Efficient retarding and water reducing agent for concrete

A technology of high-efficiency water-reducing agent and water-reducing agent, applied in the field of building materials, can solve problems such as unsatisfactory early strength effect, and achieve the effect of significant retardation, improved workability, and good water-reducing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

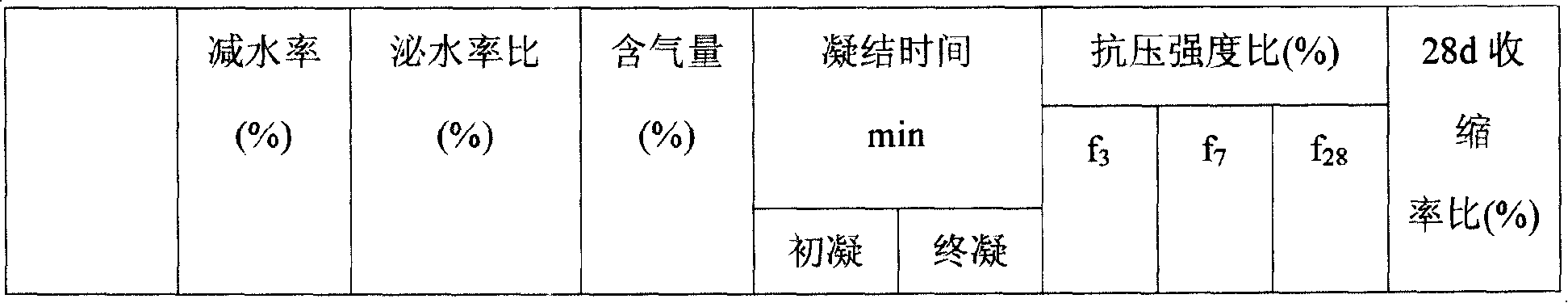

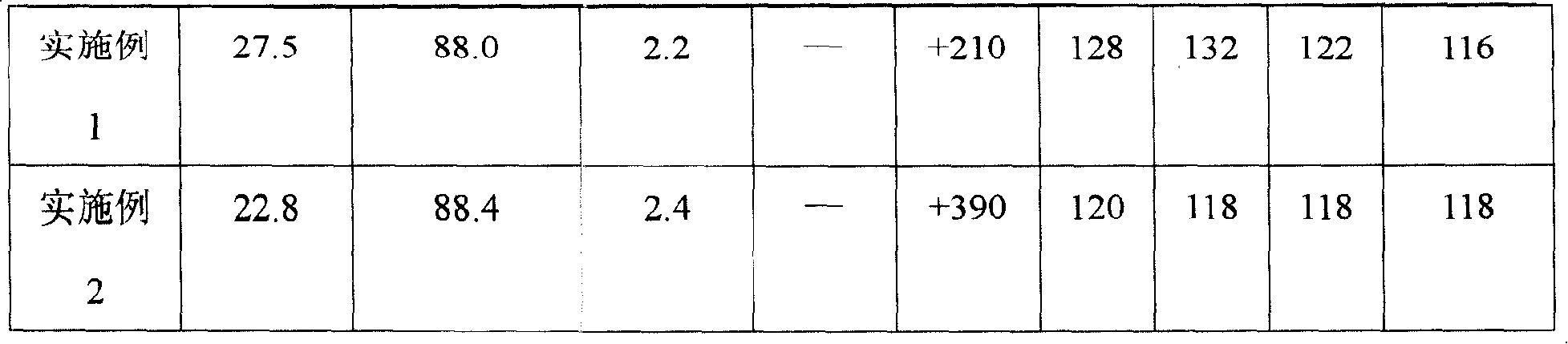

Image

Examples

Embodiment 1

[0013] Embodiment 1, a kind of retarding superplasticizer for concrete

[0014] This slow-setting high-efficiency water reducer is composed of naphthalenesulfonate formaldehyde condensation product water reducer, sulfamate water reducer, sodium gluconate, sugar calcium and shrinkage reducer. The ratio of various materials is:

[0015] Naphthalene Sulfonate Formaldehyde Condensate Superplasticizer 60%

[0016] Sulfamate superplasticizer 20%

[0017] Sodium Gluconate 4.5%

[0020] The slow-setting high-efficiency superplasticizer obtained in this example was mixed into concrete for use at a dosage of 1.0%, and its performance is given in Table 1. In this example, due to the composite effect of the sulfamate water reducer and the naphthalene water reducer, the water reducing rate of the concrete is greatly improved, and the setting time is prolonged. It is mainly used to prepare high-strength concrete above C60, and...

Embodiment 2

[0021] Embodiment 2, a kind of retarding superplasticizer for concrete

[0022] This retarding high-efficiency water reducer is composed of naphthalenesulfonic acid condensate water reducer, sodium gluconate, citric acid, sodium tripolyphosphate and shrinkage reducer. The ratio of various materials is:

[0023] Naphthalenesulfonic acid condensation product superplasticizer 86%

[0024] Sodium Gluconate 8%

[0025] Citric Acid 3.4%

[0026] Sodium tripolyphosphate 2.55%

[0028] The slow-setting high-efficiency superplasticizer obtained in this example was mixed into concrete for use at a dosage of 1.2%, and its properties are given in Table 1. In this example, due to the compound effect of various retarders, the setting time is delayed longer under the premise that the water-reducing rate of concrete meets the requirements, and the 3D strength of concrete is not affected, and the strength in the later stage is not reduced. It is mainly used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com