A kind of nano-gold submicron film, its preparation and application

A gold submicron and nano-gold technology, which is applied in the field of submicron metal particle thin film functional material devices, can solve the problems of low sensitivity, weak near-ultraviolet signal, high coating cost, etc., and achieve the effect of suitable growth rate and low stacking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

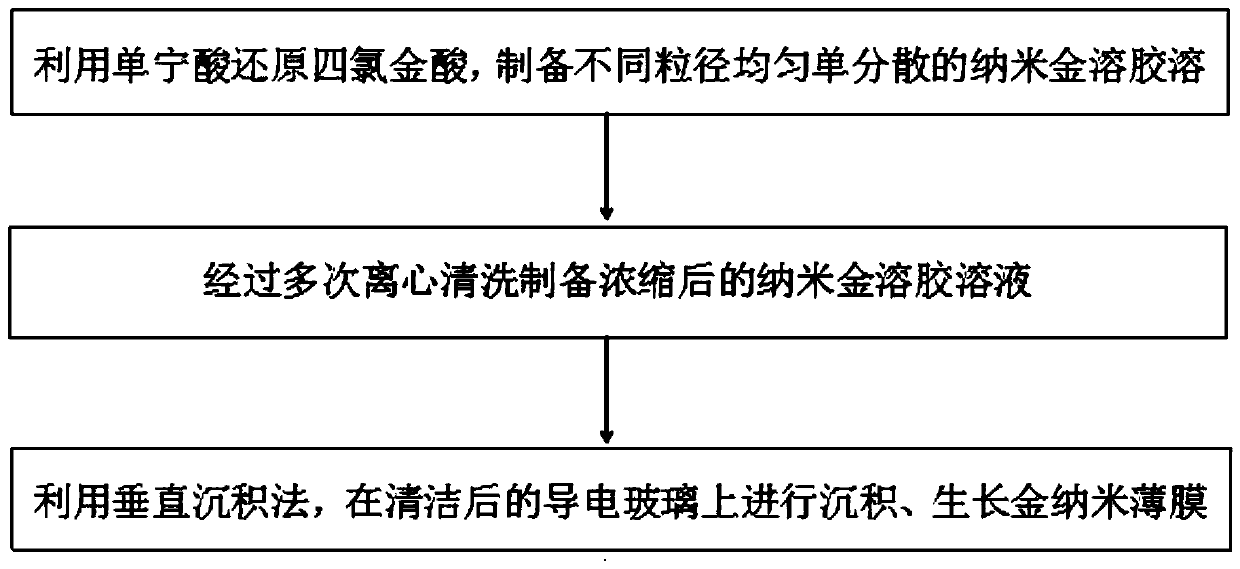

[0045] The nano-gold submicron film is prepared according to the following method, and the preparation flow chart is as follows figure 1 Shown:

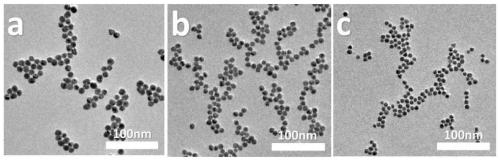

[0046] (1) To obtain a monodisperse spherical gold nanoparticle sol with uniform particle size, add deionized water and 1% HAuCl in conical flask A 4 (1 milliliter) volume ratio is 79:1; In Erlenmeyer flask B, add the C that mass fraction is 1% 6 h 5 Na 3 o 7 2H 2 O (4 ml) solution, 1% tannic acid (C 76 h 52 o 46 ) solution 50μl, K concentration of 0.1mol / L 2 CO 3 12.5 μl of aqueous solution and deionized water, the volume ratio is 320:4:1:2556.

[0047] (2) The volume ratio of Erlenmeyer flask A to Erlenmeyer flask B solution is 5:1. Put the Erlenmeyer flask A at a constant temperature of 60°C and put it in a water bath magnetic stirrer, stir evenly to 60°C, stir the Erlenmeyer flask B evenly for 15 minutes, then quickly pour it into the Erlenmeyer flask A, and mix HAuCl in the solution after mixing 4 The concentration ...

Embodiment 2

[0058] The nano-gold submicron film is prepared according to the following method, and the preparation flow chart is as follows figure 1 Shown:

[0059] (1) To obtain a monodisperse spherical gold nanoparticle sol with uniform particle size, add deionized water and 1% HAuCl in conical flask A 4 (1 milliliter) volume ratio is 79:1; In Erlenmeyer flask B, add the C that mass fraction is 1% 6 h 5 Na 3 o 7 2H 2 O (4 ml) solution, 1% tannic acid (C 76 h 52 o 46 ) solution 100μl, K concentration of 0.1mol / L 2 CO 3 25 μl of aqueous solution and deionized water, the volume ratio is 640:4:1:2556.

[0060] (2) The volume ratio of Erlenmeyer flask A to Erlenmeyer flask B solution is 5:1. Put the Erlenmeyer flask A at a constant temperature of 60°C and put it in a water bath magnetic stirrer, stir evenly to 60°C, stir the Erlenmeyer flask B evenly for 15 minutes, then quickly pour it into the Erlenmeyer flask A, and mix HAuCl in the solution after mixing 4 The concentration i...

Embodiment 3

[0065] The nano-gold submicron film is prepared according to the following method, and the preparation flow chart is as follows figure 1 Shown:

[0066] (1) To obtain a monodisperse spherical gold nanoparticle sol with uniform particle size, add deionized water and 1% HAuCl in conical flask A 4 (1 milliliter) volume ratio is 79:1; In Erlenmeyer flask B, add the C that mass fraction is 1% 6 h 5 Na 3 o 7 2H 2 O (4 ml) solution, 1% tannic acid (C 76 h 52 o 46 ) solution 500μl, K concentration of 0.1mol / L 2 CO 3 125 μl of aqueous solution and deionized water, the volume ratio is 640:4:1:2556.

[0067] (2) The volume ratio of Erlenmeyer flask A to Erlenmeyer flask B solution is 5:1. Put the Erlenmeyer flask A at a constant temperature of 60°C and put it in a water bath magnetic stirrer, stir evenly to 60°C, stir the Erlenmeyer flask B evenly for 15 minutes, then quickly pour it into the Erlenmeyer flask A, and mix HAuCl in the solution after mixing 4 The concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com