Preparation method of medium-chain and long-chain fatty acid edible oil

A medium and long-chain fatty acid and edible oil technology, which is applied in the direction of fatty acid esterification, fermentation, etc., can solve the problems of high deodorization temperature conditions and low reaction efficiency, and achieves low price, high economic benefits, and is conducive to large-scale production and manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

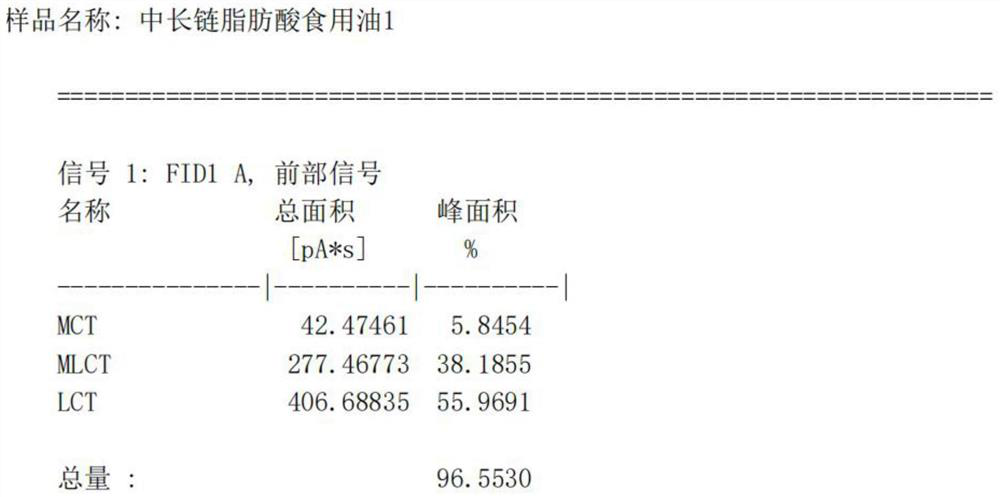

Embodiment 1

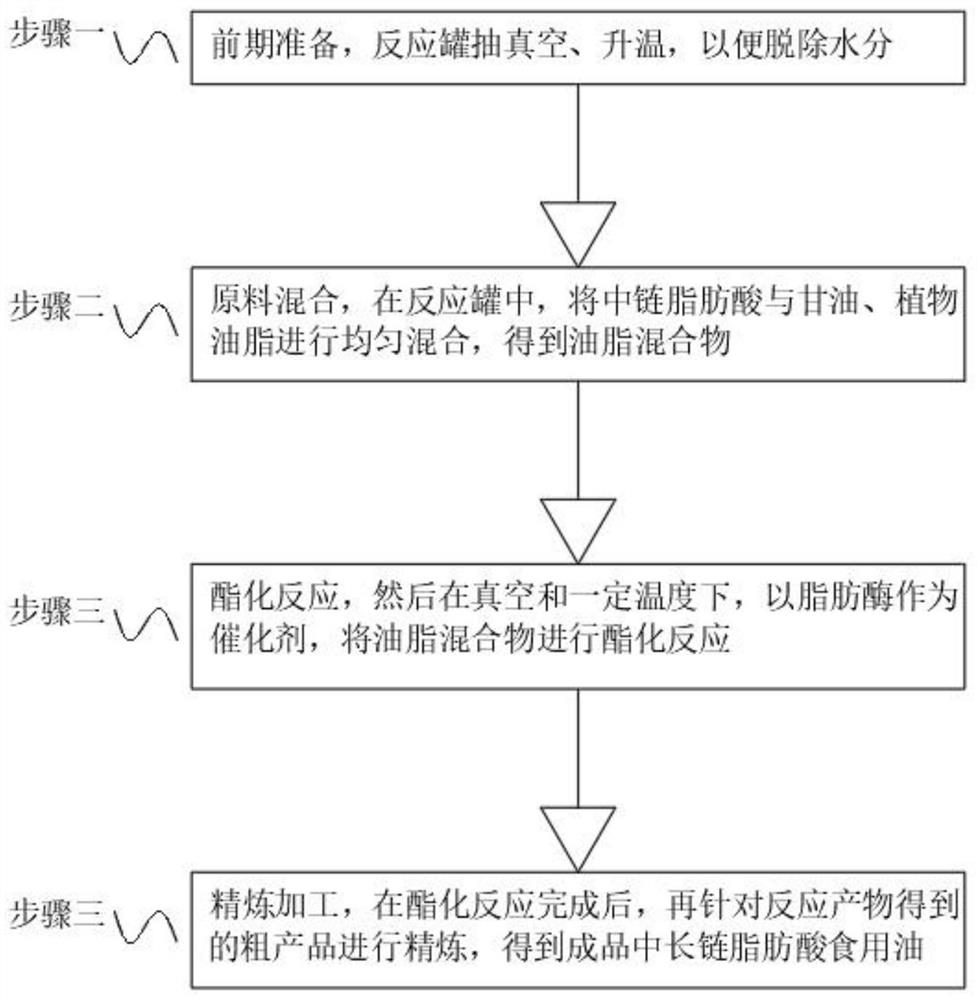

[0028] like figure 2 As shown, a method for preparing medium and long-chain fatty acid edible oil comprises the following steps:

