Patents

Literature

42results about How to "Improve early" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

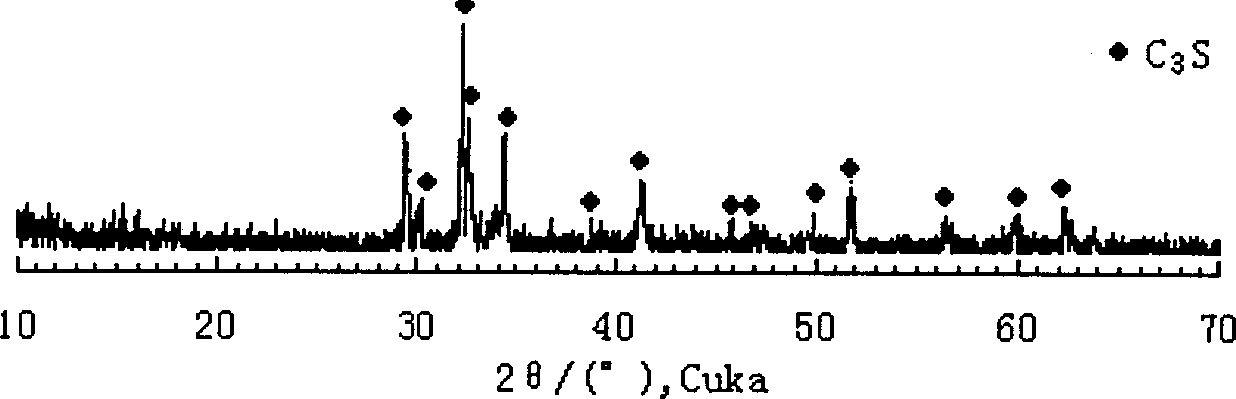

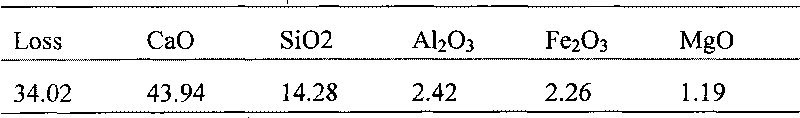

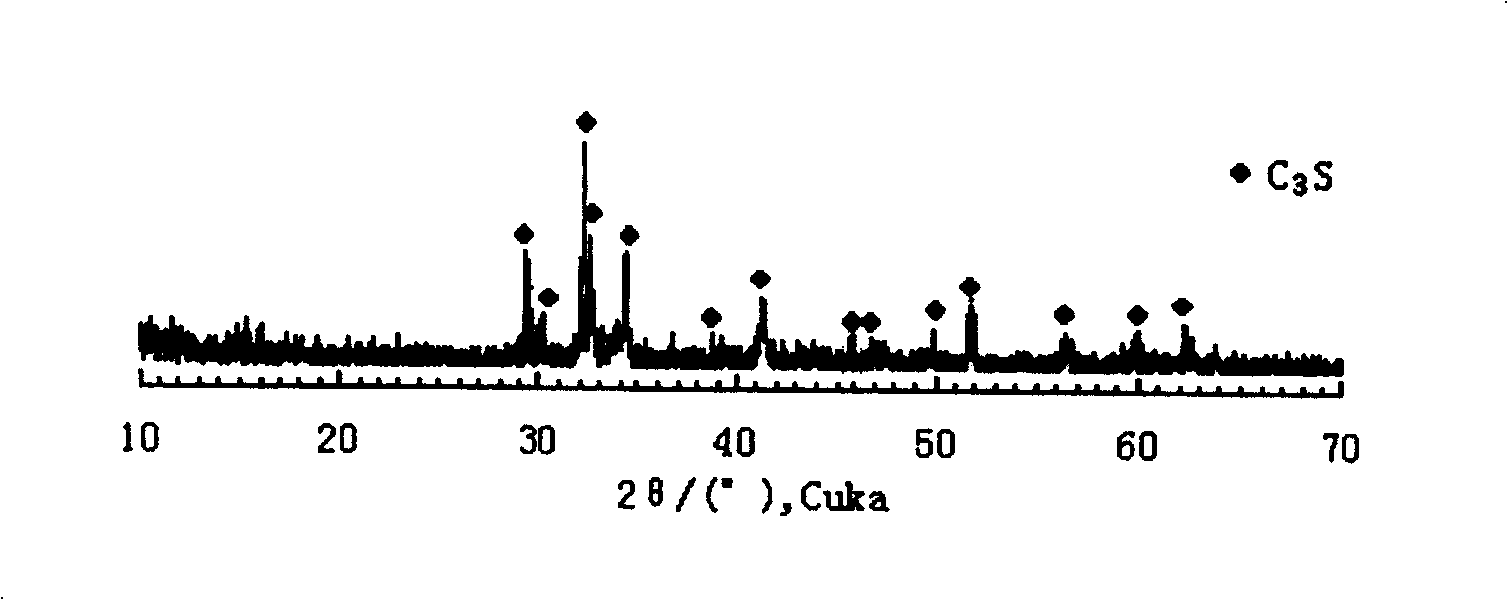

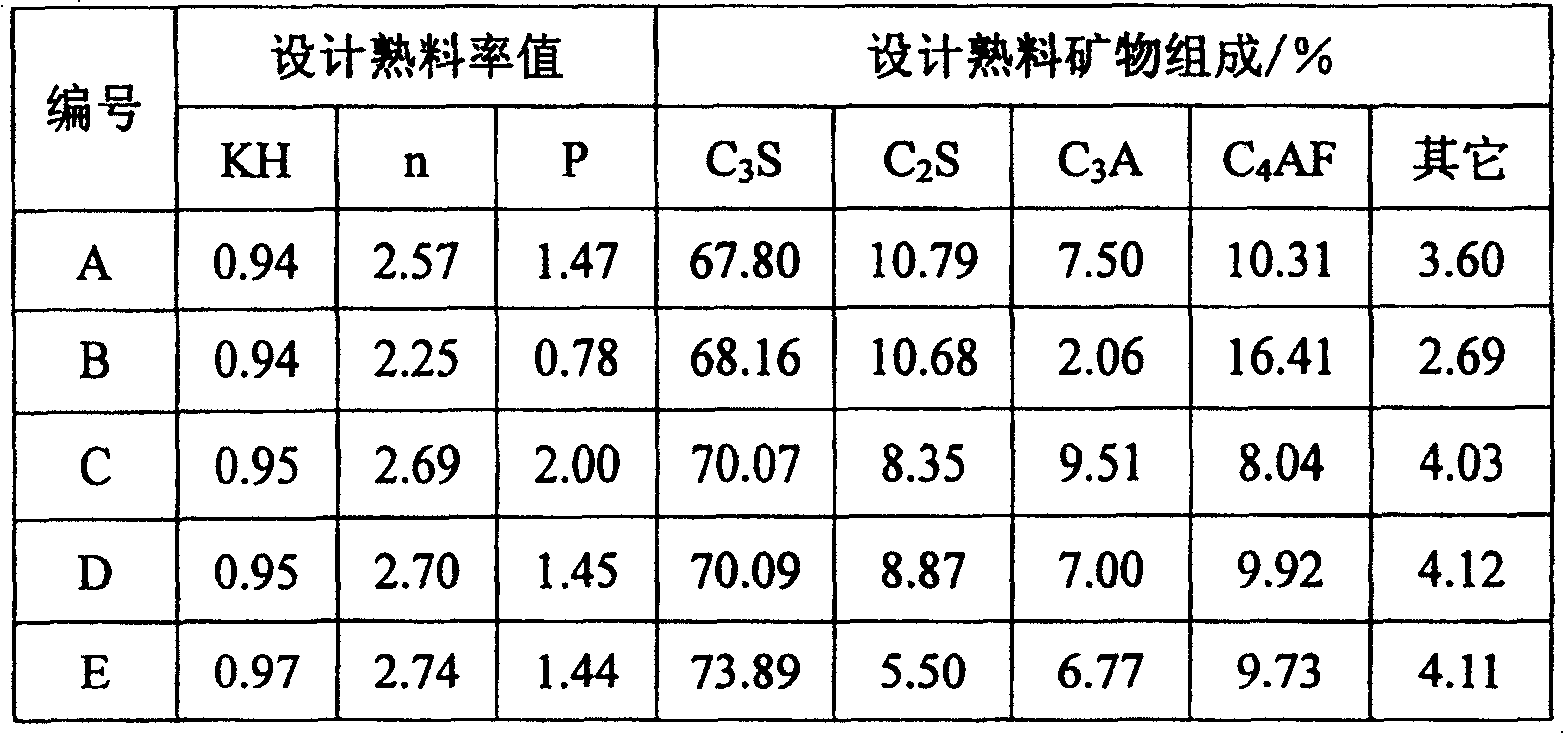

High alite silicate cement clinker and its preparation method

InactiveCN1785876APromote sustainable developmentRaw materials are cheap and easy to getPortland cementMaterials science

The present invention relates to a high-alite content Portland cement clinker prepared by using lead-zinc tails and shale instead of clay and its preparation method. Its composition includes (by wt%) 78-87% of limestone, 6-19% of lead-zinc tails, 2-11% of shale and 0-1.7% of iron ore. Said invention also provides the concrete steps of its preparation method.

Owner:NANJING TECH UNIV

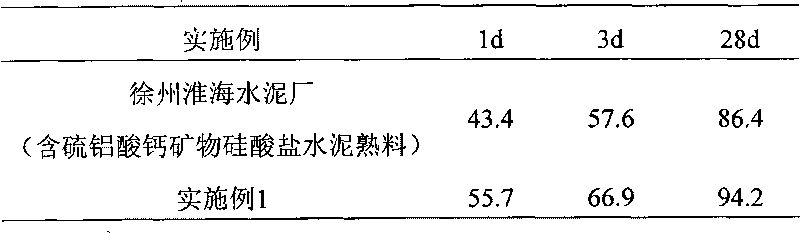

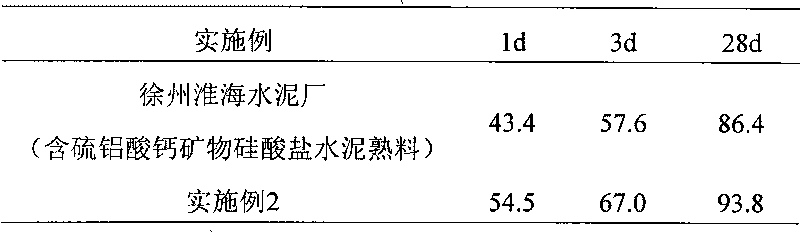

Secondary synthesis method of calcium sulfoaluminate minerals in metasilicate cement clinker

The invention relates to a secondary synthesis method of calcium sulfoaluminate minerals in a metasilicate cement clinker, comprising the following steps of: mixing a plaster in a metasilicate cement raw material and calcining; and carrying out thermal treatment on the metasilicate cement clinker containing the calcium sulfoaluminate minerals to enable the decomposed calcium sulfoaluminate minerals in the clinker is re-formed at a high-temperature state. Therefore, the invention improves the content of the calcium sulfoaluminate minerals in the clinker, sufficiently develops the superiority of the calcium sulfoaluminate minerals in the cement clinker, improves the early and long-term perofmrance of the cement clinker and increases the mixture quantity of a mixed material in the cement.

Owner:NANJING TECH UNIV

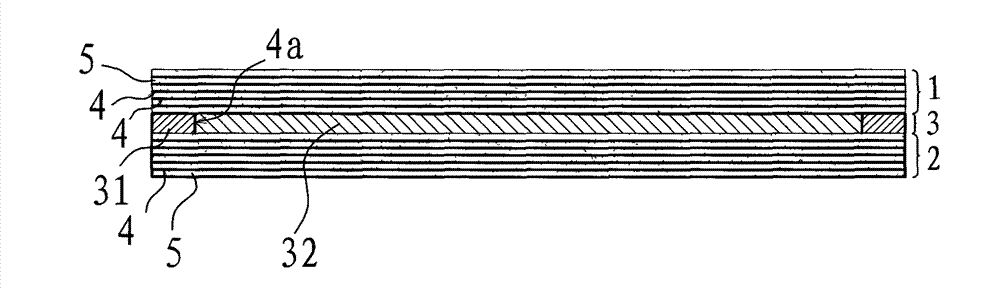

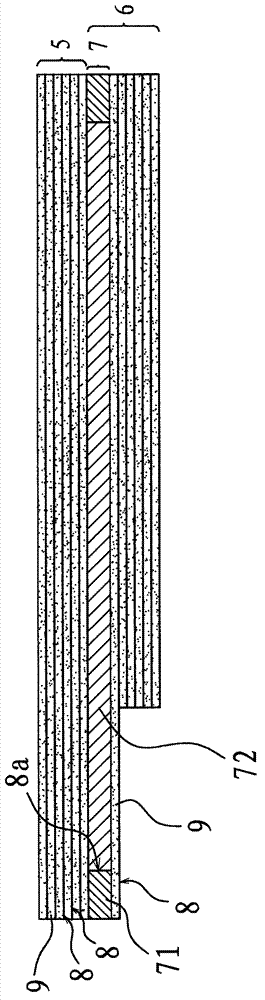

Novel inorganic fireproof door and manufacturing method thereof

ActiveCN102900334AReduce erosionImprove earlyFireproof doorsDoor leavesAging resistanceCement slurry

The invention provides a novel inorganic fireproof door and a manufacturing method thereof, belonging to the technical field of magnesite products and solving the problems of poor structural stability and easiness of frost and halogenation return phenomena of the traditional inorganic fireproof doors. The novel inorganic fireproof door comprises an upper plate layer, a lower plate layer and a middle sandwich layer, wherein the middle sandwich layer comprises a wood frame and a filler filled in a gap of the wood frame. The fireproof door can be manufactured through the following steps of: (1) preparing a magnesium chloride aqueous solution; (2) preparing magnesium-chloride cement slurry; (3) preparing a modifying agent; (4) preparing mixed slurry; (5) preparing the filler; (6) manufacturing the lower plate layer; (7) placing the wood frame; (8) rolling rims; (9) filling; (10) manufacturing the upper plate layer; (11) closing molds; (12) pressing dies; and (13) curing and then demolding. The fireproof door and the manufacturing method thereof which are disclosed by the invention can be used for saving a large quantity of natural wood and are beneficial to protecting the natural environment, and the product has the advantages of aging resistance, high firmness and difficult deformation.

