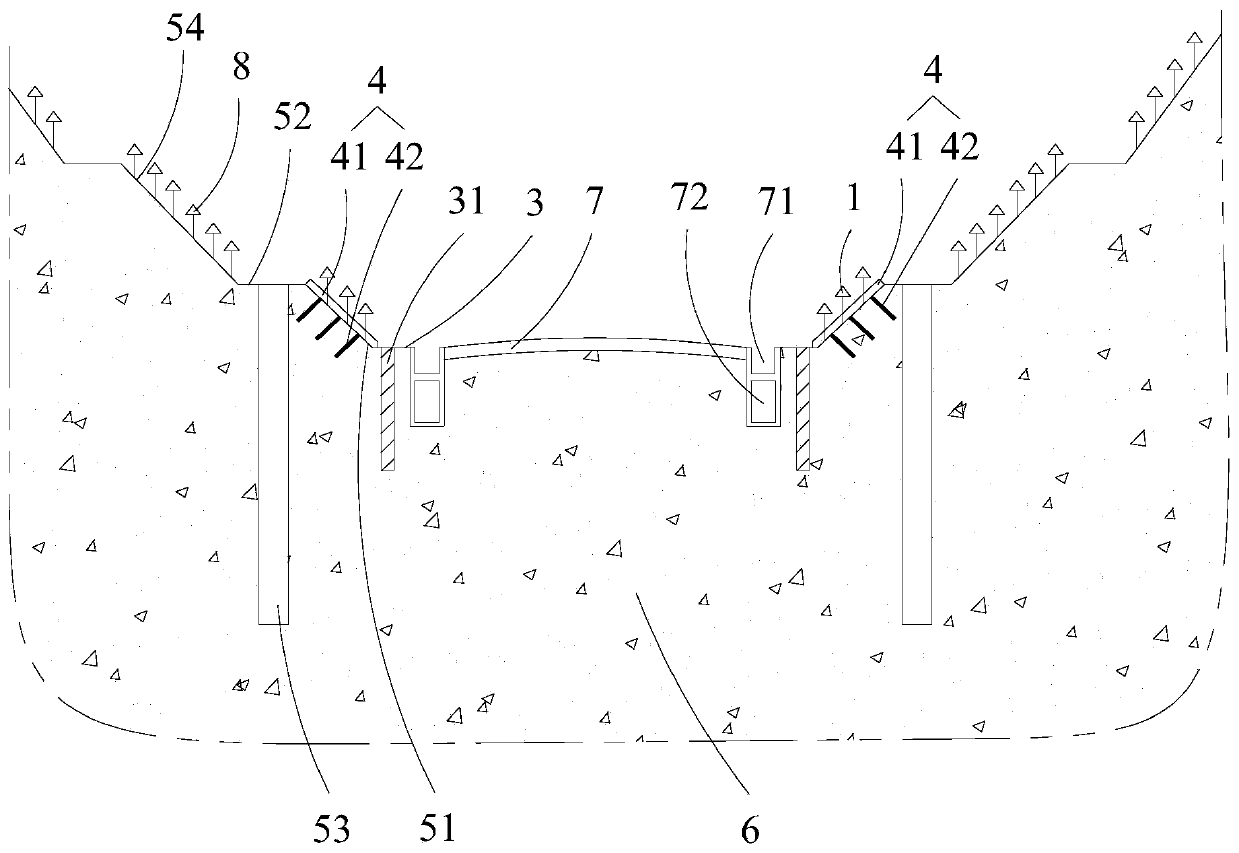

Deep roadcut green protective structure, roadcut protective system and construction methods of deep roadcut green protective structure and roadcut protective system

The invention relates to the field of side slope protection, in particular to a deep roadcut green protective structure, a roadcut protective system and construction methods of the deep roadcut greenprotective structure and the roadcut protective system. The deep roadcut green protective structure comprises a lateral ditch platform; a first side slope is disposed on the outer side of the lateralditch platform; an anchor rod assembly is disposed on the first side slope; a side slope platform is disposed at the top of the first side slope; first anchored piles are disposed in a base body belowthe side slope platform; and a plurality of ornamental plants are disposed on the first side slope. By means of the deep roadcut green protective structure, the first side slope is disposed on the outer side of the lateral ditch platform, the stability of a roadcut side slope is guaranteed through the first anchored piles and the anchor rod assembly, the visual field of a driver and a passenger is widened, the green landscape effect is good, the demand of environmental protection is better met, and the protection cost is lower.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

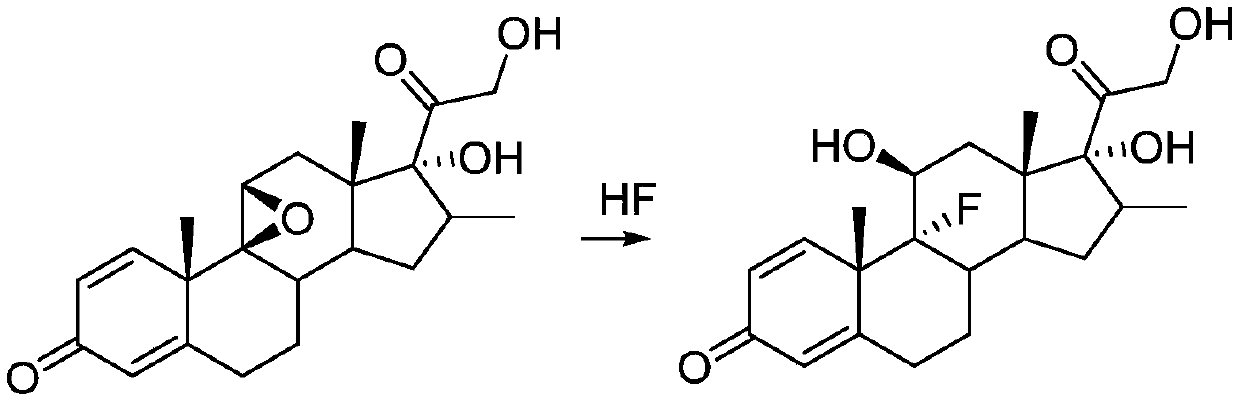

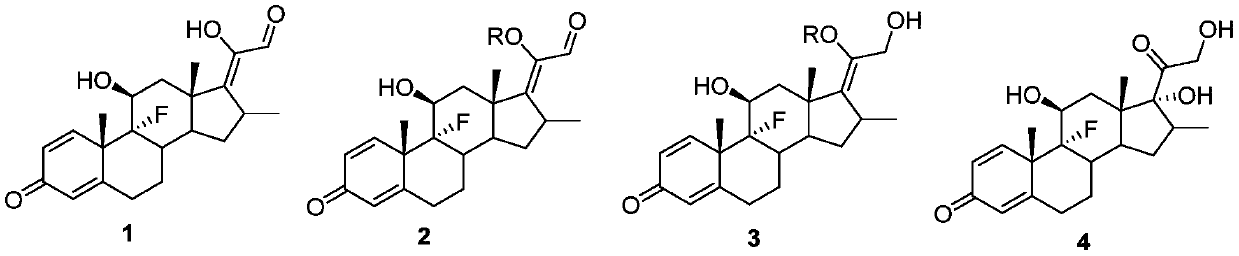

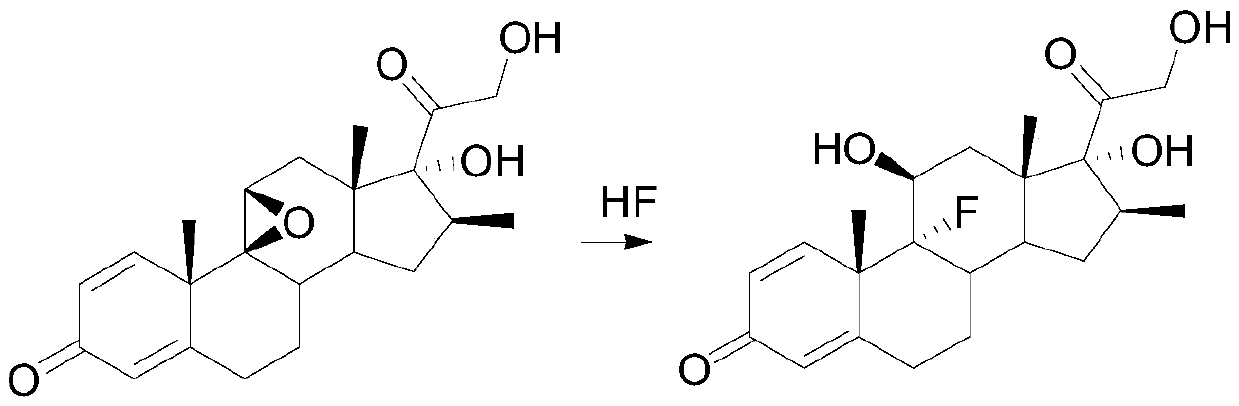

Method for recycling betamethasone or dexamethasone synthetic mother liquor materials

ActiveCN110845562AHigh medicinal valueImprove efficiencySteroidsBulk chemical productionDexamethasoneProcess engineering

The invention relates to a method for recycling betamethasone or dexamethasone synthetic mother liquor materials. The method comprises the following steps: extracting a compound shown as formula 1 from a mother liquor material; carrying out protection reaction of the 20th site hydroxyl group on the compound shown as formula 1 to obtain a compound shown as formula 2; carrying out a reduction reaction of the 21th site aldehyde group on the compound shown as formula 2 to obtain a compound shown as formula 3, and continuously carrying out oxidation reaction and hydrolysis reaction to obtain a compound shown as 4 which is betamethasone or dexamethasone. The above recycling method can convert the betamethasone or dexamethasone mother liquor material into betamethasone or dexamethasone with highmedicinal value and economic benefit, and huge economic benefit is achieved.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

