Door pocket manufacturing die with adjustable size and manufacturing method of door pocket

A manufacturing method and door cover technology, which are applied to molds, manufacturing tools, mold separation devices, etc., can solve the problems of low utilization rate of resources, easy loosening, insufficient nail holding force, etc., and achieve high utilization rate of resources, increase density, Easy and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

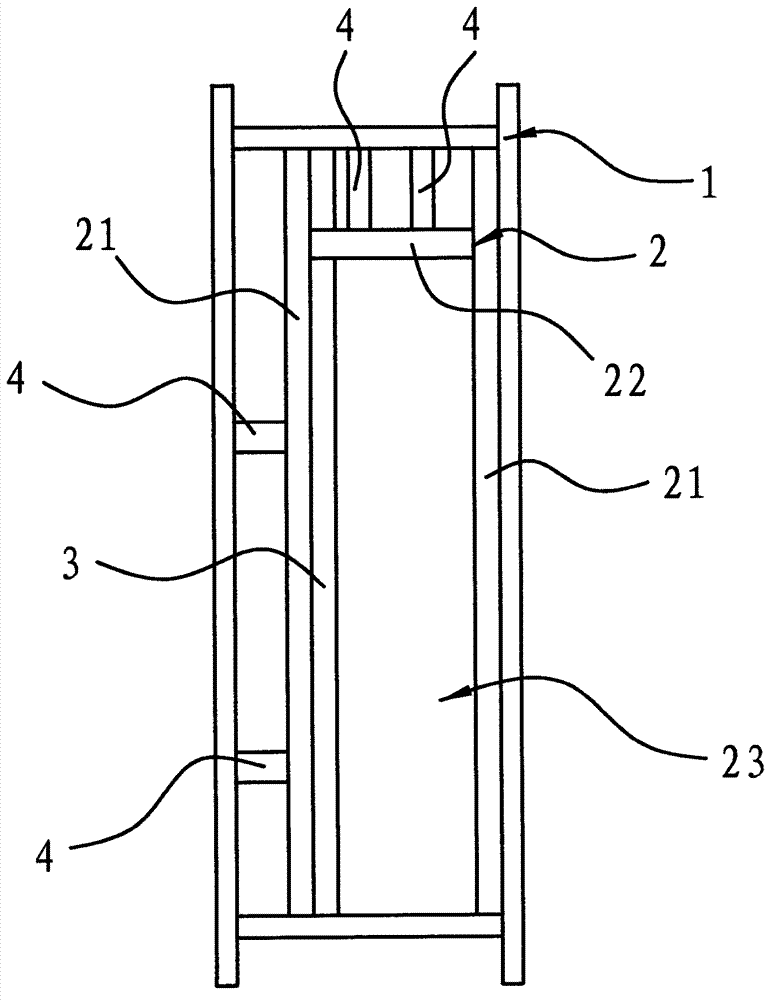

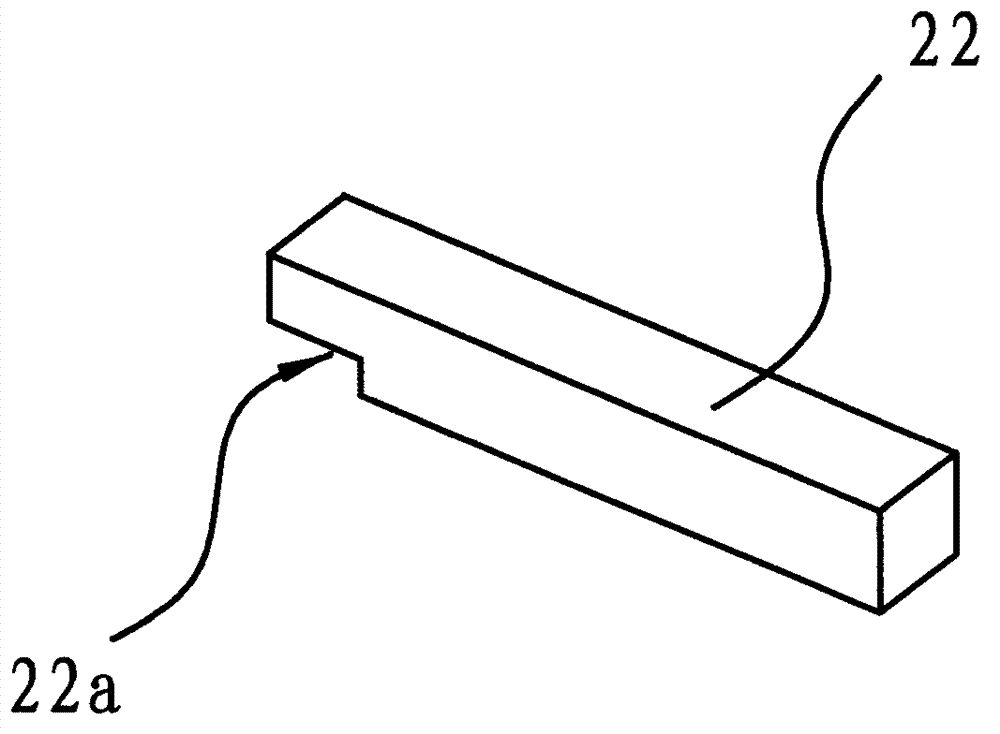

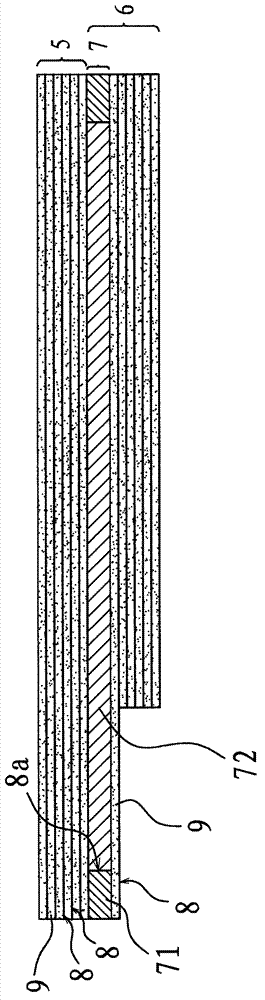

[0053] Such as figure 1 As shown, the size-adjustable door cover manufacturing mold includes a ring-shaped inner frame 2 and an outer frame 1 arranged on the periphery of the inner frame 2. The outer frame 1 is fixed and the inner frame 2 is composed of two independent fixed rods 21 and One adjusting rod 22 is spliced together, two fixed rods 21 are arranged in parallel, the adjusting rod 22 is placed between the two fixed rods 21, and the two ends respectively touch the fixed rods 21 on both sides, the above-mentioned fixed rod 21 and the adjusting rod 22 and the inner wall of the outer frame 1 are surrounded by an elongated injection-molded frame body 23. A stop mold 3 is set in the injection-molded frame body 23, and the stop mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com