Owner:浙江杭海新城控股集团有限公司

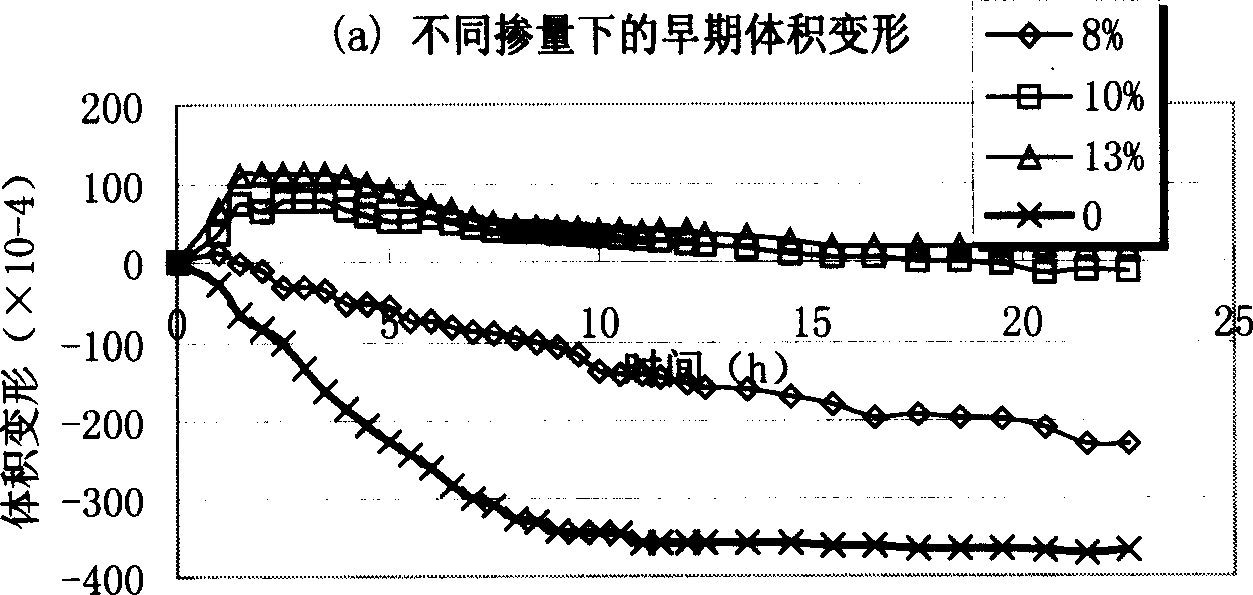

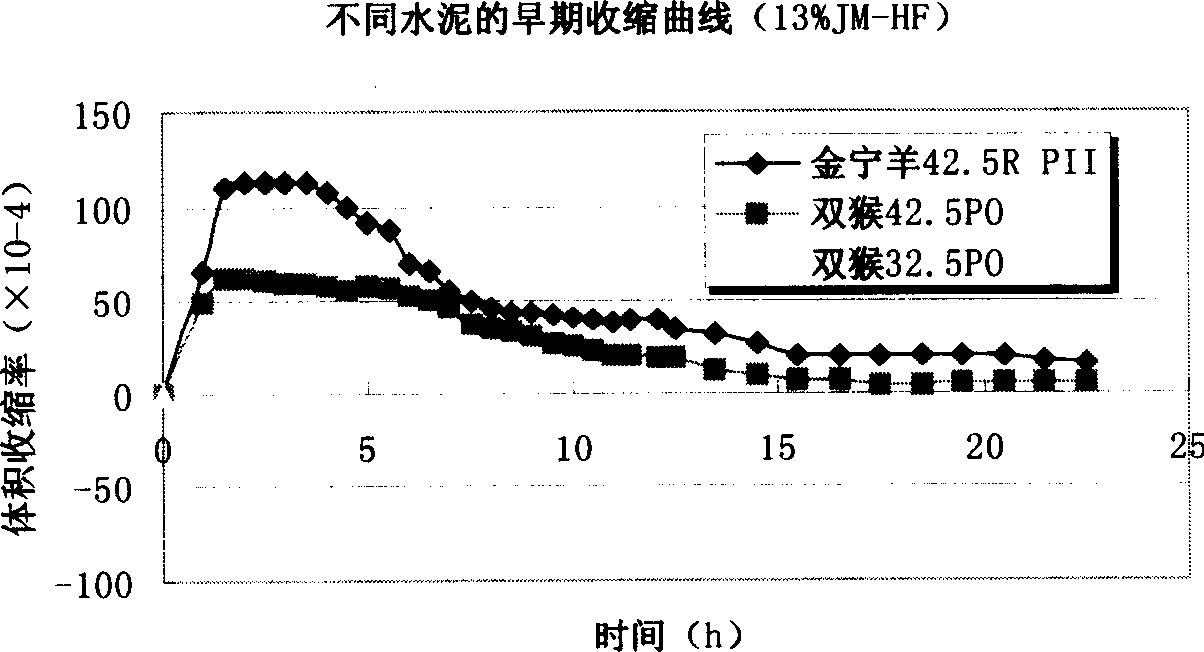

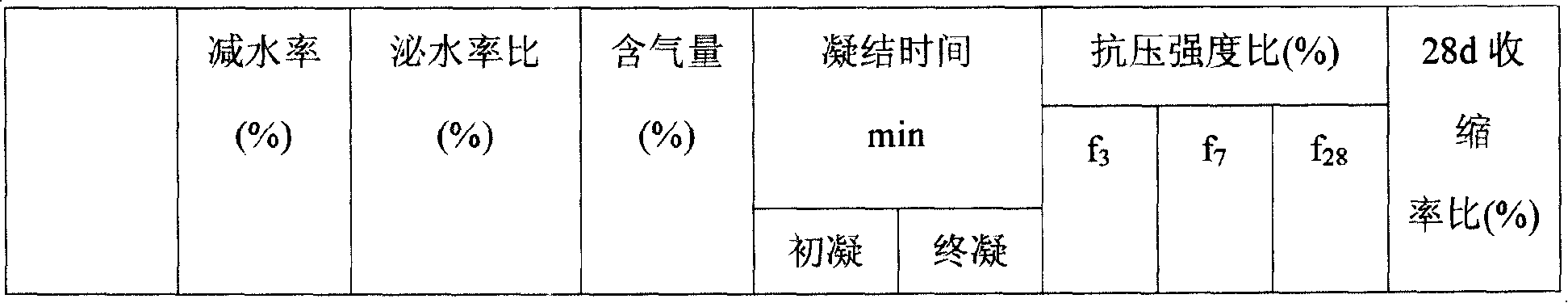

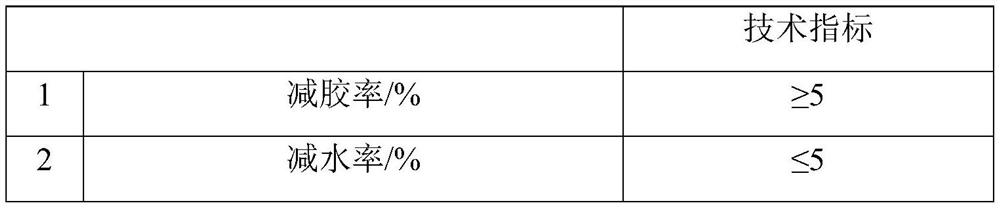

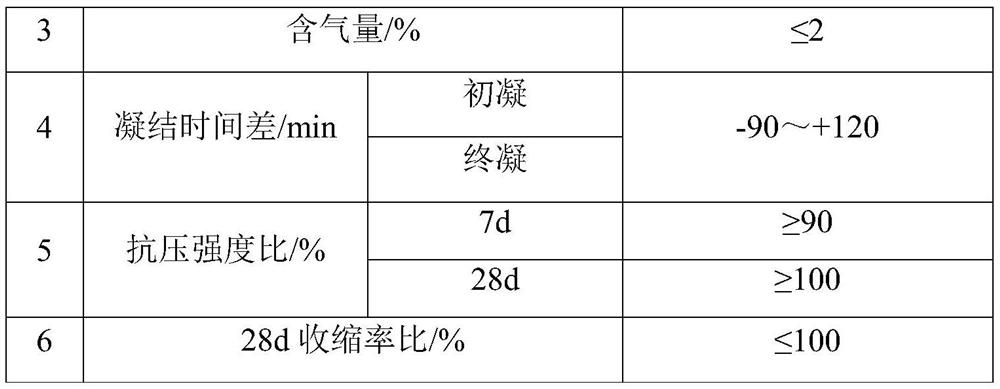

High performance grouting addition for concrete with post-tensioning binding prestressing force

The invention is a special additive for post-tensioned cohesive prestressed concrete structure, prepared of the following components in weight percent: phenyl sulfonate formaldehyde high-grade condensation compound 2-10%, aluminum powder 0.005-0.05%, anhydrite 50-70%, calcined kaoline 10-20%, kaoline 10-20%, linear high-molecular anion polysaccharide 0.05-1.5%, and triterpenoid saponin 0.05-0.1%. It has multiple functions of improving both the rheological property of grouting material and the bulk stability, and after doped, it is unnecessary to compound other materials to effectively improve the rheological property of grout, largely reducing seepage water and avoiding high separation and stratification, and it can effectively compensate shrinkage in plastic and hardening state, enhancing the bulk stability of the grout. The fluidity is basically not lost in 2 hours, the grout is full and dense in the pipeline and has strong adaptability to temperature, and the economic benefits of the technique are obvious. After doped in the cement, it adopts ordinary pressure grouting technique to be able to effectively ensure the grout basal body does not seep water after grouted and the bulk of the grout does not shrink and corrode steels.

Owner:JIANGSU SOBUTE NEW MATERIALS

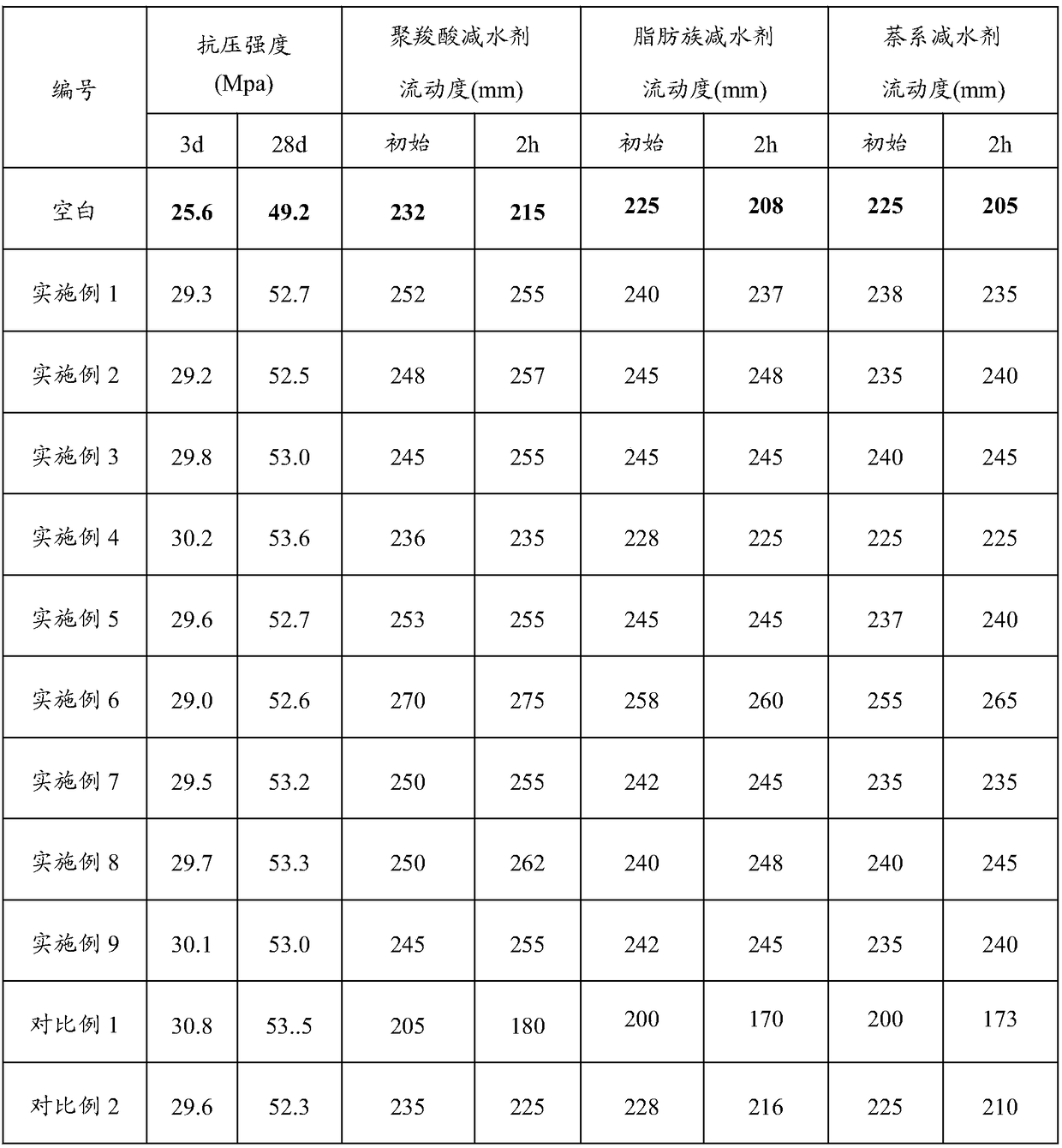

Chloride-free enhanced slump-retaining cement grinding aid and preparation method thereof

The invention provides a chloride-free enhanced slump-retaining cement grinding aid which comprises, by weight, 2-8 parts of diethanolisopropanolamine, 6-20 parts of triethanolamine, 10-25 parts of sodium formate, 0.5-2 parts of organic phosphonate retarders, 0.5-2 parts of polymeric dispersing agents, 2-4 parts of green syrup and the rest water. The grinding aid has the advantages that the diethanolisopropanolamine, the triethanolamine and the sodium formate are used in a matched manner, the early strength and the later strength of cement are remarkably improved, the organic phosphonate retarders and the polymeric dispersing agents are used in a matched manner, so that the cement has excellent slump-retaining performance, adaptability between the cement and a concrete additive is good, the early strength and the later strength of the cement are improved by 3-5MPa in actual use process, adaptability among the cement, a naphthalene water reducer, an aliphatic water reducer and a polycarboxylic acid water reducer is good, the cement paste fluidity cannot be lost within 2 hours, and the grinding aid does not contain any chloride ions and sulfate ions, is free from toxicity and corrosiveness, green and environmentally friendly and cannot damage to human bodies, buildings and the like.