Modified graphene epoxy acrylate resin and preparation method thereof

InactiveCN111303574AMeet the mechanical performance requirementsImprove stabilityCellulosePolymer science

The invention discloses a modified graphene epoxy acrylate resin and a preparation method thereof. The modified graphene epoxy acrylate resin comprises the following components in parts by weight: 60to 100 parts of acrylpimaric acid, 20 to 40 parts of thionyl chloride, 50 to 80 parts of vinyl magnesium bromide, 10 to 30 parts of graphene oxide, 100 to 200 parts of epoxidized soybean oil acrylate,50 to 80 parts of cellulose, 5 to 8 parts of a coupling agent, 20 to 30 parts of a diluent and 5 to 10 parts of benzoyl peroxide tert-butyl ester. The preparation method comprises the following steps: dissolving acrylpimaric acid into dichloromethane, adding thionyl chloride for a reaction to obtain acrylpimaric acid acyl chloride, adding vinyl magnesium bromide for a reaction to obtain acrylpimaric vinyl ketone, adding cellulose and graphene oxide to obtain a graphene oxide mixed solution, adding epoxidized soybean oil acrylate, a diluent, benzoyl peroxide tert-butyl ester and a coupling agent, and curing to obtain a target product. The green natural product is used as the raw material, so that the mechanical properties of the modified resin are enhanced, and the modified resin has the advantage of environment friendliness.

Owner:长沙而道新能源科技有限公司

Method for manufacturing composite bamboo floor block by adopting excess materials

InactiveCN101628439AMeet the needs of green environmental protectionEasy to manufactureWood working apparatusFree coolingRoom temperature

The invention relates to a method for manufacturing a composite bamboo floor block by adopting excess materials, and belongs to the technical field of decoration engineering of buildings. The method is characterized by comprising the following steps: firstly, putting bamboo floor excess materials of different types into a die, and paving a board; secondly, pressing the board for 20 to 25 minutes by a cold press, and tabling and prepressing the board; thirdly, thermally pressing the board for 30 to 40 minutes at the temperature of between 130 and 140 DEG C under the pressure of 10 to 30MPa; fourthly, cooling the board to 50 to 120 DEG C, then maintaining the pressure for 30 to 35 minutes under the pressure of 5 to 25MPa, and naturally cooling the board to normal temperature to obtain the composite bamboo floor block; and finally, polishing and edging the composite bamboo floor block. Therefore, trivial bamboo floor excess materials which are used as wastes in the prior home decoration process are fully utilized. Meanwhile, the new manufactured bamboo floor block has high adaptability for different habitable rooms during paving, is skid-proof and abrasion-resistant, and has mosaic beautiful effect that the prior bamboo floor blocks cannot reach.

Owner:TECSUN SUZHOU HOMES

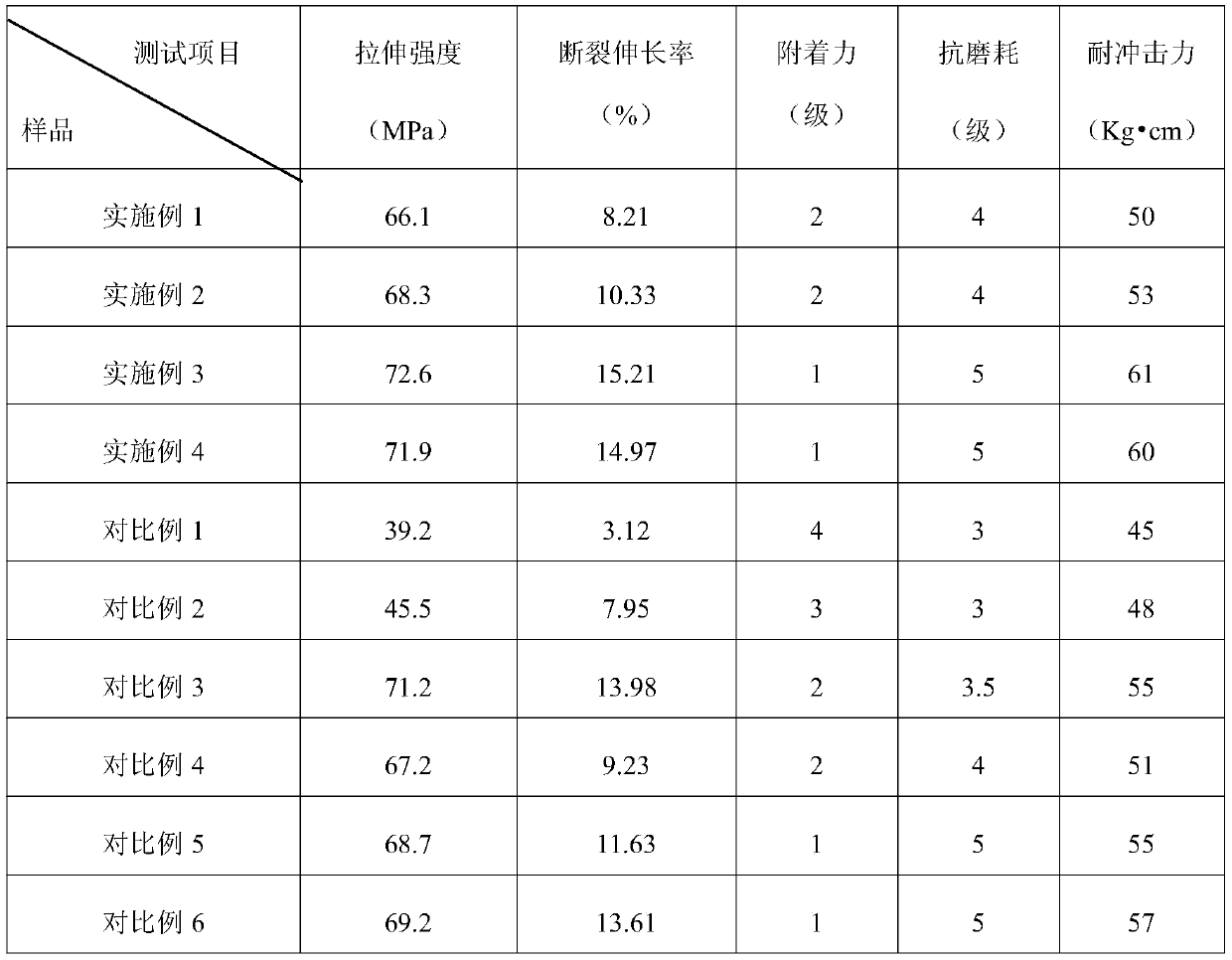

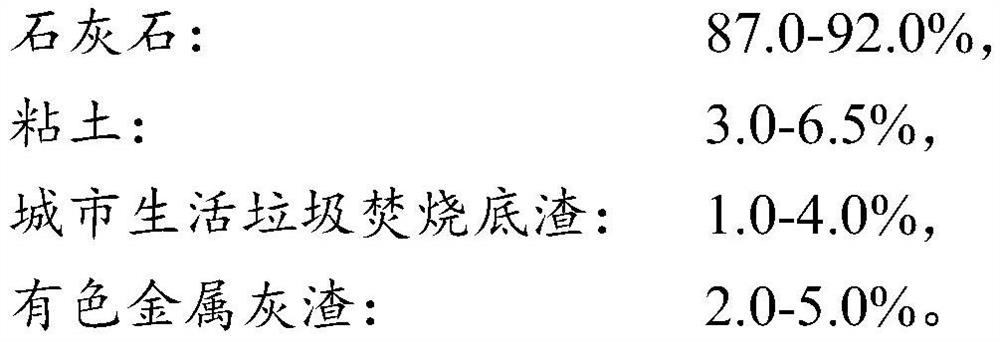

Calcined clinker prepared by replacing part of clay with municipal solid waste incineration bottom slag and preparation method of calcined clinker

The invention belongs to the field of cement, and particularly relates to a calcined cement clinker prepared by replacing part of clay with municipal solid waste incineration bottom slag and a preparation method of the calcined cement clinker. The raw material of the cement clinker is prepared by replacing part of clay with municipal solid waste incineration bottom slag, and the raw material of the cement clinker comprises the following components in percentage by mass: 87.0-92.0% of limestone, 3.0-6.5% of clay, 1.0-4.0% of municipal solid waste incineration bottom slag and 2.0-5.0% of non-ferrous metal ash. According to the clinker ingredients, the production cost of the clinker is effectively reduced, the use of clay resources can be reduced, a new path is opened up for comprehensive utilization of municipal solid waste incineration bottom slag resources, meanwhile, the quality of the cement clinker is kept unchanged, and the production requirements are met.

