Patents

Literature

50results about How to "Moderate growth rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Safe feed for truogx sinensis

ActiveCN103478457AHigh medicinal valueModerate growth rateAnimal feeding stuffMultivitaminGrowth hormone

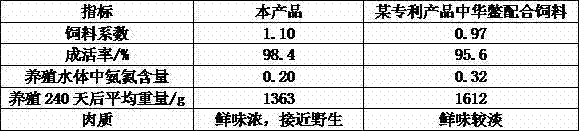

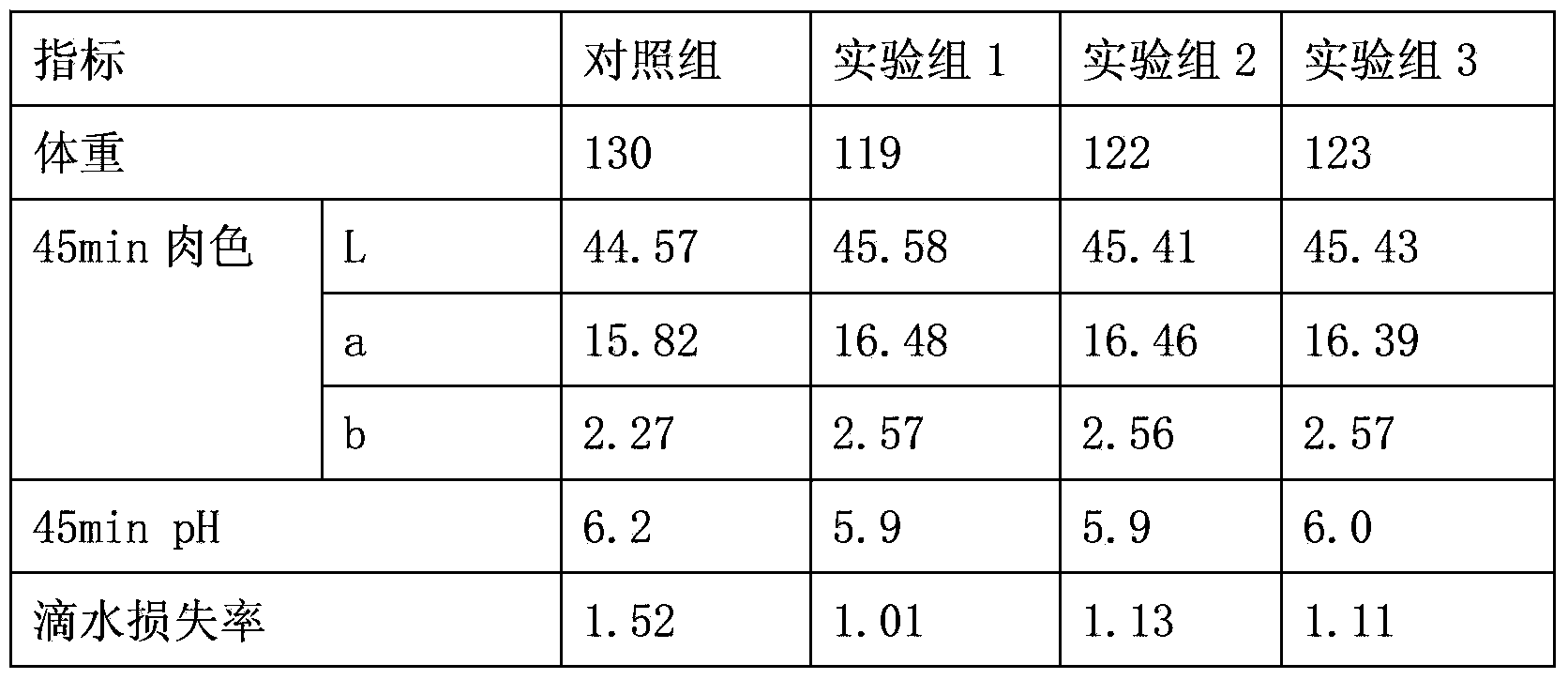

The invention discloses a feed, and in particular relates to a feed for feeding truogx sinensis. The feed comprises the following raw materials in parts by weight: 50-60 parts of starch, 5-10 parts of fish powder, 10-15 of bean pulp, 5-10 parts of tenebrio moliter, 5-10 parts of earthworm, 1-5 parts of purslane, 0.3-0.5 part of red-knees herb, 0.4-0.6 part of eclipta alba, and 0.2-0.3 part of multivitamins. The safe feed for truogx sinensis does not contain artificially synthesized growth hormones or minerals, so that truogx sinensis grows at a reasonable speed, the meat is close to a wild state, and the medicinal value is high.

Owner:贺州市八步区市场监督管理局

Bloat and grainsick preventing and treating feed for beef cattle and production method thereof

The invention discloses a bloat and grainsick preventing and treating feed for beef cattle. The feed comprises following raw materials in parts by weight: 0.3-0.5 part of magnesium sulfate, 0.3-0.5 part of sea salt, 5-10 parts of atractylodes macrocephala koidz, 10-15 parts of pericarpium citri reticulatae, 5-10 parts of pine needles, 10-15 parts of hawthorn leaves, 2-5 parts of lactic acid bacteria, 2-5 parts of bifidobacterium, 2-5 parts of bacillus subtilis and 0.5-1 part of cellulase. The feed can be used for nourishing the stomach and dispelling cold and can effectively prevent and treat bloat and grainsick; the treatment course is short and the effect is rapid; antibiotics are not used; the relapse possibility of bloat and the grainsick is small; the sources of the raw materials are wide, the cost is low and the production process is simple.

Owner:广西武宣金泰丰农业科技发展有限公司

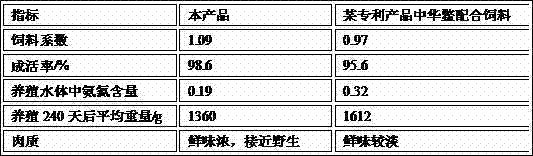

Truogx sinensis composite forage

ActiveCN103493992AHigh medicinal valueModerate growth rateAnimal feeding stuffBiotechnologyGrowth hormone

The invention discloses truogx sinensis composite forage. The truogx sinensis composite forage comprises, by weight, 50-60 parts of starch, 5-10 parts of fish meal, 10-15 parts of soybean meal, 5-10 parts of tenebrio molitor, 5-10 parts of earthworm, 1-6 parts of pine needle powder, 0.3-0.5 parts of red-knees herb, 0.4-0.6 parts of eclipta prostrate and 0.2-0.3 parts of composite vitamins. The truogx sinensis composite forage does not contain synthetic growth hormones and mineral matters. Through use of the truogx sinensis composite forage, truogx sinensis has a reasonable growth speed, meat quality similar to meat quality of wild truogx sinensis and has a high medicinal value.

Owner:贺州市八步区市场监督管理局

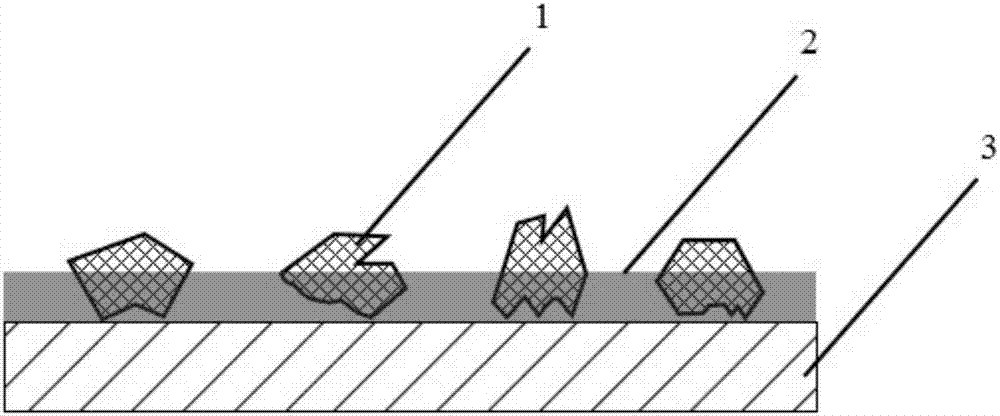

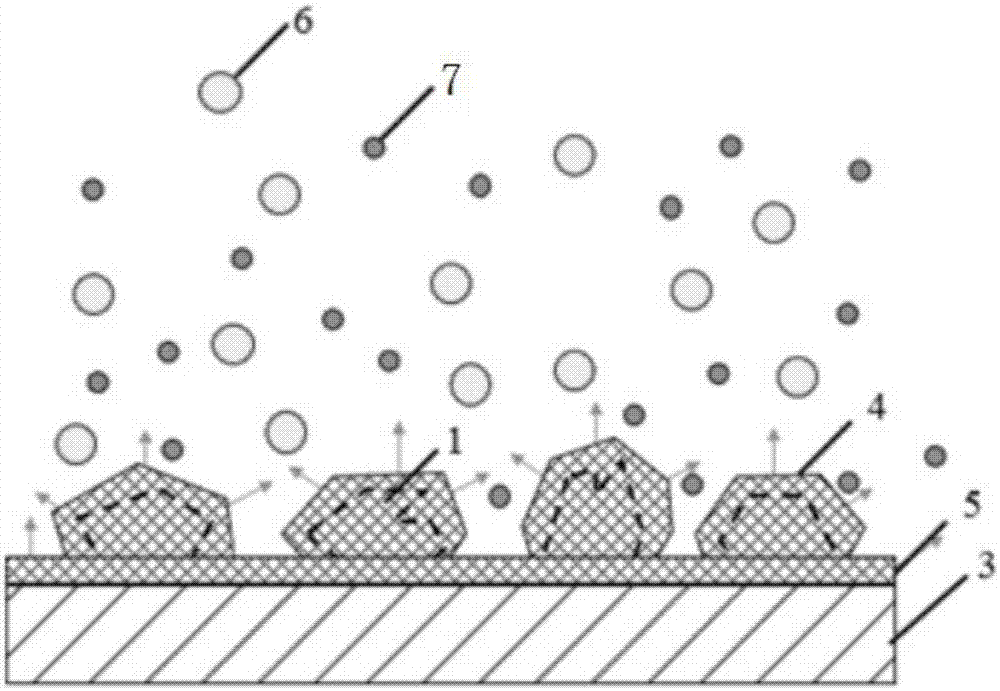

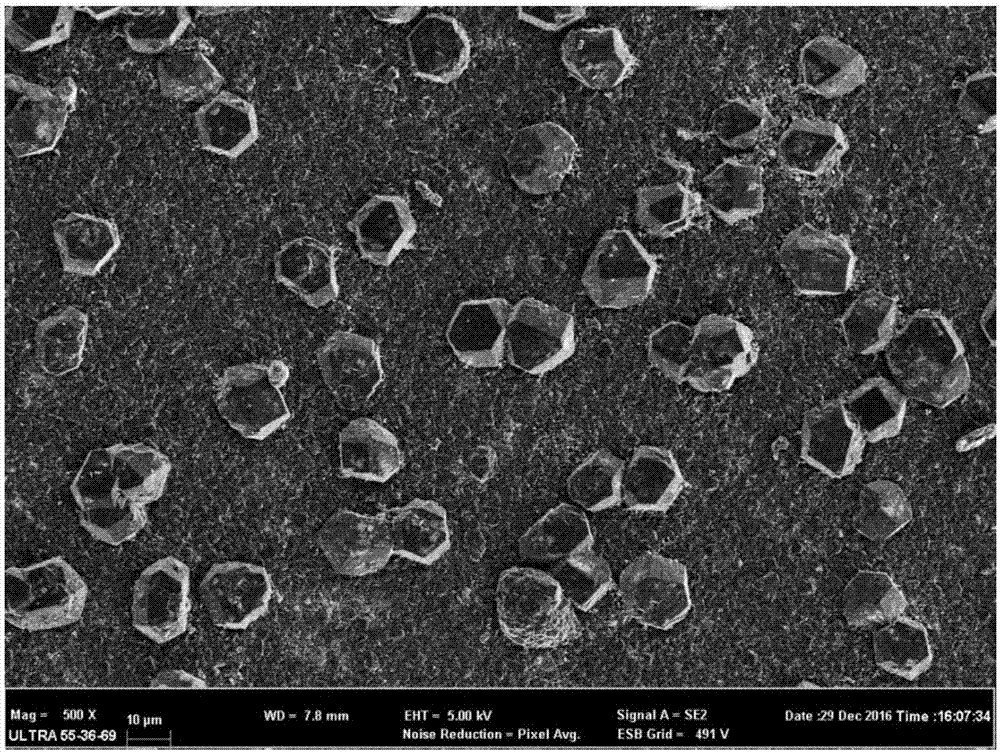

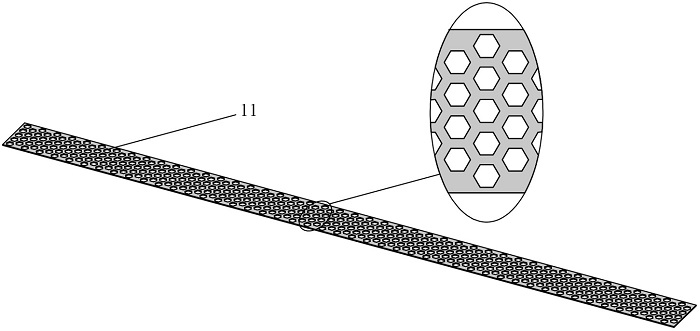

Method for preparing single-layer diamond abrasive tool through chemical vapor deposition

The invention discloses a method for preparing a single-layer diamond abrasive tool through chemical vapor deposition. According to a silicon carbide base body, a diamond abrasive material is mixed into a photoresist solution and is subject to ultrasonic vibration, rotating whirl coating is used for evenly dispersing diamond abrasive particles, uniform distribution of the particles on a base body substrate can be achieved, the CVD method is adopted to enable the diamond coating bonding agent to be subject to deposition between the diamond abrasive particles and the silicon carbide base body, the abrasive material and the base body are firmly connected together, and meanwhile, the abrasive particles grow to become high-grade cubic octahedral single-crystal particles. The prepared single-layer diamond abrasive tool is high in abrasive particle holding force, the exposure height is large, the chipping containing space is large, defects of electroplating and brazing single-layer diamond abrasive tools are overcome, and the method is suitable for preparing fine granularity (five micrometers to 100 micrometers) single-layer diamond abrasive tools. The prepared single-layer diamond abrasive tool has the wide application prospect in high-precise grinding fields of crisp and hard materials of semiconductors, optical crystals, artificial sapphire, glass and the like