Owner:UNIV OF JINAN

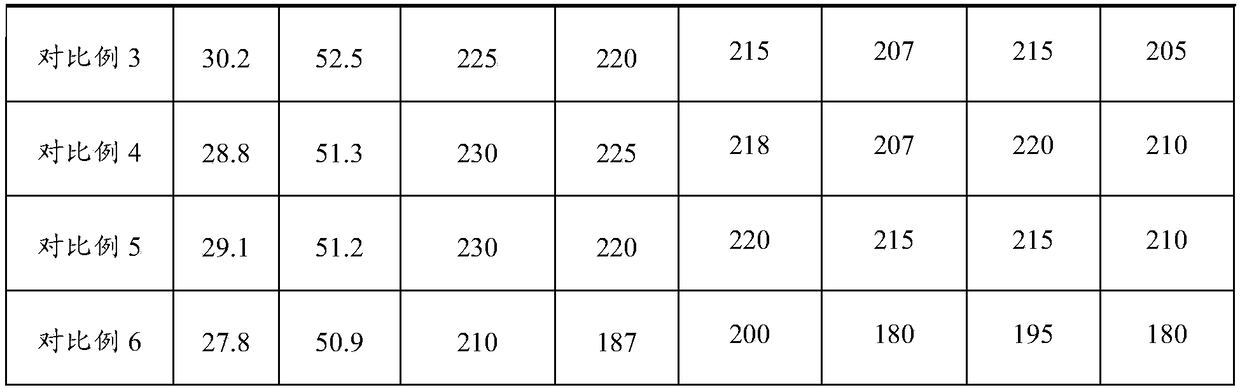

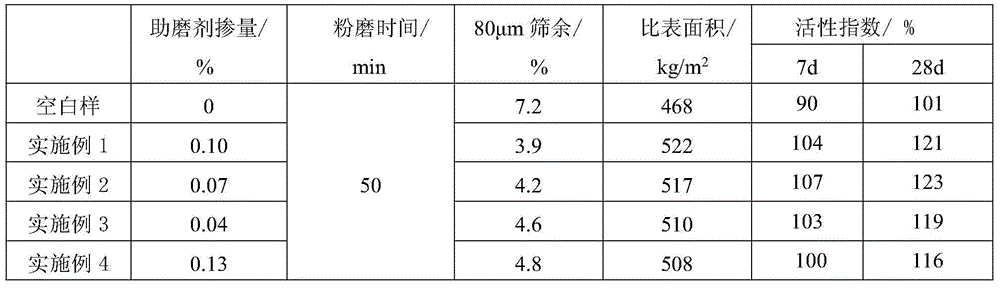

Granulated blast furnace slag liquid composite grinding aid

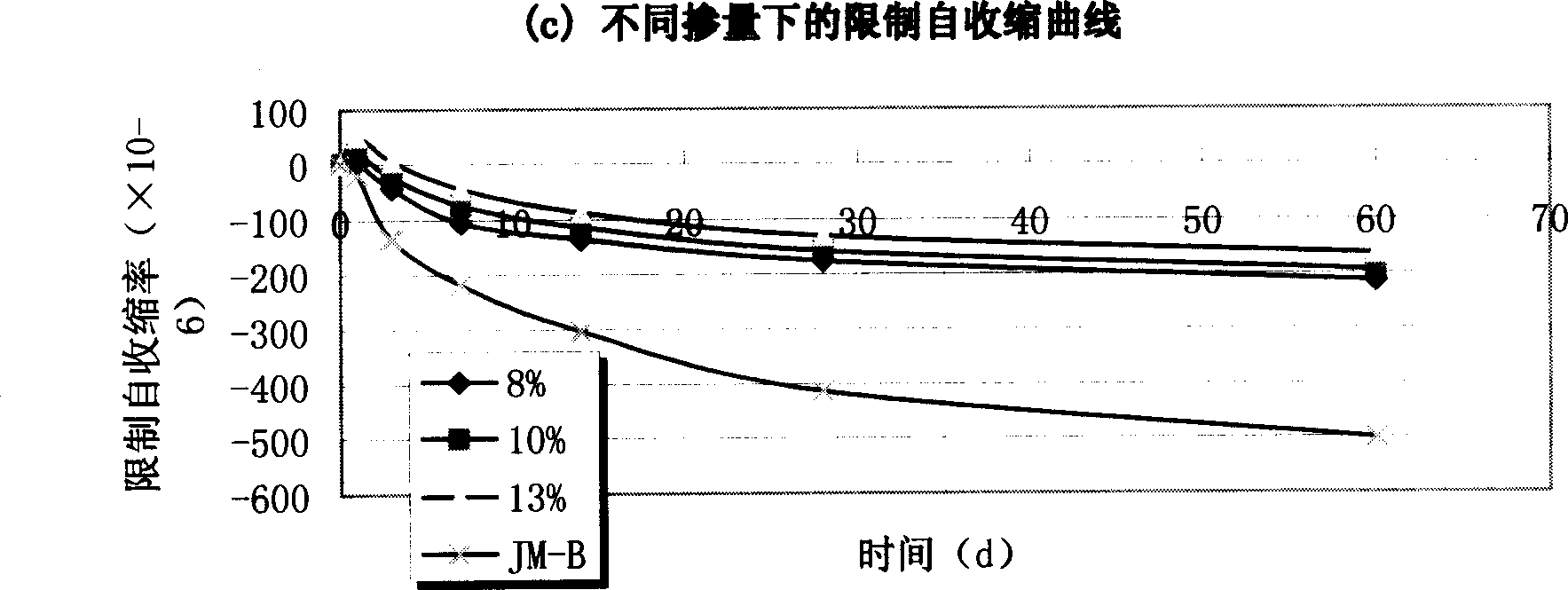

The invention relates to a granulated blast furnace slag liquid composite grinding aid and belongs to the technical field of granulated blast furnace slag grinding process admixtures. The granulated blast furnace slag liquid composite grinding aid is prepared from triethanolamine, mixed alcohol, propanetriol, molasses, potassium carbonate, sodium pyrophosphate, sodium sulfate and water; and the granulated blast furnace slag liquid composite grinding aid is formed by composition of the most common chemical raw materials and industrial wastes, and has the advantages of low toxicity, no volatilization, stable sources, sufficient sources and low cost. After the granulated blast furnace slag liquid composite grinding aid provided by the invention is added into a grinding machine, the distribution and appearance of slag powder particles can be improved, the adverse effects on quality of slag powder are avoided, the effects of saving power consumption and improving grinding efficiency can be realized, and the granulated blast furnace slag liquid composite grinding aid has the advantages of better increasing the yield and improving the quality of the slag powder. Under the situation of same grinding time, the specific surface area of the slag powder is effectively improved, the screening residues are reduced, and the activity indexes of the slag powder in the early stage (7d) and the late stage (28d) are significantly improved.

Owner:SHENYANG JIANZHU UNIVERSITY

High-strength high-temperature-resistant flame-retardant concrete viscosity modifier as well as preparation method and application thereof

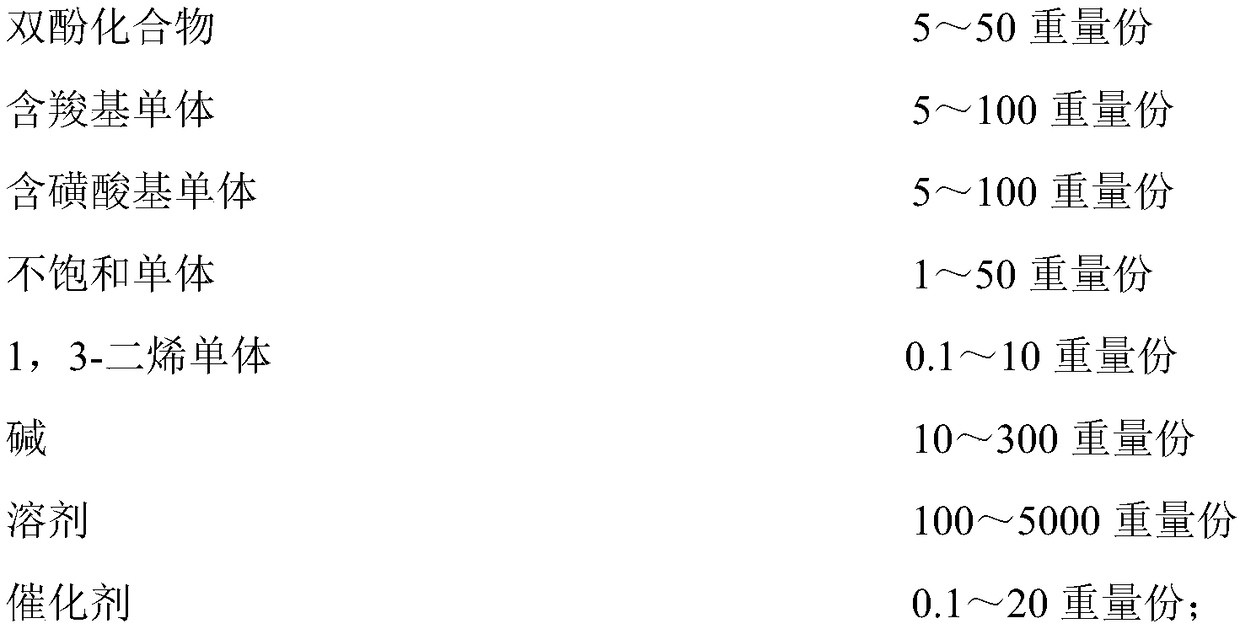

The invention belongs to the field of concrete admixtures and relates to a concrete viscosity modifier and preparation thereof. The concrete viscosity modifier provided by the invention comprises a polymer containing double bonds and a double-bond photocatalyst, wherein the polymer containing double bonds is prepared from the following raw material components in parts by weight: 5-50 parts of bisphenol compounds, 5-100 parts of carboxyl-containing monomers, 5-100 parts of monomers containing sulfonic groups, 1-50 parts of unsaturated monomers, 0.1-10 parts of 1,3-diene monomer, 10-300 parts ofalkali, 100-5000 parts of a solvent and 0.1-20 parts of a catalyst, wherein the total addition amount of the carboxyl-containing monomers and the monomers containing sulfonic groups is not less than50 parts by weight. The prepared concrete viscosity modifier has the advantages of being soluble, easy to construct and excellent in cohesiveness; and when the concrete viscosity modifier is added into cement and other materials to prepare concrete, the obtained concrete has high strength and aging resistance.

Owner:SICHUAN UNIV

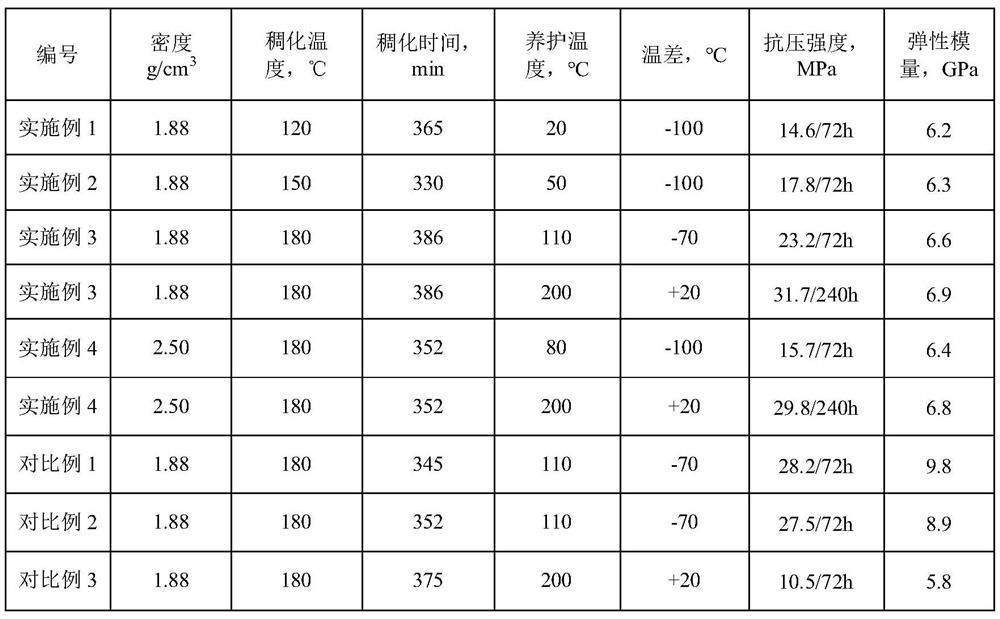

High-temperature-resistant large-temperature-difference elastic-tough cement paste system and preparation method thereof

InactiveCN112479635AImprove mechanical propertiesImprove sealingDrilling compositionThermodynamicsEngineering

The invention provides a high-temperature-resistant large-temperature-difference elastic-tough cement paste system, which comprises the following components in parts by weight: 100 parts of G-grade oil well cement, 2-10 parts of retarder, 1-8 parts of fluid loss agent, 2-15 parts of elastic material, 0.05-3 parts of toughening material, 0-75 parts of strength stabilizing material, 2-8 parts of expanding agent, 0.5-4 parts of early strength agent, 0-300 parts of a weighting agent, 0-10 parts of an interfacial cementation enhancer, 0.5-3 parts of a defoaming agent and 35-200 parts of water. According to the invention, the requirement for one-time sealing of an ultra-long sealing section of an ultra-deep high-temperature high-pressure oil-gas well can be met, the overall sealing performance of a cement sheath of the ultra-long sealing section is improved, and a wellhead is prevented from being under pressure.