[0029] Step 1. Preliminary preparation, vacuuming the reaction tank, heating up and dehydrating;

[0030] Step 2: Mixing raw materials, 14 parts of medium chain fatty acids, 2 parts of glycerol, 46.9 parts of sunflower oil, 34 parts of soybean oil, 3 parts of linseed oil, and 0.1 part of vitamin E, put into the reaction tank in turn, and vacuumed at 95 ° C Dehydration, then stirring and mixing for 10min to obtain the oil mixture before the reaction;

[0031] Step 3, esterification reaction, put the immobilized lipase into a fixed container to form a lipase fixed bed, let the pre-reaction oil mixture cooled to 65°C circulate through the lipase fixed bed for transesterification, and terminate the reaction after 8 hours of reaction , the catalyst and grease are separated;

[0032] Step 4, refining and processing, carrying out refining operations s...

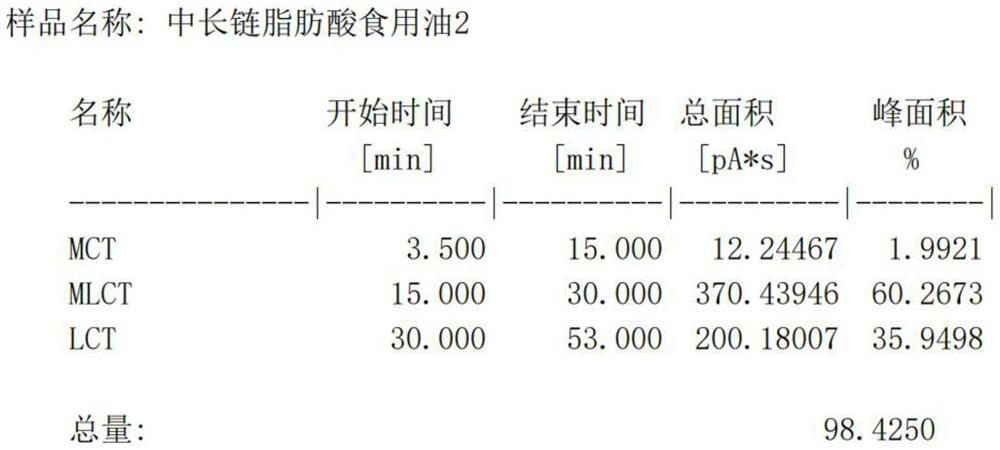

Embodiment 2

[0035] like image 3 As shown, a method for preparing medium and long-chain fatty acid edible oil comprises the following steps:

[0036] Step 1. Preliminary preparation. The reaction tank is equipped with a stirrer. The vertical stirring of the agitator can make the materials mix efficiently from bottom to top. The reaction tank is first evacuated and heated for drying and dehydration;

[0037] Step 2, mixing raw materials, 20 parts of medium-chain fatty acids, 5 parts of glycerol, and 75 parts of soybean oil, put into the reaction tank successively, dehydrated in vacuum at 95 ° C, and then stirred and mixed for 10 min to obtain the oil mixture before the reaction;

[0038] Step 3, esterification reaction, before the reaction, the oil mixture is cooled to 45°C, lipase is added, and the transesterification reaction is carried out, and the reaction is terminated after 24 hours;

[0039] Step 4, refining and processing, refining the structural fat obtained by the esterification...

Embodiment 3

[0042] like Figure 4 As shown, a method for preparing medium and long-chain fatty acid edible oil comprises the following steps:

[0043] Step 1. Preliminary preparation, first vacuum dry the mixing tank for use;

[0044] Step 2: Mix the raw materials, put 11% of medium chain fatty acid, 2% of glycerol, 86.9% of vegetable oil and 0.1% of vitamin E into the mixing tank, which accounts for 11% of the total mass of the mixture before the total reaction. , mixed for 10min to make it uniform. Among them, 86.9% of vegetable oils include: 70.9% rapeseed oil, 16% coconut oil;

[0045] Step 3, esterification reaction, put the immobilized lipase into the fixed-bed reactor, let the mixture cooled to 60 ° C flow through the fixed-bed reactor to carry out the transesterification reaction, the reaction is terminated after 10 hours, and the catalyst and grease are separated. ;

[0046] Step 4, refining and processing, refining the structural fat obtained by the esterification reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com