Owner:SHANGHAI JIAO TONG UNIV +1

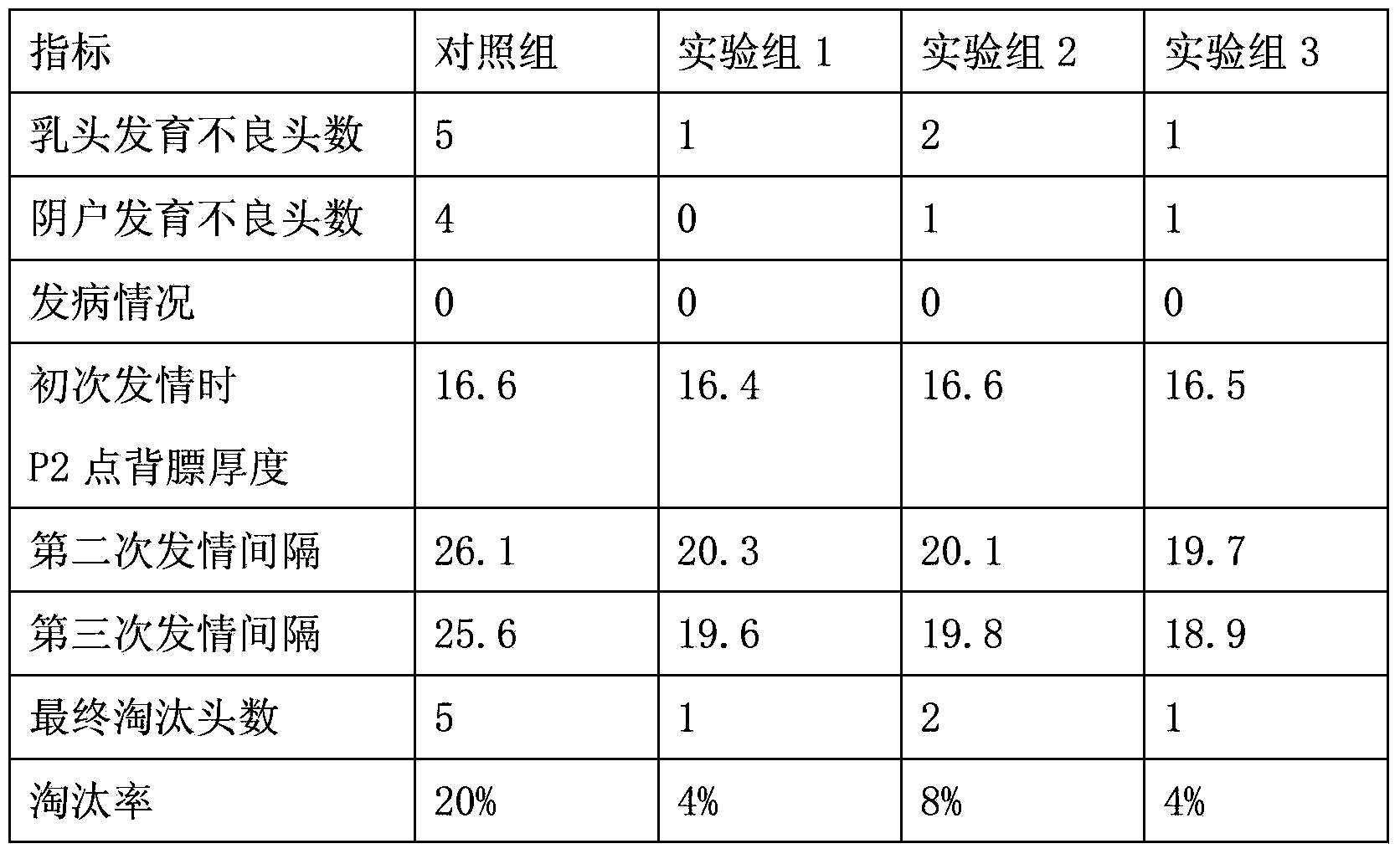

Feed for reserved sows, and preparation method and application thereof

ActiveCN103355535AImprove reproductive abilityImprove immunityAnimal feeding stuffAnimal scienceCnidium monnieri

The invention discloses a feed for reserved sows. The feed is prepared from the following components: corn, sorghum, bran, rice bran, grass meal, soybean meal, sunflower meal, corn germ meal, shell powder, fish meal, mushroom, decavitamin, a composite multi-mineral, and a core additive. The core additive is prepared from the following components: motherwort herb, herba epimedii, dodder, garlic, wolfiporia extensa, houttuynia cordata, and cnidium monnieri. The feed for the reserved sows can provide basic nutrients for the reserved sows; at the same time, with the addition of the core additives, the feed can guarantee the reserved sows have stronger breeding ability during a breeding period, and also can improve own immunity of the reserved sows; and the feed has the advantages of high security, wide raw material sources and low price.

Owner:勐腊县旭东生猪饲养有限责任公司

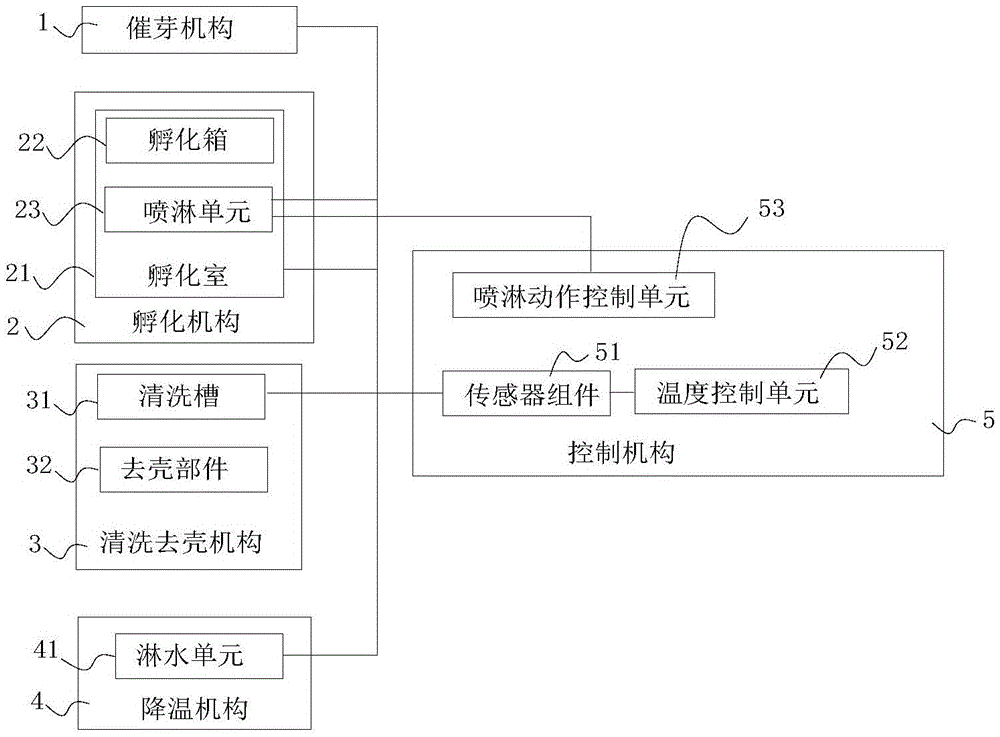

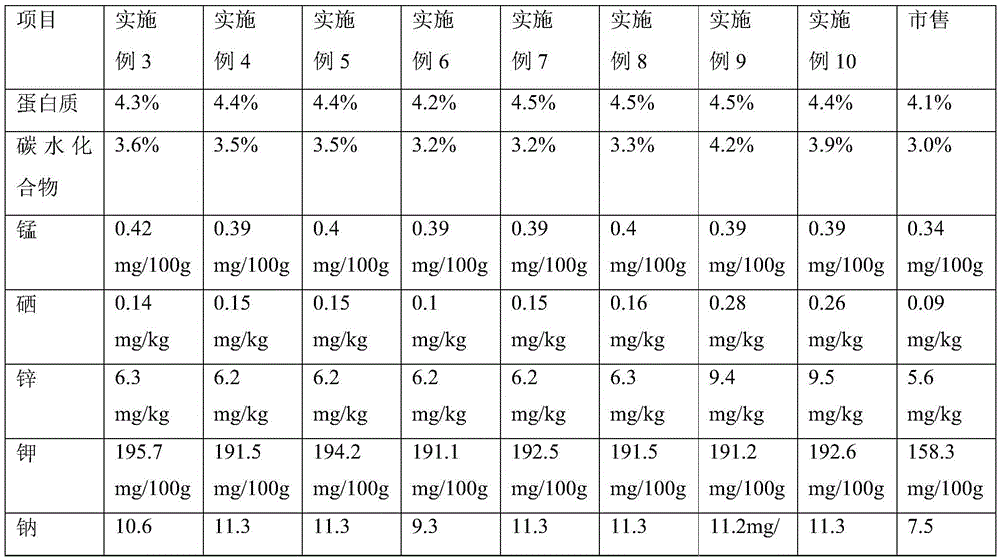

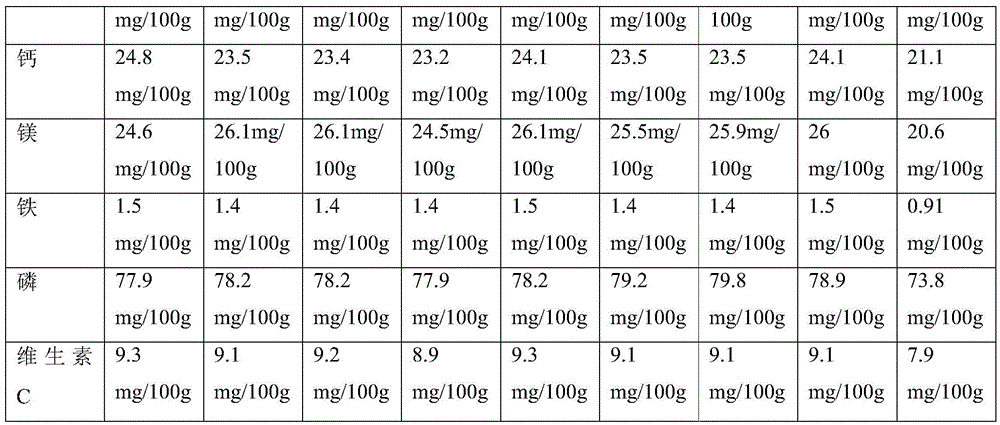

Bean sprout cultivating method and bean sprout cultivating system

ActiveCN105638420AAvoid Nutrient LossHigh nutritional valueAgriculture gas emission reductionCultivating equipmentsSprouted SeedsIncubation temperature

The invention discloses a bean sprout cultivating method and a bean sprout cultivating system. The method comprises the following steps: S1, accelerating germination, i.e. soaking bean sprout seeds in seed soaking liquid for 3 to 8 hours, wherein, a temperature of the seed soaking liquid is 20 DEG C to 28 DEG C; S2, carrying out incubation, i.e. setting the incubation temperature to be 25 DEG C to 28 DEG C, and carrying out water spraying processing on the seeds subjected to germination acceleration at interval of preset time so as to obtain first bean sprout crude products, wherein the preset time is 2 h to 6 h, water spraying time every time is 4 min to 10 min, and the water temperature is 15 DEG C to 23 DEG C; S3, cleaning and shelling, i.e. carrying out cleaning and shelling on the first bean sprout crude products to obtain second bean sprout crude products, wherein cleaning fluid is water of 10 DEG C to 15 DEG C; and S4, cooling, i.e. cooling the second bean sprout crude products by water of 5 DEG C to 10 DEG C to obtain bean sprouts. When the method provided by the invention is adopted, in the process of cultivating the bean sprouts, nutritional ingredients are lost a little, and the content of nutritional ingredients in the products, which are beneficial to human bodies, is high.

Owner:HUBEI YURUYI BUD TECH CO LTD

Forage having effects of preventing and treating parotitis of palea steindachneri

The invention discloses forage having effects of preventing and treating parotitis of palea steindachneri. The forage comprises, by weight, 50-60 parts of starch, 5-10 parts of fish meal, 10-15 parts of isatis root, 5-10 parts of honeysuckle flower, 5-10 parts of andrographis paniculata, 1-5 parts of purslane herb, 0.3-0.5 parts of fruit of xanthium sibiricum and 0.2-0.3 parts of a vitamin B-vitamin C compound having a ratio of 1: 2. A use method of the forage comprises that the forage in a form of paste adheres to mashed fish or animal internal organs, the mixture is putted on a forage table so that palea steindachneri can ingest the mixture by itself, and the forage is applied three times a day and is continuously used for a treatment course comprising 4-7 days. The forage has a parotitis treatment effective rate more than 82% and does not contain synthetic growth hormones and minerals. Palea steindachneri utilizing the forage has a reasonable growth speed, meat quality similar to meat quality of wild palea steindachneri, and a high medicinal value.