Owner:CHINA PETROLEUM & CHEM CORP +1

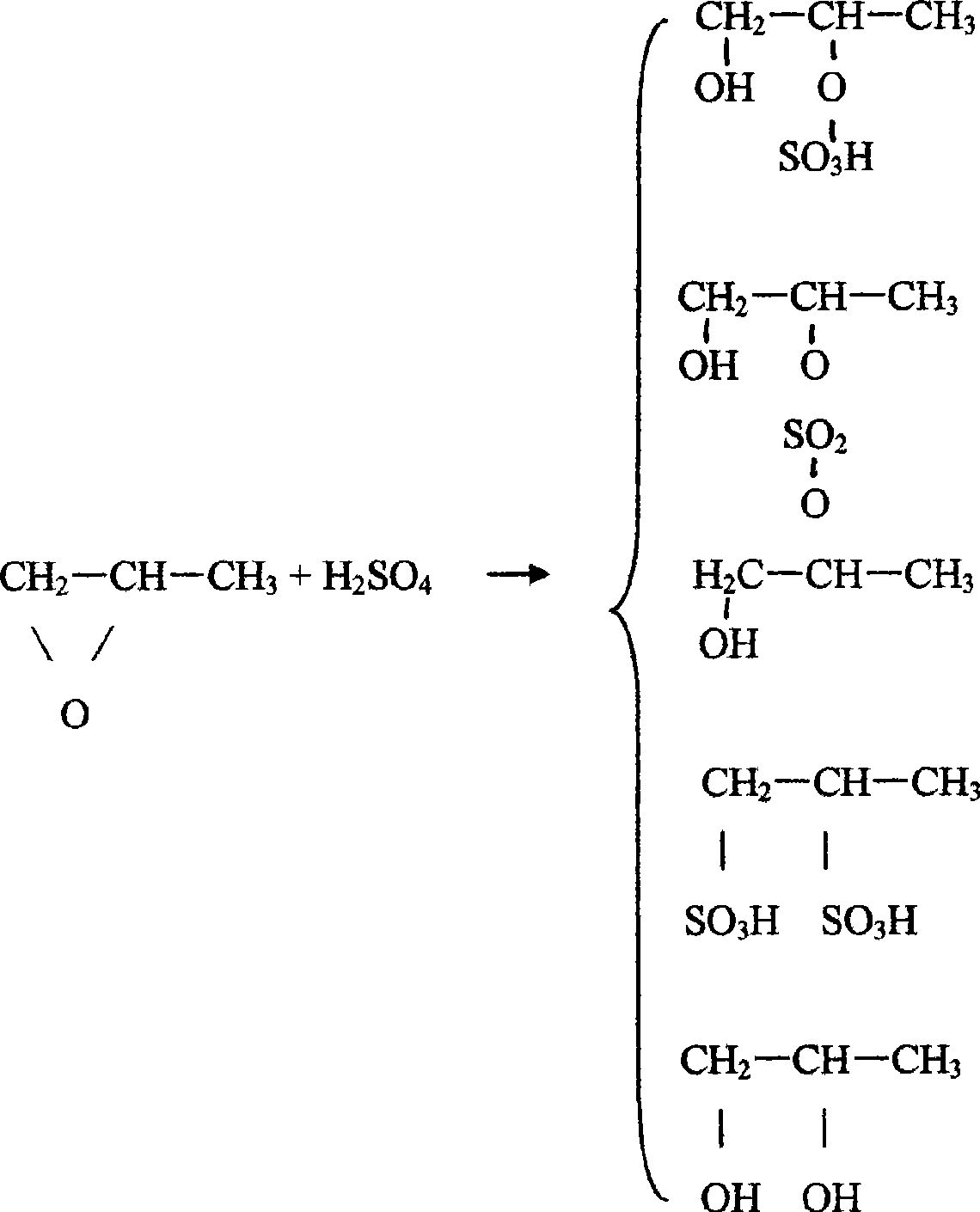

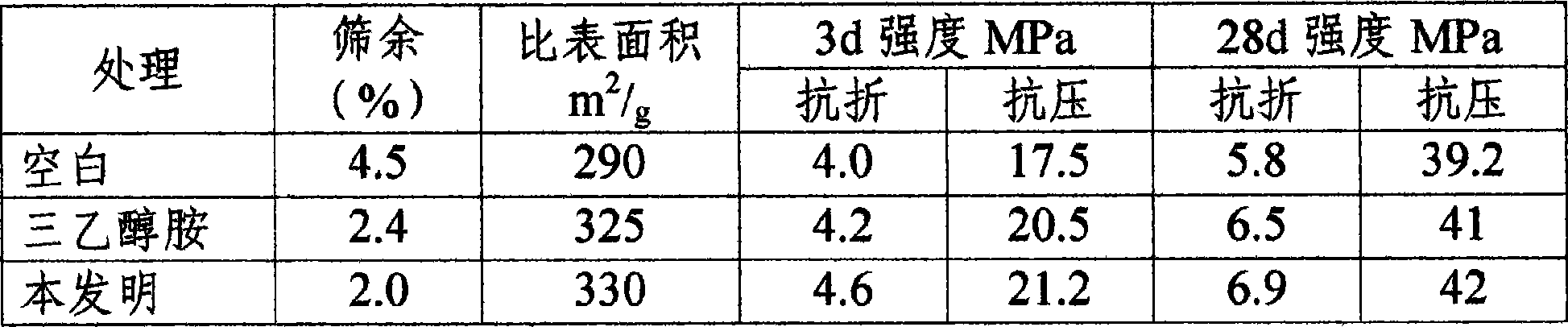

Alcohol ester cement grinding aid and method for producing the same

InactiveCN101428984AImprove performanceReduction of sieve residueCement productionAlcoholPolymer science

The invention discloses an alcohol ester cement grinding aid and a preparation method thereof, which belongs to a cement process admixture and a preparation method thereof. The cement grinding aid is a reaction product of epoxy propane with the concentration of 1 mol and H2SO4 with the concentration of between 1.5 and 2.5 mol under appropriate pressure and temperature conditions. The alcohol ester cement grinding aid has steady performance, adapts to use under the state of higher temperature of a grinder, is favorable for improving grinding efficiency, reduces the weight of screen residue of cement after the use compared with the prior grinding aid, improves the specific surface area, obviously improves early and final set strengths, reduces use cost, contributes to energy conservation and consumption reduction, and is suitable to be promoted and used in large and middle cement production enterprises.

Owner:山东华科节能科技有限公司 +2

Polycarboxylate water reducing agent for concrete

The invention discloses a polycarboxylate water reducing agent for concrete. The polycarboxylate water reducing agent is characterized by mixing the following raw materials in parts by weight: 40-50 parts of a high-property polycarboxylate water reducing agent, 5-7 parts of borax, 1-2 parts of triethanolamine, 1-2 parts of magnesium borate, 2-3 parts of cyanuric acid triene propyl ester, 1-2 parts of calcium chloride, 1-2 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 0.3-1 part of dimethyl sulfoxide, 2-4 parts of sulfamic acid and 0.8-2 parts of thickening agent. The water reducing agent disclosed by the invention has a good water reducing effect and remarkable delayed coagulation action, and is capable of improving strength of concrete at early stage and different stages and capable of improving the mechanical properties of the concrete, reducing surface shrinkage and crack and improving anti-permeability and durability of the concrete.

Owner:ANHUI FUNAN LVYUAN CHEM

Curing liquid applicable to calcium phosphate-based bone cement as well as preparation method and application of curing liquid

ActiveCN109125804AImprove curing effectImprove early strengthTissue regenerationProsthesisCalcium biphosphatePhosphate

The invention provides curing liquid applicable to calcium phosphate-based bone cement as well as a preparation method and application of the curing liquid. The curing liquid applicable to the calciumphosphate-based bone cement comprises the following components by mass percentage: 2-9% of citric acid, 1-6% of PVP, 5-25% of phosphate and 1-5% of PVA. The invention creatively utilizes the abilityof phosphate to promote early hydration products; an acidic environment is provided by citric acid; PVP has a molecular mediated effect on calcium phosphate deposition; PVA has a water-retaining function; through the synergistic effect of citric acid, phosphate, PVP and PVA, the mechanical properties of calcium phosphate bone cement such as curing ability, early strength, late strength and the like are significantly improved, the medical value of calcium phosphate bone cement is expanded, at the same time, calcium phosphate bone cement is closer to clinical use standards, and calcium phosphatebone cement has broad application prospects.

Owner:JINAN UNIVERSITY

Door pocket manufacturing die with adjustable size and manufacturing method of door pocket

The invention provides a door pocket manufacturing die with an adjustable size and a manufacturing method of a door pocket, belonging to the technical field of manufacturing the door pocket. The problems that the conventional door pocket of poor is poor in structural stability and the die size is single can be solved. The door pocket manufacturing die comprises an inner frame and an outer frame; the inner frame is formed by splicing a plurality of independent rod bodies, and enclose to form an injection molding frame body; a seam allowance die is arranged inside the injection molding frame body and is tightly adhered to the inner side wall of the injection molding frame body. The method for manufacturing a door pocket by using the die comprises the steps of: firstly, preparing a magnesium chloride solution, magnesium chloride cement slurry, a modifying agent, mixed slurry and a filler; manufacturing a lower panel layer and an upper panel layer by using the die; placing a wooden framework, rolling edges and filling, then closing and pressing the upper panel layer and the lower panel layer; curing and maintaining and then conducting de-molding so as to obtain the frame; repeating the steps to obtain the residual frames; and finally, splicing and connecting the frames. The door pocket manufacturing die with the adjustable size has a simple structure, and can be used for manufacturing the frames with different shapes and sizes.

Owner:浙江杭海新城控股集团有限公司

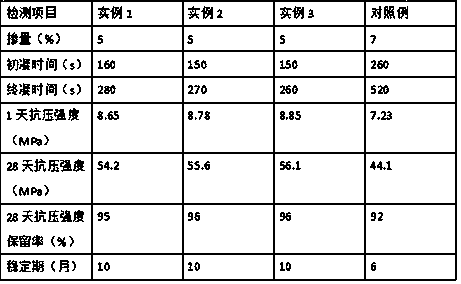

Preparation method of alkali-free accelerator

The invention relates to a preparation method of an alkali-free accelerator, and belongs to the technical field of cement additives. The preparation method comprises the following steps: heating buffalo milk with high milk fat content, which is used as a raw material, mixing the heated buffalo milk with ginger juice and coconut juice, enabling ginger protease in the ginger juice to react with caseins in the milk to form protein-enriched jello within a short time under the synergistic effect of the coconut juice, then smashing the jello, placing the jello into a high-temperature and high-humidity environment for natural mildewing to obtain a mildewy object, continuously fermenting the mildewy object in a sealed manner, mixing a fermentation product with an aluminum sulfate solution and lemon juice for ultrasonic oscillating reaction, and finally preparing the alkali-free accelerator. The accelerator prepared by the preparation method disclosed by the invention contains no alkali, is lowin loss of long-term strength of hardened cement paste and extremely high in stability, and has a wide application prospect.

Owner:CHANGZHOU LANXU CHEM CO LTD

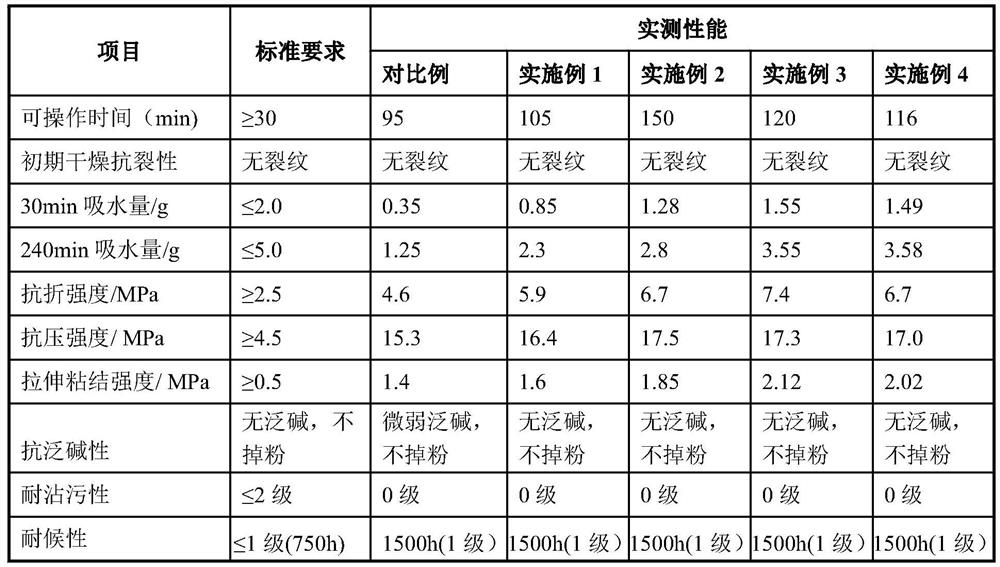

High-performance facing mortar and preparation method thereof

The invention belongs to the technical field of building materials, and provides high-performance facing mortar and a preparation method thereof. The high-performance facing mortar is prepared from white Portland cement, sulphoaluminate cement, superfine gypsum powder, calcium sulfate whiskers, superfine slag powder, high-activity metakaolin, modified styrene-acrylic emulsion, terpene emulsion, anair entraining agent, an antifoaming agent, a wetting agent, a water repellent, a leveling agent, an inorganic pigment and quartz sand. The preparation method comprises the following steps: mixing white Portland cement, sulphoaluminate cement, ultrafine gypsum powder, calcium sulfate whiskers, superfine slag powder and high-activity metakaolin, then adding other raw materials, conducting mixing,adding water accounting for 20-25% of the total weight of the high-performance facing mortar, and conducting uniform stirring before usage. The high-performance facing mortar provided by the inventionhas good physical and mechanical properties and decorative properties; in particular, the frosting problem of the facing mortar is practically solved, the facing mortar is endowed with excellent stain resistance, and the high-performance facing mortar can meet the use requirements for adjustable setting time and operable time and improves construction efficiency.

