Steam-curing-free ultrahigh-performance concrete manhole cover as well as preparation method thereof

An ultra-high-performance, concrete technology, which is applied in the field of manhole inspection wells or similar covers, can solve the problems of cast iron inspection manhole covers with no obvious cost-effective advantages, large maintenance equipment investment, and low recovery value, so as to save steam curing energy Energy consumption, save steaming equipment and steaming energy consumption, cycle life cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

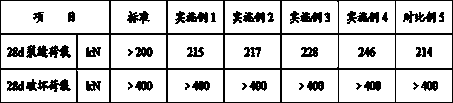

Examples

Embodiment 1

[0029] A non-steam curing ultra-high-performance concrete inspection well cover, including an ultra-high-performance concrete body and a steel skeleton, and the ultra-high-performance concrete body is composed of the following raw materials in weight percentage: 46.5% of river sand, high-activity and low-shrinkage admixture 10%, polycarboxylate superplasticizer 0.59%, highly active molecular grade activated catalyst 0.1%, S95 mineral powder 5%, cement 23.6%, copper-plated steel fiber 6% and water 8.21%.

[0030] The preparation method of the non-steam curing ultra-high performance concrete inspection manhole cover specifically includes the following steps:

[0031] Pour river sand, high-activity low-shrinkage admixture, polycarboxylate superplasticizer, high-activity molecular-level activated catalyst, S95 mineral powder, cement, and water into the mixer in turn and stir for 3 minutes, then add steel fiber and stir for 4 minutes, and mix well The prepared slurry is poured into...

Embodiment 2

[0033] A non-steam curing ultra-high-performance concrete inspection well cover, including an ultra-high-performance concrete body and a steel skeleton, and the ultra-high-performance concrete body is composed of the following raw materials in weight percentage: 46.5% of river sand, high-activity and low-shrinkage admixture 10%, polycarboxylate superplasticizer 0.58%, highly active molecular grade activated catalyst 0.2%, S95 mineral powder 6%, cement 22.5%, copper-plated steel fiber 6% and water 8.22%.

[0034] The preparation method of the non-steam curing ultra-high performance concrete inspection manhole cover specifically includes the following steps:

[0035] Pour river sand, high-activity low-shrinkage admixture, polycarboxylate superplasticizer, high-activity molecular-level activated catalyst, S95 mineral powder, cement, and water into the mixer in turn and stir for 4 minutes, then add steel fiber and stir for 4 minutes, and mix well The prepared slurry is poured into...

Embodiment 3

[0037] A non-steam curing ultra-high performance concrete inspection manhole cover, comprising an ultra-high performance concrete body and a steel skeleton, the ultra-high performance concrete body is composed of the following raw materials in weight percentage: 45.8% of river sand, high activity and low shrinkage admixture 11%, polycarboxylate superplasticizer 0.51%, highly active molecular grade activated catalyst 0.3%, S95 mineral powder 7%, cement 20%, copper-plated steel fiber 7% and water 8.39%.

[0038] The preparation method of the non-steam curing ultra-high performance concrete inspection manhole cover specifically includes the following steps:

[0039] Pour river sand, high-activity low-shrinkage admixture, polycarboxylate superplasticizer, high-activity molecular-level activated catalyst, S95 mineral powder, cement, and water into the mixer in turn and stir for 3 minutes, then add steel fiber and stir for 5 minutes, and mix well The prepared slurry is poured into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com