Owner:GUIPING PRODIVITY PROMOTION CENT

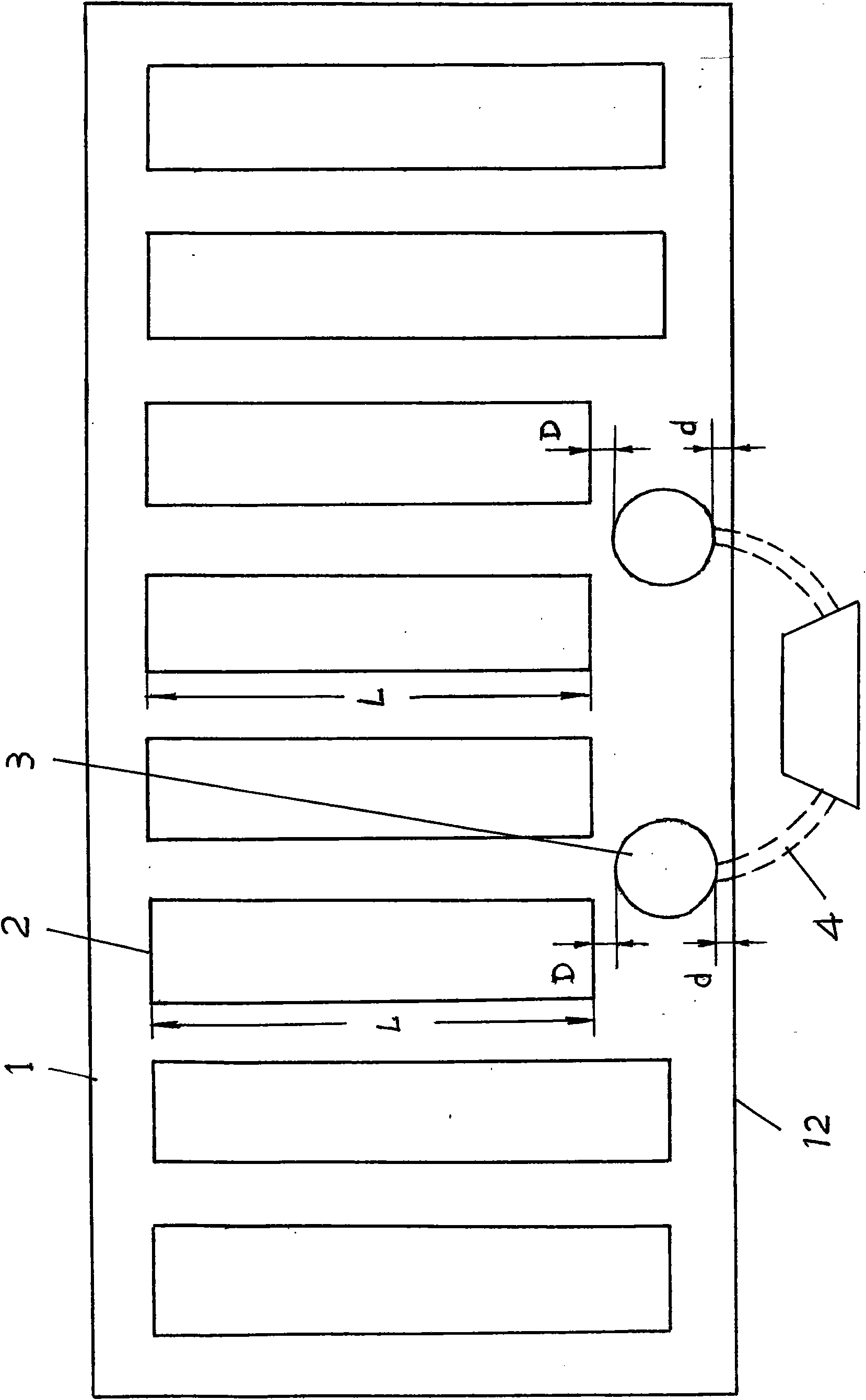

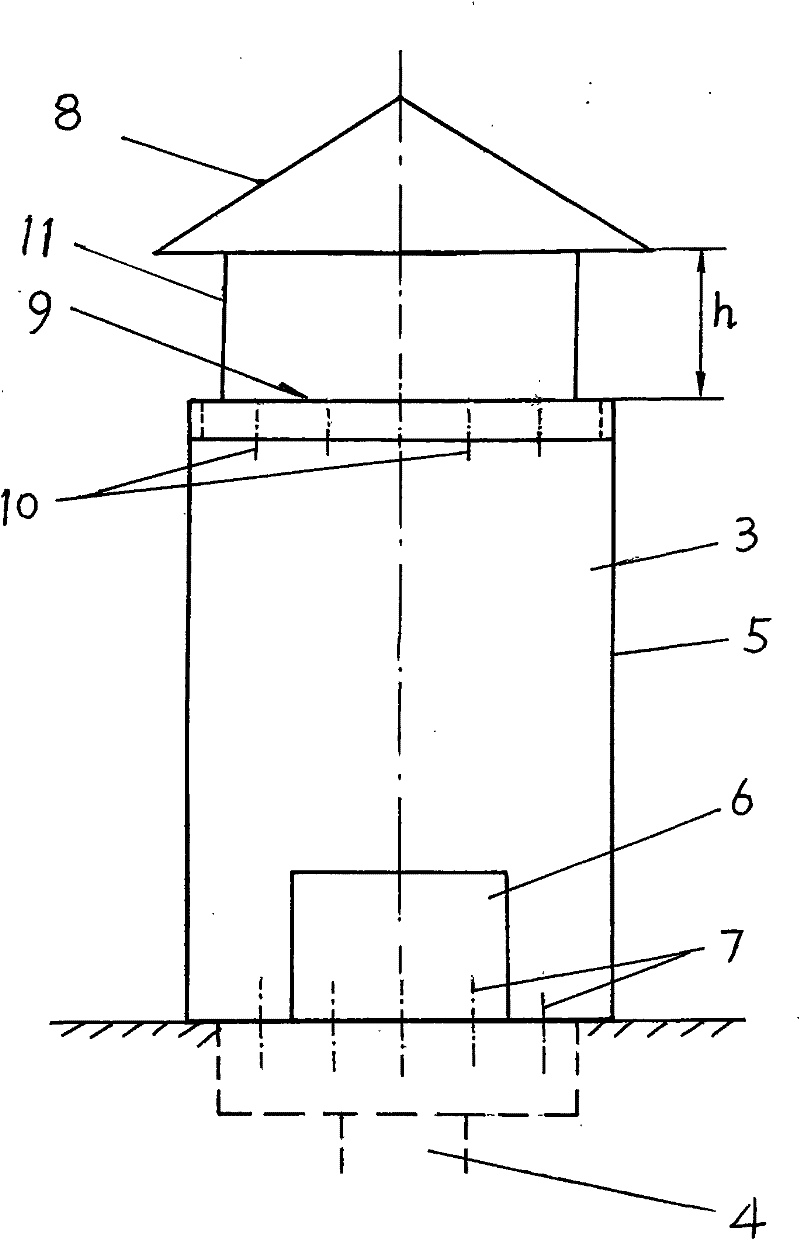

Dry heat type secondary fermentation method for planting agaricus blazei and dry heat type heating device

InactiveCN101933440AIncrease temperatureIncrease concentrationBio-organic fraction processingOrganic fertiliser preparationHeating timeAgaricus blazei

The invention provides a dry heat type secondary fermentation method for planting agaricus blazei and a dry heat type heating device. The dry heat type heating device is characterized in that the dry heat smoke and fire generated by a built-in range directly heat the culture medium in a mushroom house to complete the secondary fermentation method. The method comprises the following steps that: the built mushroom houses face south; in each mushroom house, 2 to 3 heating ranges are built, each range is arranged on the south of the mushroom house and between bed frames of two mushroom beds closer to the middle, and the range is 20 to 50cm away from the ends of the two bed frames; the ranges are heated after the culture medium is put on the mushroom beds in the mushroom house, the hot smoke directly enters the mushroom house for heating, when the temperature rises to be between 56 and 58 DEG C, the temperature is kept for 48 to 52 hours, and when the temperature drops to be between 40 and 45 DEG C, the temperature is kept for 72 to 120 hours; and the dry heat type heating equipment or device is a built-in range with a cylindrical range body, the range opening faces south, and a smoke-dispersing top cover is arranged above the hot smoke-discharging opening of the range body. The dry heat type heating device has the advantages of simple operation, short heating time, energy and labor conservation, small nutrient loss, a small number of ranges, low environmental pollution and the like.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

Truogx sinensis feed for preventing gill rot and dysentery

ActiveCN103478459AHigh medicinal valueModerate growth rateAnimal feeding stuffAnimal scienceGrowth hormone

The invention discloses a feed, and in particular relates to a feed for feeding truogx sinensis. The feed comprises the following raw materials in parts by weight: 50-60 parts of starch, 15-20 parts of bean pulp, 5-10 parts of tenebrio moliter, 0.3-0.5 part of red-knees herb, 1-5 parts of purslane, and 0.2-0.3 part of multivitamins. The truogx sinensis feed does not contain artificially synthesized growth hormones or minerals, so that truogx sinensis grows at a reasonable speed, the meat is close to a wild state, and the medicinal value is high.

Owner:贺州市八步区市场监督管理局

Feed for masked palm civets in maturity period

InactiveCN105325707AImprove immunityGuaranteed tasteFood processingAnimal feeding stuffAnimal scienceAntioxidant

The invention discloses feed for masked palm civets in a maturity period. The feed is prepared from following components: corn, bran, beanstalks, rapeseed meal, tomatoes, distillers' grains, sesame seed cakes, black beans, fish meal, Shiitake, an antioxidant, multi-vitamins, complex multi-minerals and a core additive, wherein the core additive is prepared from following components: greater celandine herbs, malaytea scurfpea fruits, green tea, liquorice, manyprickle acanthopanax, heartleaf houttuynia, Japanese cayratia herbs and danshen roots. Not only can the feed for the masked palm civets in the maturity period provide the masked palm civets in the maturity period with basic nutrient substances, but also by the aid of addition of the core additive, the feed can ensure that the masked palm civets keep meat taste in the maturity period, avoid meat aging of the masked palm civets in the maturity period and improve the immunity of the masked palm civets in the maturity period, is high in safety and low in cost and adopts widely sourced raw materials.

Owner:扬州市宏大饲料有限公司

Healthy feed for truogx sinensis

ActiveCN103478458AHigh medicinal valueModerate growth rateAnimal feeding stuffAnimal scienceGrowth hormone

The invention discloses a feed, and in particular relates to a feed for feeding truogx sinensis. The feed comprises the following raw materials in parts by weight: 50-60 parts of starch, 20-25 parts of bean pulp, 5-10 parts of earthworm, 1-5 parts of purslane, 0.4-0.6 part of eclipta alba, and 0.2-0.3 part of multivitamins. The truogx sinensis feed does not contain artificially synthesized growth hormones or minerals, so that truogx sinensis grows at a reasonable speed, the meat is close to a wild state, and the medicinal value is high.

Owner:贺州市八步区市场监督管理局

Feed for mature commercial pigs, and preparation method and application thereof

ActiveCN103355537AImprove immunityGuaranteed tasteFood processingAnimal feeding stuffAnimal scienceRHODIOLA ROSEA ROOT

The invention discloses a feed for mature commercial pigs. The feed is prepared from the following components: corn, bran, broken rice, rapeseed meal, cottonseed meal, vinasse, casing powder, silkworm chrysalis powder, fish meal, mushroom, an antioxidant, decavitamin, a composite multi-mineral, and a core additive. The core additive is prepared from the following components: aloe, nutmeg, astragalus root, eucommia ulmoides, acanthopanax senticosus, dodder, panax notoginseng, and rhodiola rosea. The feed for the mature commercial pigs can provide basic nutrients for the mature commercial pigs; at the same time, with the addition of the core additive, the feed can ensure the commercial pigs to keep meat taste in a mature period, can avoid aging of mature pork, can also increase own immunity of the mature commercial pigs, and has the advantages of high security, wide raw material sources and low price.

Owner:贵州省独山县川旺饲料有限公司

Method for intercropping cultivation of acanthopanax sessiliflorus and ganoderma tsugae

ActiveCN105613030AImprove land utilizationEfficient use ofCultivating equipmentsMushroom cultivationAdditive ingredientGanoderma tsugae

The invention provides a method for intercropping cultivation of acanthopanax sessiliflorus and ganoderma tsugae. The method comprises the following steps: cultivating acanthopanax sessiliflorus seedlings to form a plurality of planting rows; and when the height of the acanthopanax sessiliflorus reaches 0.8m-1.0m, cultivating ganoderma tsugae hyphal fragments among the plurality of planting rows. The method adopts the process for intercropping cultivation of the acanthopanax sessiliflorus and the ganoderma tsugae, and the utilization rate of lands is improved, so that previous lands which are only used for cultivating the acanthopanax sessiliflorus are used for cultivating the acanthopanax sessiliflorus and the ganoderma tsugae at the same time, and the utilization rate of the lands is improved by one time. With the adoption of the method provided by the invention, the space utilization efficiency also can be effectively improved; and the acanthopanax sessiliflorus mainly grows in middle and upper spaces, and the ganoderma tsugae grows in a lower space, so that the acanthopanax sessiliflorus and the ganoderma tsugae are not influenced by each other in space, the cultivation space is utilized very well, and the same space has more output. The ganoderma tsugae cultivated by the method has a proper growth speed, a moderate size and good quality, and the content of effective nutritional ingredients is high, so that the method is a cultivation mode capable of protecting forest resources and improving the quality of ganoderma.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Gosling compound feed and preparation method thereof

ActiveCN103875991ADon't worry about drug resistanceDon't worry about drug residuesAnimal feeding stuffDiseaseBiotechnology

The invention discloses a gosling compound feed and a preparation method thereof. The gosling compound feed comprises the following raw materials in parts by weight: 10-20 parts of mulberry leaf powder, 15-20 parts of kudzuvine root vine powder, 15-20 parts of corn flour, 10-15 parts of peanut vine powder, 10-15 parts of peanut bran, 3-5 parts of fish meal, 5-10 parts of calcium amino acid and 2-3 parts of swamp mahogany leaf. A method for using the gosling compound feed comprises the following steps: adding the finished feed to proper amount of green grass and uniformly stirring for feeding. The gosling compound feed does not contain antibiotics and artificially synthesized growth hormone and is capable of preventing the gosling from being infected with diseases, guaranteeing growth of the gosling at reasonable speed, improving the resistance and immunity of the gosling and providing a solid foundation for the healthy growth of the gosling; meanwhile, the problem of drug residual is avoided.