Owner:TONGJI UNIV

Ultra-high temperature elasticity and toughness agent for oil and gas well cementing and composition and application thereof

ActiveCN110257030AImprove brittlenessImprove toughnessSolid waste managementDrilling compositionNano al2o3Basalt fiber

The invention relates to an ultra-high temperature elasticity and toughness agent for oil and gas well cementing and a composition thereof. The ultra-high temperature elasticity and toughness agent comprises the following components which are mixed in a weight ratio: 60%-90% of polytetrafluoroethylene rubber powder, 5%-20% of basalt fibers, and 5%-20% of nano aluminum oxide fibers. The use temperature of the ultra-high temperature elasticity and toughness agent of the invention can reach 265 DEG C. When the addition amount of the agent is 2.5%-5% of the dry powder weight of oil well cement, the ultra-high temperature elasticity and toughness agent can significantly reduce the elastic modulus of cement stone, enhance the compressive strength of the cement stone and significantly improve the impact resistance of the cement stone, which effectively solves the problems of obvious hard brittleness, poor strain resistance, easy damage of the cement stone and the like of the cement stone for ultra-high temperature oil and gas well cementing and is beneficial to the insurance of the integrity of a wellbore of an ultra-high temperature oil and gas well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

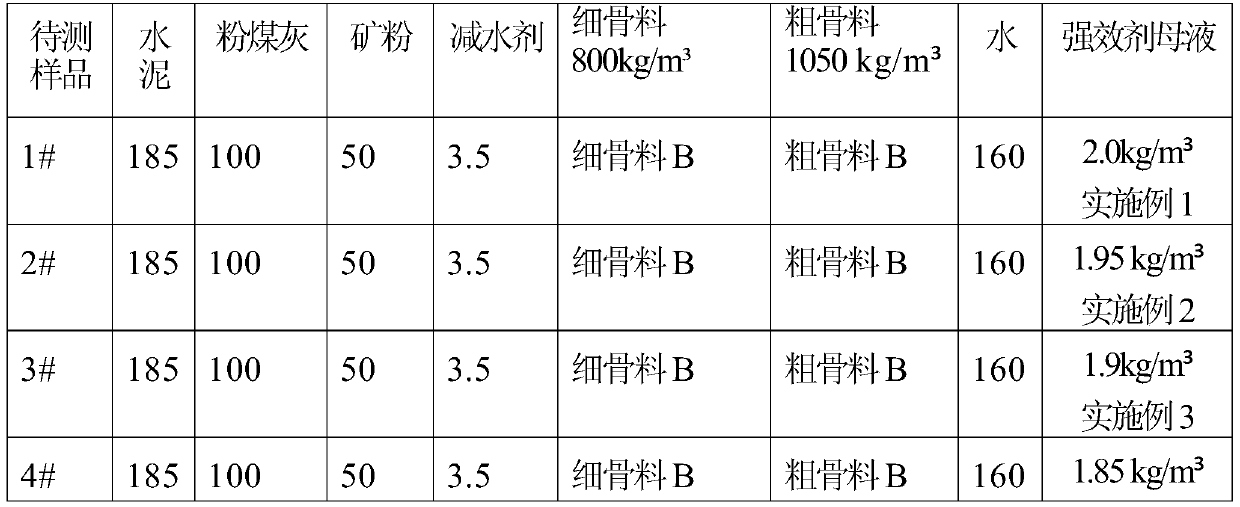

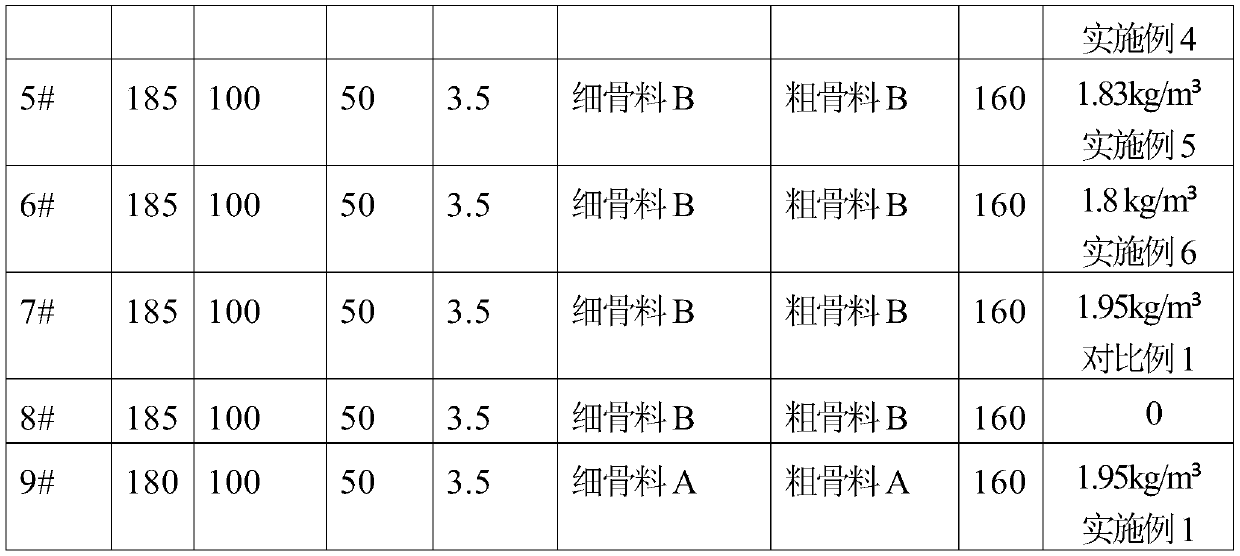

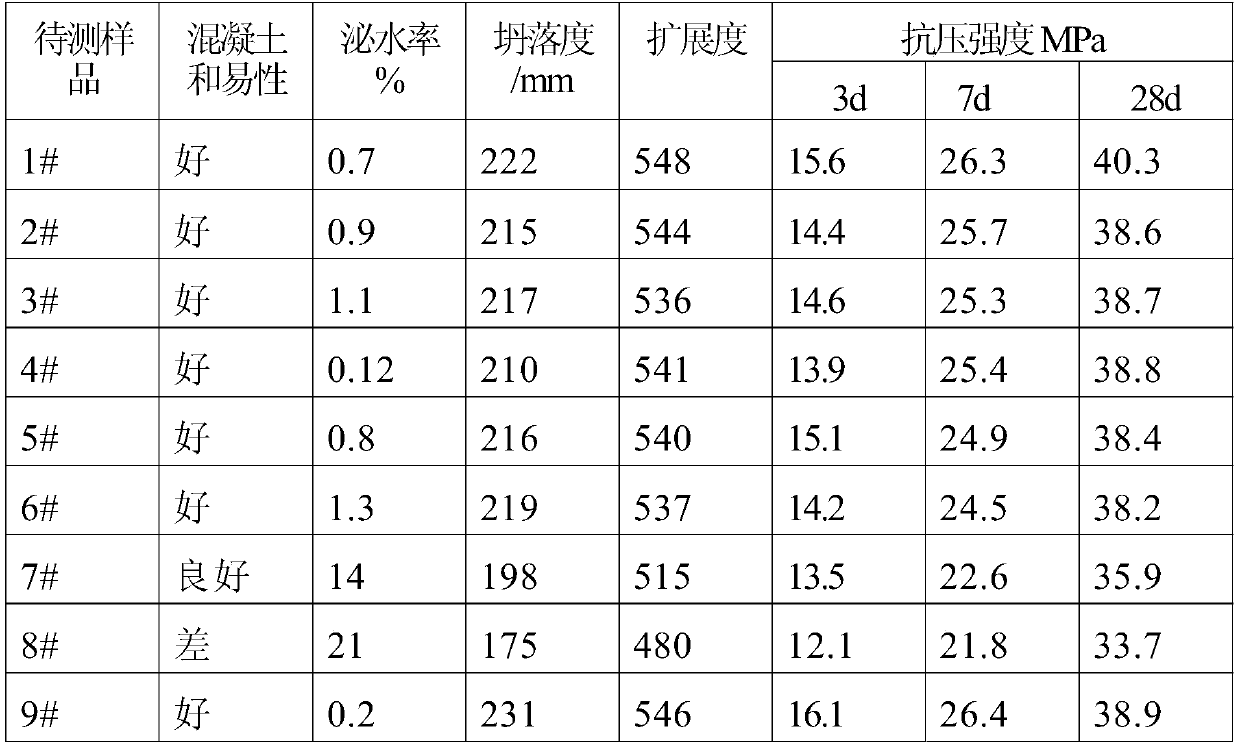

Intensifier suitable for concrete prepared from manufactured sand and preparation method of mother solution thereof

The invention relates to an intensifier suitable for concrete prepared from manufactured sand. The intensifier is prepared from the following components in parts by weight: 1 to 8 parts of TPEG, 8 to20 parts of triethanolamine, 4 to 15 parts of gellan gum, 3 to 10 parts of polyisoprene rubber latex, 3 to 10 parts of modified starch, 6 to 20 parts of sodium lignin sulfonate and 1 to 8 parts of filler. Compared with the prior art, the concrete intensifier has the advantages that the dosage of the modified starch and water is adjusted, and a proper amount of gellan gum and polyisoprene rubber latex is added, so that the thickening and water retention functions of the product on the concrete are improved on the basis of an original technique, the bad effects of multiple edges and corners andhigh mud and powder content of the manufactured sand on the concrete workability are improved, the sensitivity to use of water reducing agents such as polycarboxylic acid and the like in the manufactured sand concrete is reduced, the workability of the manufactured sand concrete is obviously improved, the bleeding and segregation phenomena are relieved, the homogeneity of the manufactured sand concrete is increased, and the strength dispersion of a solidification body of the manufactured sand concrete is reduced.