Owner:兰溪南方水泥有限公司

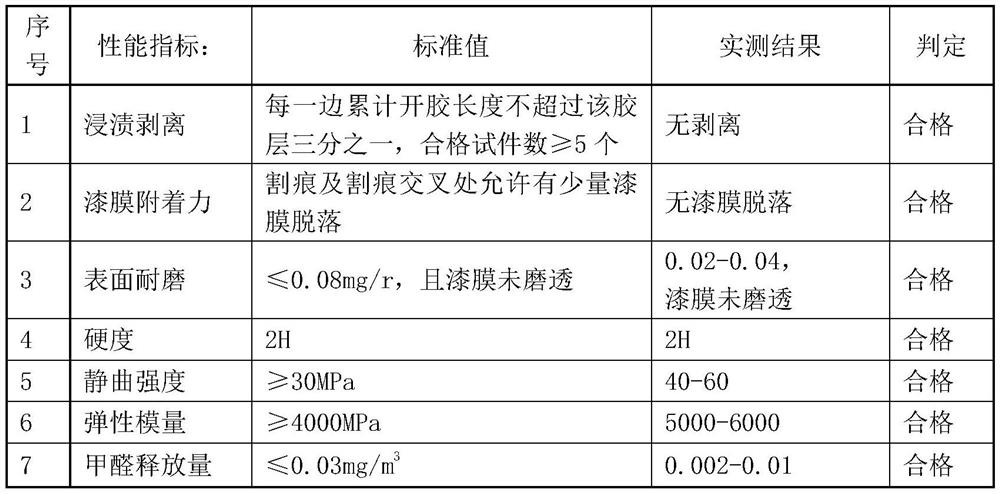

Production process for formaldehyde-free multi-layer solid-wood composite floor and floor

InactiveCN111906880AStability up to standardWater resistance up to standardWood veneer joiningWood veneerSolid wood

The invention belongs to the technical field of building materials, and relates to a production process for a formaldehyde-free multi-layer solid-wood composite floor. The production process for the formaldehyde-free multi-layer solid-wood composite floor comprises the working procedures of gluing and veneering, cold-pressing, hot-pressing or curing, cutting, priming paint coating, forming, finishing paint coating, and packaging and finished product obtaining, wherein in the working procedure of gluing and veneering, the surface of a criss-cross multi-layer plate base material is coated with awater-based styrene-butadiene rubber emulsion, a single-side gluing amount is 100-200 g / m <2>, and a layer of hard broad-leaved wood veneer / wood skin with a thickness of 0.6-1.2 mm is pasted after gluing. According to the invention, by adjusting and optimizing the technological parameters, the formaldehyde-free multi-layer solid-wood composite floor with the physical and mechanical properties meeting the requirements of various indexes is prepared. The production process is simple, easy to operate and low in cost, and the characteristics of being aldehyde-free, green and environment-friendlyare met; and the stability, water resistance, impregnation peeling performance and other performance of the prepared formaldehyde-free multi-layer solid-wood composite floor reach the standard, the formaldehyde release amount is lower than 0.03 mg / m <3>, the standard requirements of 'aldehyde-free artificial plates and products thereof' are met, and other harmful organic volatile matters are avoided, so that the requirements of being green and environment-friendly are met.

Owner:圣象地板(句容)有限公司

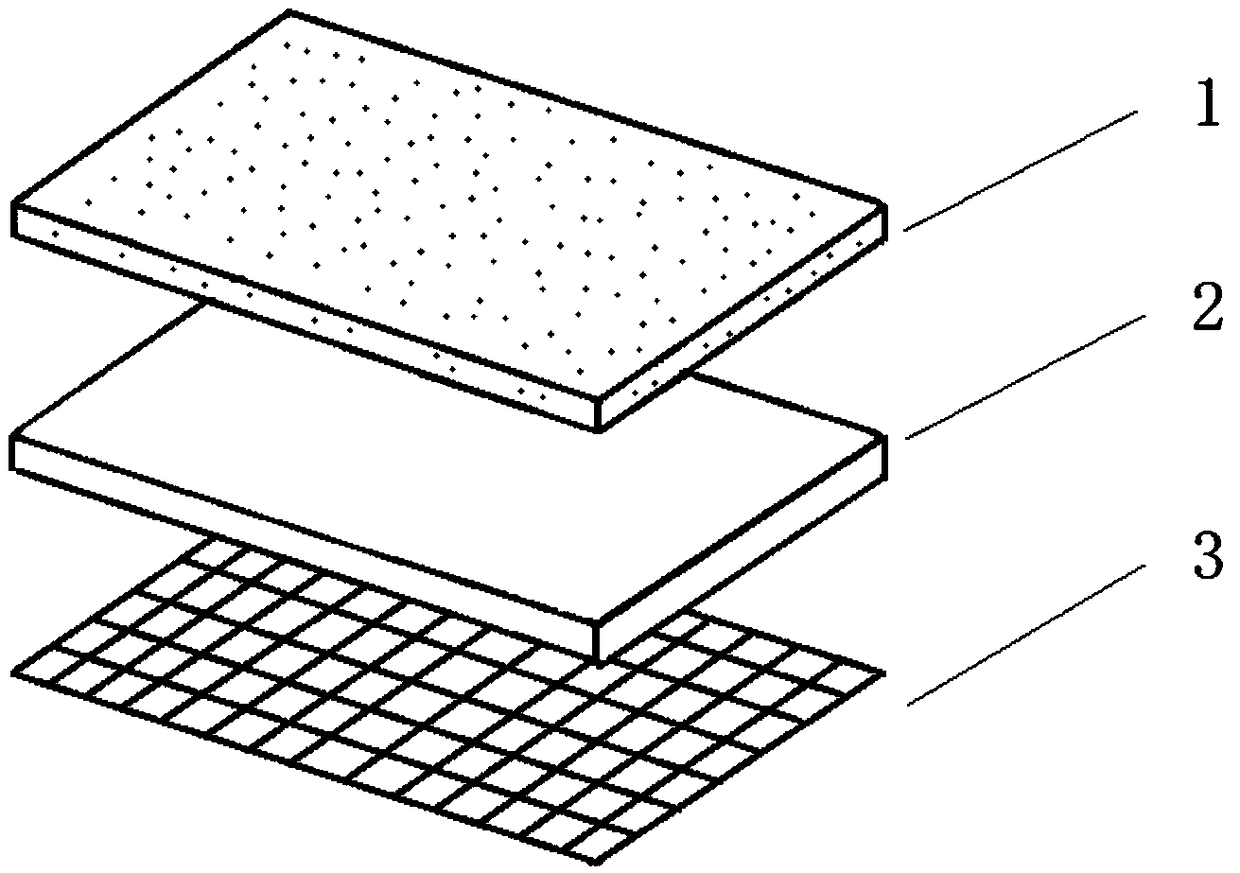

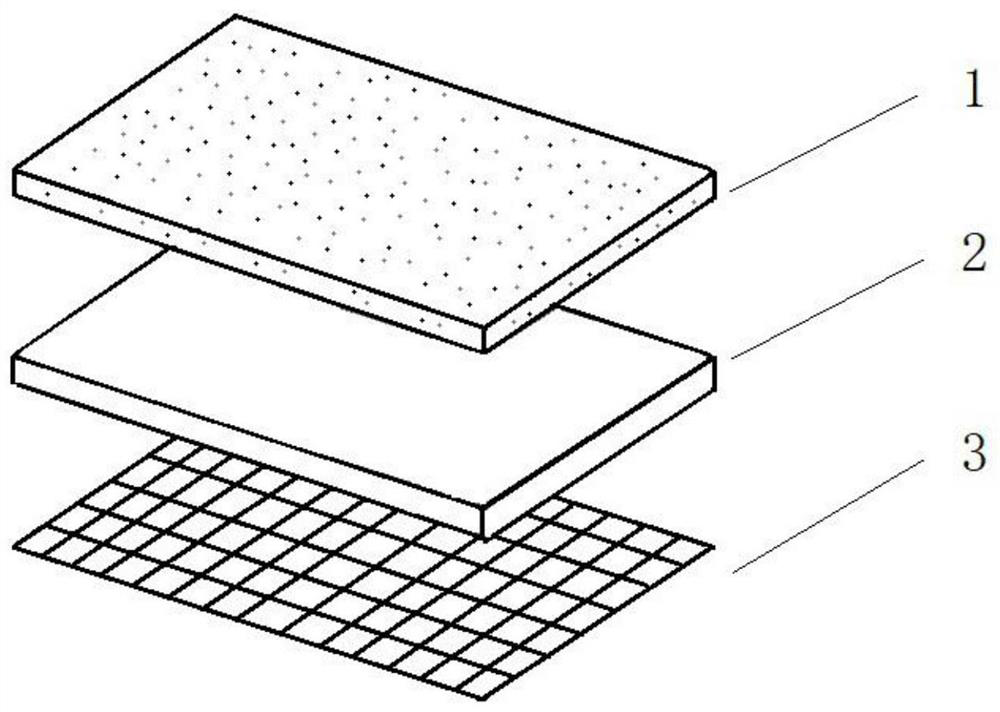

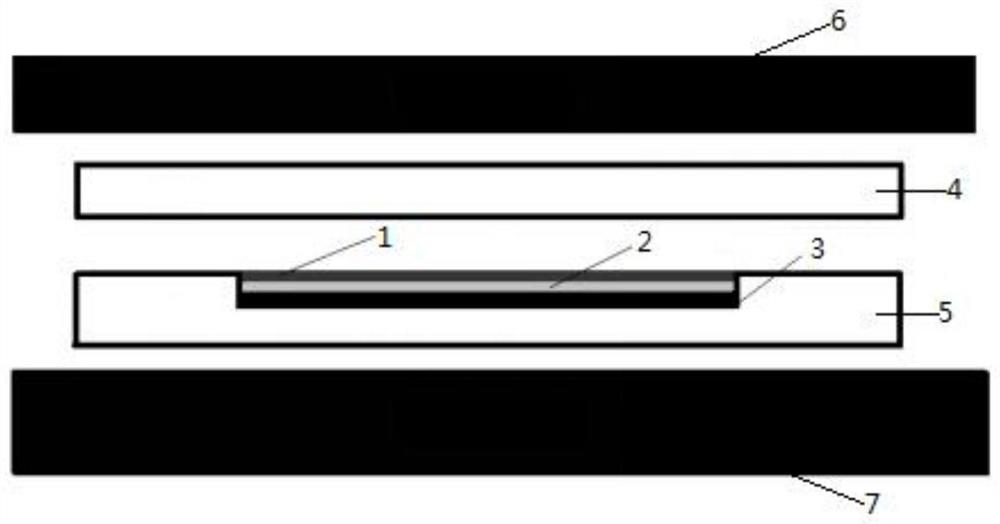

Flax composite floor and preparation method thereof

ActiveCN109263173AOptimize structureLow surface permeabilityLaminationLamination apparatusRosinEnvironmental resistance