Owner:象州县水产畜牧兽医局

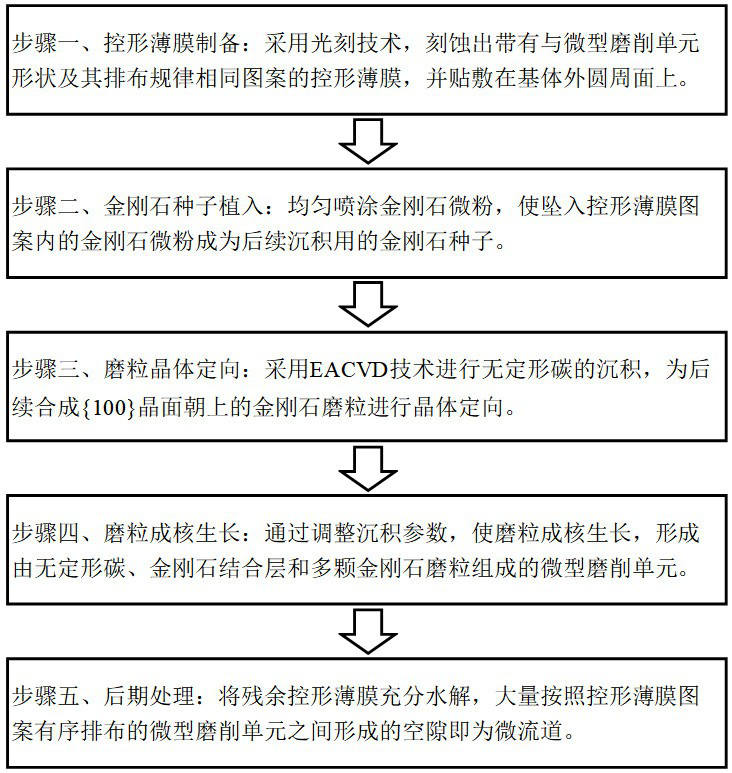

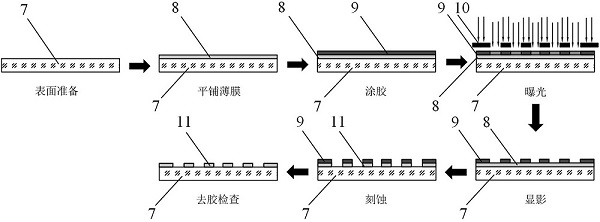

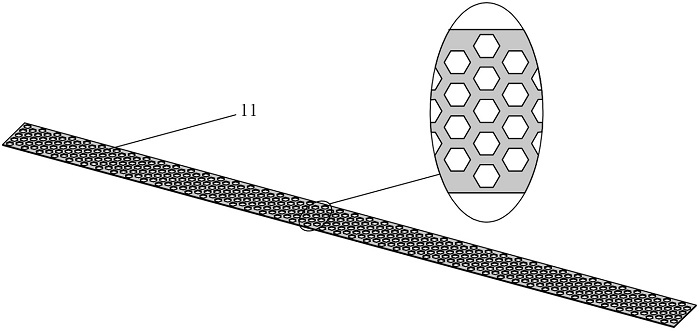

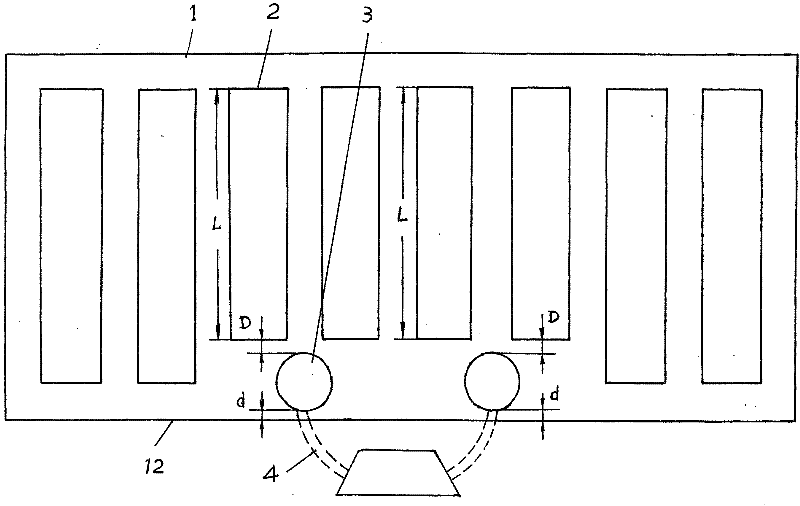

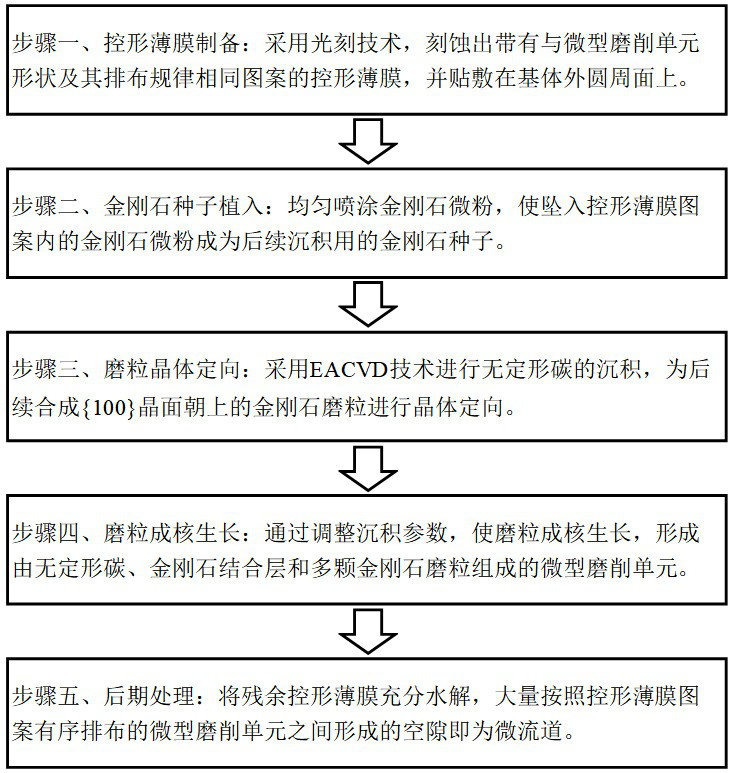

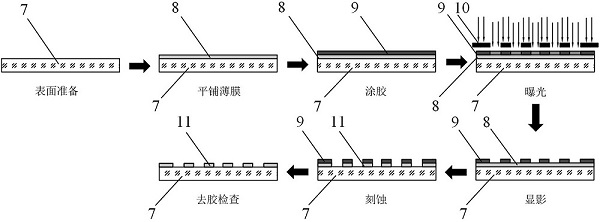

Preparation method of diamond grinding wheel with orderly-arranged crystal orientation abrasives

ActiveCN111941300ALow cost of preparationShort time consumptionGrinding devicesChemical vapor deposition coatingDiamond grindingNucleation growth

The invention discloses a preparation method of a diamond grinding wheel with orderly-arranged crystal orientation abrasives. The preparation method comprises the following steps that a shape controlfilm is prepared by adopting a photoetching technology and adhered to the outer circumferential surface of a substrate, and diamond micro-powder is uniformly sprayed as diamond seeds for subsequent deposition; a layer of amorphous carbon is deposited on the diamond seeds by adopting an EACVD technology, and crystal orientation is performed on subsequently synthesized diamond abrasive particles; deposition parameters are adjusted, nucleation growth is performed on the abrasive particles to form diamond abrasive particles with {100} crystal surfaces as the top surfaces, {111} crystal surfaces asthe side surfaces and larger exposure heights, a micro grinding unit is formed by the diamond abrasive particles, the amorphous carbon and a diamond bonding layer, and a plurality of micro grinding units are orderly arranged according to a photoetching pattern of the shape control film; and the shape control film is removed through ultrasonic cleaning, gaps between a large number of micro grinding units are micro flow channels, and a grinding wheel finished product is obtained through drying. According to the preparation method, crystal orientation can be performed on the diamond abrasive particles, the abrasives can be arranged orderly, and the grinding performance of the grinding wheel is remarkably improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

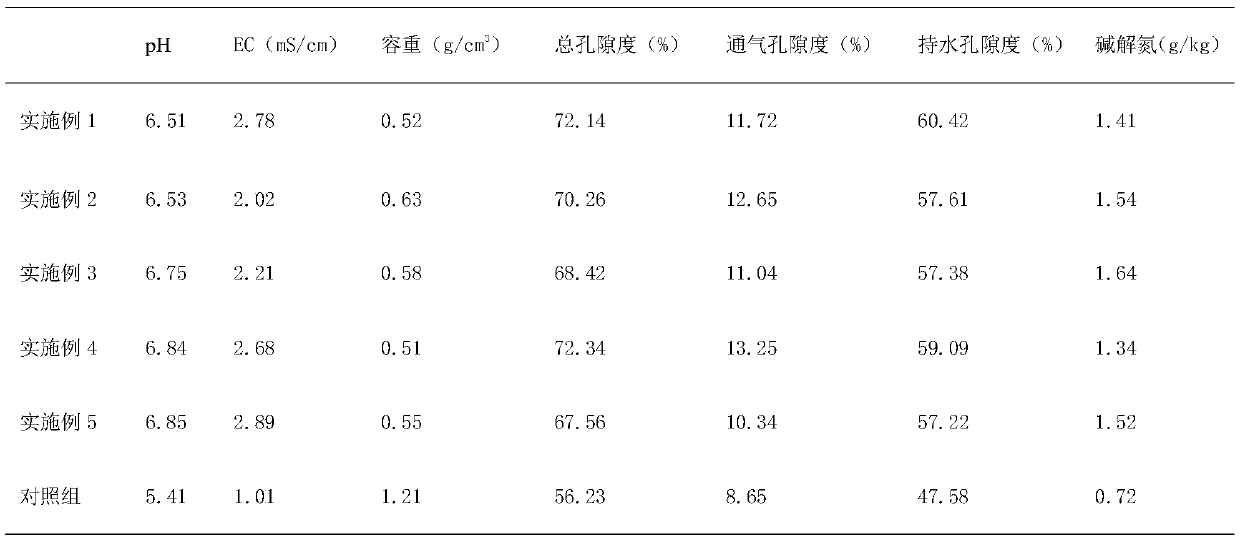

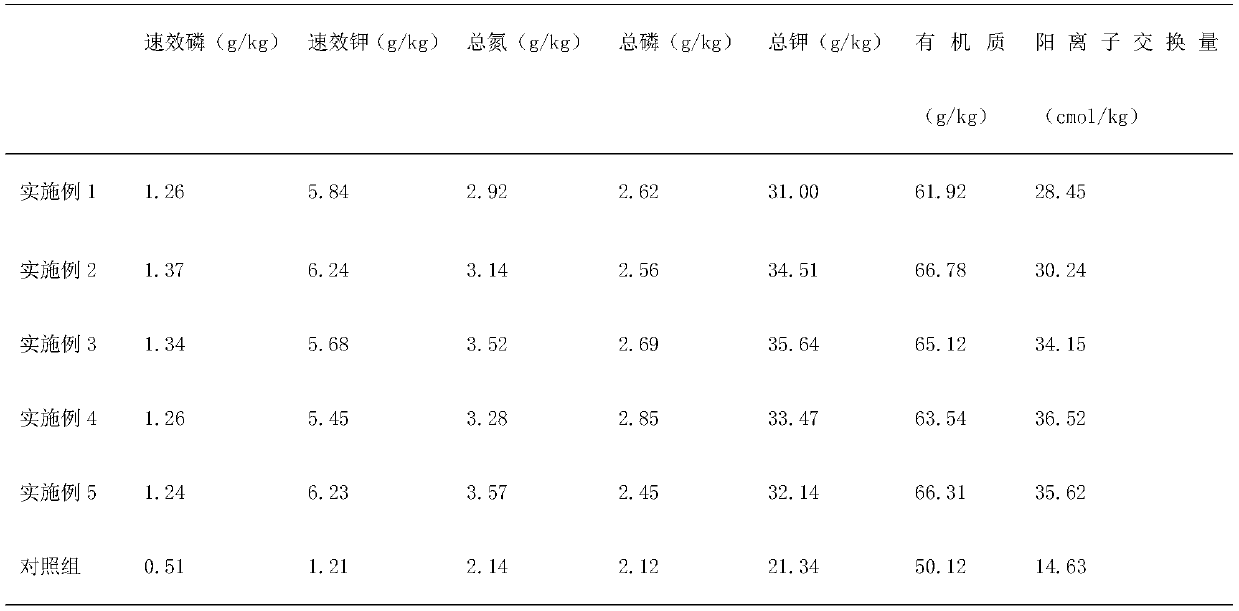

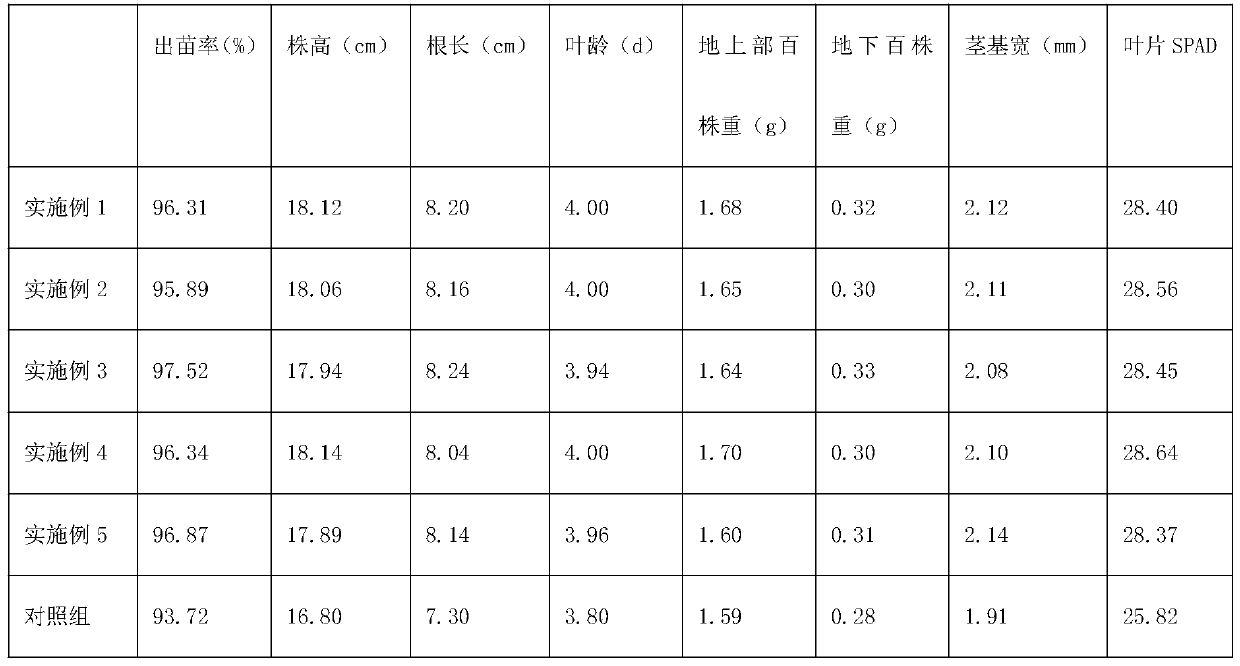

Rice seedling raising substrate and preparation method thereof

PendingCN111587764AImprove physical and chemical parametersModerate growth rateGrowth substratesCulture mediaBiomassAgricultural crops

The present invention discloses a rice seedling raising substrate and a preparation method thereof. The rice seedling raising substrate comprises the following raw materials in parts by weight: 50-80parts of fermented straw, 5-10 parts of rice field soil, 10-20 parts of a filler, 8-15 parts of biomass organic raw material powder, 0.01-0.03 part of a rooting agent, 10-15 parts of a binder, 0.03-0.05 part of an anti-mold agent, 0.05-0.1 part of a flocculant, 0.5-1.0 part of a water retaining agent and 0.5-1.0 part of an acid-base regulator. Crop straw is fully fermented, reuse and sustainable development are realized, and at the same time the rice seedling raising substrate significantly improves growth indexes of seedlings and promotes increase of output.

