Flax composite floor and preparation method thereof

A composite floor and linen technology, applied in the field of floor decoration materials, can solve the problems of poor fire and moisture resistance, adverse effects, unfriendly environment, etc., and achieve the effects of low surface permeability, high fracture resistance, and low surface permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method for the flax composite floor described in the above technical solution, comprising the following steps:

[0043] (1) mixing flax stalk scraps, water-based polyurethane, linseed oil and rosin to obtain a flax stalk composite raw material;

[0044] (2) calcium carbonate, water-based polyurethane, linseed oil and rosin are mixed to obtain calcium carbonate composite raw material;

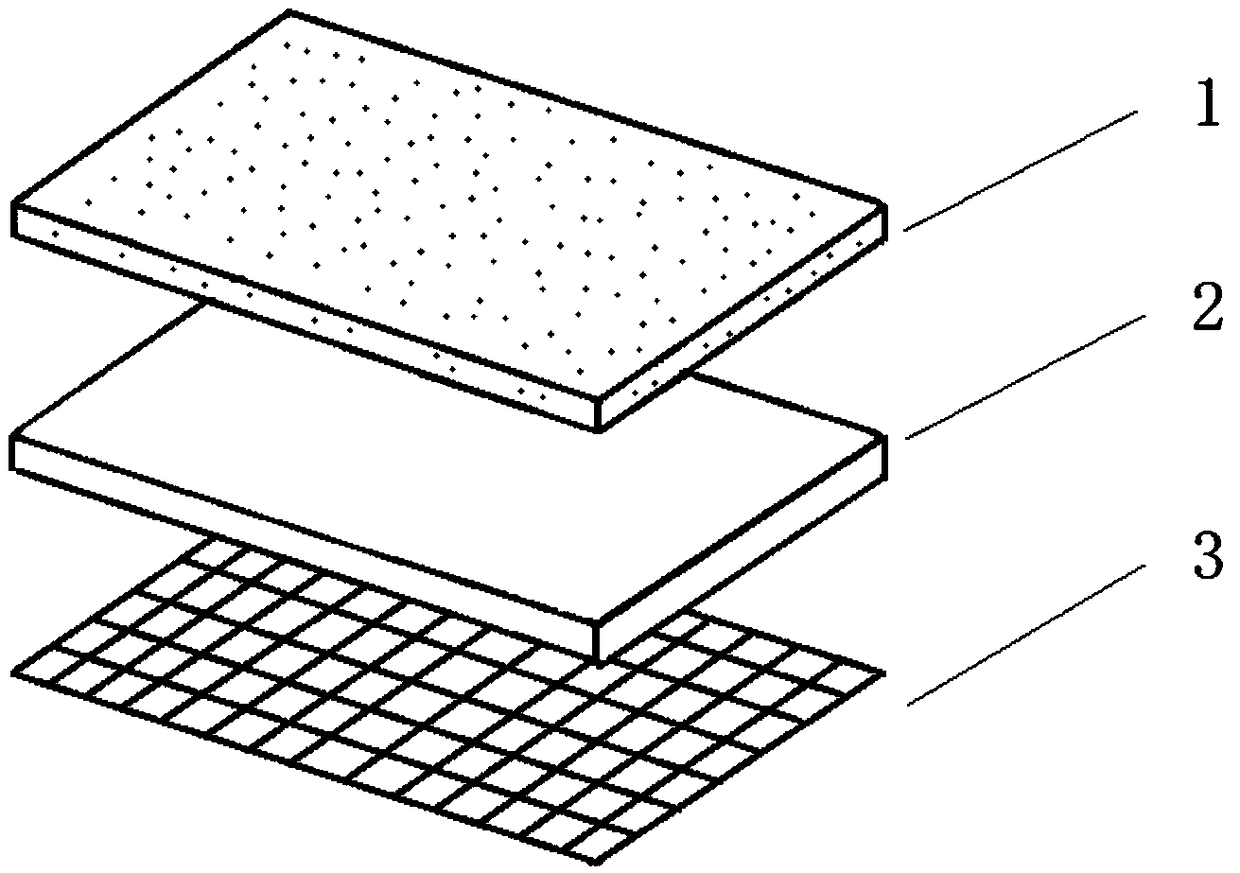

[0045] (3) The jute coarse cloth, the calcium carbonate composite raw material obtained in the step (2) and the flax stalk composite raw material obtained in the step (1) are sequentially stacked and molded to obtain a flax composite floor;

[0046] The steps (1) and (2) are not in chronological order.

[0047] In the present invention, the dosage of each component in the preparation method is consistent with the dosage of the components in the technical solution of the above-mentioned linen composite floor, and will not be repeated here....

