Dry heat type secondary fermentation method for planting agaricus blazei and dry heat type heating device

A secondary fermentation method and secondary fermentation technology, applied in fertilization devices, applications, preparation of organic fertilizers, etc., can solve the problems of large nutrient loss, large consumption of coal or firewood, and high cost, so as to improve the temperature of the mushroom house, reduce the Humidity, the effect of neat fruiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

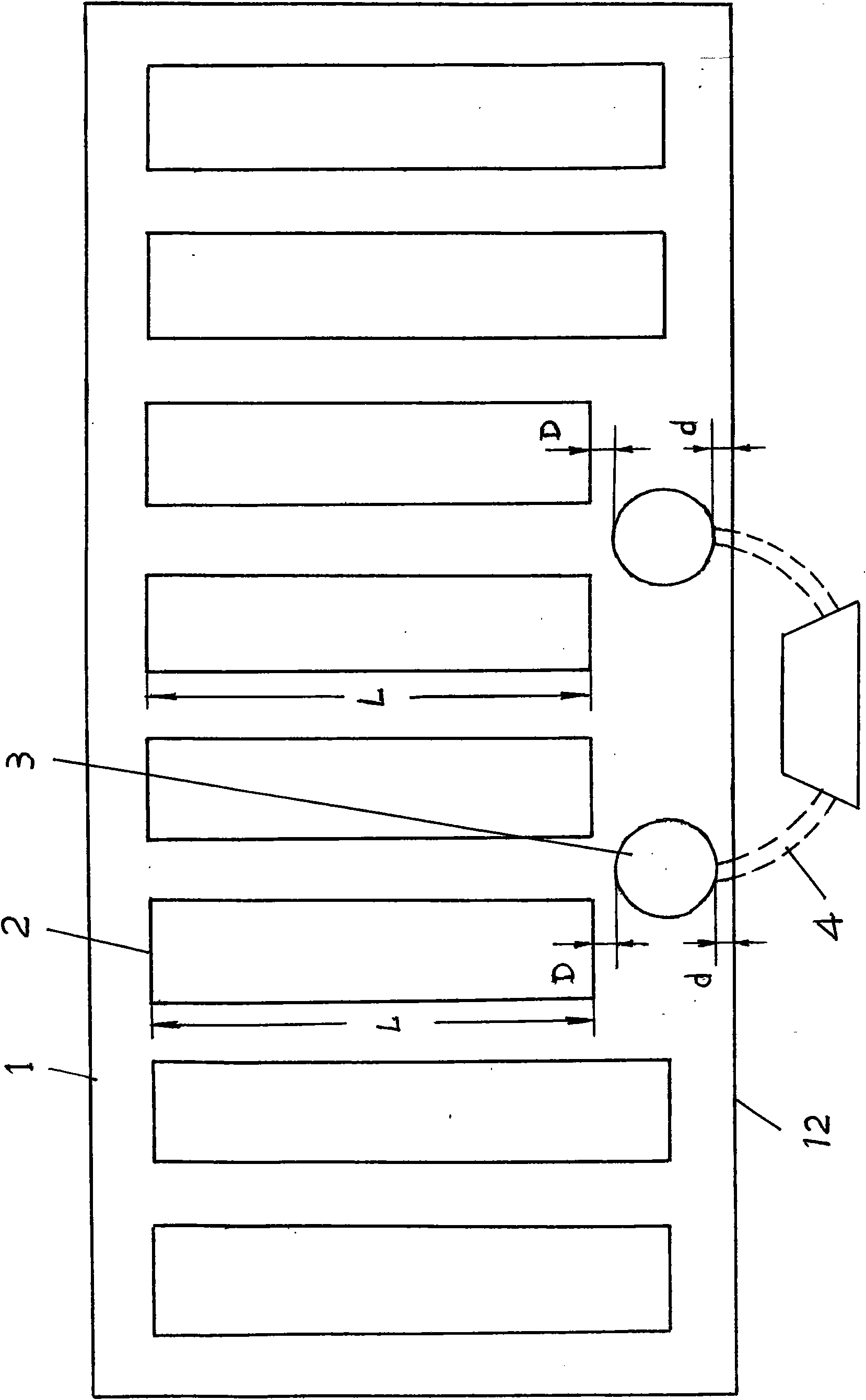