Owner:CHINA NAT RICE RES INST

Compound feed for controlling goose hepatitis and preparation method thereof

ActiveCN103947870ADon't worry about drug resistanceDon't worry about residueFood processingDigestive systemAnimal scienceHouttuynia

The invention discloses a compound feed for controlling goose hepatitis and a preparation method thereof. The compound feed comprises the following raw materials by weight: 10-20 parts of folium isatidis; 10-20 parts of mulberry leaf powder; 15-20 parts of kudzu root vine powder; 8-15 parts of corn flour; 5-10 parts of peanut vine powder; 3-5 parts of peanut bran; 15-20 parts of bagasse pith; 2-5 parts of calcium amino acid; 2-3 parts of cordate houttuynia; and 2-3 parts of swamp mahogany leaves. The using method comprises adding the feed finished product into a proper amount of grass, and uniformly stirring for feeding. The compound feed of the invention contains no antibiotics or artificially synthesized growth hormone, not only prevents geese from getting hepatitis which influences the quality of goose livers, but also provides geese with energy and nutrients such as protein and the like required by the growth process.

Owner:象州县水产畜牧兽医局

Forage for obsolete mother Hu sheep and its preparation method and use

ActiveCN104106736AImprove immunityGuaranteed tasteFood processingAnimal feeding stuffAnimal scienceAntioxidant

The invention discloses forage for an obsolete mother Hu sheep and its preparation method and use. The forage is prepared from corn, wheat bran, soybean straw, rapeseed meal, malt root, vinasse, sesame cake, malt root, fish meal, mushroom, an anti-oxidant, composite vitamins, composite polymineral and a core additive. The core additive is prepared from aloe, lawn pennywort herb, radix astragali, licorice root, semen pharbitidis, fructus quisqualis, flos farfarae and pine needle. The forage can provide basic nutrients for the mother Hu sheep. Through use of the core additive, the forage guarantees a taste of obsolete mother Hu sheep meat, avoids aging of the obsolete mother Hu sheep and improves immunity of the obsolete mother Hu sheep. The forage has high safety, a wide raw material source and a low price.

