Synthesis method of hyperbranched unsaturated polyoxyethylene ether as well as product and application thereof

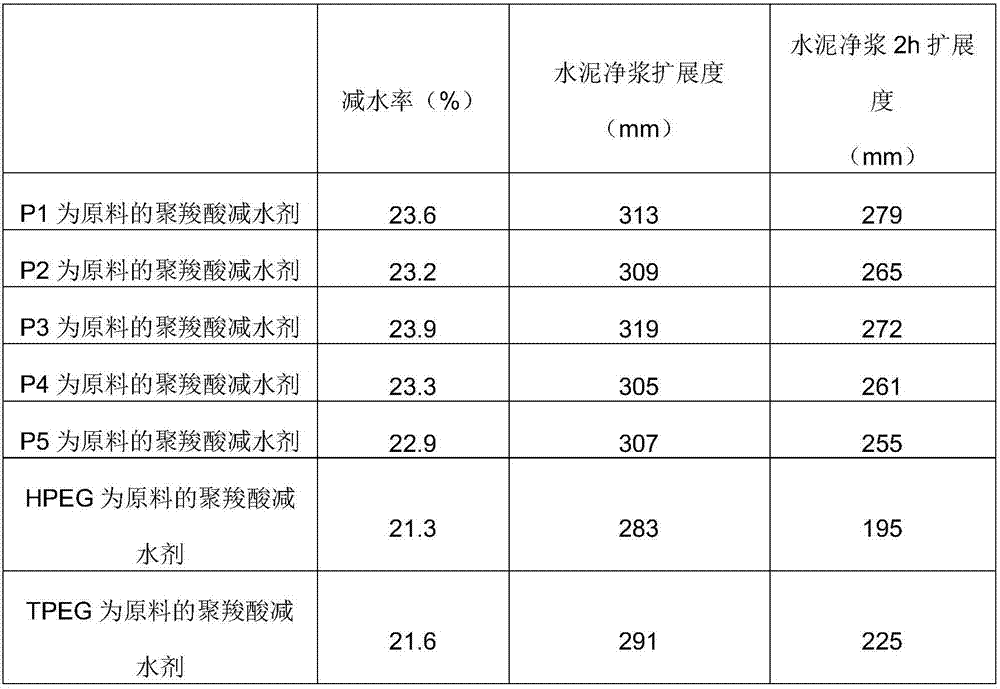

A technology of polyoxyethylene ether and synthesis method, which is applied in the synthesis of unsaturated polyoxyethylene ether and the field of hyperbranched unsaturated polyoxyethylene ether, which can solve the problem of being unable to further increase the molecular chain density and relative molar ratio of polyoxyethylene ether Can not be further improved, polycarboxylate water reducer performance bottleneck and other problems, to achieve excellent retarding effect, broad application prospects and market potential, high water reducing rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

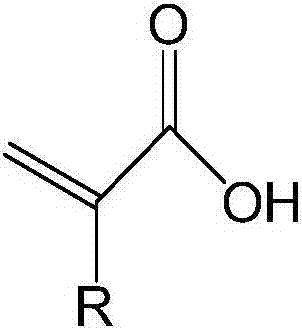

[0022] According to the synthetic method of the hyperbranched unsaturated polyoxyethylene ether of the first aspect, comprise the following steps: S1: add polyhydroxyl compound and unsaturated carboxylic acid X in reaction container:

[0023]

[0024] Wherein, R is H or an alkyl group of C1-C8; an esterification catalyst and a polymerization inhibitor are added, and an esterification reaction is carried out at a reaction temperature of 65°C-95°C to obtain intermediate A; wherein, the esterification The catalyst is p-toluenesulfonic acid, and the polymerization inhibitor is hydroquinone or / and p-quinone; S2: adding the intermediate A, ethylene oxide, and anionic ring-opening polymerization to the pressurized reaction device Catalyst, under the reaction temperature of 160 DEG C to 185 DEG C and the pressure in the reaction vessel of 0.15 Mpa to 0.25 Mpa, the anionic ring-opening polymerization reaction is carried out to obtain the hyperbranched unsaturated polyoxyethylene ethe...

Embodiment 1

[0035] S1: Add 500 g of tetramethanol, 380 g of acrylic acid, 10 g of p-toluenesulfonic acid, and 1.2 g of hydroquinone into the reaction vessel, and mechanically stir for 5 hours at a reaction temperature of 80° C. to complete the esterification reaction to obtain intermediate A1;

[0036] S2: Add 150g of the intermediate A1, 2000g of ethylene oxide, and 20g of sodium ethoxide to the pressurized reaction device, and carry out anionic ring-opening polymerization reaction at a reaction temperature of 170°C and a pressure of 0.15Mpa in the reaction vessel. The time is 6 hours, and the hyperbranched unsaturated polyoxyethylene ether P1 is prepared.

Embodiment 2

[0038] S1: Add 550g of pentaerythritol, 500g of methacrylic acid, 15g of p-toluenesulfonic acid and 1.8g of p-quinone to the reaction vessel, and mechanically stir for 4.5h at a reaction temperature of 90°C to complete the esterification reaction and obtain intermediate A2 ;

[0039] S2: Add 175g of the intermediate A2, 3000g of ethylene oxide, and 25g of potassium ethylate to the pressurized reaction device, and carry out anionic ring-opening polymerization at a reaction temperature of 165°C and a pressure of 0.20Mpa in the reaction vessel. The time is 5.5h, and the hyperbranched unsaturated polyoxyethylene ether P2 is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com