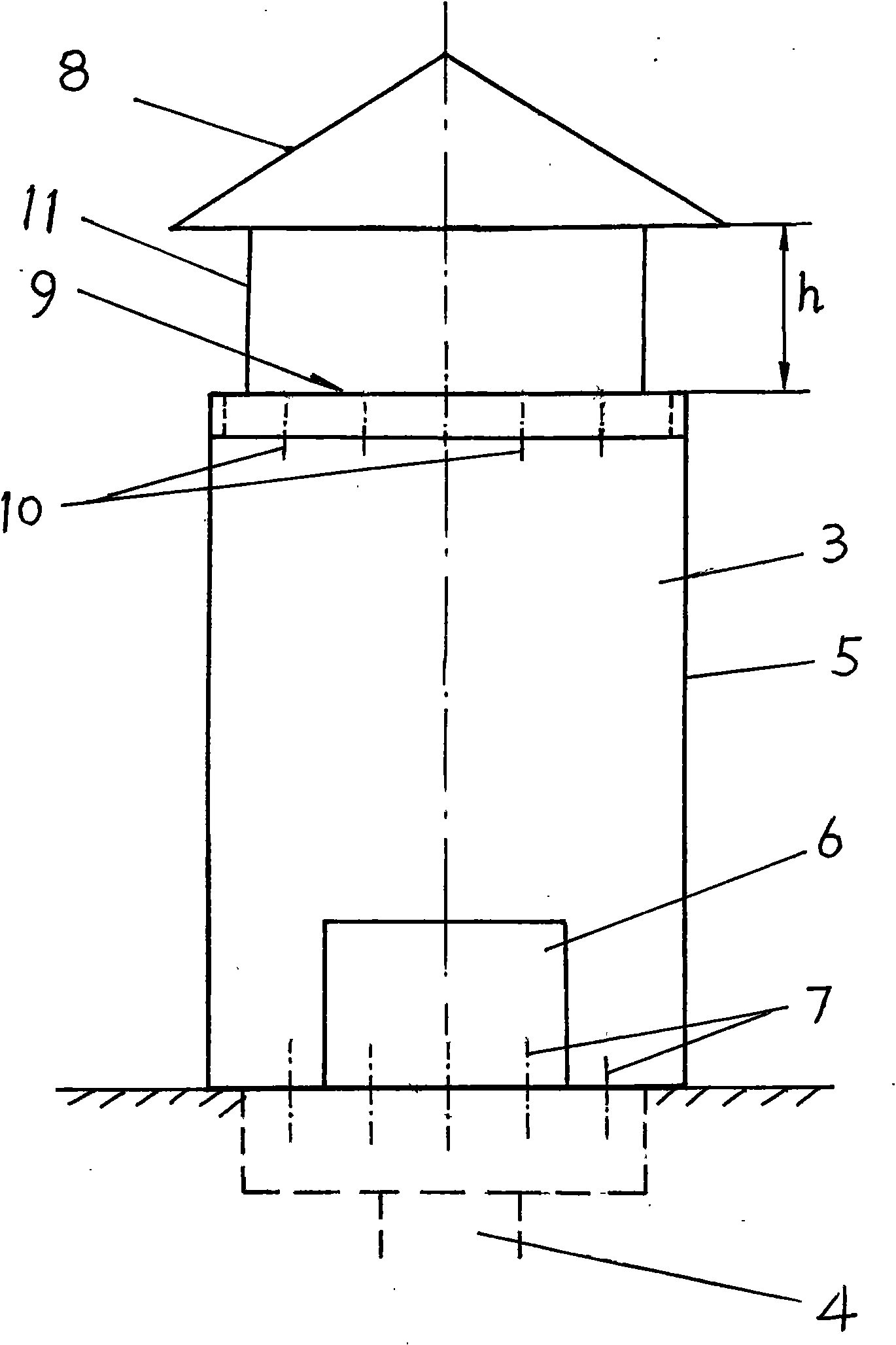

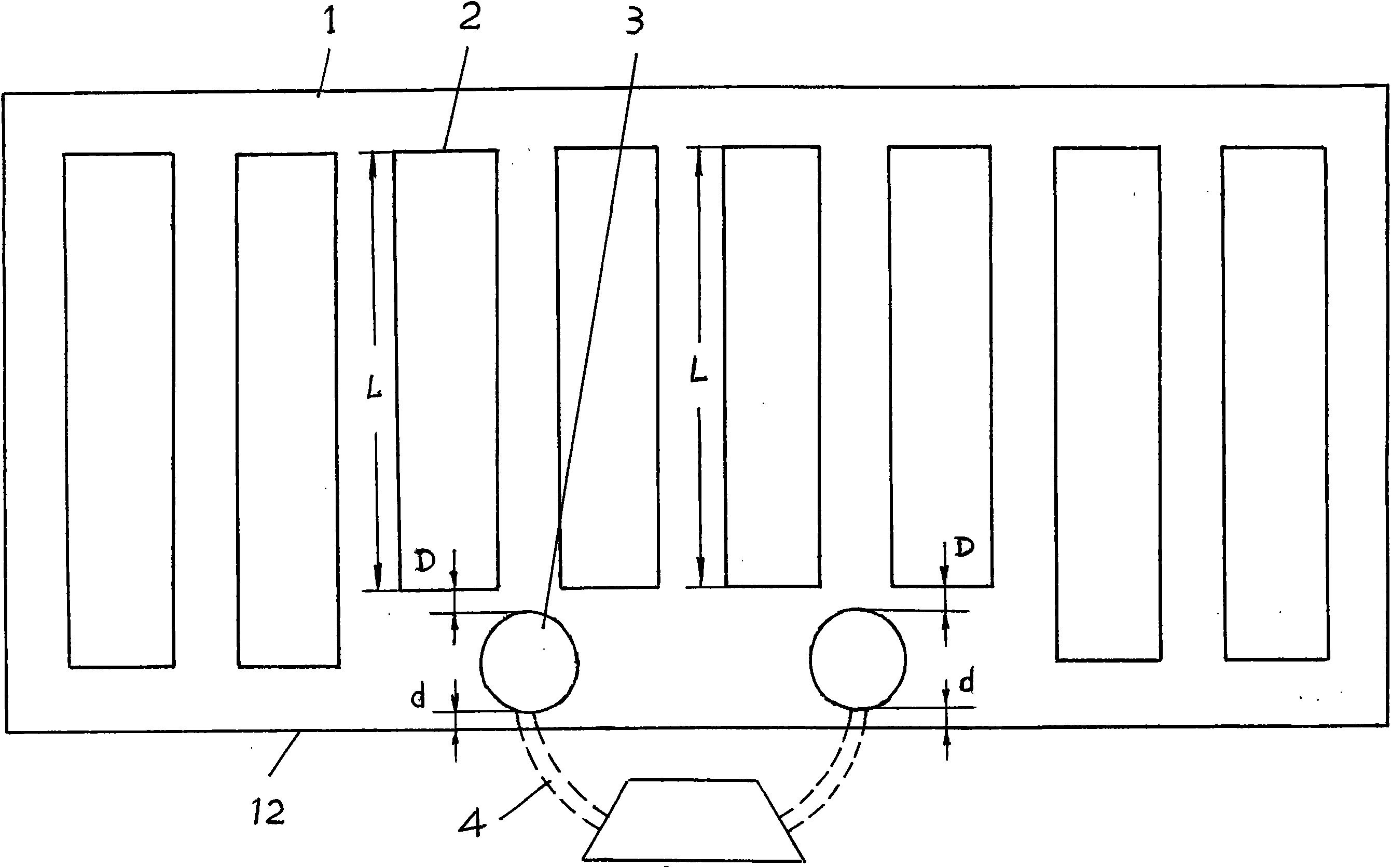

[0017] With reference to the accompanying drawings, it can be known that this dry heat type heating device for the dry heat type secondary fermentation new method of cultivating Agaricus blazei of the present invention, that is, the specific parts that constitute the structure of the heating stove body include; 1 ~ mushroom house (also It is called mushroom shed), 2~mushroom bed, 3~stove (it is a built-in heating stove, which can be made of discarded empty gasoline barrels), 4~oxygen supply channel (it can be an oxygen supply channel opened underground), 5~stove stove Body barrel-shaped shell, 6 ~ stove mouth, 7 ~ ventilation hole (also known as stove chamber vent, connected with the air outlet of the oxygen supply channel), 8 ~ (arc or conical) top cover, 9 ~ heat exhaust Gas outlet (consisting of several exhaust holes with a diameter of 2-5cm), 10~exhaust holes with a diameter of 2-5cm at the exhaust heat exhaust gas outlet, 11~top cover bracket, 12~south side of the mushroom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com