Owner:北京玉璋农业科技研发有限公司

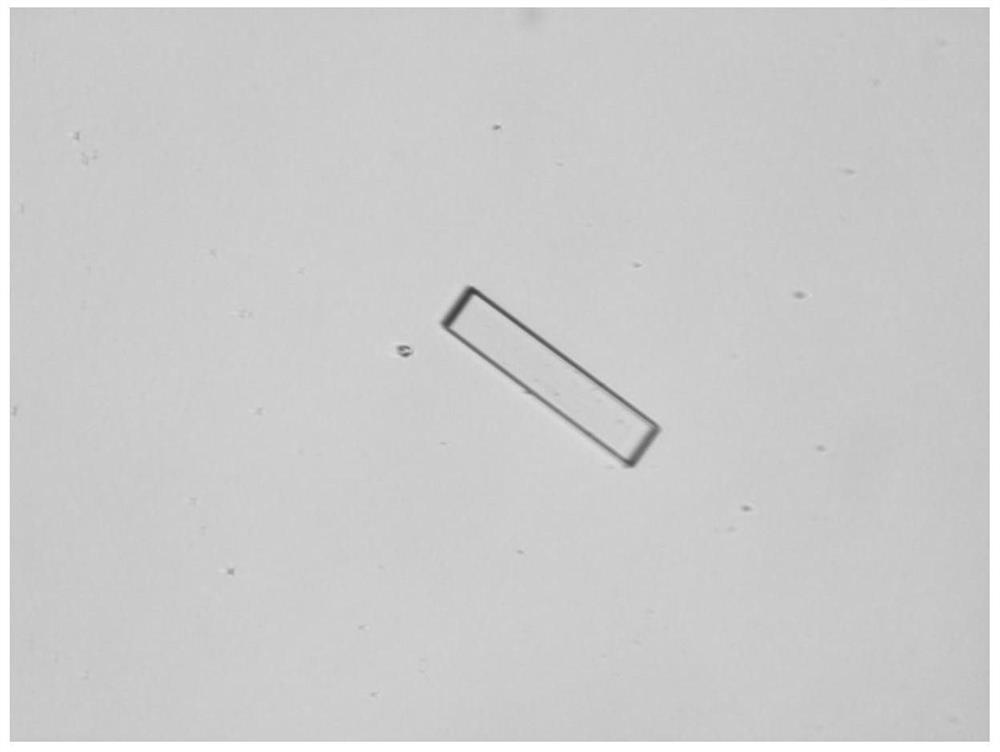

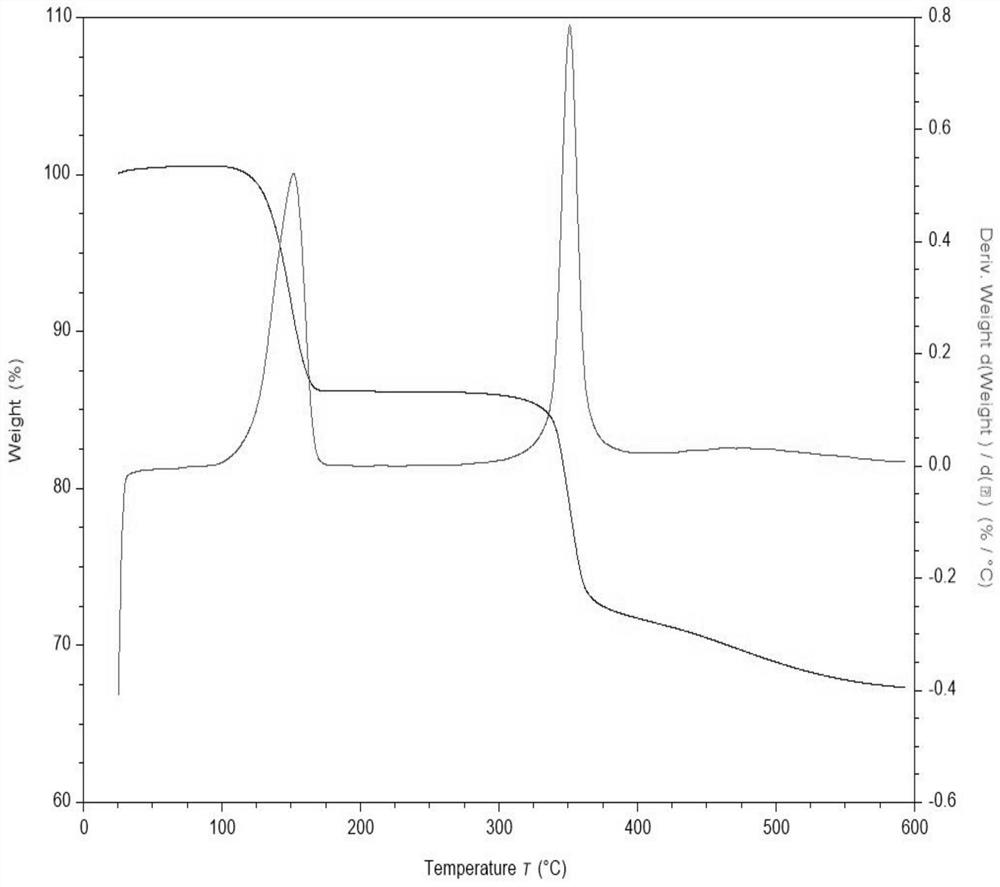

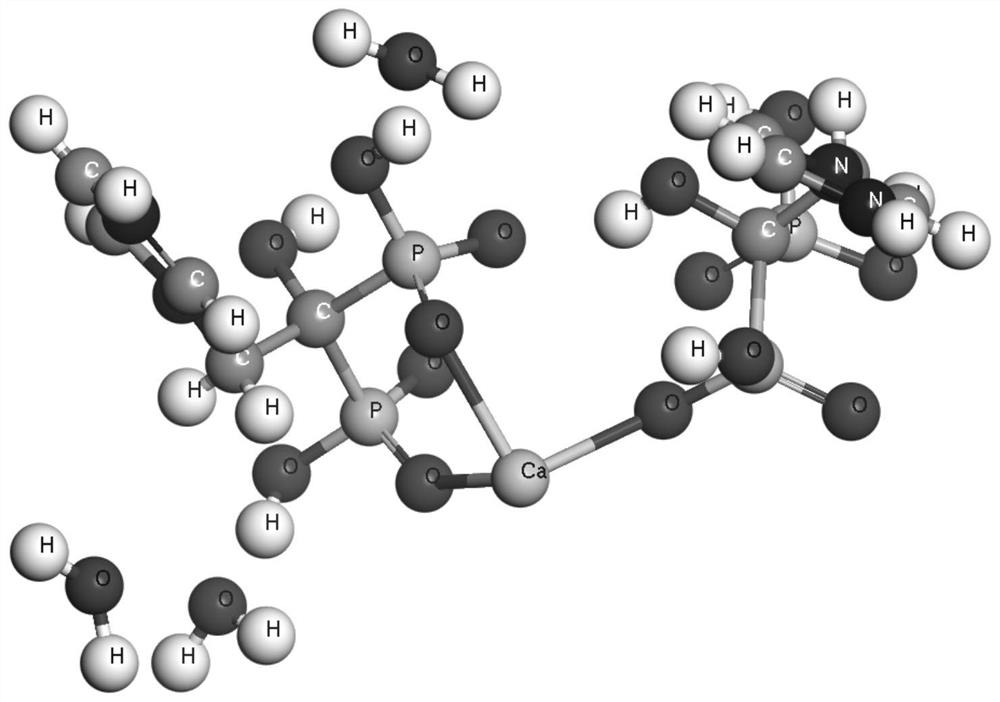

Zoledronic acid calcium complex and preparation method thereof

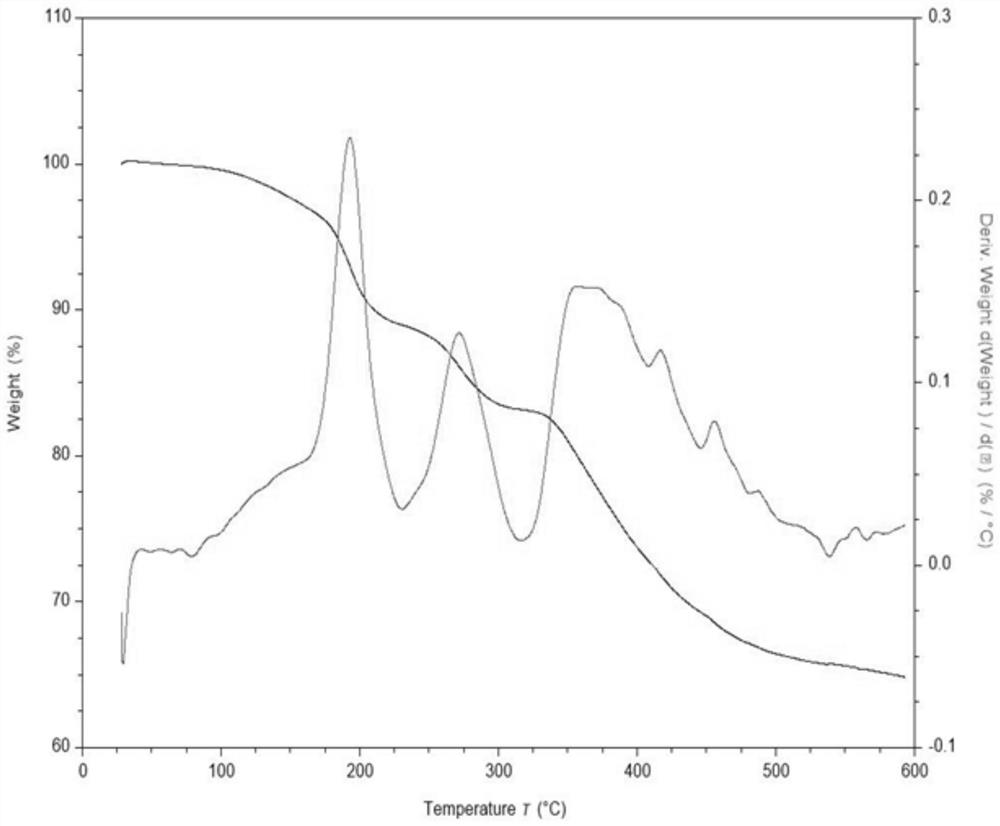

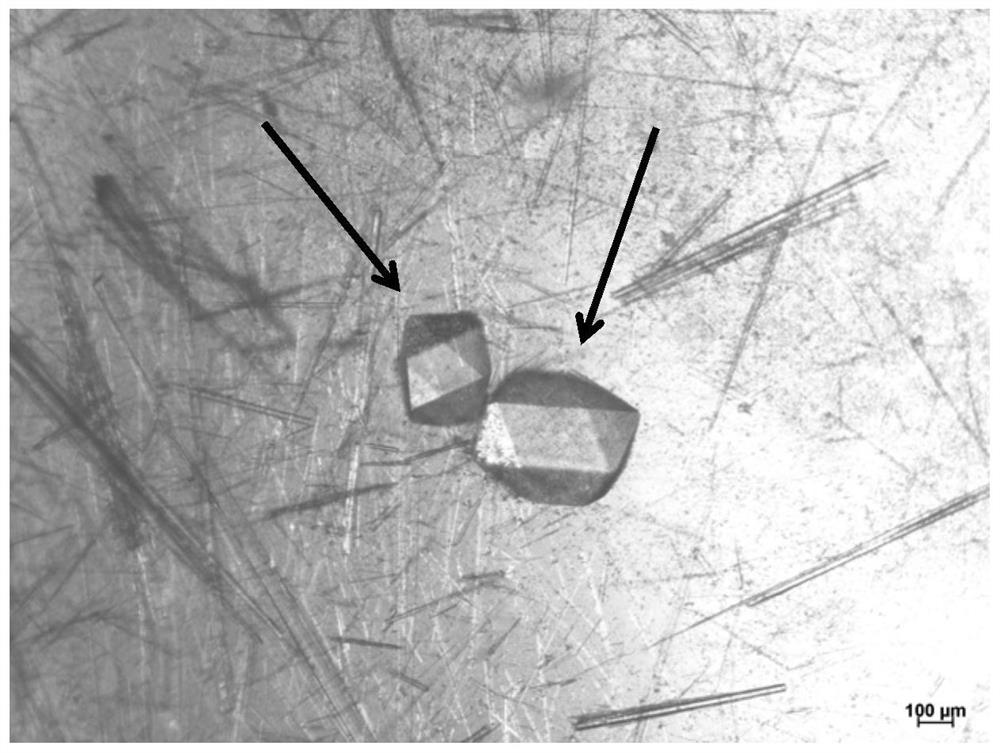

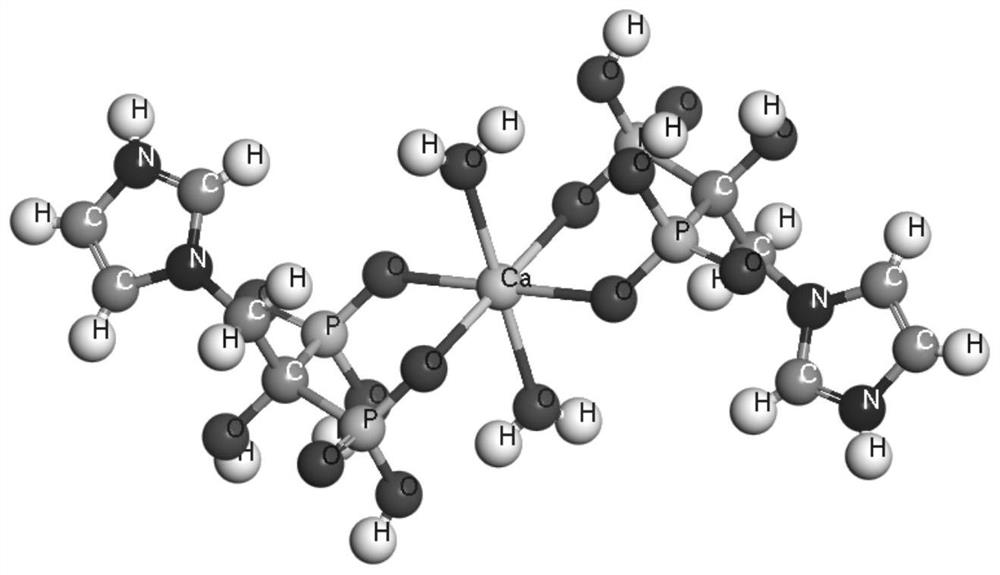

InactiveCN112778365AEasy to prepareModerate crystal growth rateGroup 5/15 element organic compoundsOrganic chemistry methodsMonoclinic crystal systemZoledronic acid

The invention discloses a zoledronic acid calcium complex and a preparation method thereof. The chemical formula of the zoledronic acid calcium complex is Ca(Zol)(H2O).2H2O, wherein Ca represents calcium, Zol represents zoledronic acid, H2O represents water, the crystal system is a monoclinic system, the space group is P21 / N, the lattice constant beta is equal to 95.753 degrees, and z is equal to 4. The preparation method comprises the steps of by taking calcium salt and zoledronic acid as raw materials and deionized water as a solvent, adjusting the pH value to 4-5 by using a sodium hydroxide solution, standing at the temperature of 20-200 DEG C for 3-30 days, filtering, washing and drying to obtain a flat rectangular transparent crystal, namely, the zoledronic acid calcium complex. The preparation method is very simple, the crystal growth speed is moderate, the stress is small, the uniformity is good, the crystal has a very complete appearance, and the crystal has important potential application prospects in the fields of drug slow release, targeted transportation, bone tissue repair and the like.

Owner:SOUTH CHINA UNIV OF TECH

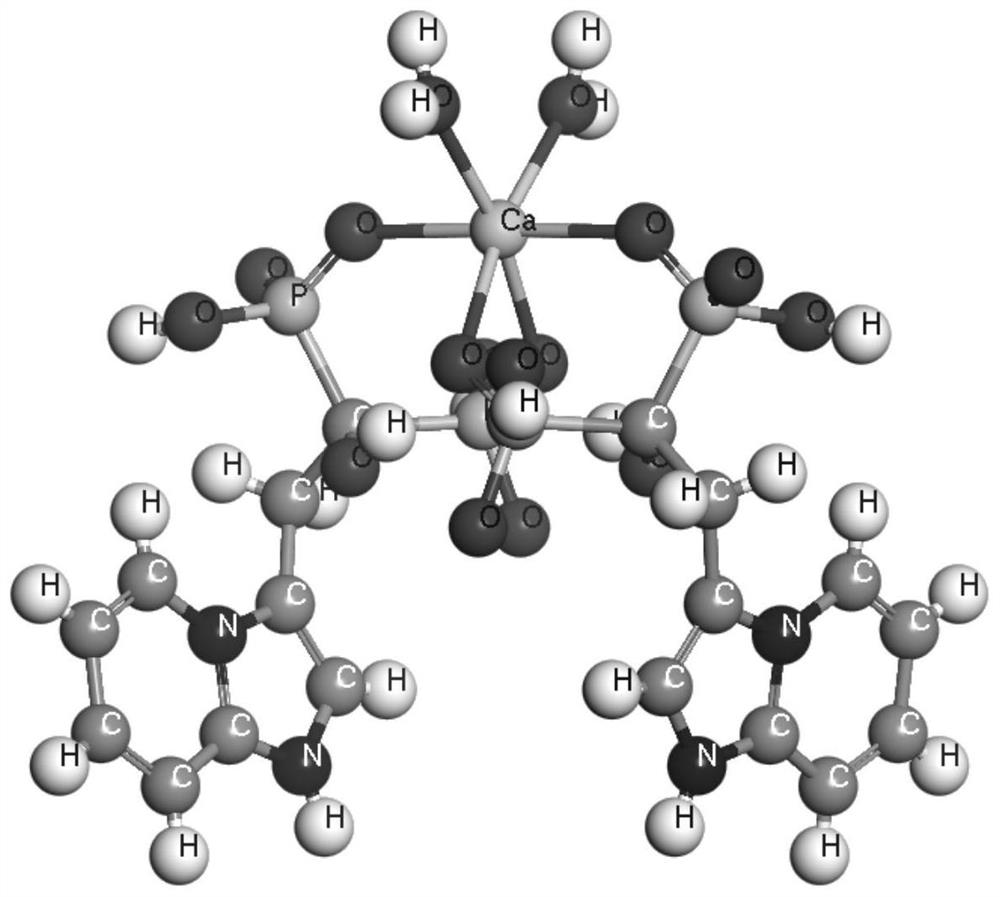

Minodronate calcium complex and preparation method thereof

InactiveCN112724175AEasy to prepareReduce stressGroup 5/15 element organic compoundsOrganic chemistry methodsCrystal systemSolvent

The invention discloses a minodronate calcium complex and a preparation method thereof, the chemical formula of the minodronate calcium complex is Ca (Min) 2 (2H2O), Ca represents calcium, Min represents minodronate, H2O represents water, the crystal system is a monoclinic system, the space group is C2 / C, the lattice constant beta is equal to 106.444 degrees, and z is equal to 4. The preparation method comprises the following steps: by taking calcium salt and minodronic acid as raw materials and deionized water as a solvent, adjusting the pH value to 3-5 by using a sodium hydroxide solution, standing at 20-200 DEG C for 3-24 hours, filtering, washing and drying to obtain a colorless transparent parallelogram crystal, namely the minodronate calcium complex. The preparation method disclosed by the invention is extremely simple, moderate in crystal growth speed, small in stress, good in uniformity and very complete in appearance, and has important potential application prospects in the fields of drug sustained release, targeted delivery, bone tissue repair and the like.

Owner:SOUTH CHINA UNIV OF TECH

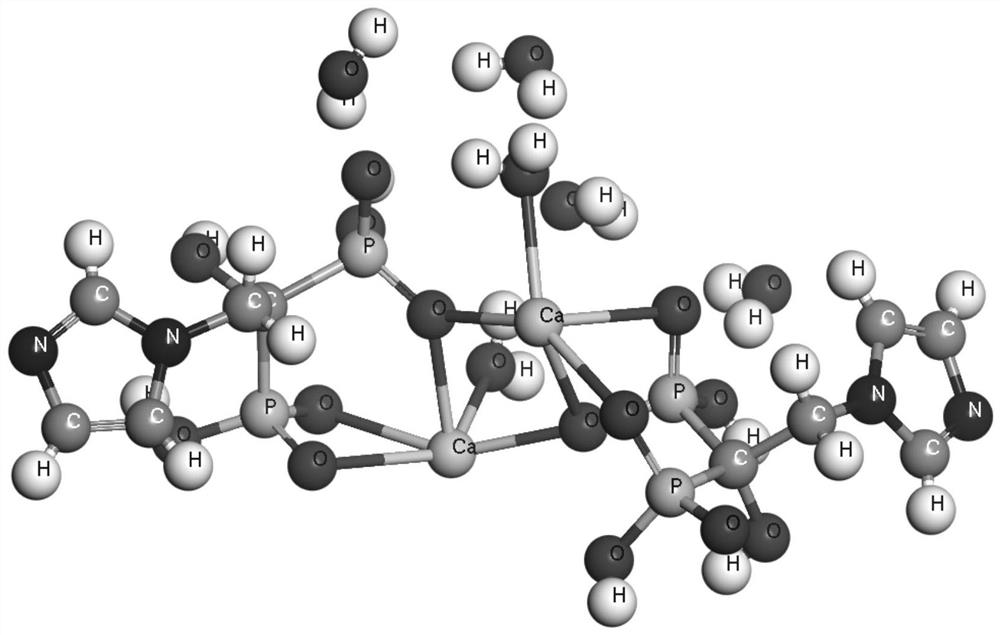

Blocky calcium diphosphonate complex and preparation method thereof

InactiveCN112646193AEasy to prepareReduce stressGroup 5/15 element organic compoundsOrganic chemistry methodsCrystal systemSkeletal tissue

The invention discloses a blocky calcium bisphosphonate complex and a preparation method thereof. The chemical formula is Ca(2Zol)(2H2O), wherein Ca represents calcium, Zol represents 1-hydroxy-2- (imidazole-1-yl)-ethylidene-1, 1-diphosphoric acid, H2O represents water, the crystal system is a triclinic system, the space group is P-1, the lattice constants are alpha=105.648, beta=109.149 degrees, gamma=97.8570 degrees, and z=1. The preparation method comprises the following steps: taking calcium salt and 1-hydroxy-2-(imidazole-1-yl)-ethylidene-1, 1-diphosphoric acid as raw materials and deionized water as a solvent, adjusting the pH value to 2.5-3.5 by using a sodium hydroxide solution, standing at 20-30 DEG C for 20-60 days, and performing filtering, washing and drying to obtain a blocky transparent crystal, namely, the blocky calcium bisphosphonate complex. The preparation method disclosed by the invention is extremely simple, moderate in crystal growth speed, small in stress, good in uniformity and very complete in appearance, and has important potential application prospects in the fields of drug sustained release, targeted delivery, bone tissue repair and the like.

