Preparation method of alkali-free accelerator

A technology of quick-setting agent and preparation steps, which is applied in the field of preparation of alkali-free quick-setting agent, and can solve problems such as poor stability, polluting the environment, and large loss of strength of hardened slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

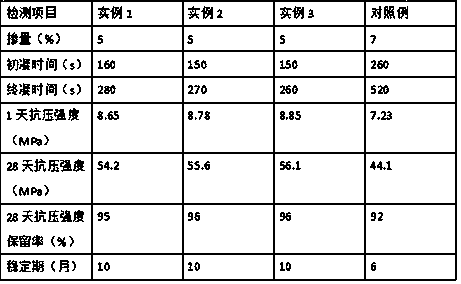

Examples

example 1

[0020] Take a fresh coconut, use a hole opener to make a round hole with a diameter of 5cm on the coconut shell, pour out the coconut juice for later use, chop the young ginger and wrap it with gauze, press the gauze with a stone and squeeze it, and collect the gauze Ginger juice flowing out of the medium, mix the ginger juice and spare coconut milk at a volume ratio of 3:10 to obtain a mixed solution; take fresh buffalo milk, pour it into a pot and boil it, and pour the boiled buffalo milk into the above-mentioned opened coconut milk In the shell, when the buffalo milk is cooled to 50°C, pour the above mixture of 3 times the mass of buffalo milk into the coconut shell, put the coconut shell in the refrigerator, let it stand at 4°C for 40 minutes, cut the coconut shell and filter , separated and removed the filtrate to obtain a gel-like product; put the gel-like product into a tissue pulverizer, pulverize it for 20 minutes to obtain a pulverized product, put the pulverized prod...

example 2

[0022] Take a fresh coconut, use a hole opener to make a round hole with a diameter of 5cm on the coconut shell, pour out the coconut juice for later use, chop the young ginger and wrap it with gauze, press the gauze with a stone and squeeze it, and collect the gauze Ginger juice flowing out of the medium, mix the ginger juice and spare coconut milk at a volume ratio of 3:10 to obtain a mixed solution; take fresh buffalo milk, pour it into a pot and boil it, and pour the boiled buffalo milk into the above-mentioned opened coconut milk In the shell, when the buffalo milk is cooled to 55°C, pour the above mixed solution that is 4 times the mass of the buffalo milk into the coconut shell, put the coconut shell in the refrigerator, let it stand at 5°C for 45 minutes, cut the coconut shell and filter , separated and removed the filtrate to obtain a gel-like product; put the gel-like product into a tissue pulverizer, pulverize it for 25 minutes to obtain a pulverized product, put the...

example 3

[0024]Take a fresh coconut, use a hole opener to make a round hole with a diameter of 5cm on the coconut shell, pour out the coconut juice for later use, chop the young ginger and wrap it with gauze, press the gauze with a stone and squeeze it, and collect the gauze Ginger juice flowing out of the medium, mix the ginger juice and spare coconut milk at a volume ratio of 3:10 to obtain a mixed solution; take fresh buffalo milk, pour it into a pot and boil it, and pour the boiled buffalo milk into the above-mentioned opened coconut milk In the shell, when the buffalo milk is cooled to 60°C, pour the above mixed solution that is 5 times the mass of the buffalo milk into the coconut shell, put the coconut shell in the refrigerator, let it stand at 6°C for 50 minutes, cut the coconut shell and filter , separate and remove the filtrate to obtain a gel-like product; put the gel-like product into a tissue pulverizer, pulverize for 30 minutes to obtain a pulverized product, put the pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com