The invention belongs to the technical field of floor decoration materials, and particularly relates to a flax composite floor. The flax composite floor comprises a flax straw dust composite layer, acalcium carbonate composite layer and a hessian layer which are sequentially bonded; the flax straw dust composite layer comprises flax straw dust, waterborne polyurethane, linseed oil and rosin; thecalcium carbonate composite layer comprises calcium carbonate, the waterborne polyurethane, the linseed oil and the rosin. The flax composite floor has the advantages that component materials in the floor does not volatilize pollutants, the purposes of green and environmental friendliness are really achieved, composite material structures are allowed to be optimized by three layers of composite structures to be conformed to actual using demands, the content of all raw materials is optimized, so that the composite floor has higher breaking strength and lower surface permeability, therefore a provided product does not volatilize pollutants, and green and environmental friendliness of the flax composite floor are achieved.

Owner:TAIYUAN UNIV OF TECH

High-strength assembled curtain wall structure

The invention discloses a high-strength assembled curtain wall structure. The high-strength assembled curtain wall structure comprises a combined column, a combined plate, a first connecting part anda second connecting part, the combined column is of a cylindrical structure and is provided with connecting grooves, fixing holes are formed in inner circles of the connecting grooves, an inserting groove is formed in the left side face of the combined column, an inserting plate is arranged on the right side face of the combined column, and the combined plate is of a rectangular plate structure. In the high-strength assembled curtain wall structure, the combined column and the combined plate are spliced to form the curtain wall, three-dimensional splicing design can be performed according to actual needs, disassembling, assembling and secondary utilization are convenient, and the demands for environmental protection are met. The building curtain wall formed by assembling the combined column and the combined plate replaces an original welding-type assembly building curtain wall, it is avoided that a surface layer is damaged by welding and accordingly easily rusts, the service life of the curtain wall structure is prolonged, high attractiveness and high strength are realized, and the high-strength assembled curtain wall structure is suitable for popularization.

Owner:李丹丹

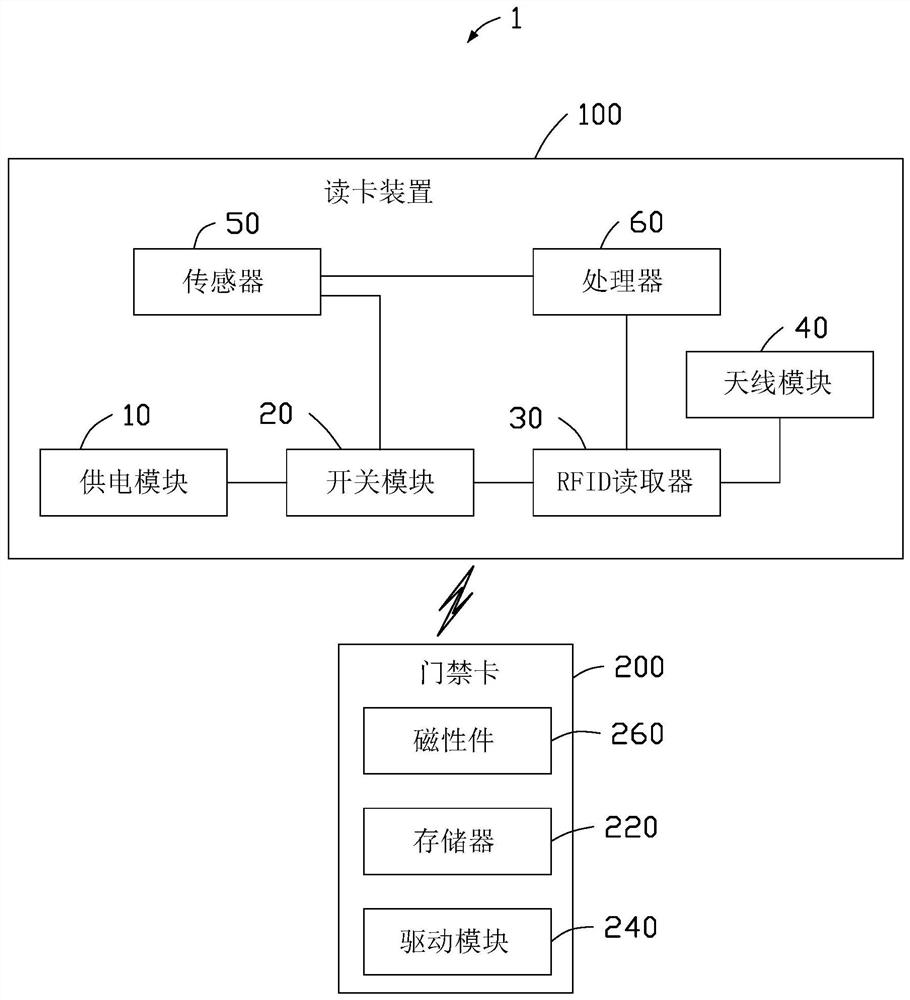

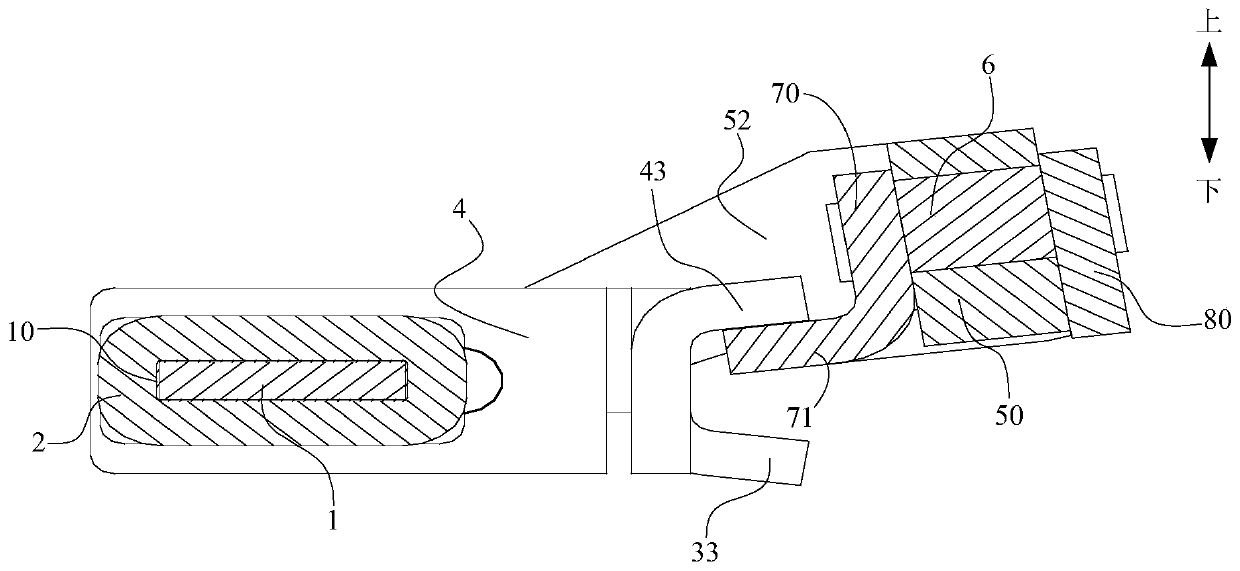

Card reading device and access control system

InactiveCN111798604ASave electricityLow costIndividual entry/exit registersComputer hardwareEngineering

A card reading device is used for carrying out identity authentication on an entrance guard card and comprises a power supply module, a wireless tag reader, a switch module and a sensor. The switch module is electrically connected or disconnected with the power supply module and the wireless volume label reader. The sensor is electrically connected to the switch module and is used for detecting the magnetic field change of the entrance guard card; when the card reading device is idle, the switch module is in an open state, and the power supply module does not supply power to the wireless tag reader. When the sensor detects the change of the magnetic field, a detection signal is output to the switch module to close the switch module, and the power supply module supplies power to the wireless tag reader. The invention further provides an access control system comprising the card reading device.