Owner:SOUTH CHINA UNIV OF TECH

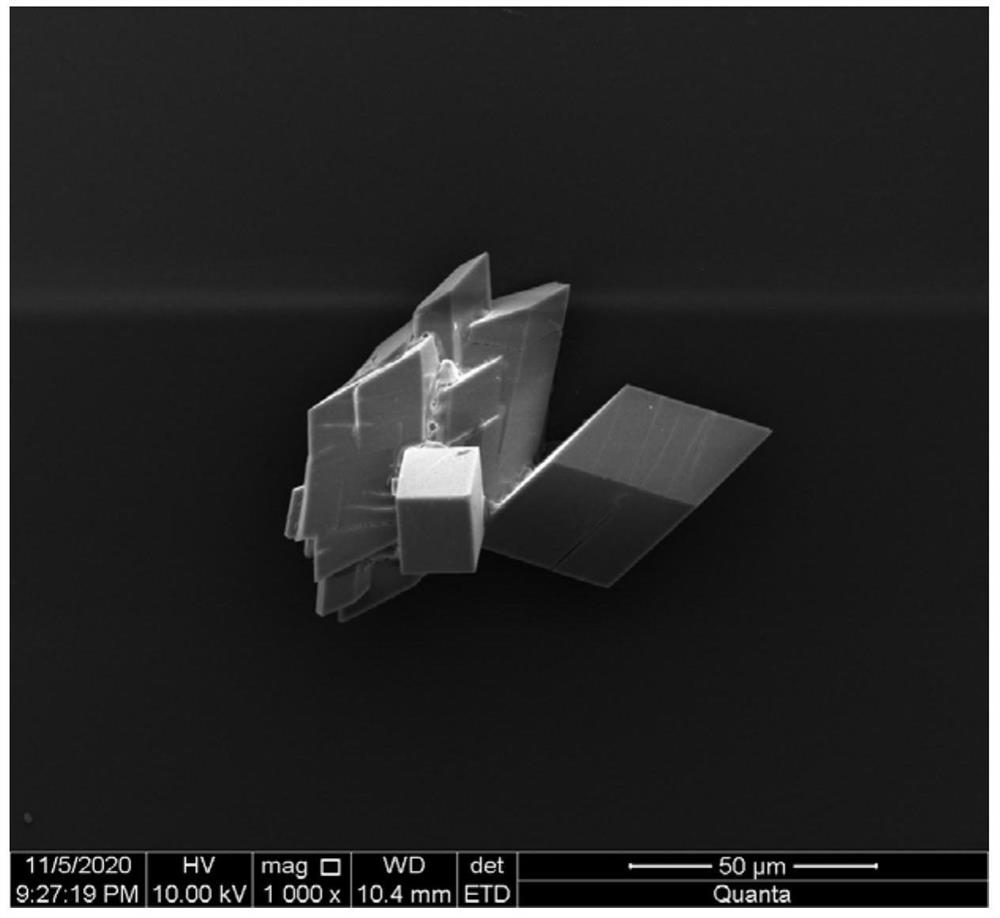

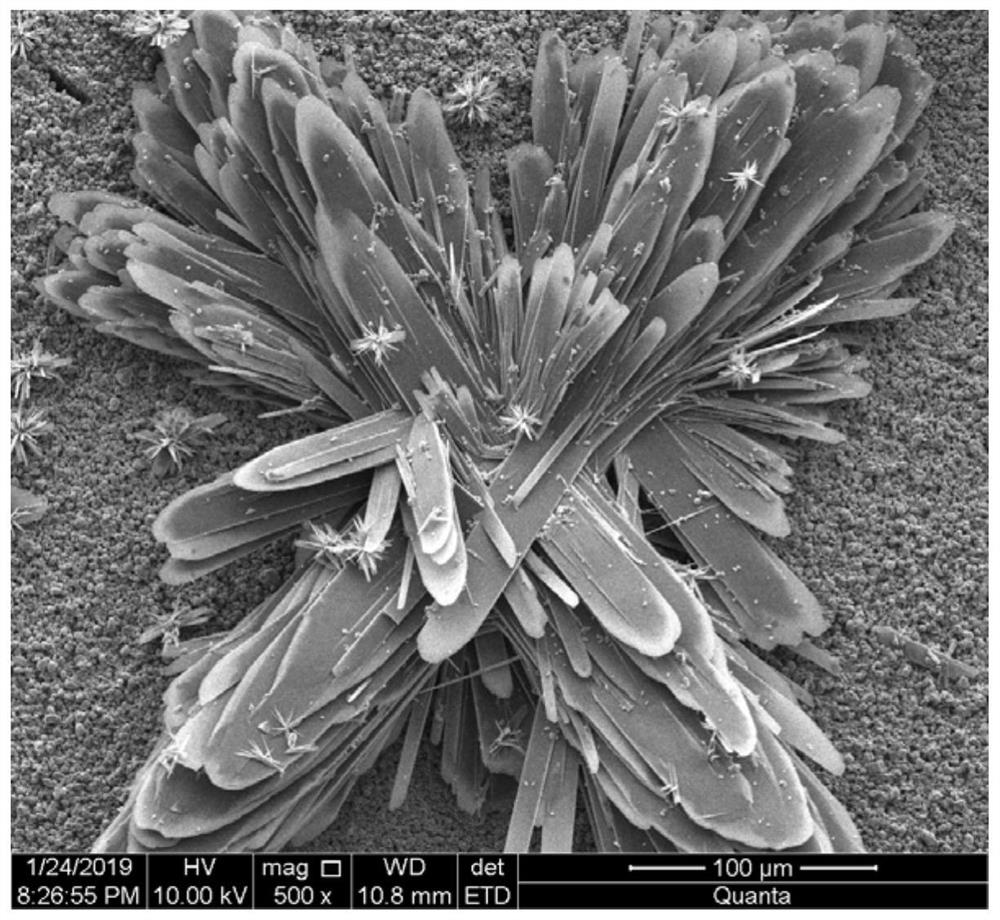

Lamellar calcium diphosphonate complex and preparation method thereof

InactiveCN112724174AEasy to prepareReduce stressGroup 5/15 element organic compoundsOrganic chemistry methodsCrystal systemSolvent

The invention discloses a lamellar calcium bisphosphonate complex and a preparation method thereof, the chemical formula of the lamellar calcium bisphosphonate complex is Ca (Zol) 2.3 H2O, Ca represents calcium, Zol represents 1-hydroxy-2-(imidazole-1-yl)-ethylidene-1, 1-diphosphoric acid, H2O represents water, the crystal system is an orthorhombic crystal system, the space group is PBCA, and the lattice constant is z = 8. The preparation method comprises the following steps: by taking calcium salt and 1-hydroxy-2-(imidazole-1-yl)-ethylidene-1, 1-diphosphoric acid as raw materials and deionized water as a solvent, adjusting the pH value to 1.5-2.5 by using a sodium hydroxide or hydrochloric acid solution, standing at 20-200 DEG C for 24-72 hours, filtering, washing and drying to obtain a flaky transparent crystal, namely the lamellar calcium bisphosphonate complex. The lamellar calcium bisphosphonate complex is extremely simple in preparation method, moderate in crystal growth speed, small in stress, good in uniformity and very complete in appearance, and has important potential application prospects in the fields of drug sustained release, targeted delivery, bone tissue repair and the like.

Owner:SOUTH CHINA UNIV OF TECH

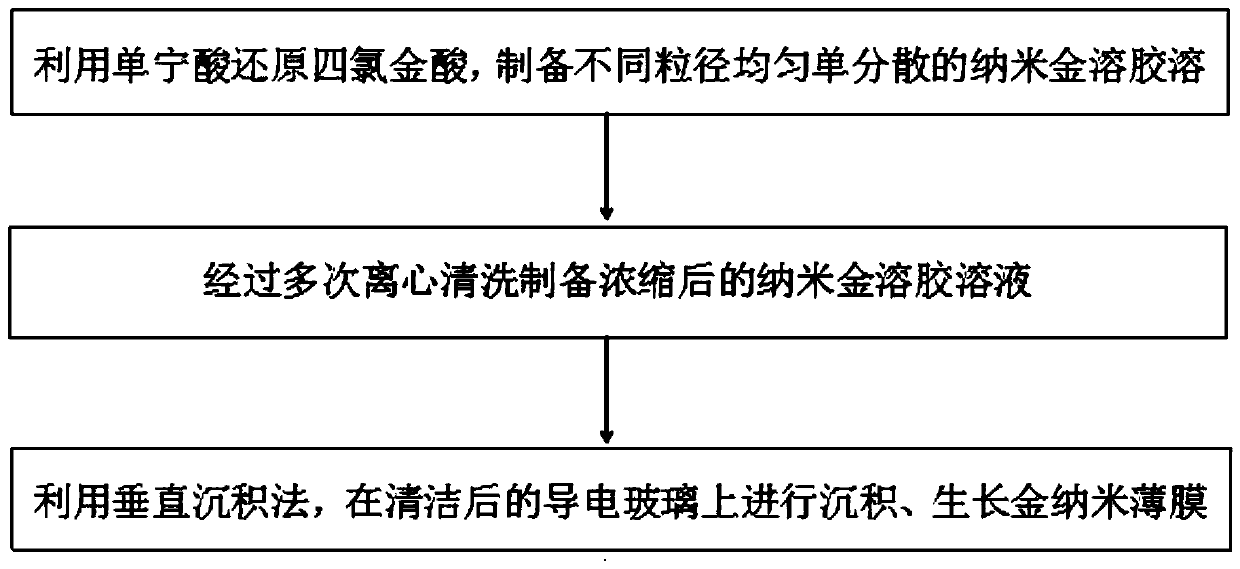

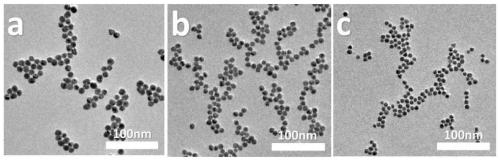

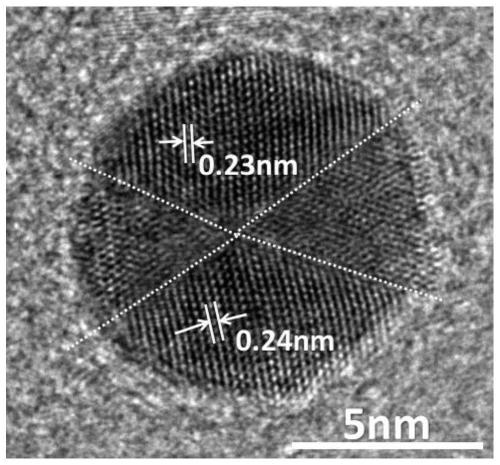

A kind of nano-gold submicron film, its preparation and application

ActiveCN109295443BExhibits resonant coherent propertiesNo horizontal depositionMaterial nanotechnologyLiquid/solution decomposition chemical coatingSurface plasmonPhysical chemistry

The invention belongs to the field of submicron metal particle film functional material devices, and particularly relates to a nanogold submicron film and application thereof. The nanogold submicron film is arranged on a base, the particle size range of the nanogold submicron film is 5-14 nm, and the thickness is 150-550 nm; and the nanogold submicron film forms a resonance absorption band in a near ultraviolet region and shows resonance coherence characteristics of local surface plasmas. The nanogold submicron film can be used as a detecting element of a near ultraviolet resonance instrumentor a near ultraviolet detector.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of feed of paguma larvata at maturity stage

InactiveCN105360653AImprove immunityGuaranteed tasteFood processingAnimal feeding stuffAgricultural scienceFodder

The invention discloses a preparation method of a feed of paguma larvata at a maturity stage. The feed of paguma larvata at the maturity period can provide basic nutrients for the paguma larvata at the maturity stage, at the same time, a core additive is added, so that mouthfeel of meat of the paguma larvata at the maturity stage can be guaranteed, aging of the paguma larvata at the maturity stage can be avoided, immunity of the paguma larvata at the maturity stage is enhanced, and the feed of the paguma larvata at the maturity stage has the advantages of high security, wide raw material source and low cost.

Owner:扬州市宏大饲料有限公司

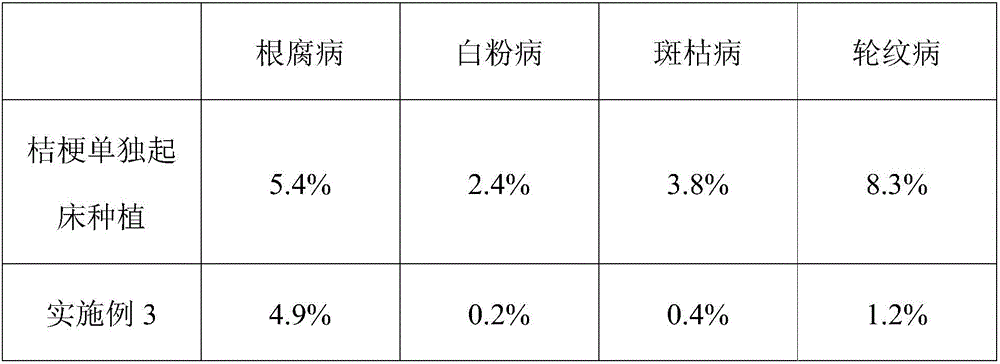

Platycodon grandiflorum and cordyceps militaris integrated cultivation method

ActiveCN106797797ALess field managementPromote growthCultivating equipmentsMushroom cultivationCordycepsCordyceps militaris

The invention relates to the technical field of plant cultivation, in particular to a platycodon grandiflorum and cordyceps militaris integrated cultivation method. According to the method, platycodon grandiflorum is cultivated in a manner of get-out-of-bed cultivation, and then cordyceps militaris is cultivated in a work road between platycodon grandiflorum cultivation beds. The method can increase the land utilization rate and enhance the benefit, and dual harvesting of the two crops can be practically realized.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Artificial cultivation method of Agaricus sp.

InactiveCN108925361AStrong growthSuitable for growthCultivating equipmentsMushroom cultivationMushroomMushroom bodies

The invention relates to an artificial cultivation method of Agaricus sp.. The method comprises the following steps: (1) separating the fruit tissue of Agaricus sp. and inoculating the fruit tissue toa sterile culture medium, and performing cultivation at an ambient temperature of 18-24 DEG C and an air humidity of 70-75% RH under a dark condition, so as to obtain a cultivating fungus bags; (2) performing soil-covering cultivation on the fungus bags, in the period of spawn running, controlling the environmental temperature to be 13-20 DEG C, the soil moisture to be 63-67% and the air humidityto be 68-72% RH, and in the period of fruiting, controlling the ambient temperature to be 13-20 DEG C, the soil moisture to be 63-67% and the air humidity to be 83-87%RH, and continuing to perform cultivation until the mushroom is produced. The cultivation method is simple and convenient to operate, and at the same time, by controlling the temperature, air humidity and soil moisture required fordifferent growth stages of the Agaricus sp., the Agaricus sp. having thick mushroom stems, intact mushroom bodies, white color and good tissue quality is obtained.