Embodiment 1

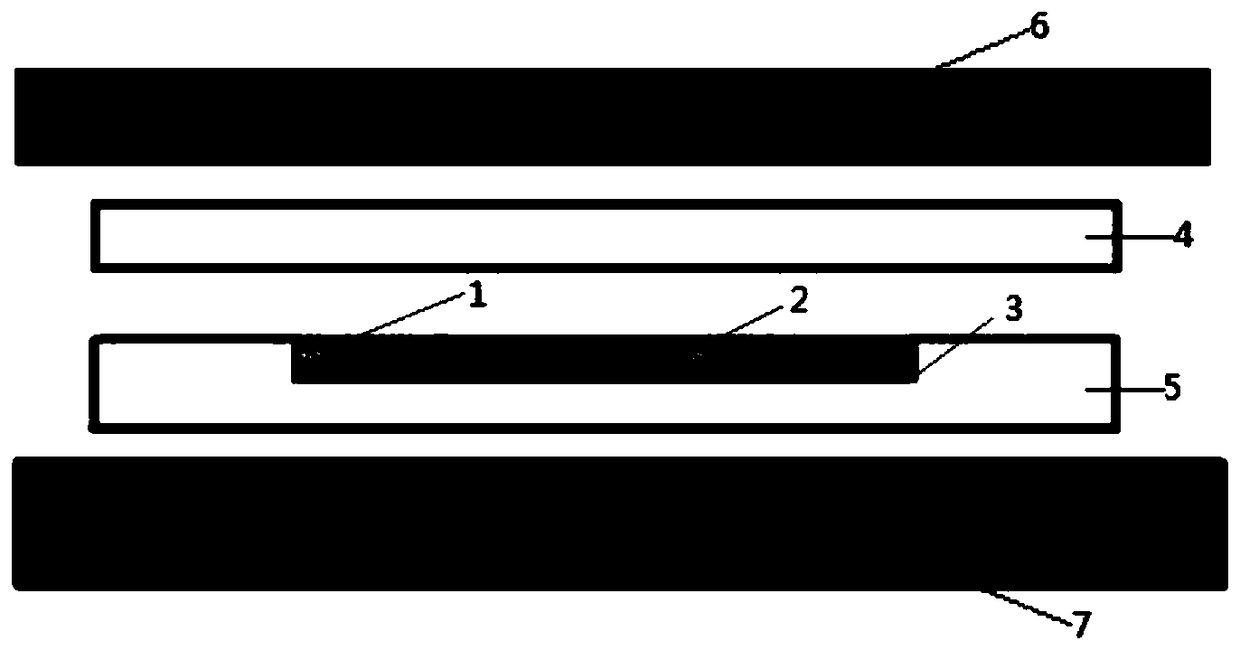

[0057] The flax stalk scraps were dried at 80°C for 24h, and the calcium carbonate was dried at 80°C for 24h. Mix 8g of dried flax stalk scraps with 10g of water-based polyurethane, 2g of linseed oil and 2g of rosin at a speed of 200r / min for 10min to obtain a flax stalk composite material; 20g of dried calcium carbonate and 6g of water-based Polyurethane, 2 g of linseed oil and 2 g of rosin were stirred and mixed for 10 min at a speed of 200 r / min to obtain a calcium carbonate composite raw material. Such as figure 2 The relative relationship between the material shown and the flat vulcanizing machine, the area is 10cm 2 The jute coarse cloth (the size of the jute coarse cloth mainly depends on the size of the flat vulcanizing machine mold, that is, the size of the jute coarse cloth should adapt to the length and width of the mold), the calcium carbonate composite raw material and the flax stalk composite raw material are laid sequentially under the flat vulcanizing machine...

Embodiment 2

[0060] The flax stalk scraps were dried at 80°C for 24h, and the calcium carbonate was dried at 80°C for 24h. Mix 7g of dried flax stalk scraps with 12g of water-based polyurethane, 2g of linseed oil and 2g of rosin at a speed of 200r / min for 10min to obtain a flax stalk composite material; mix 18g of dried calcium carbonate and 10g of water-based Polyurethane, 2 g of linseed oil and 2 g of rosin were stirred and mixed for 10 min at a speed of 200 r / min to obtain a calcium carbonate composite raw material. Set the area to 10cm 2 The jute coarse cloth, calcium carbonate composite raw material and flax stalk composite raw material are sequentially laid in the rectangular concave cavity under the mold of the flat vulcanizer, and the surface of the concave cavity composite raw material is rolled by a pressure roller to fill the cavity with the raw material. cavity, and make the surface of the raw material flat, align the upper and lower molds of the mold and put them into the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com