A kind of retarded clinker and preparation method thereof

A clinker, retarding technology, applied in the field of cement, can solve the problems of fast heat release, short initial setting time, short cement setting time, etc., to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

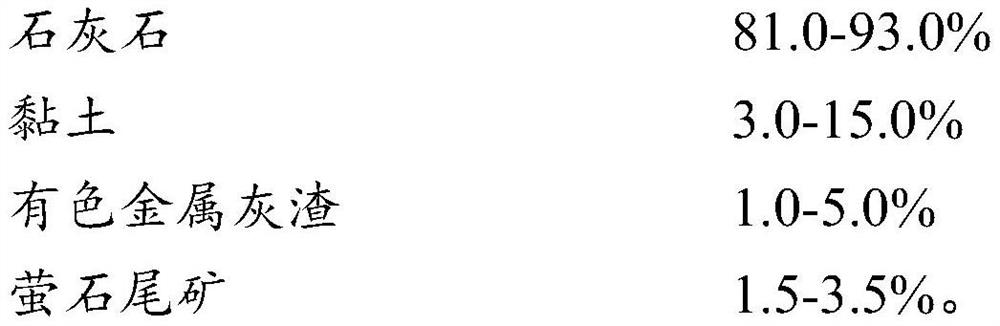

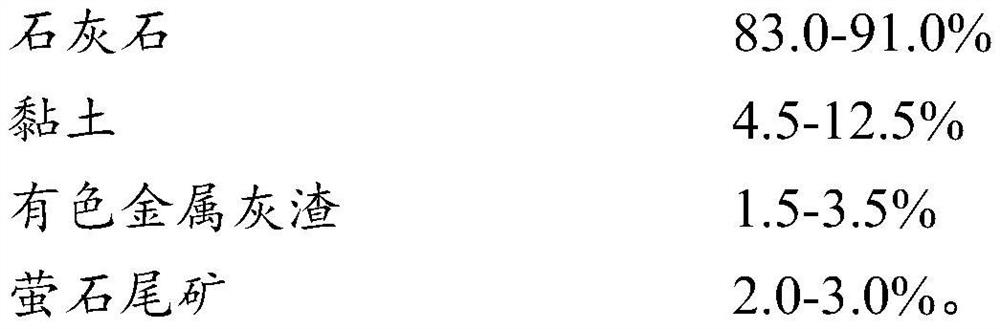

[0091] A retarded clinker, the corresponding raw meal is composed of the following components in mass fractions (that is, mass percentages):

[0092] Limestone, 85%;

[0093] Clay, 10%;

[0094] Non-ferrous metal slag, 2.5%;

[0095] Fluorite tailings, 2.5%.

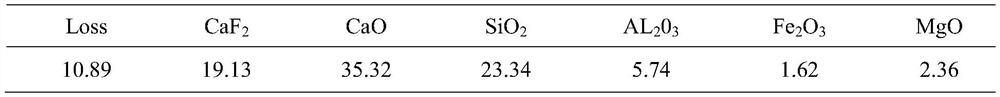

[0096] Among them, the fluorite tailings are the waste fluorite tailings beneficiation powder produced by Jinshi Resources Group Zhejiang Zijing Mining Co., Ltd. during the processing of fluorite ore. The specific quality is as follows (by mass percentage), and some constant components are not listed. :

[0097] Fluorite tailings quality

[0098]

[0099] The specific quality of other components is as follows (in mass percentage), and some constant components are not listed:

[0100]

[0101] The specific quality of the clinker is as follows (in terms of mass percentage), and some constant components are not listed, wherein the amount of pulverized coal added is 2.8% of the quality of the clinker:

[0102] ...

Embodiment 2

[0112] Example 2 The influence of the addition amount of fluorite tailings on the retarding time of clinker

[0113] A retarded clinker, the corresponding raw meal is composed of the following components in mass fractions (that is, mass percentages):

[0114] Limestone, 84.7%;

[0115] Clay, 9.8%;

[0116] Non-ferrous metal slag, 2.5%;

[0117] Fluorite tailings, 3.0%.

[0118] Among them, the specific quality of fluorite tailings is as follows (in mass percentage), and some constant components are not listed:

[0119] Fluorite tailings quality

[0120]

[0121] The specific quality of other components is as follows (in mass percentage), and some constant components are not listed:

[0122]

[0123]

[0124] The preparation method of the above-mentioned retarded clinker is based on Example 1, and some conditions are modified. The modification content is: the decomposition temperature in the decomposition furnace in step (5) is 890 ° C, the firing temperature in t...

Embodiment 3

[0125] Example 3 Effect of fluorite tailings addition on clinker retardation time

[0126] A retarded clinker, the corresponding raw meal is composed of the following components in mass fractions (that is, mass percentages):

[0127] Limestone, 89.2%;

[0128] Clay, 5.0%;

[0129] Non-ferrous metal slag, 3.6%;

[0130] Fluorite tailings, 2.2%.

[0131] Among them, the specific quality of fluorite tailings is as follows (in mass percentage), and some constant components are not listed:

[0132] Fluorite tailings quality

[0133]

[0134] The specific quality of other components is as follows (in mass percentage), and some constant components are not listed:

[0135]

[0136] The preparation method of the above-mentioned retarded clinker is based on the modification of some conditions on the basis of Example 1, and the modification content is: the decomposition temperature in the decomposition furnace of step (5) is 880 ° C, and the firing temperature in the rotary kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com