Owner:YONGLIN BIOTECH

A kind of flax composite floor and preparation method thereof

ActiveCN109263173BLow surface permeabilityHigh breaking strengthLaminationLamination apparatusEnvironmental engineeringLinseed oil

The invention belongs to the technical field of floor decoration materials, and particularly relates to a flax composite floor. The flax composite floor comprises a flax straw dust composite layer, acalcium carbonate composite layer and a hessian layer which are sequentially bonded; the flax straw dust composite layer comprises flax straw dust, waterborne polyurethane, linseed oil and rosin; thecalcium carbonate composite layer comprises calcium carbonate, the waterborne polyurethane, the linseed oil and the rosin. The flax composite floor has the advantages that component materials in the floor does not volatilize pollutants, the purposes of green and environmental friendliness are really achieved, composite material structures are allowed to be optimized by three layers of composite structures to be conformed to actual using demands, the content of all raw materials is optimized, so that the composite floor has higher breaking strength and lower surface permeability, therefore a provided product does not volatilize pollutants, and green and environmental friendliness of the flax composite floor are achieved.

Owner:TAIYUAN UNIV OF TECH

solar panel light controller

The invention provides a solar battery panel light direction controller, which is used to control the light direction of the solar battery panel, including a light receiver, a vertical control circuit and a horizontal control circuit. The light-direction controller of the solar panel of the present invention has a cross-section of the upper part of the shading plate in the shape of a "ten" and a cross-section of the lower part of a "Y" shape. The solar light signal controls the vertical control circuit or the horizontal control circuit, thereby controlling the second control motor or the first control motor, and then adjusting the direction of the solar panel so that the solar panel always receives the sun's rays at the maximum angle and absorbs solar energy to the greatest extent .

Owner:李豹

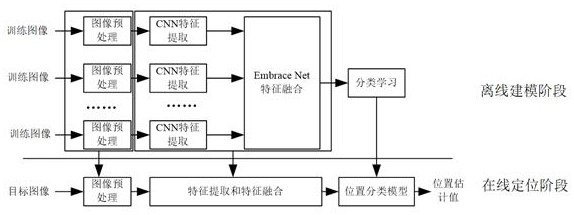

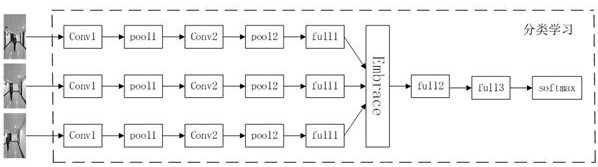

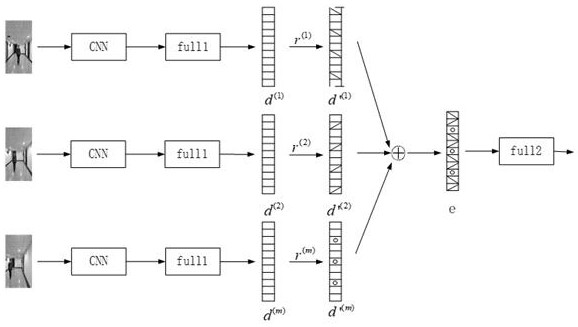

Image positioning method based on data modal missing and Embedded Net

PendingCN113822349AOvercoming Signal Attenuation ProblemsLow costCharacter and pattern recognitionNeural architecturesTraining data setsFeature (machine learning)

The invention discloses an image positioning method based on data modal missing and Embedded Net, which is composed of two stages of off-line modeling and on-line positioning, and comprises the following steps: S1, collecting training images, preprocessing the training images, carrying out category division, and taking the training images as a training data set; S2, extracting features of the training images and fusing with the features; performing offline classification learning to obtain a feature extraction network, a feature fusion network and a position classification model of optimal parameters; S3, collecting a target image, and performing image preprocessing on the target image; and S4, performing feature extraction and feature fusion on each target image, and then obtaining a position estimation value of the target. The multi-image measurement technology and the machine learning technology are combined, target positioning for the indoor complex environment is achieved, follow-up positioning work is conducted through the images collected by the camera, the problem of signal attenuation is solved, and the implementation cost of the scheme is reduced.

