Dry heat type mushroom house or mushroom shed device for producing edible mushrooms

A technology for edible fungi and mushroom house, applied in the field of edible fungi production, can solve the problems of cumbersome and troublesome operation procedures, serious environmental pollution, low utilization rate of heat energy, etc., and achieves the effects of simple and easy operation mode, improved environmental pollution, and fewer constructions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

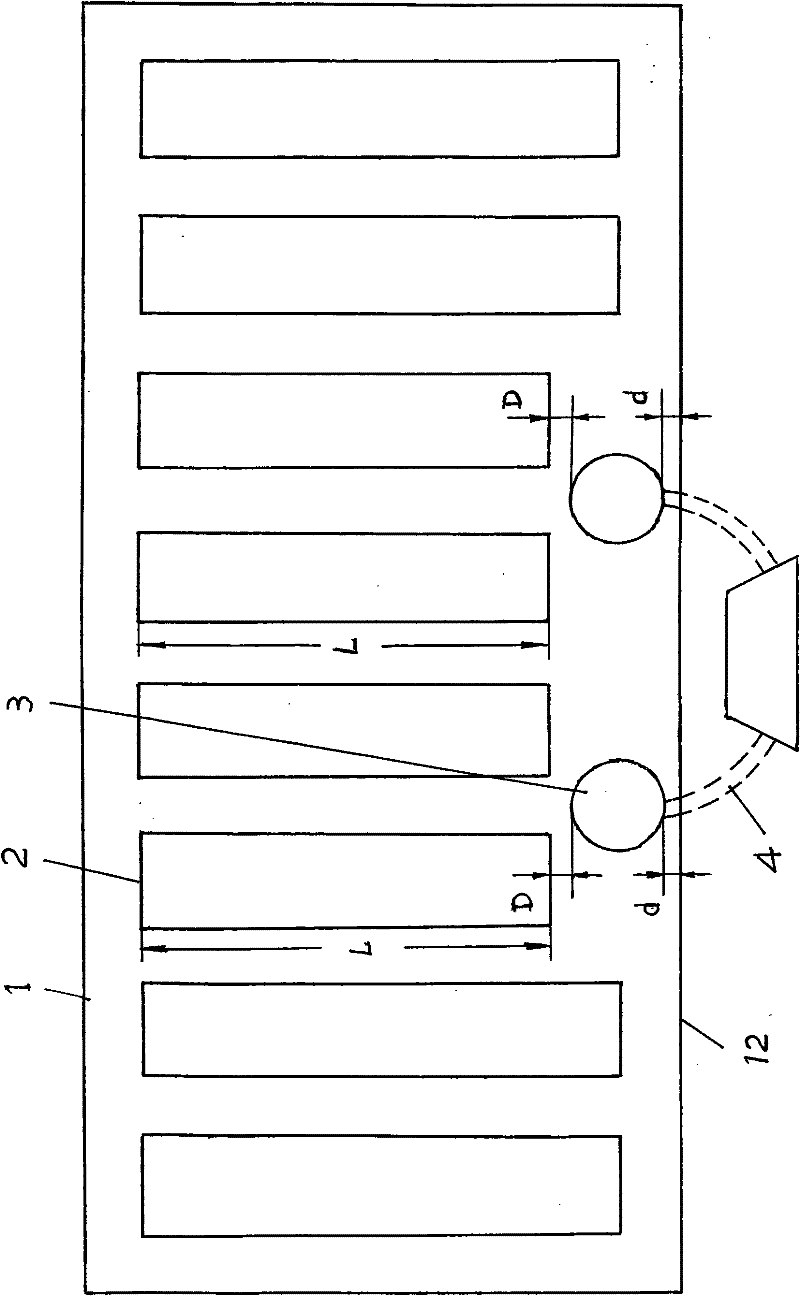

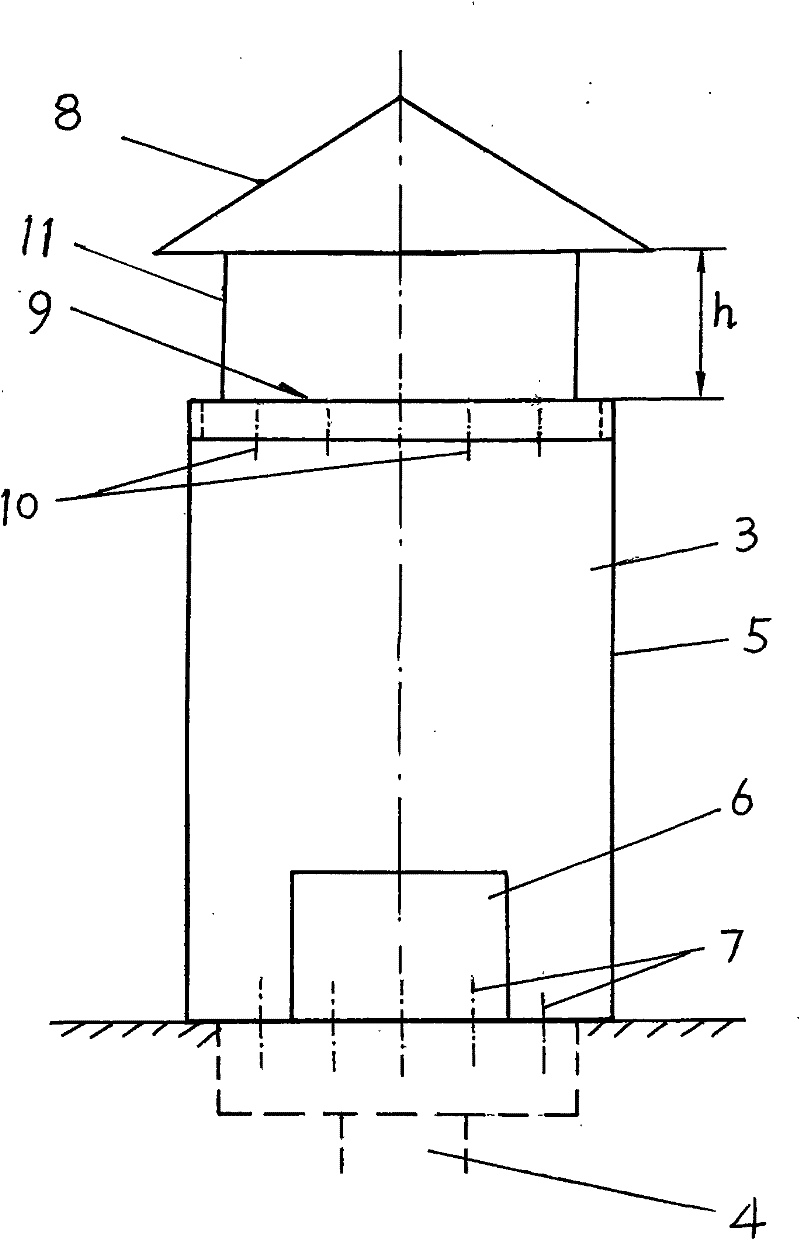

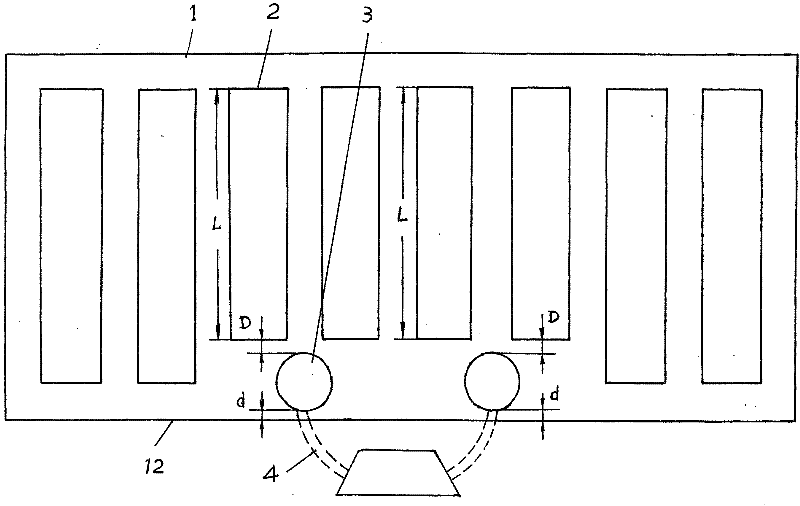

[0025]With reference to the attached drawings, it can be known (note: taking the mushroom house with length 20m×width 10m and 8 beds as an example, the stoves of the two built-in heating stoves are respectively selected to be located between the third and fourth beds from the left in the mushroom house. between the 5th and 6th beds), the specific structural components of the dry-heat mushroom house or mushroom shed device of the present invention include; 1- mushroom house (also known as mushroom shed) , 2 ~ mushroom bed, 3 ~ stove (built-in heating stove, which can be made of discarded empty gasoline drums), 4 ~ oxygen supply channel (it can be an oxygen supply channel opened underground, and the diameter of the oxygen supply channel is at least 20× 20cm), 5~the barrel-shaped shell of the stove body, 6~the stove mouth, 7~ventilation hole (also known as the stove vent, connected with the air outlet of the oxygen supply channel), 8~(arc or tapered) top Hood, 9~exhaust heat exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com