Owner:广东基业长青建筑科技有限公司

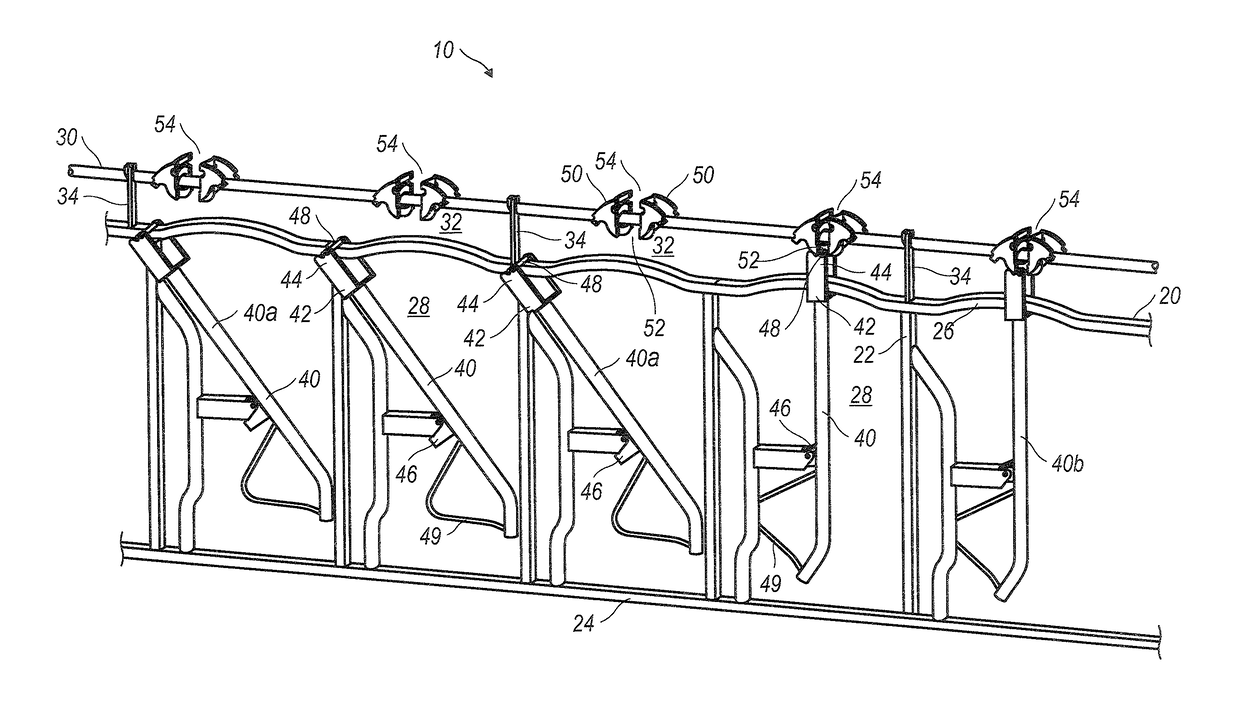

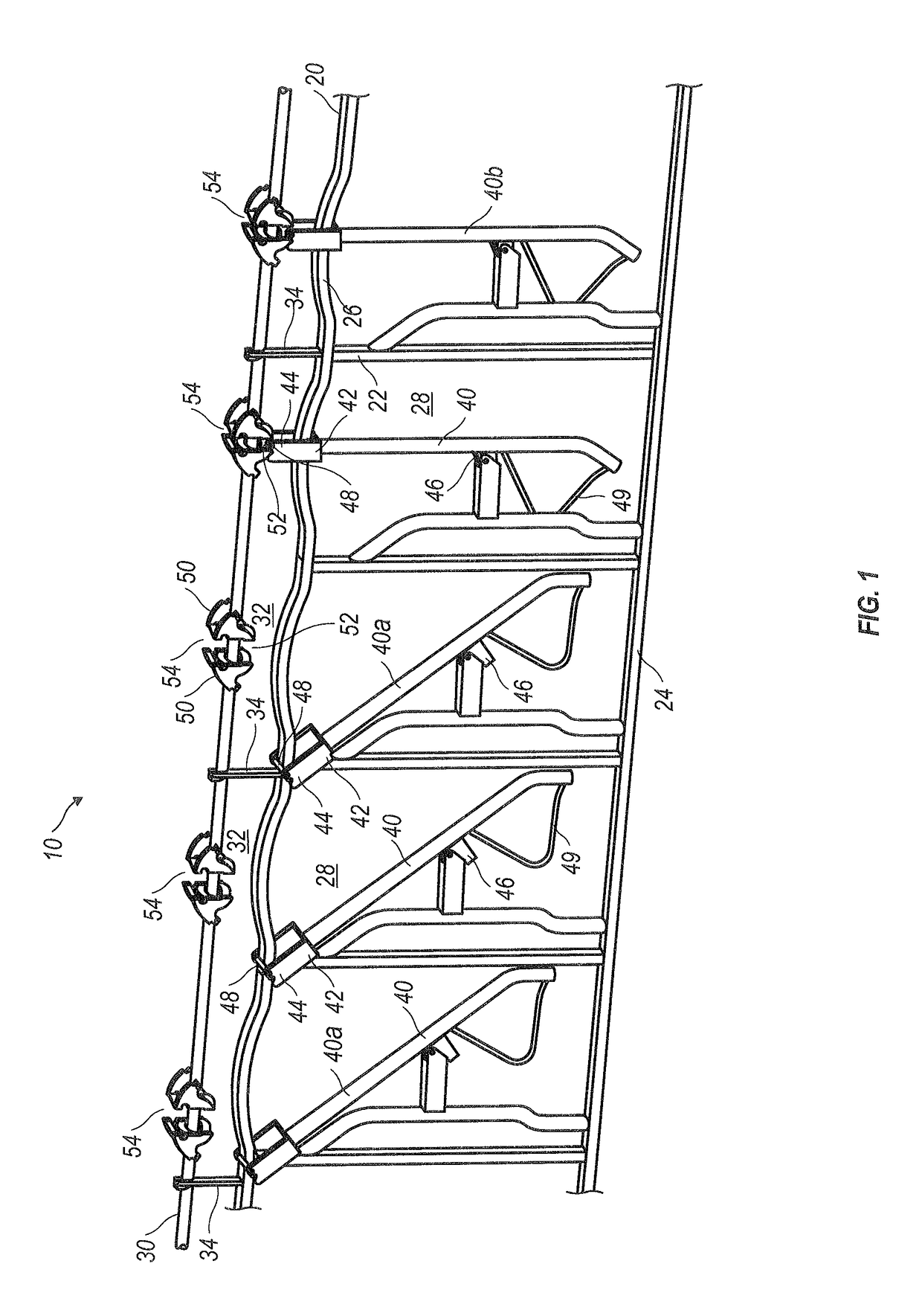

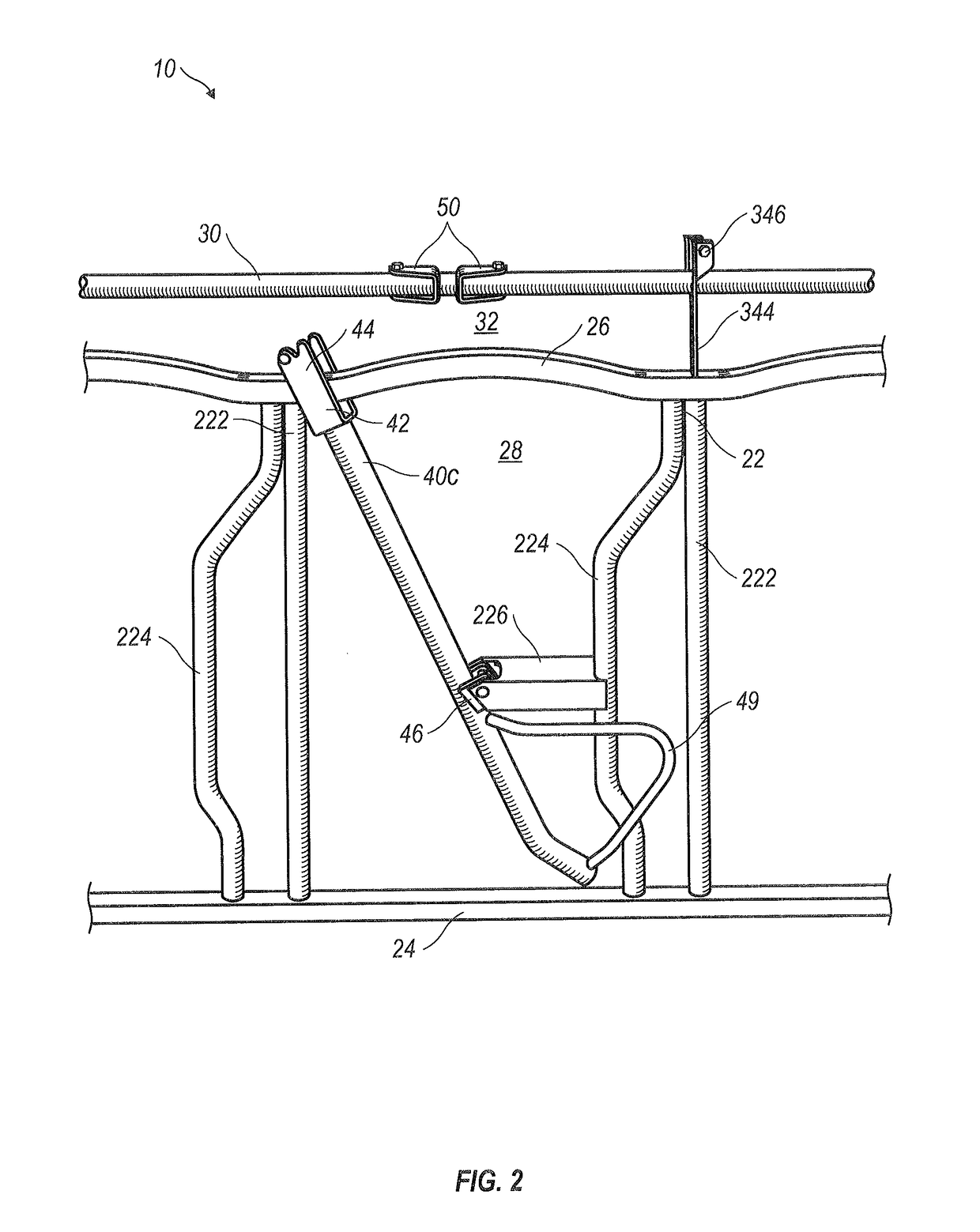

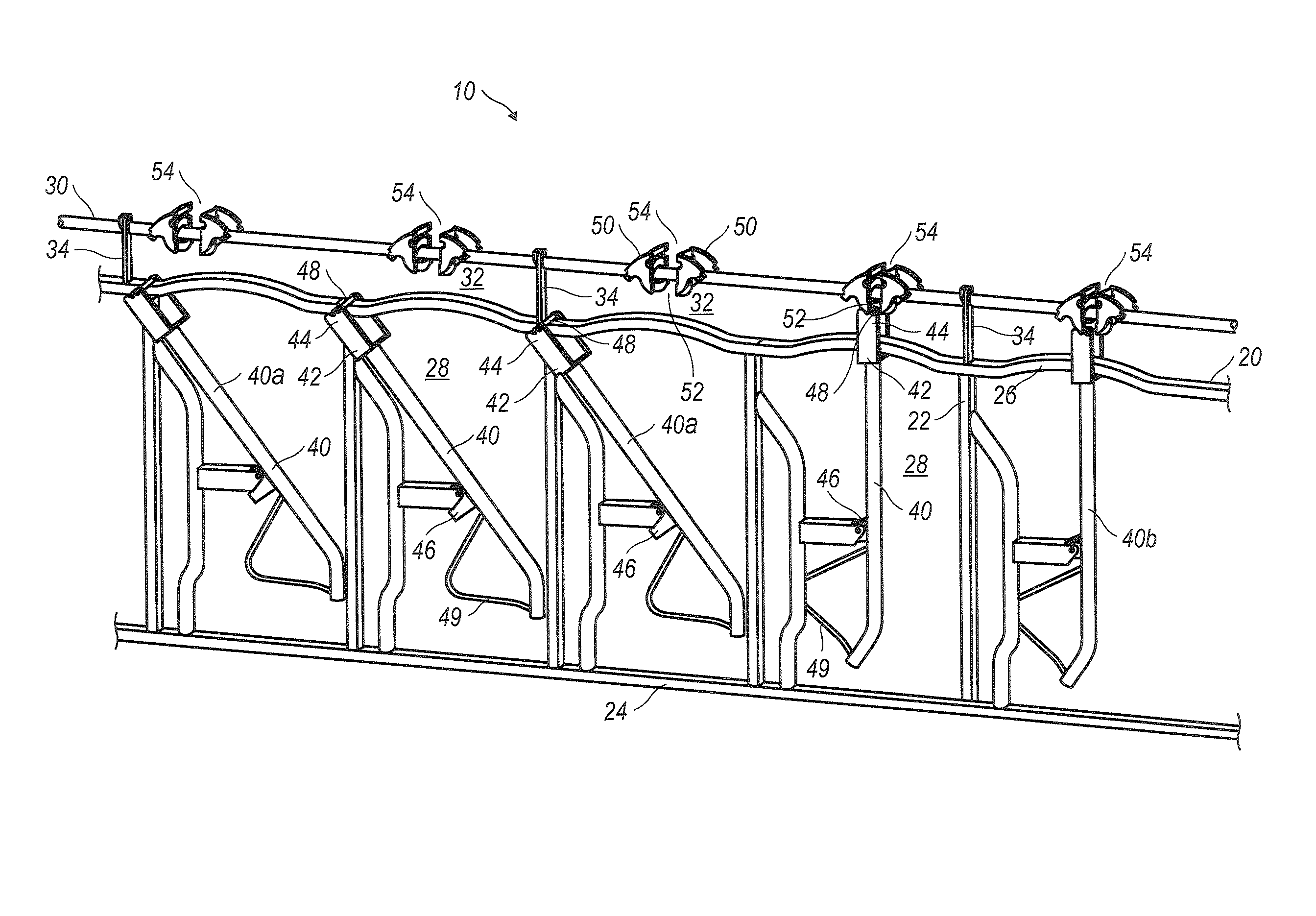

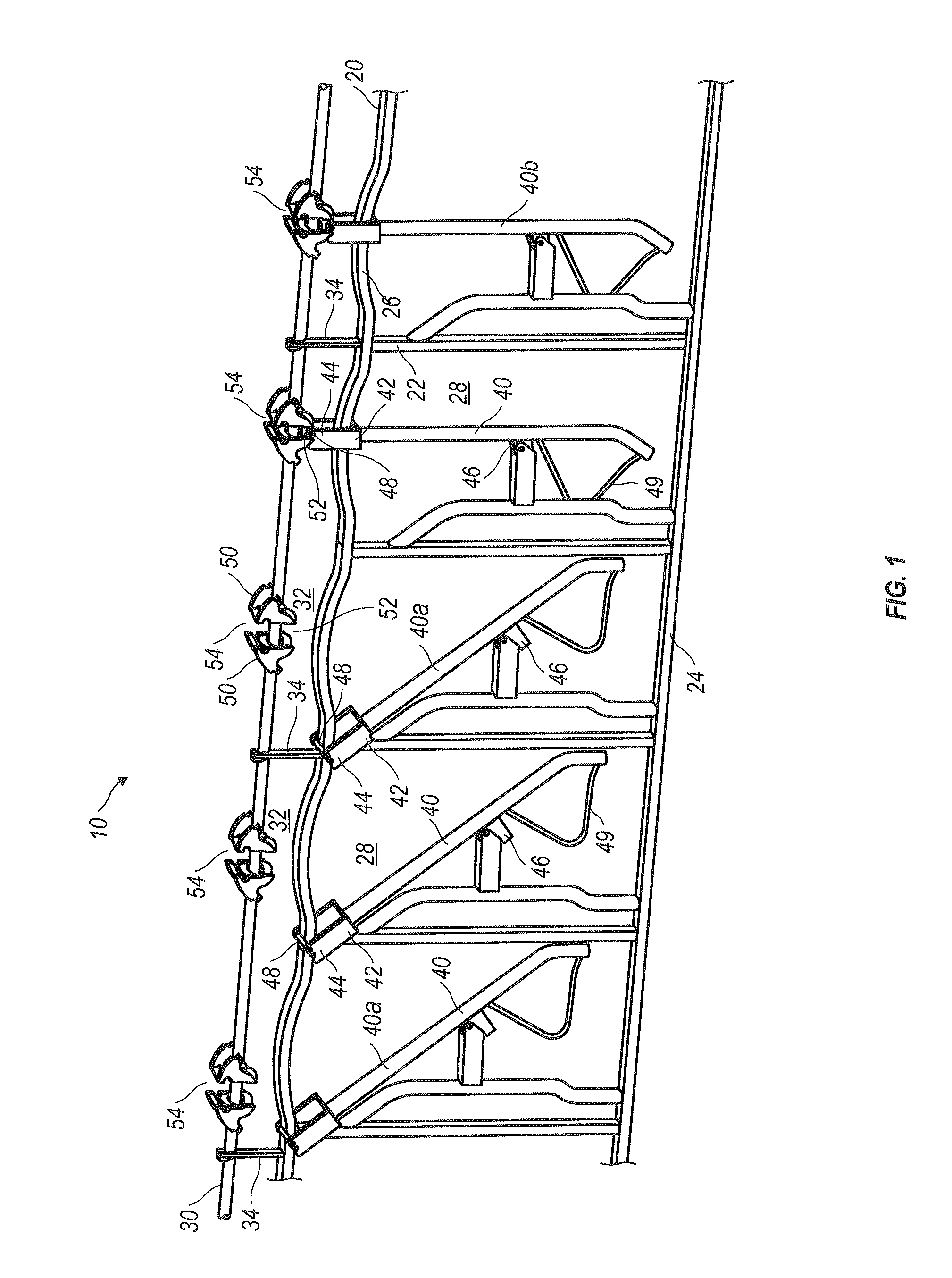

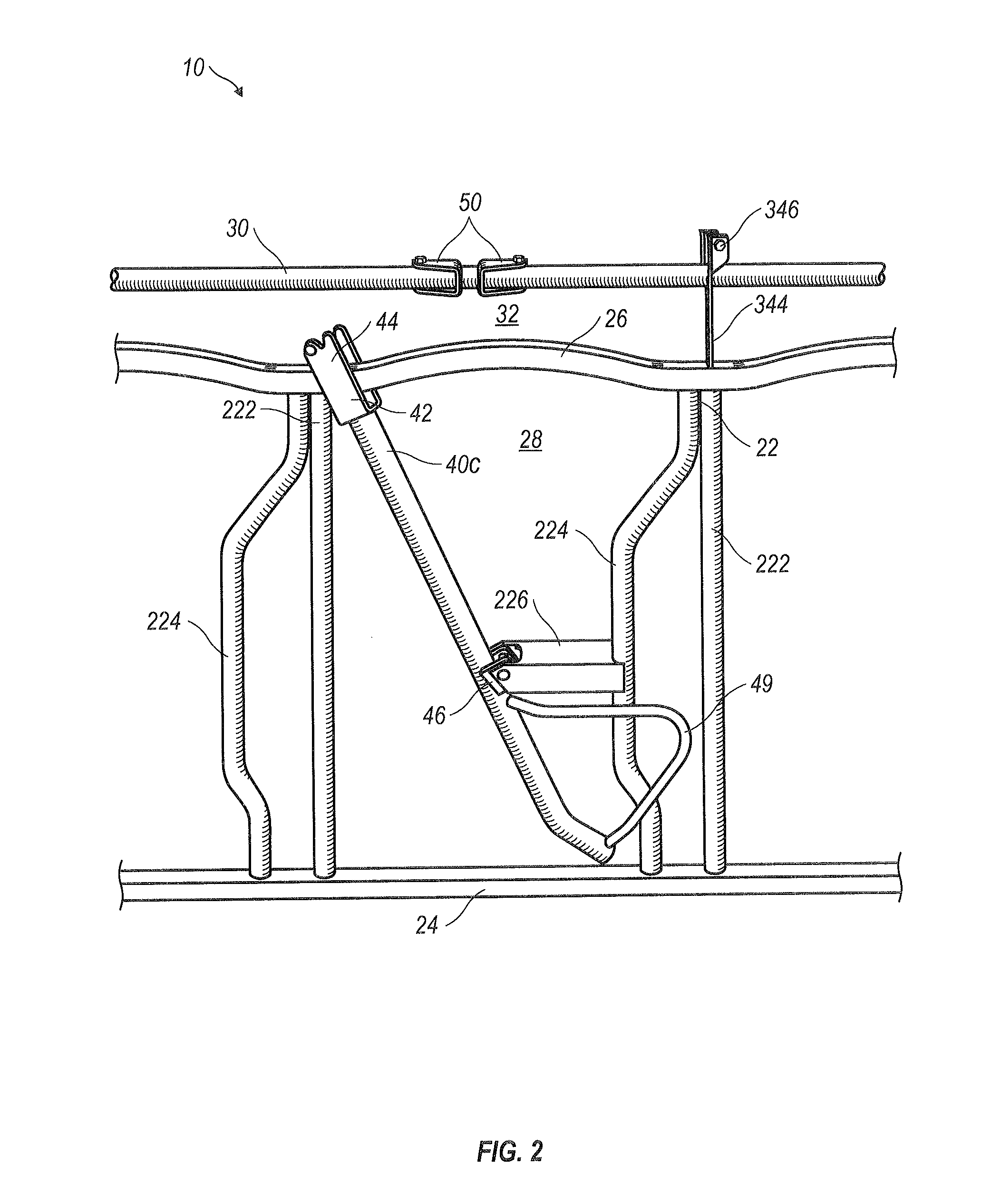

Livestock stanchion with improved support yoke

InactiveUS20180317446A1Increase in sizeIncrease engagementAnimal housingEngineeringMechanical engineering

A livestock stanchion with an improved support yoke including at least one releaseable support yoke comprising a mounting member fixed to and projecting upward from a horizontal rail. A support space formed in an upper end of each mounting member supports a locking bar. A removable pin for a support yoke crosses the upper region of a support space to prevent dislodging of the locking bar. The mounting member can be a plate or have a generally “V,”“U,”“H,” circular, arcuate or poloygonal shaped cross section.

Owner:DASILVEIRA SOUTHWEST INC

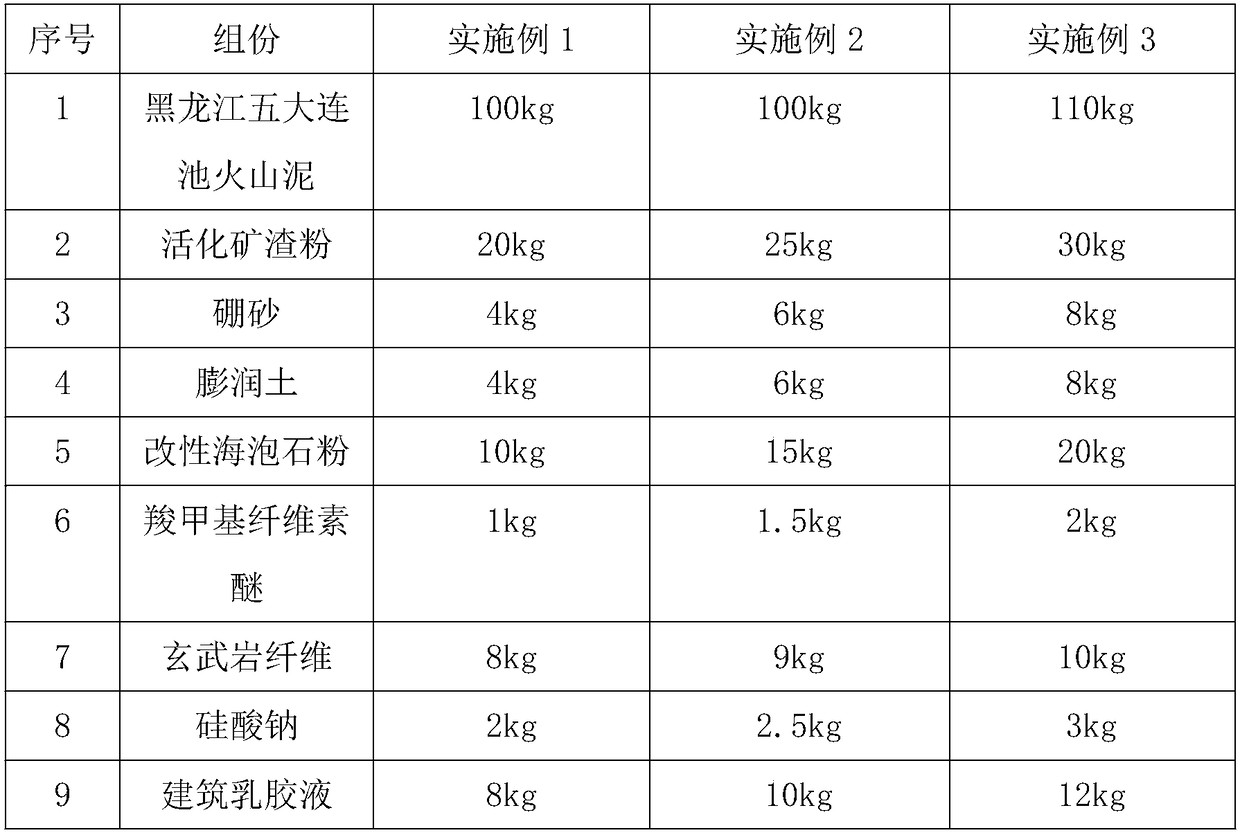

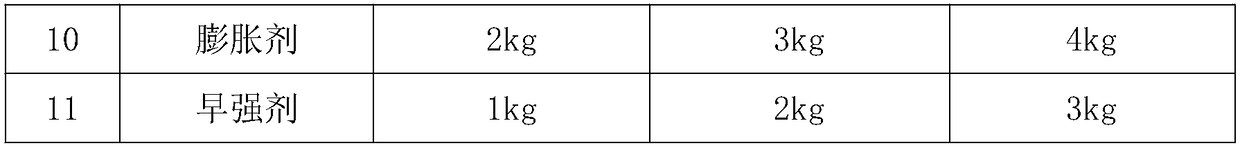

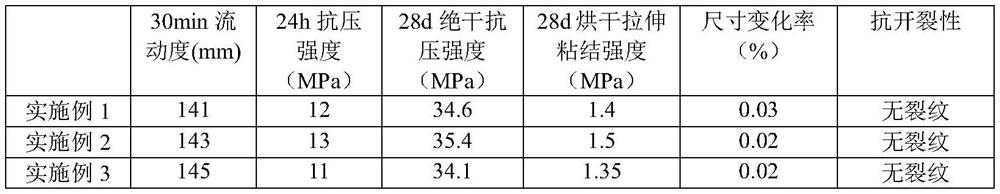

Environment-friendly compound enhanced type cement and preparation method thereof

The invention discloses environment-friendly compound enhanced type cement and a preparation method thereof and relates to the technical field of building materials. The cement is prepared from the following raw materials: volcanic mud of Wudalianchi of Heilongjiang, activated slag powder, borax, bentonite, modified sepiolite powder, carboxymethylcellulose ether, basalt fibers, sodium silicate, building latex liquid, an expanding agent and an early strength agent. According to the preparation method of the environment-friendly compound enhanced type cement, the raw materials are mixed and ground to prepare the cement. The preparation method of the cement provided by the invention is simple and convenient; the cement has the characteristics of good strength, structure stability, anti-seepage and waterproof performance, anti-freezing and heat-resisting performance, corrosion and weathering resisting performance and the like and has a wide application field and a long service life.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

High-strength gypsum-based self-leveling mortar and preparation method thereof

The invention discloses high-strength gypsum-based self-leveling mortar which comprises building gypsum, water, cement, silica fume, fly ash, sand aggregate, a water-retaining agent, a retarder, a water reducing agent, a defoaming agent and rubber powder, and the sand aggregate is ore sand and / or stone powder. The invention also discloses a preparation method of the high-strength gypsum-based self-leveling mortar. According to the high-strength gypsum-based self-leveling mortar provided by the invention, the coal ash or the silica fume is subjected to alkaline excitation on the basis of compounding a small amount of cement in the building gypsum, and the coal ash and / or the silica fume are / is adopted, so that the hydration heat release of the cement can be reduced, and the compactness of a hardened body is enhanced; the fluidity, cohesiveness and water-retaining property of the mortar are improved by using the glass sphere form of the fly ash and the co-doped sand aggregate, and finally the chemical admixture with good compatibility is supplemented for modification treatment, so that the physical and mechanical properties of the cementing material are effectively improved, resources are reasonably utilized on the premise that the gypsum-based self-leveling mortar has relatively high strength, and the gypsum-based self-leveling mortar is suitable for industrial production. The cost of the gypsum-based self-leveling mortar is reduced.