Owner:NANJING UNIV OF POSTS & TELECOMM

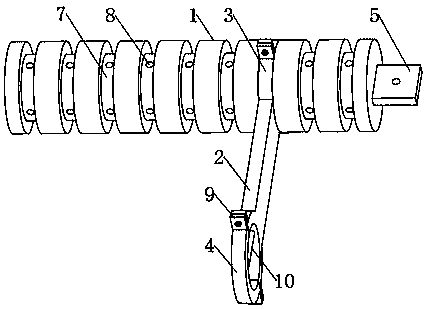

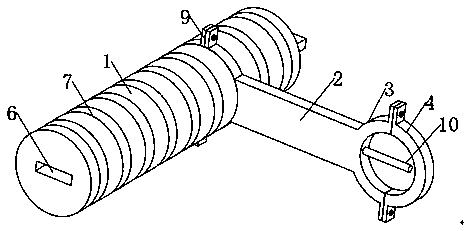

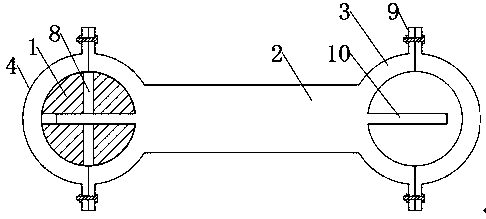

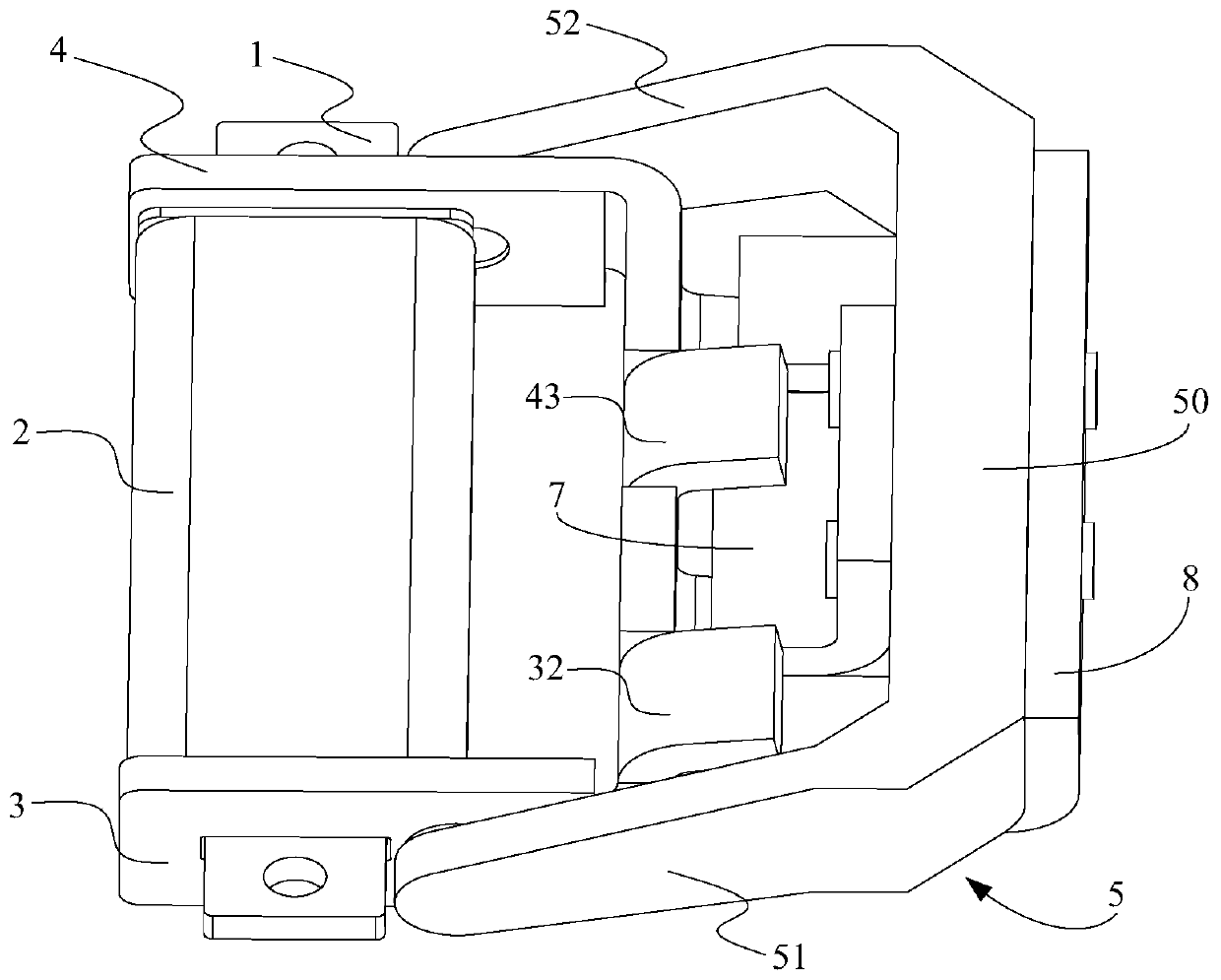

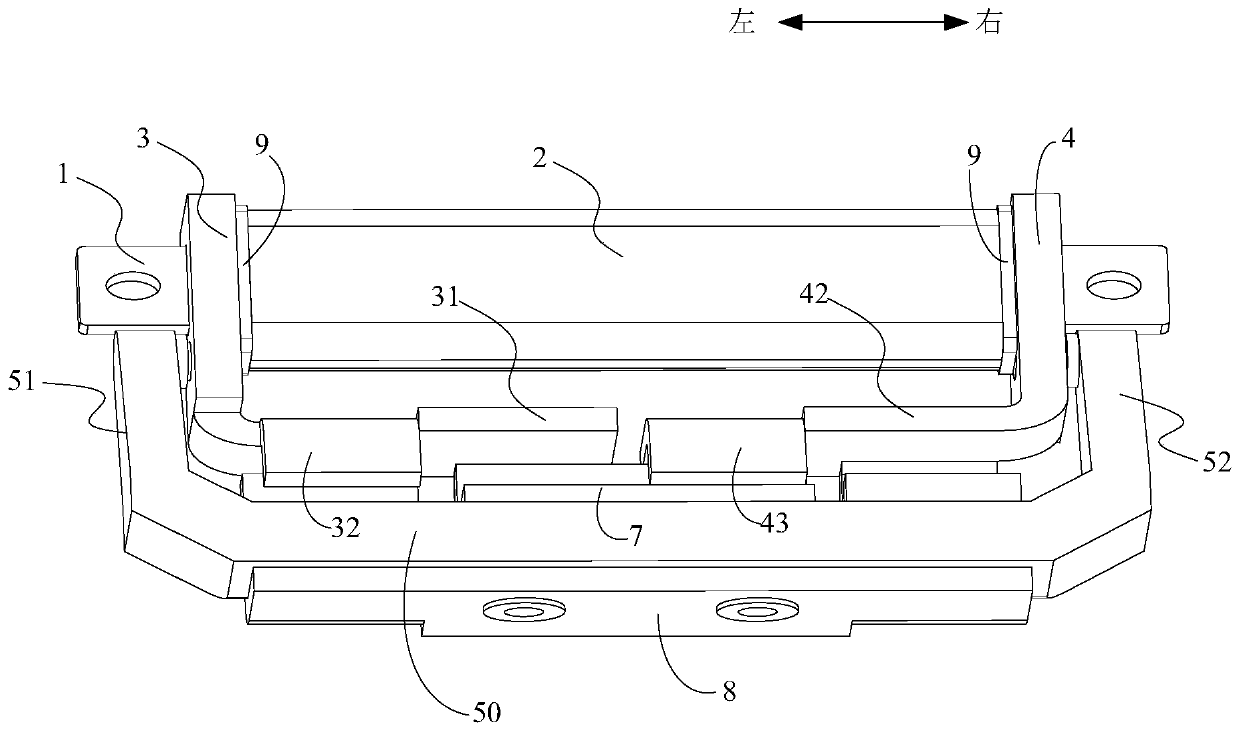

power generation device

ActiveCN107809153BImprove experienceMeet the needs of green environmental protectionFrom muscle energyMachines/enginesEngineeringPole piece

The invention discloses a power generation device. The power generation device includes a winding core, a winging coil coiling the winding core, a left core connected to the left end of the winding core, a right core connected to the right end of the winding core, a rocker arm including two movable connection parts connected to the left core and the right core respectively in a movable manner anda fixed connection part connected to the movable connection part, a permanent magnet arranged on the rocker arm, an inner pole piece and an outer pole piece connected to the two electrodes of the permanent magnet. When the rocker arm swings to a first extreme position along a first direction under the drive of external forces, the inner pole piece is in contact with the right core, and the outer pole piece is in contact with the left core. When the rocker arm swings to a second extreme position along a second direction which is opposite to the first direction under the drive of external force,the inner pole piece is in contact with the left core and the outer pole is in contact with the right core. The power generation device provided by the invention solves problems that a conventional battery adopted by a low power consumption electronic product is short in service life and requires frequent change.

Owner:BYD CO LTD

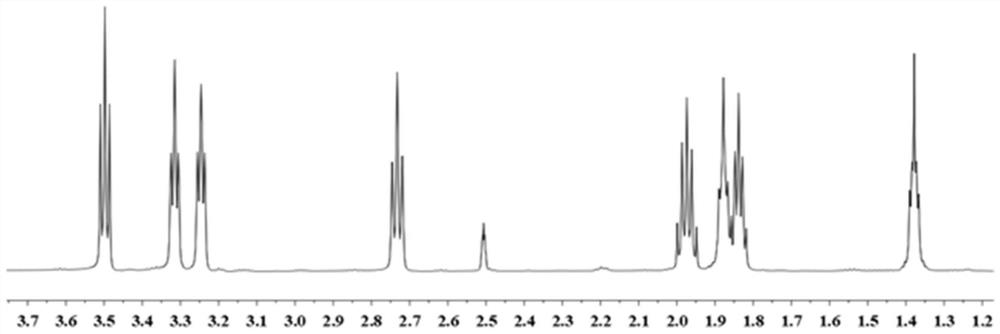

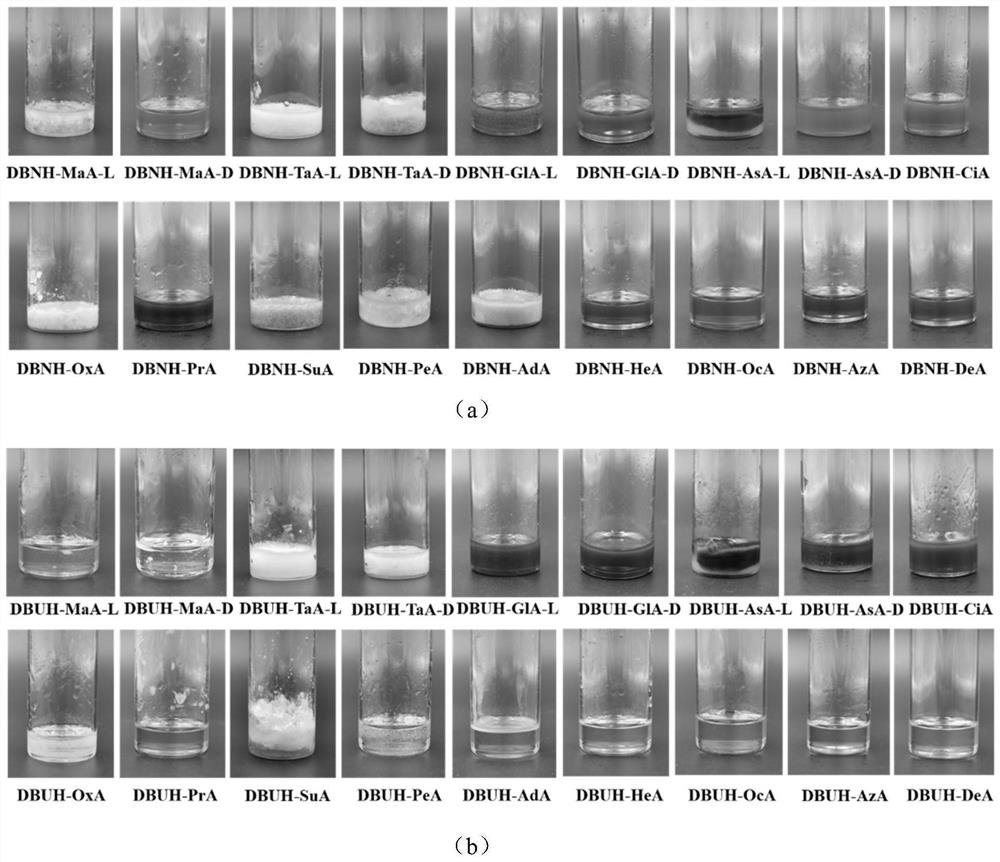

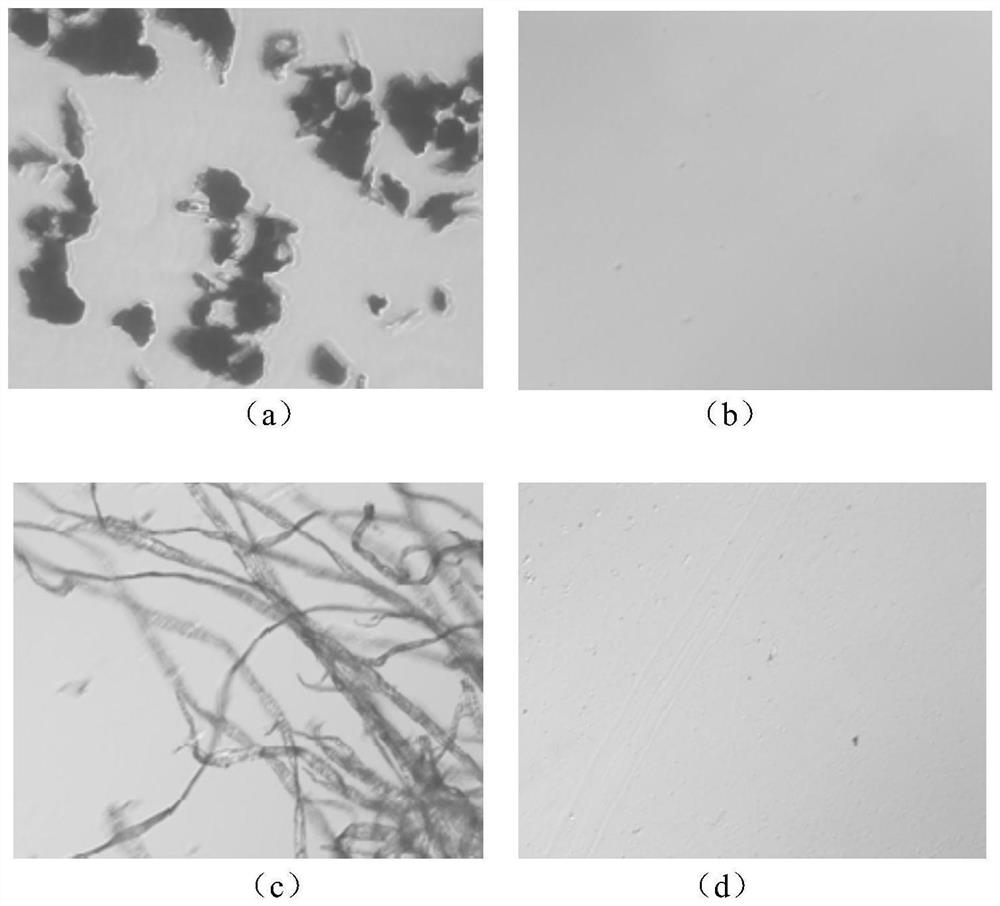

Multi-element ionic liquid as well as preparation method and application thereof

ActiveCN114195791AEasy to makeLow costOrganic compound preparationOrganic chemistry methodsCelluloseOrganic acid

