Novel inorganic fireproof door and manufacturing method thereof

A manufacturing method and technology for fire doors, applied to fire doors, door leaves, windows/doors, etc., can solve problems such as poor structural stability, easy deformation and damage, complex components, etc., achieve anti-aging and high firmness, protect the natural environment, Good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

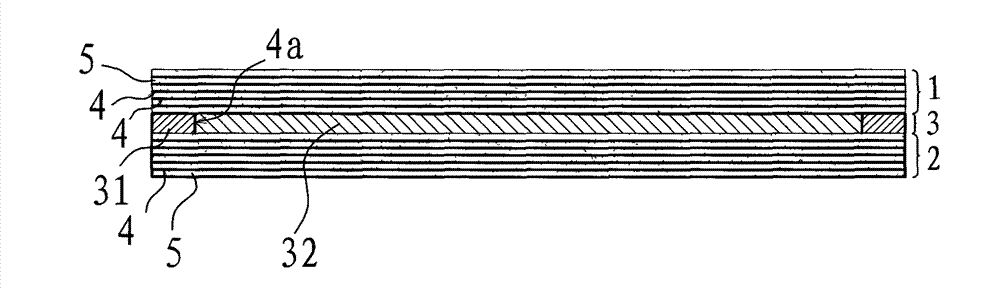

[0049] Such as figure 1 with figure 2 As shown, the new inorganic fire door consists of an upper panel layer 1, a lower panel layer 2 and an intermediate sandwich layer 3 sandwiched between the upper panel layer 1 and the lower panel layer 2. The intermediate sandwich layer 3 includes a square frame-shaped The wooden frame 31 and the filling material 32 filled in the middle gap of the wooden frame 31.

[0050] Both the upper panel layer 1 and the lower panel layer 2 are formed by alternate bonding of multiple layers of non-alkali glass fiber mesh cloth 4 and magnesite mixed slurry 5, and the alkali-free glass fiber mesh cloth 4 in the lower panel layer 2 The edge is extended around and rolled upwards, and the frame part of the wooden frame 31 is rolled up to form the cladding layer 4a, and the packing material 32 is tightly filled to tightly squeeze the cladding layer 4a located inside the frame on the frame.

[0051] The manufacture method of above-mentioned novel inorgani...

Embodiment 2

[0066] The structure of the fire door to be prepared in this embodiment is the same as that in Embodiment 1.

[0067] The manufacture method of above-mentioned novel inorganic fireproof door comprises the steps:

[0068] Step 1, prepare the magnesium chloride aqueous solution of 22 degrees Baume;

[0069] Step 2, preparing magnesium chloride cement slurry: uniformly mixing magnesium oxide and magnesium chloride aqueous solution, the weight-number ratio of magnesium oxide and magnesium chloride aqueous solution is 0.5:1;

[0070] Step 3, preparation of modifying agent, modifying agent is made up of following composition and proportion (parts by weight): barium silicate 2, sodium silicate 3.5, polymer waterproof rubber powder 20, construction gypsum 311.5, bentonite 140, mica powder 60, lithium silicate 2.5, polyvinyl alcohol 8, flocculant 2.5, talcum powder 150, pozzolan 300;

[0071] Step 4, prepare mixed slurry: add modifier to the magnesium chloride cement slurry, stir unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com