Owner:于爱民

Bloat and grainsick preventing and treating feed for beef cattle and production method thereof

ActiveCN103719556BImprove qualityGreat tasteFood processingAnimal feeding stuffBifidobacteriumAntibiotic Y

The invention discloses a bloat and grainsick preventing and treating feed for beef cattle. The feed comprises following raw materials in parts by weight: 0.3-0.5 part of magnesium sulfate, 0.3-0.5 part of sea salt, 5-10 parts of atractylodes macrocephala koidz, 10-15 parts of pericarpium citri reticulatae, 5-10 parts of pine needles, 10-15 parts of hawthorn leaves, 2-5 parts of lactic acid bacteria, 2-5 parts of bifidobacterium, 2-5 parts of bacillus subtilis and 0.5-1 part of cellulase. The feed can be used for nourishing the stomach and dispelling cold and can effectively prevent and treat bloat and grainsick; the treatment course is short and the effect is rapid; antibiotics are not used; the relapse possibility of bloat and the grainsick is small; the sources of the raw materials are wide, the cost is low and the production process is simple.

Owner:广西武宣金泰丰农业科技发展有限公司

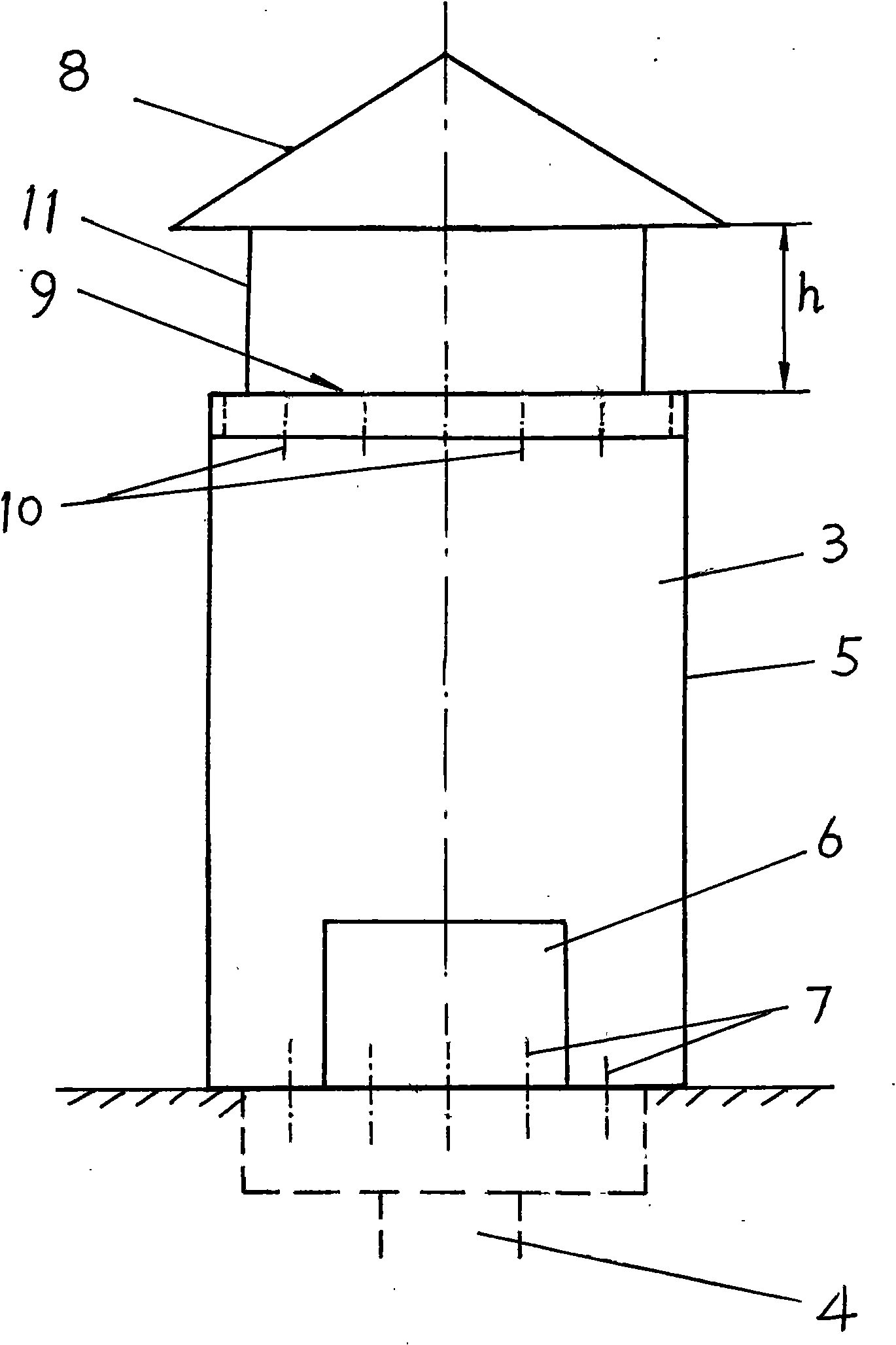

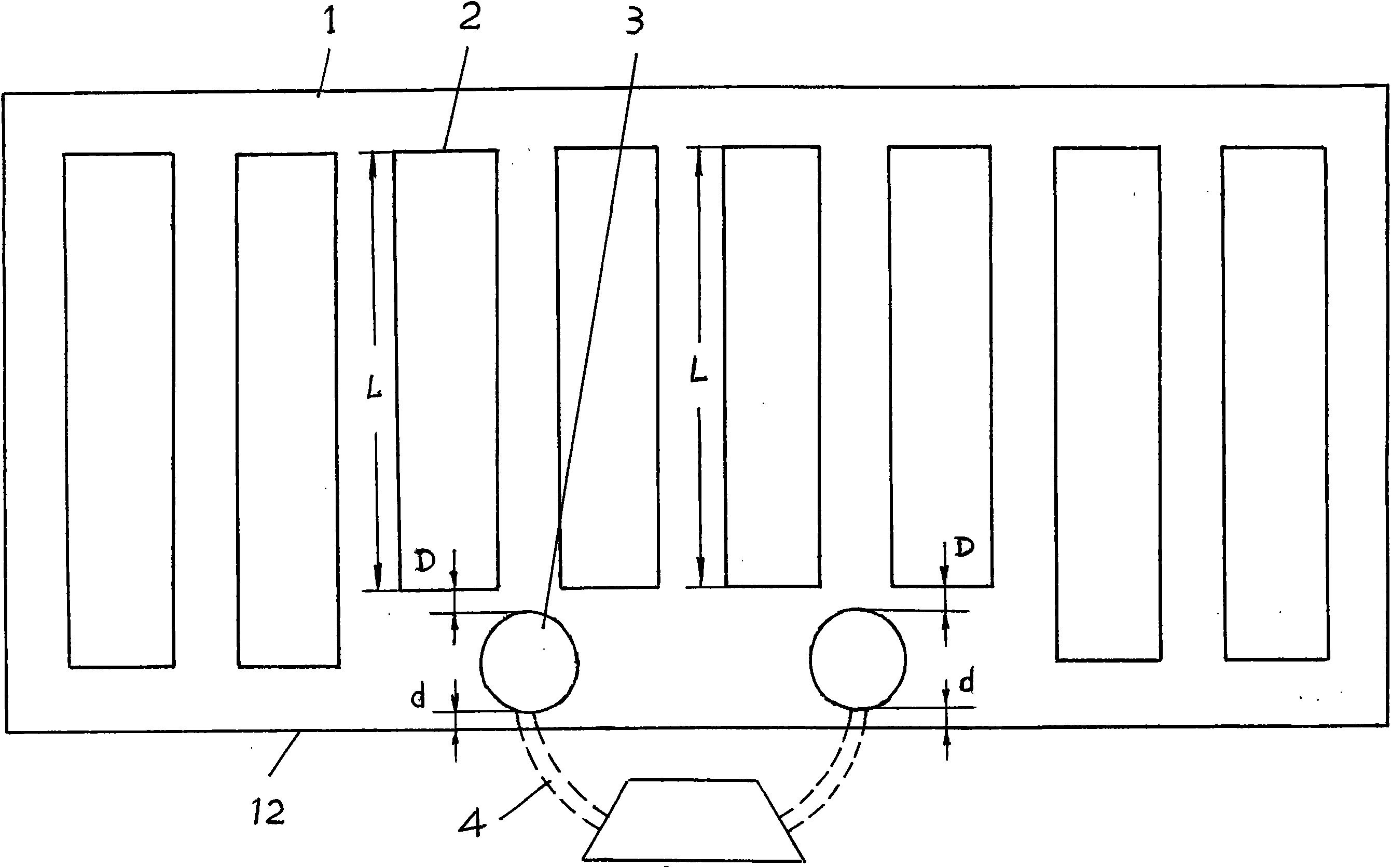

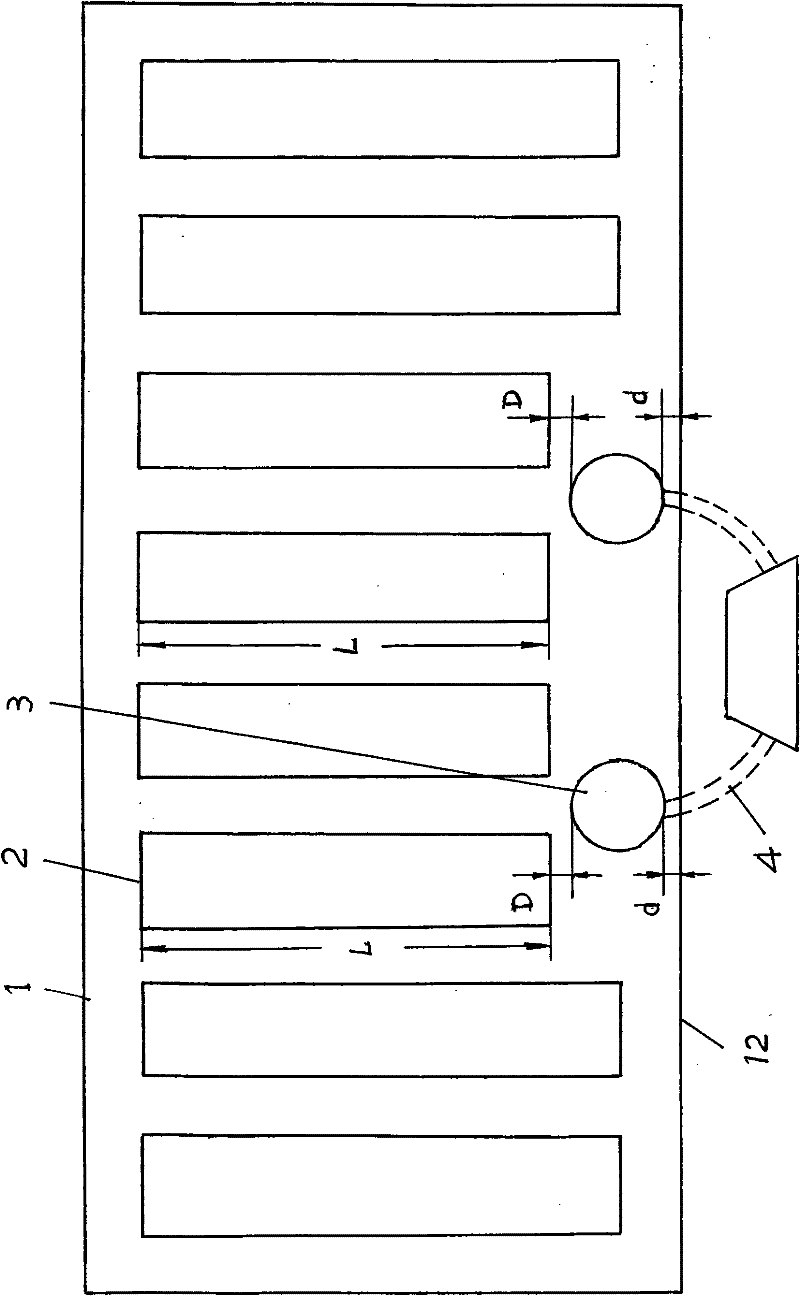

Dry heat type mushroom house or mushroom shed device for producing edible mushrooms

The invention discloses a dry heat type mushroom house or mushroom shed device for producing edible mushrooms. The device is characterized in that: the built mushroom house or mushroom shed has a north-orientated and south-facing structure; two longer sides of the mushroom house are positioned at a south position and a north position and are in the east-west direction; eight to ten mushroom beds are arranged in each mushroom house; two to four indoor heating stoves are built inside the mushroom house so as to form a built-in heating stove structure; each stove body has a vertically upright barrel structure; a heat exhaust gas outlet of the stove is communicated with the mushroom house; a stove opening of the stove is formed in a south-facing direction; the distance from the stove opening to a shed wall side on the south side is at least 20cm; a top cover capable of dispersing exhaust gas is arranged above the heat exhaust gas outlet of each stove; and a plurality of exhaust through holes are uniformly distributed at the heat exhaust gas outlet. When used for performing secondary fermentation or pasteurization and disinfection, the dry heat type mushroom house or mushroom shed device has the advantages of simple operation, short heating time, energy and labor conservation, capacity of sterilizing nuciform and other harmful bacteria, good sterilization and disinfection effect, small number of constructed stoves serving as mushroom house heating equipment, and contribution to improving and lightening environmental pollution.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

A kind of domestication method of rapid current fish

ActiveCN104756907BModerate growth rateGentle temperamentClimate change adaptationPisciculture and aquariaIchthyophthirius multifiliisObserved Survival

The invention discloses a torrent fish domesticating method. After first filial generation of acipenser dabryanus of 1-5 ages is raised in a culture pond, and then the torrent fishes to domesticated are added to the pond for raising. According to the domesticating method, the acipenser dabryanus and the torrent fishes are raised together, so that the stress response of wild fishes can be reduced, and the ichthyophthirius multifiliis infection resistance and the large individual characteristics of the acipenser dabryanus are utilized, and torrent is created by fishtailing to drive the activity of the wild fishes; the large cluster of the wild fishes is reduced and the probability of reciprocal infection of the ichthyophthirius multifiliis is reduced; as a result, the ichthyophthirius multifiliis can be effectively prevented, the survival rate is increased, the drug use is reduced and the pollution to the water environment is reduced.

Owner:CHINESE STURGEON RES INST CHINA THREE GOR

Preparation method of diamond grinding wheel with orderly arrangement of crystal oriented abrasives

ActiveCN111941300BEfficient orientationQuick orientationGrinding devicesChemical vapor deposition coatingMetallurgyCrystal orientation

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com