The invention belongs to the technical field of cellulose solutions, and discloses a polybasic ionic liquid and a preparation method and application thereof, the ionic liquid has one of the following general formulas: C + A2-C + and C + A3-C +-C +, in the general formulas, C + is a super alkali cation, and A2-and A3-in the general formulas are binary and ternary organic acid anions. The ionic liquid disclosed by the invention is simple to prepare and low in cost, and is prepared only by reacting organic super alkali with binary and ternary organic acids under a solvent-free condition, and subsequent separation and purification are not needed. According to the invention, polybasic organic acid is introduced into the super-alkaline ionic liquid to prepare the polybasic super-alkaline ionic liquid. The multi-element ionic liquid has a multi-cation and multi-anion structure, can provide more hydrogen bond binding sites and is beneficial to dissolution of cellulose, and the cellulose membrane material can be obtained after the dissolved cellulose is solidified and regenerated by water.

Owner:SOUTH CHINA UNIV OF TECH

Method for prolonging fragrance retention time of essence

PendingCN111100755AKeep fragrance for a long timeDoes not affect the effectEssential-oils/perfumesOrganic chemistrySoluble polymer

The invention discloses a method for prolonging the fragrance retention time of essence, which comprises the following steps: proportionally mixing a water-soluble polymer and essence, granulating themixture by a dry granulator, and performing screening to obtain modified essence. According to the method for prolonging the fragrance retention time of the essence, the modified essence is obtainedafter the water-soluble polymer and the essence are mixed in proportion, subjected to dry granulation and sieved, the fragrance retention time of the essence can be prolonged, the water-soluble polymer material is dissolved after encountering water, the essence is released, the method is convenient to use, and the effect of the essence is not affected.

Owner:南京亿华药业有限公司

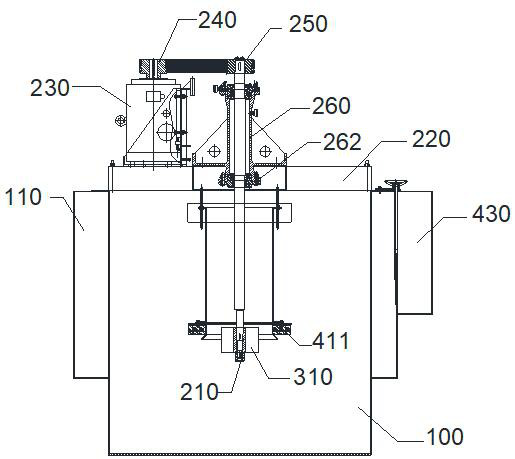

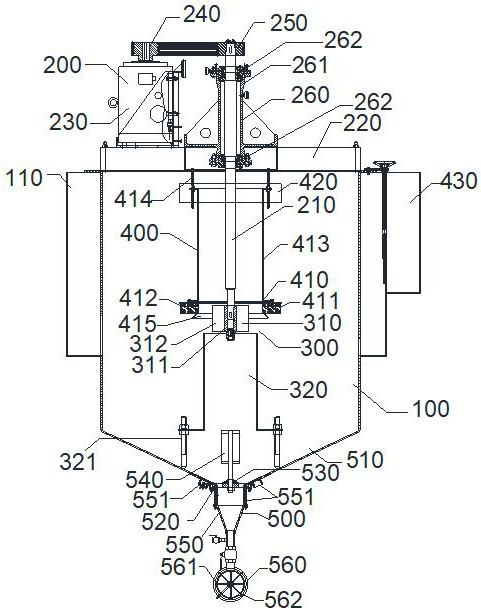

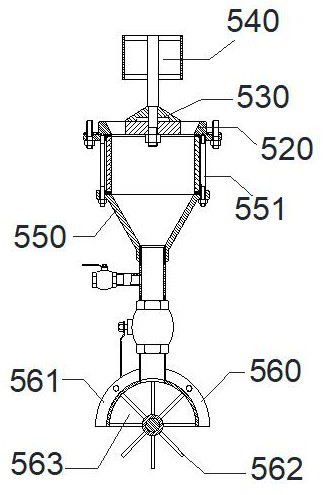

Ore dressing machine and intelligent ore dressing method

PendingCN114798154AReduce rotation speedFloating fastNon-rotating vibration suppressionWet separationMining engineeringMechanical engineering

The invention relates to the technical field of gravity ore dressing equipment, in particular to an ore dressing machine and an intelligent ore dressing method.The ore dressing machine is characterized by comprising an ore dressing tank provided with a feeding port, a driving mechanism arranged at the top of the ore dressing tank and a transmission shaft driven by the driving mechanism and arranged in the center of the ore dressing tank; the high-density mineral separation mechanism is arranged at the bottom of the transmission shaft, and the medium-low-density mineral separation mechanism is arranged above the high-density mineral separation mechanism; the high-density mineral separation mechanism comprises a first impeller arranged at the bottom of the transmission shaft; the medium-low density mineral separation mechanism comprises a damping assembly arranged on the upper portion of the first impeller and used for reducing the movement intensity of ore pulp, and at least one overflow opening formed in the upper portion of the mineral separation tank. The ore dressing machine has the advantages of being simple in structure, high in ore dressing efficiency, good in operation stability and the like, the ore dressing machine takes water as an ore dressing medium, ore dressing can be achieved without adding chemical agents, and the green and environment-friendly requirements are met.

Owner:冉冰

A kind of retarded clinker and preparation method thereof

ActiveCN112341014BProlonged initial settingExtension of timeSolid fuelsCement productionClinker (waste)Nonferrous metal

The invention belongs to the field of cement, and particularly relates to a retarded clinker and a preparation method thereof. The raw material of the slow-setting clinker of the present invention is composed of the following components in mass fractions: limestone, 81.0-93.0%; clay, 3.0-15.0%; non-ferrous metal ash, 1.0-5.0%; fluorite tailings, 1.5‑3.5%. Wherein, the content of calcium fluoride in the fluorite tailings is 15-30%. By adding a certain amount of fluorite tailings, the invention prolongs the initial setting and final setting time of the clinker, and realizes the production of the retarded clinker, thereby meeting the performance requirements of the retarded cement for special projects; The performance is still maintained, so it can ensure the quality of concrete while meeting the requirements for the retarding characteristics of cement; at the same time, the effective use of fluorite tailings broadens the utilization of fluorite tailings, and reduces the stacking and external discharge of waste-producing enterprises. Meet the needs of green environmental protection.

Owner:兰溪南方水泥有限公司 +1

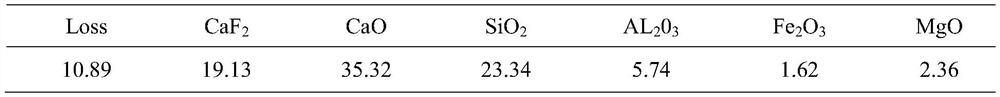

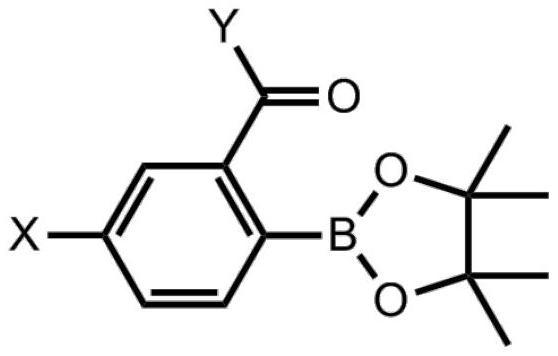

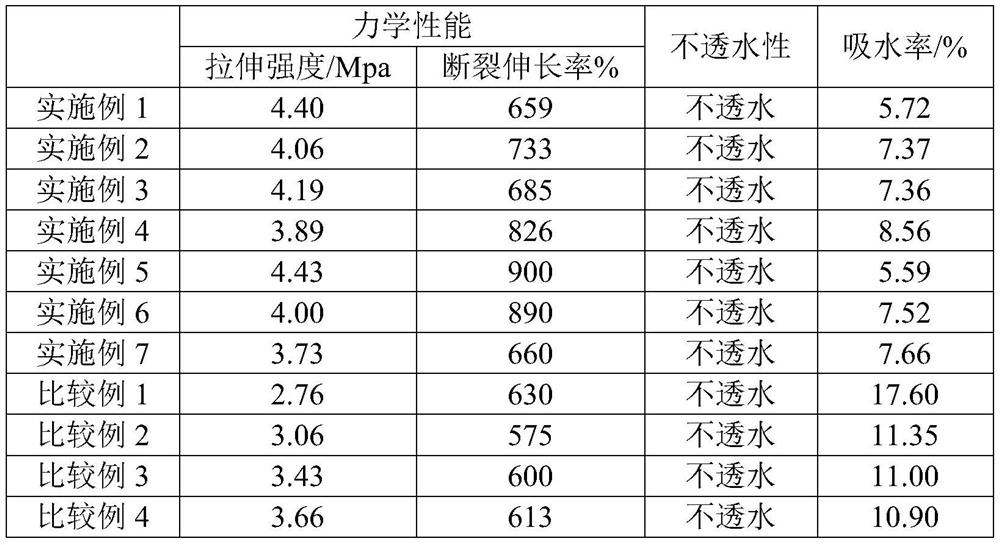

Waterborne polyurethane dispersion, preparation method thereof and self-crosslinking waterborne polyurethane waterproof coating

