A kind of preparation method of retarding type ether polycarboxylate water reducer

A technology of retarding ether and polycarboxylic acid, which is applied in the field of construction admixtures, can solve the problems of different components of retarders during standing time, excessive slump loss, and influence on engineering construction, and achieve excellent dispersibility and The effects of slump retention, reduced negative impact, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

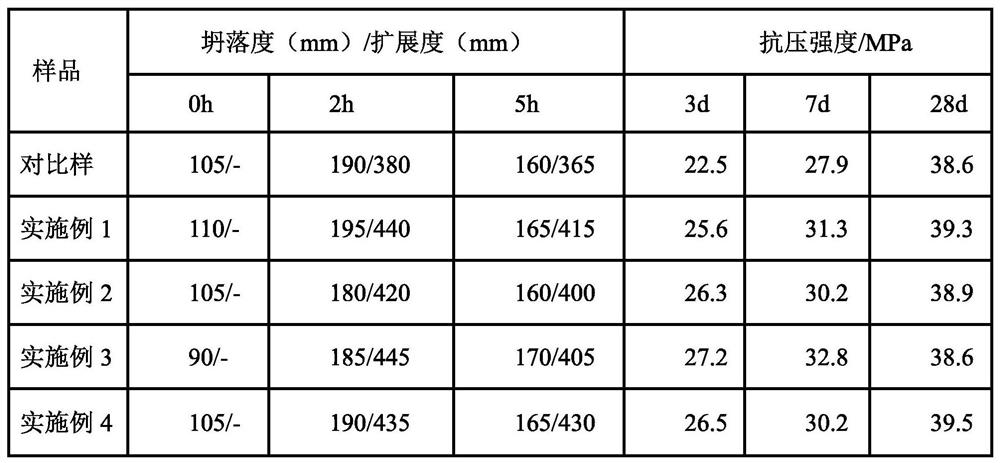

Examples

Embodiment 1

[0025] (1) Preparation of esterification monomer: by weight, 100 parts of sucrose, 32 parts of crotonic acid, 0.5 part of supported solid acid catalyst SO 4 2- / SiO 2 -TiO 2 and 1.5 parts of p-benzoquinone were added to the first reaction device equipped with a condensing device, and under the protection of nitrogen, they were reacted at a constant temperature of 95 ° C for 4 hours. Esterified monomer of crotonic acid mixture;

[0026] (2) Copolymerization reaction: in parts by weight, first 200 parts of allyl polyoxyethylene polyoxypropylene ethers with a molecular weight of 3000, 2.5 parts of azobisisobutyronitrile, 0.08 parts of zirconium chloride and 275 parts of water are added to In the second reaction device; 8 parts of esterified monomers prepared in step (1), 5 parts of methacrylic acid-beta-hydroxyethyl phosphate, 12 parts of acrylic acid and 20 parts of water are mixed uniformly in the first dropping device ; 1 part of ammonium persulfate and 20 parts of water a...

Embodiment 2

[0029] (1) Preparation of esterification monomer: by weight, 100 parts of sucrose, 40 parts of crotonic acid, 1.2 parts of supported solid acid catalyst SO 4 2- / SiO 2 -TiO 2 Add 1 part of 4-tert-butylcatechol into the first reaction device equipped with a condensing device, under the protection of nitrogen, react at a constant temperature of 115 ° C for 5 hours, after the reaction is completed, the temperature is lowered to 40 ° C, and the sugar-containing product is obtained Esterification monomers of mixtures of esterification products and crotonic acid;

[0030] (2) Copolymerization reaction: by weight, first 200 parts of molecular weight are 5000 4-hydroxybutyl vinyl ether polyoxyethylene ether, 3 parts of azobisisobutylamidine hydrochloride, 0.1 part of zinc chloride and 270 parts of water are added in the second reaction device; 5 parts of esterified monomers prepared in step (1), 3 parts of methacrylic acid-beta-hydroxyethyl phosphate, 15 parts of acrylic acid and 2...

Embodiment 3

[0033] (1) Preparation of esterification monomer: by weight, 100 parts of glucose, 214 parts of crotonic acid, 0.8 part of supported solid acid catalyst SO 4 2- / SiO 2 -TiO 2 and 0.8 parts of 2,5-di-tert-butylhydroquinone into the first reaction device equipped with a condensing device, under the protection of nitrogen, react at a constant temperature of 105 °C for 5 hours, after the reaction is completed, the temperature is lowered to 40 °C, That is, the esterification monomer containing the mixture of sugar esterification products and crotonic acid is obtained;

[0034](2) Copolymerization reaction: by weight, first add 200 parts of methallyl alcohol polyoxyethylene ether with a molecular weight of 2400, 1 part of azobisisobutylamidine hydrochloride, 0.5 part of manganese sulfate and 282 parts of water In the second reaction device; 10 parts of esterified monomers prepared in step (1), 7 parts of acrylic acid-beta-hydroxyethyl phosphate, 10 parts of acrylic acid and 20 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com