Owner:重庆杰博思石膏有限公司

Efficient retarding and water reducing agent for concrete

The present invention relates to one kind of efficient retarding and water reducing agent for concrete suitable for commercial concrete, pumped concrete and bulk concrete. The efficient retarding and water reducing agent consists of water reducing agent 0-90 wt%, retarder I 1-15 wt%, retarder II 0.5-25 wt% and shrinkage reducing agent 0.05-0.2 wt%. The efficient retarding and water reducing agent has simple preparation process, and has the effects of delaying the setting of concrete, raising early strength, reducing water, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Novel geological polymer and preparation method thereof

The invention discloses a novel geological polymer and a preparation method thereof. The novel geological polymer is prepared from the following components by mass percent: 10-45 pelelith micropowder, 18-50 dolomite micropowder, 5-28 superfine slag powder of iron tailings and 2-20 an alkali-activator. The geological polymer provided by the invention has properties of early strength and rapid hardening, is good in volume stability, chemically corrosion-resistant, high in interface bonding force, good in anti-permeability, good in high temperature resistance, hydrothermal action-resistant and good in durability, is capable of automatically adjusting temperature and humidity, and the like; the pelelith micropowder in the novel geological polymer is light in mass and high in strength, has heat insulation property, sound absorption property, fire resistance, acid and alkali resistance and corrosion resistance, is free from pollution and radioactivity, and the like, thus being an ideal, natural, environment-friendly and energy-saving raw material; the dolomite powder in the novel geological polymer is beneficial to the improvement of early and late stages compressive strengths of the geological polymer; if the powder is finer and the mixing amount is more, an early enhancement effect is more remarkable.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

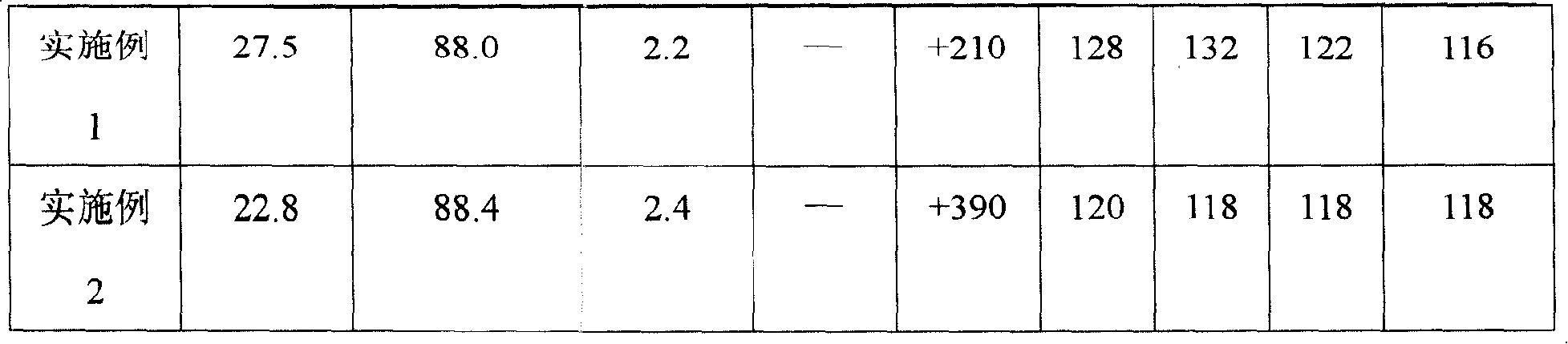

Wet-mixing mortar thickness conditioning agent as well as preparation method and application thereof

The invention provides a wet-mixing mortar thickness conditioning agent as well as a preparation method and application thereof, and belongs to the technical field of mortar additives. The technical problems that the conventional wet-mixing mortar has low adhesive property and low peaceability are solved. The wet-mixing mortar thickness conditioning agent provided by the invention comprises the following components in parts by weight: 0.05 to 1.5 parts of aliphatic polyoxyethylene ether sodium sulfate, 3 to 5 parts of thickening agent and 90 to 120 parts of water. The preparation method of thewet-mixing mortar thickness conditioning agent comprises the following steps: mixing the aliphatic polyoxyethylene ether sodium sulfate, the thickening agent and the water according to the parts by weight and stirring uniformly. Application of the wet-mixing mortar thickness conditioning agent to preparation of the wet-mixing mortar comprises the following steps: adding the wet-mixing mortar thickness conditioning agent, in an amount which is 1.0 to 1.8 percent of the total weight of the cementing material, into the wet-mixing mortar, and stirring uniformly. The wet-mixing mortar thickness conditioning agent provided by the invention enhances the water-retaining property, the adhesive property and the peaceability of the wet-mixing mortar and improves the properties of the wet-mixing mortar.