PendingCN114805734AGood mechanical propertiesLow water absorptionPolyurea/polyurethane coatingsIsocyanateKetone

The invention discloses a water-based polyurethane dispersion, a preparation method of the water-based polyurethane dispersion and a self-crosslinking type water-based polyurethane waterproof coating. The self-crosslinking type water-based polyurethane waterproof coating comprises the water-based polyurethane dispersion, the waterborne polyurethane dispersoid is prepared by the following steps: reacting components A) polyisocyanate, B) polyether polyol and / or polyether monohydric alcohol, C) micromolecular dihydric alcohol, D) dyhydroxy carboxylic acid, E) o-carbonyl phenylboronic acid ester compound and F) amino compound to generate a polymer precursor, and then reacting the polymer precursor with G) hydrazide compound to generate an aldehyde / ketone-hydrazine cross-linked polyurethane polymer. And water is introduced to form a waterborne polyurethane dispersion. The self-crosslinking type waterborne polyurethane waterproof coating disclosed by the invention has excellent mechanical properties, low water absorption and heat / acid / alkali resistance, is an environment-friendly polymer waterproof coating, and can be used for waterproofing of outer walls, toilets, kitchens, basements and the like.

Owner:WANHUA CHEM GRP CO LTD

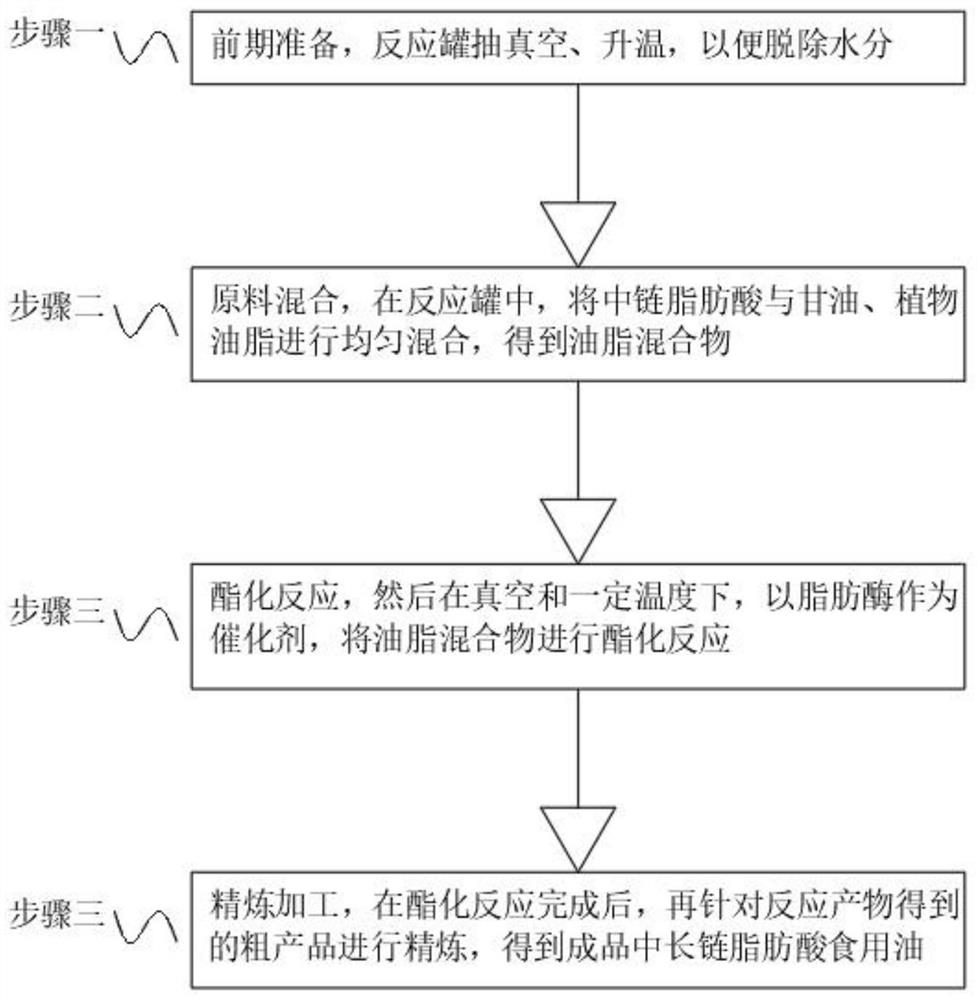

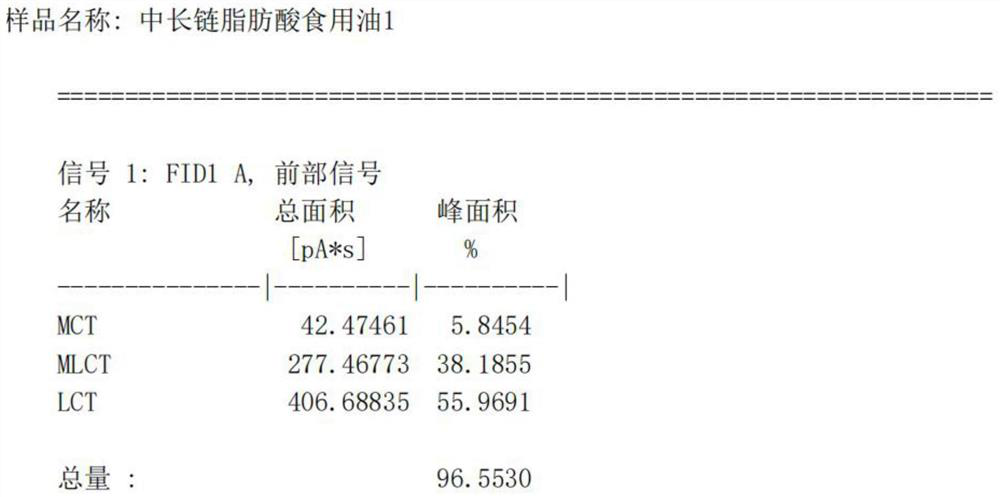

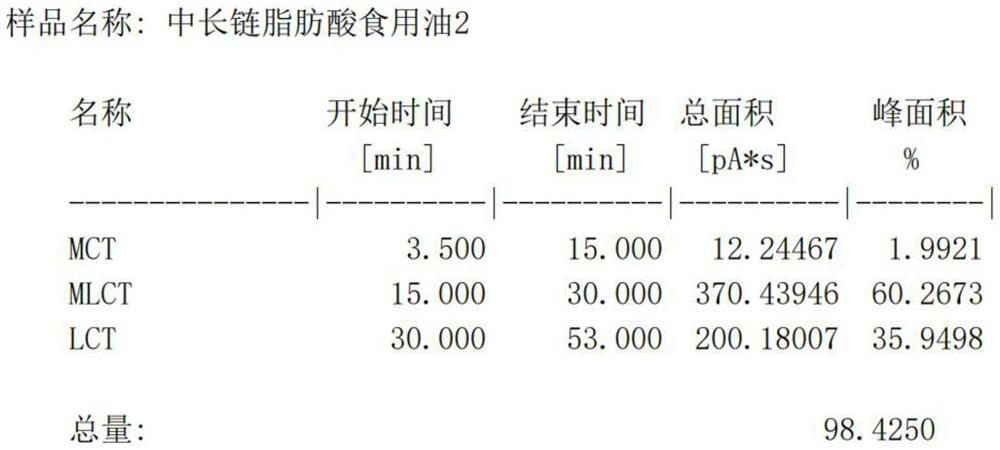

Preparation method of medium-chain and long-chain fatty acid edible oil

InactiveCN114807257AImprove dehydration efficiencyImprove reaction efficiencyFatty acid esterificationFermentationLong chain fatty acidGlycerol

The invention discloses a preparation method of medium-chain and long-chain fatty acid edible oil, and relates to the field of edible oil and fat. The preparation method of the medium-chain and long-chain fatty acid edible oil comprises the following steps: step 1, early-stage preparation: vacuumizing and heating a reaction tank so as to remove water; step 2, raw material mixing: uniformly mixing medium-chain fatty acid with glycerol and vegetable fat in a reaction tank to obtain a fat mixture; step 3, esterification reaction: carrying out esterification reaction on the grease mixture in vacuum and at a certain temperature by taking lipase as a catalyst; step 4, refining processing: after the esterification reaction is completed, refining a crude product obtained from a reaction product to obtain a finished product of the medium-chain and long-chain fatty acid edible oil; the main characteristic component of the finished product medium-and-long-chain fatty acid edible oil prepared in the step 4 is medium-and-long-chain fatty glyceride. The preparation method provided by the invention has the characteristics of high reaction efficiency, low raw material price, low energy consumption and the like.

Owner:青岛和合汇途工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com