Method for manufacturing composite bamboo floor block by adopting excess materials

A technology for floor boards and bamboo floor boards, which is applied to the manufacturing and processing of floor boards, and uses surplus materials to manufacture composite bamboo floor boards, which can solve problems such as economic loss, irregularity, waste, etc., achieve high adaptability, and is conducive to popularization and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

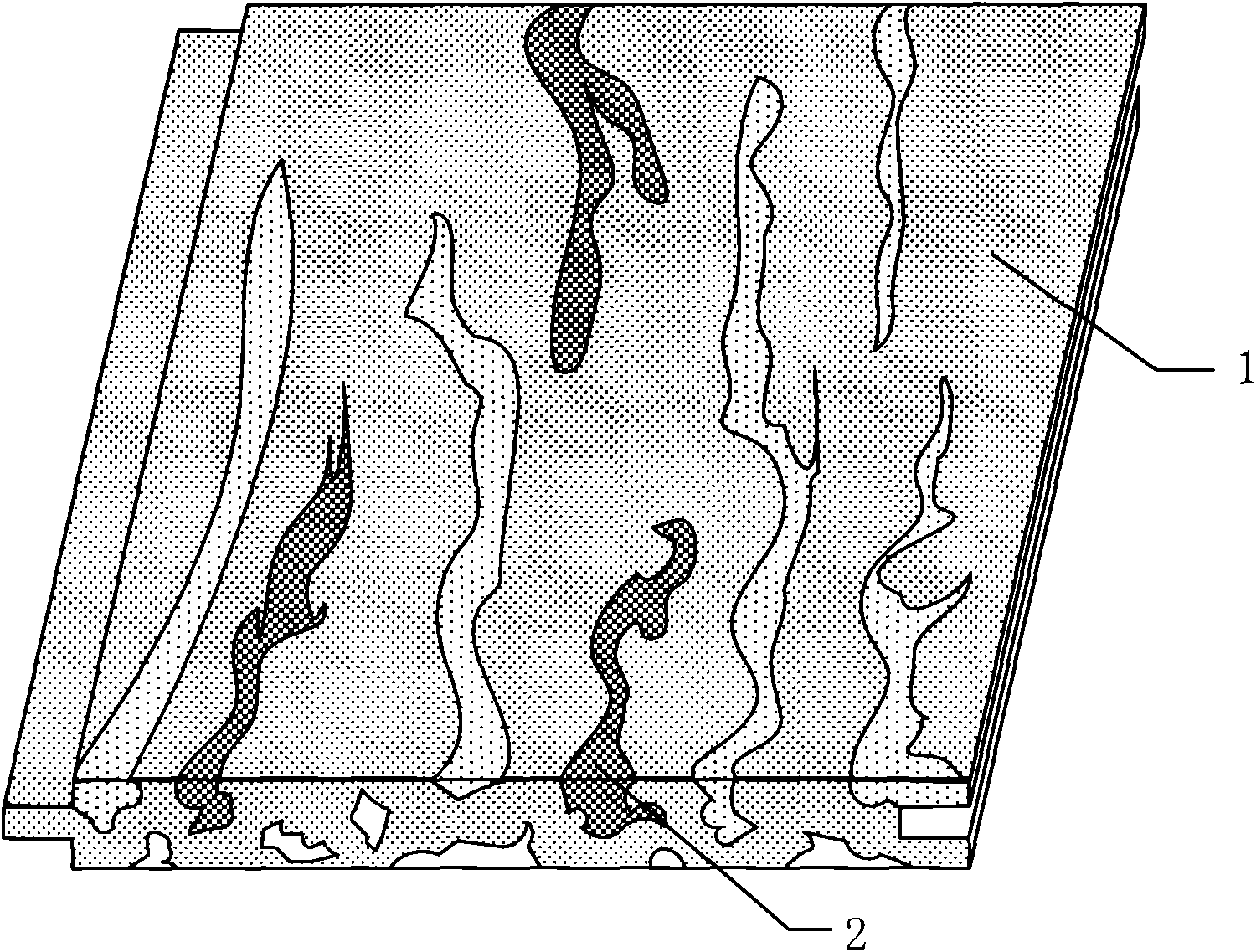

[0031] Such as figure 1 The shown composite bamboo floor board using surplus materials is manufactured as follows: first, the bamboo floor surplus materials of different types and colors account for 45% according to the bamboo floor surplus materials 1 with a bamboo age of more than four years; The following bamboo floor surplus material 2 accounts for 10% ratio and puts into the mould, carries out planking. During this period, the leftover bamboo flooring materials are stacked to a certain thickness in a manner consistent with the grain direction, so as to ensure that the remaining bamboo flooring materials fill the mold as much as possible, which is convenient for subsequent processing.

[0032] Subsequently, a cold press is used to carry out 20 minutes of pre-pressing for the remaining bamboo floor after planking. In this way, the gap between the remaining floor materials during the laying process is eliminated. During the process, if a large pressing gap is found, the mol...

Embodiment 2

[0038] Such as figure 1 The composite bamboo floor board that adopts surplus material as shown can be obtained by the following method: first, the bamboo floor surplus material of different types and different colors accounts for 60% according to the bamboo floor surplus material 1 with a bamboo age of more than four years; The remaining material 2 of the bamboo floor below the age of four years accounts for 30% of the ratio and puts it into the mould, and carries out planking. During this period, the leftover bamboo flooring materials are stacked to a certain thickness in a manner consistent with the grain direction, so as to ensure that the remaining bamboo flooring materials fill the mold as much as possible, which is convenient for subsequent processing.

[0039] Subsequently, a cold press is used to prepress the rest of the bamboo floor after planking for 20 to 25 minutes. In this way, the gap between the remaining floor materials during the laying process is eliminated. D...

Embodiment 3

[0045] Such as figure 1 The manufacturing method of the composite bamboo floor boards shown using surplus materials is as follows: first, the bamboo floor surplus materials of different types and colors account for 50% according to the bamboo floor surplus materials 1 with bamboo age of more than four years; Bamboo floor surplus material 2 below the year accounts for 20% ratio and puts into the mould, carries out planking. During this period, the leftover bamboo flooring materials are stacked to a certain thickness in a manner consistent with the grain direction, so as to ensure that the remaining bamboo flooring materials fill the mold as much as possible, which is convenient for subsequent processing. Subsequently, a cold press is used to carry out a 20-minute fitting pre-press on the remaining bamboo flooring after planking. In this way, the gap between the remaining floor materials during the laying process is eliminated. During the process, if a large pressing gap is fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com