Owner:吉林鹏霖混凝土有限公司

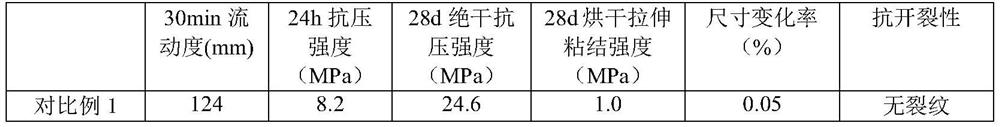

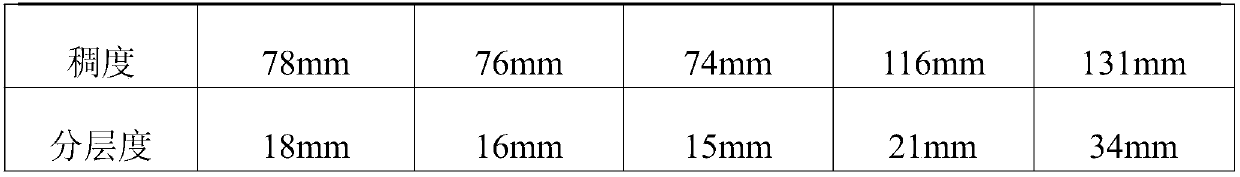

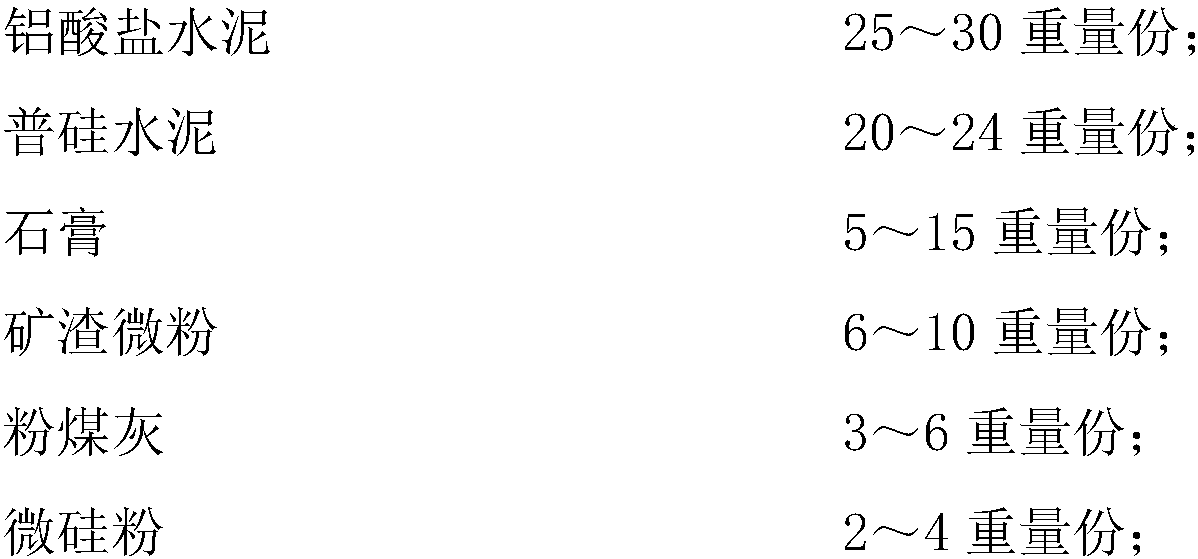

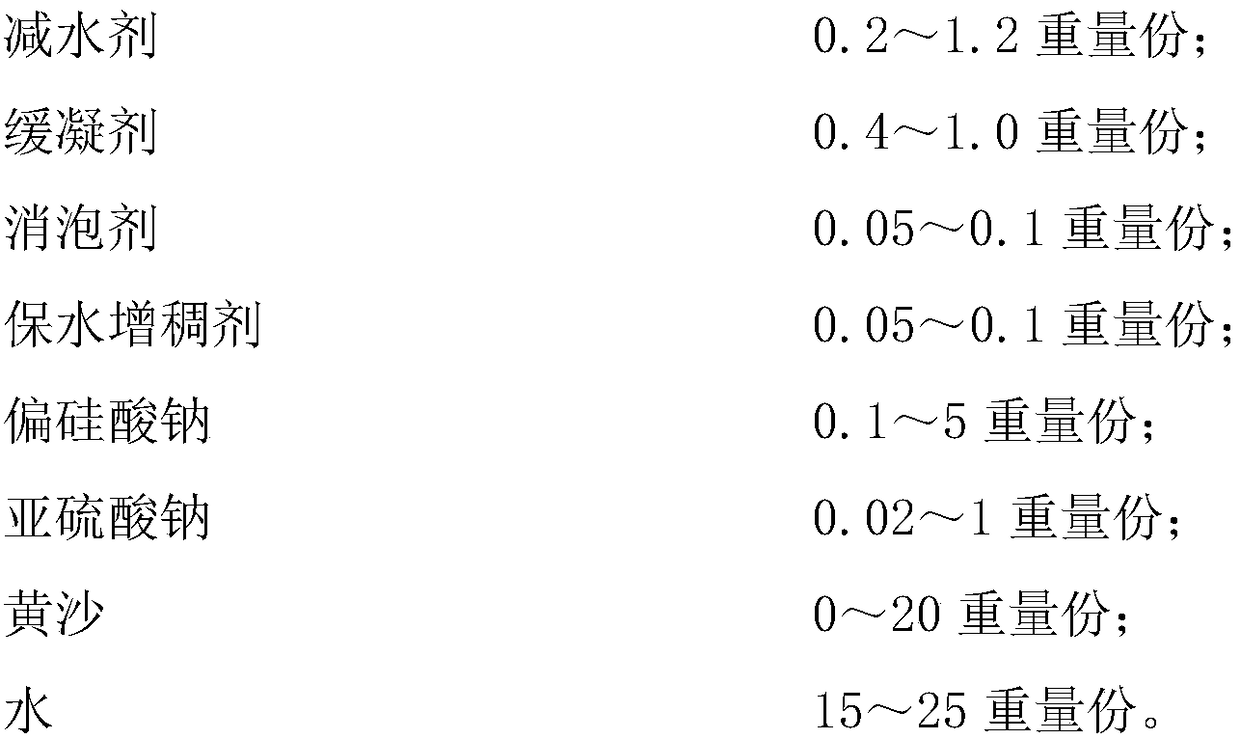

Ultra-early strong single-component grouting material

The invention discloses an ultra-early strong single-component grouting material which comprises the following components: aluminate cement, general silica cement, gypsum, superfine slag powder, fly ash, silica fume, a water reducing agent, a retarder, a defoamer, a water-retaining thickener, sodium metasilicate, yellow sand and water. The ultra-early strong single-component grouting material usedfor road grouting reinforcement, provided by the invention, has relatively high early and late mechanical properties and durability, extremely low thermal conductivity coefficient, no shrinkage-cracking, and good acid resistance and water resistance, and is extremely durable in a variety of harsh climates.

Owner:SHANGHAI LIYANG ROAD REINFORCEMENT TECH +1

High-speed rail concrete base repairing material and repairing method thereof

The invention discloses a high-speed rail concrete base repairing material and a repairing method thereof, and belongs to the technical field of building repairing materials and repairing methods. The repairing material is formed by compounding and stirring magnesium ammonium phosphate cement, an additive, a mineral admixture, aggregate and fiber in a water environment. The repairing material has the advantages of high early strength and high strength, and realizes rapid repairing in the window period of the high-speed rail; the binding power is strong and close to the linear expansion coefficient; the repairing material has good durability, and can overcome the defects that an organic repairing material is easy to age and short in service life; the defect of brittle failure of a cement-based material is overcome; according to the repairing method, a nanometer permeable material is adopted to seal and reinforce a degraded concrete base layer, the defect that other repairing materials cannot improve the performance of base layer concrete is overcome, and the binding power of the base layer and the repairing layer is enhanced; and independent packaging is adopted to meet the requirement for short window period time, repairing of the high-speed rail concrete base is efficiently completed, and the material and the method are suitable for large-area popularization.

Owner:京沪高速铁路股份有限公司 +2

Concrete micro-expansion reinforcing agent, preparation method thereof, concrete and application thereof

PendingCN112592088AImprove compactnessImprove early strengthBridge materialsCalcium silicateAluminate

The invention provides a concrete micro-expansion reinforcing agent, a preparation method thereof, concrete and application thereof, and the reinforcing agent comprises the following raw materials inpercentage by mass based on the mass of the concrete micro-expansion reinforcing agent: 59.5%-89.7% of quick-hardening sulphoaluminate cement, 10%-40% of anhydrite and 0.3%-0.5% of nano calcium silicate hydrate whisker. The concrete micro-expansion reinforcing agent is prepared by taking high-temperature calcined minerals and natural minerals as main components and compounding a silicate cement mineral activation functional component and a hydration promoting component, and is a concrete performance reinforcing material capable of optimizing cement hydration. The cement hydration degree is improved, the cement hydration product proportion is adjusted, the cement hydration product crystallization configuration is improved, admixture redispersion and hydration are promoted, the effects of shrinkage reduction, compaction, reinforcement, crack resistance, waterproofness and the like are achieved, the compactness, early strength and later strength of concrete can be effectively improved, and the durability of the concrete is obviously improved.

Owner:新疆荣高鸿骏新材料技术有限公司

Steam-curing-free ultrahigh-performance concrete manhole cover as well as preparation method thereof

The invention discloses a steam-curing-free ultrahigh-performance concrete manhole cover as well as a preparation method thereof. The steam-curing-free ultrahigh-performance concrete manhole cover comprises an ultrahigh-performance concrete body and a reinforcement framework, wherein the ultrahigh-performance concrete body is prepared from the following stepsraw materials: river sand, high-activity low-shrinkage admixture, mineral powder, cement, a high-activity molecular activated catalyst, awater reducer, steel fibers and water. The invention also discloses a method for preparing the steam-curing-free ultrahigh-performance concrete manhole cover. By adopting a normal-temperature maintenance way, the process is simple, and the production cost and energy consumption can be reduced. The ultrahigh-performance concrete manhole cover prepared by adopting the normal-temperature maintenance way is excellent in performance, excellent in anti-permeability, anti-frozen-molten performance, corrosion resistance, high temperature resistance, erosion resistance and the like.

Owner:常州绿玛特建筑科技有限公司

Preparation process of modified paraffin for hardwood table and chair coating materials

InactiveCN105622868AEndothermic peak temperature increasesImprove heat resistanceCoatingsParaffin waxChemistry

The invention relates to a preparation process of modified paraffin for hardwood table and chair coating materials. The preparation process comprises: cutting 50 g of refined paraffin into small blocks, adding to a four-necked flask, carrying out water bath heating, melting, stirring, and carrying out thermal insulation at a temperature of 75-85 DEG C; taking 8-12 g of a methyl acrylate monomer, and adding to the four-necked flask in a dropwise manner while introducing high-purity N2 for protection, wherein 0.5-0.7 g of an initiator is dissolved in the methyl acrylate monomer; carrying out a thermal insulation reaction for a certain time, and pouring out the reactant inside the flask while hot to obtain a grafted copolymer crude product; carrying out precipitation separation on the product by using acetone, washing a plurality of times, and drying to achieve a constant mass so as to obtain the grafted paraffin fine product. According to the present invention, the endothermic peak temperature of the prepared grafted paraffin product is substantially improved so as to substantially improve heat resistance; and the early-stage heat resistance and the late-stage heat resistance of the grafted paraffin product are significantly improved, such that the disadvantage that the easy migration of the existing coating material causes pollution on clothes and the like can be improved by adopting the grafted paraffin product as the main raw material of the redwood furniture paraffin-based coating material.

Owner:李林君

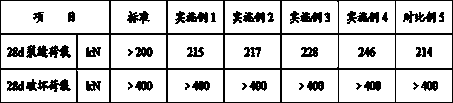

Livestock stanchion

ActiveUS9089106B2Increase in sizeIncrease engagementAnimal housingTaming and training devicesEngineeringCanis lupus familiaris

An improved livestock stanchion including a plurality of forked vertical posts fixed between a substantially horizontal base rail and a horizontal rail to form a co-planar frame having at least one livestock opening. The horizontal rail can be serpentine in form to reduce the likelihood of head, horn or ear strikes as the animal's head enters a livestock opening. A locking bar rests in at least one releaseable support yoke mounted to the frame to allow easy installation and removal of a locking bar and its appurtenances. An end lap between adjacent locking bars provides for a strong releaseable couple. An offset pivot member and an offset latch pin of a pivoting restraining stanchion provide early engagement of a latch pin to a latching mechanism such as a pair of opposing latch dogs mounted on a locking bar above the horizontal rail.

Owner:DASILVEIRA SOUTHWEST INC

Cement grinding aid

The invention discloses a cement grinding aid which comprises the following components: 20-30% of ethylene glycol, 20-30% of sorbitol, 40-50% of diethylene glycol, 5-10% of glycerol, 2-3% of sodium thiosulfate and 1-5% of sodium carbonate. According to the prepared composite cement grinding aid, the granularity of cement particles can be controlled to be 3-10 microns, and the grain composition of the cement particles is optimized; the effect of cement hydration is promoted, the 3d compressive strength is improved by 20.1%, the 28d compressive strength is improved by 19.5%, and the early-stage and later-stage compressive strength of the cement is remarkably improved.

Owner:陶静芳

High alite silicate cement clinker and its preparation method

InactiveCN100429170CPromote sustainable developmentRaw materials are cheap and easy to getPortland cementMaterials science

The present invention relates to a high-alite content Portland cement clinker prepared by using lead-zinc tails and shale instead of clay and its preparation method. Its composition includes (by wt%) 78-87% of limestone, 6-19% of lead-zinc tails, 2-11% of shale and 0-1.7% of iron ore. Said invention also provides the concrete steps of its preparation method.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com