Production method and product of cement retarder from ardealite

A technology of cement retarder and production method, which is applied in the field of cement retarder made from phosphogypsum, can solve problems such as inability to popularize in a large area, complex production process, secondary pollution, etc., and achieve low product cost, simple method, good retardation coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

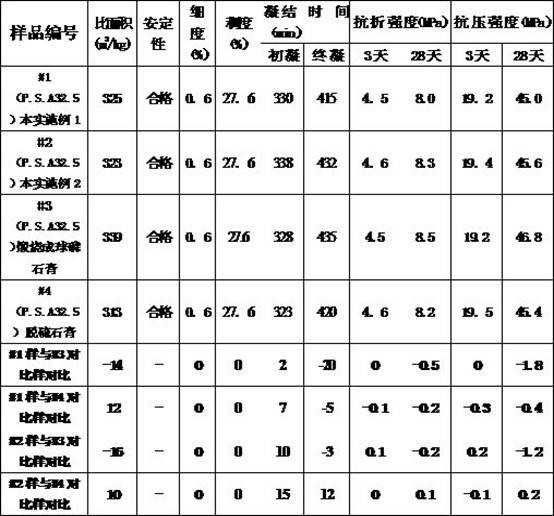

Examples

Embodiment 1

[0025] A, measure the mass percentage content of fluorine (F) in phosphogypsum by fluoride ion selective electrode method to be 0.1%; Measure free phosphoric acid (in P in phosphogypsum by quinoline phosphomolybdic acid gravimetric method) 2 o 5 Calculated) the mass percentage content is: 0.41%. Determination of attached water in phosphogypsum by gravimetric method (H 2 O) The mass percentage content is: 26.4%.

[0026] According to 100 tons of phosphogypsum, the amount of fluoride ions is 0.1 tons, and the amount of CaO required for theoretical neutralization is 0.295 tons. The calculation formula is:

[0027] 100×0.1%×56 / 38 = 0.15.

[0028] Based on 100 tons of phosphogypsum, free phosphoric acid (in P 2 o 5 Calculated) is 0.41 tons, the amount of CaO required for neutralization in theory is 0.49 tons, the calculation formula is:

[0029] 100×0.41%×168 / 142 = 0.49.

[0030] B. Add 100 tons of phosphogypsum to the mixer, then add 5 tons of quicklime powder with a finene...

Embodiment 2

[0037] A, measure the mass percent content of fluorine (F) in phosphogypsum by the fluoride ion selective electrode method and be 0.15%; Measure free phosphoric acid (in P in phosphogypsum by the quinoline phosphomolybdic acid gravimetric method) 2 o 5 Calculated) the mass percentage content is: 0.62%. Determination of attached water in phosphogypsum by gravimetric method (H 2 O) The mass percentage content is: 27.25%.

[0038] Based on 100 tons of phosphogypsum, the amount of fluoride ions is 0.15 tons, and the amount of CaO required for theoretical neutralization is 0.22 tons. According to 100 tons of phosphogypsum, free phosphoric acid (in P 2 o 5 Calculated) is 0.41 tons, and the amount of CaO required for neutralization in theory is 0.73 tons.

[0039] B. Add 100 tons of phosphogypsum to the mixer, then add 6 tons of quicklime powder with a fineness of 100 mesh, 15 tons of cement kiln dust, and 6 tons of grinding aids. The grinding aids are: triisopropanolamine 50 %,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com