Method for recycling betamethasone or dexamethasone synthetic mother liquor materials

A technology of dexamethasone and betamethasone, which is applied in the production of steroids, bulk chemicals, organic chemistry, etc., and can solve the problems of waste of polluted materials, excessive tar, and failure to recycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

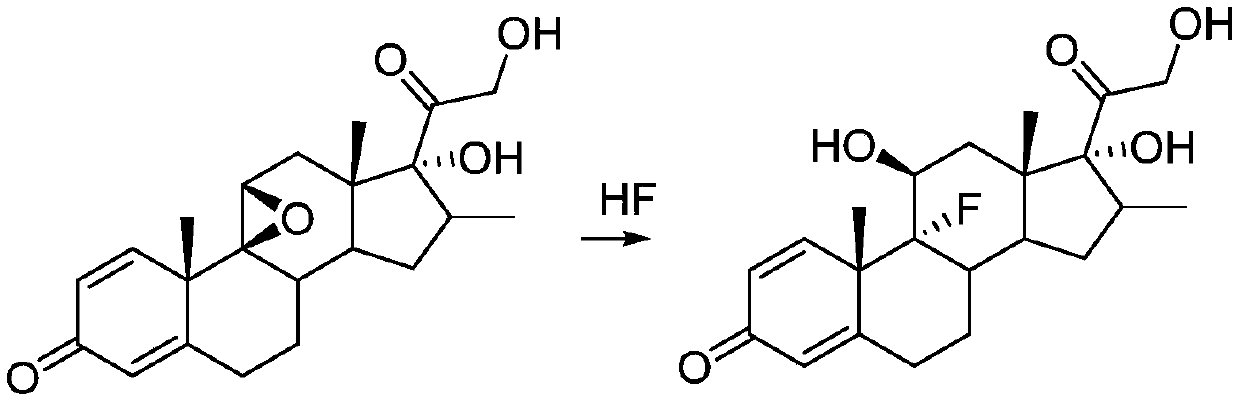

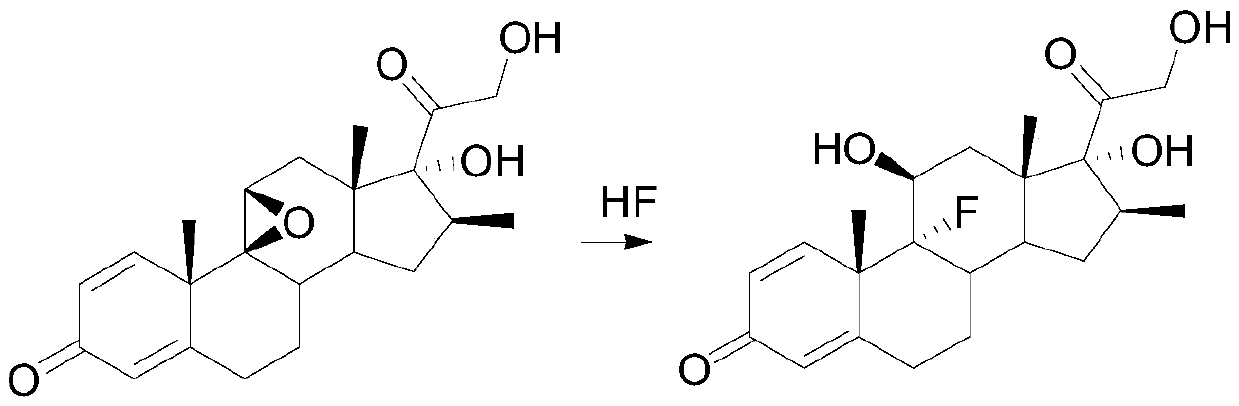

Image

Examples

Embodiment 1

[0054]

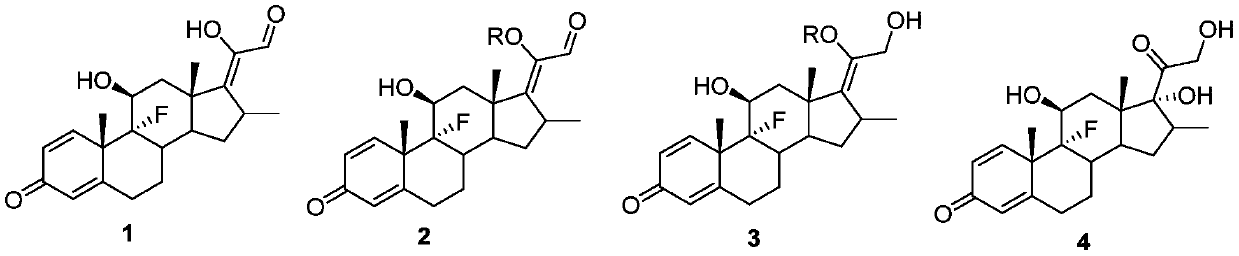

[0055] Collect 2000mL of the masterbatch solution of betamethasone produced in the above fluorine synthesis step, concentrate under reduced pressure until there is no fraction, add dichloromethane and heat to reflux, add 100g of silica gel and stir for 1h, filter, collect the filtrate, concentrate to a small volume, Add 200 mL of ethyl acetate to replace, concentrate to a paste, cool to room temperature, and filter to obtain a brown solid, which is dried to obtain 45 g of solid 1a (shown below), with a purity of 71%. After further column chromatography purification, the structure was determined to be 1a structure, MS-ESI (m / z): 375.2[M+H] + , 1 HNMR (400MHz, DMSO d6 ):δ9.62(s,1H),7.71(s,1H),7.29(d,J=10.4,1H),6.20-6.23(m,1H),6.01(s,1H),5.40-5.42(m ,1H),4.07-4.10(m,1H),3.34-3.32(m,2H),2.32-2.66(m,4H),1.86-2.00(m,2H),1.19-1.52(m,12H)

[0056] 1) Protective reaction:

[0057]

[0058] In a three-neck flask, add 30g of the above solid 1a, 150mL of dichloromethane, ...

Embodiment 2

[0065]

[0066] Collect 2000 mL of the dexamethasone masterbatch solution after the above fluorine synthesis step, concentrate under reduced pressure until there is no fraction, add ethyl acetate and heat to reflux, add 100 g of silica gel and stir for 1 hour, filter, collect the filtrate, concentrate to a small volume, Cool down to room temperature for crystallization, filter to obtain a yellow solid, and dry to obtain 33 g of solid 1b with a purity of 76%.

[0067] 1) Protective reaction:

[0068]

[0069] In the three-necked flask, add 30g of solid 1b, 100mL of DMF, 10g of potassium carbonate and 30mL of dimethyl carbonate, the reaction temperature is raised to 80-85°C for 2-3h, the dimethyl carbonate and part of the DMF are concentrated under reduced pressure, and then the system is poured into into 300mL of ice water, stirred evenly, and filtered to obtain the wet product of compound 2b-2, which was directly used in the next reaction.

[0070] 2) Reduction reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com