Granulated blast furnace slag liquid composite grinding aid

A technology for granulating blast furnace slag and grinding aid, which is applied in the field of granulated blast furnace slag liquid compound grinding aid to achieve the effects of saving power consumption, sufficient supply, and improving the distribution and morphology of powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

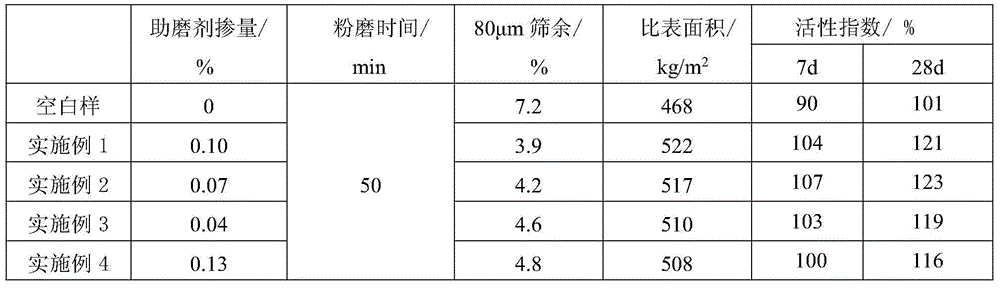

Examples

Embodiment 1

[0024] A liquid composite grinding aid for granulated blast furnace slag, which is prepared from triethanolamine, mixed alcohol, glycerol, molasses, potassium carbonate, sodium pyrophosphate, sodium sulfate and water, and the parts by weight of each substance are: 20 parts by weight of triethanolamine, 18 parts by weight of mixed alcohol, 7 parts by weight of glycerin, 5 parts by weight of molasses, 2 parts by weight of potassium carbonate, 1 part by weight of sodium pyrophosphate, 2 parts by weight of sodium sulfate, and 45 parts by weight of water.

[0025] The granulated blast furnace slag liquid composite grinding aid of the present invention adopts a conventional preparation method, mixes the above-mentioned substances according to the proportion, and stirs evenly to obtain the granulated blast furnace slag liquid composite grinding aid.

Embodiment 2

[0027] A liquid composite grinding aid for granulated blast furnace slag, which is prepared from triethanolamine, mixed alcohol, glycerol, molasses, potassium carbonate, sodium pyrophosphate, sodium sulfate and water, and the parts by weight of each substance are: 25 parts by weight of triethanolamine, 17 parts by weight of mixed alcohol, 8 parts by weight of glycerol, 6 parts by weight of molasses, 2 parts by weight of potassium carbonate, 2 parts by weight of sodium pyrophosphate, 1 part by weight of sodium sulfate, and 42 parts by weight of water.

[0028] The granulated blast furnace slag liquid composite grinding aid of the present invention adopts a conventional preparation method, mixes the above-mentioned substances according to the proportion, and stirs evenly to obtain the granulated blast furnace slag liquid composite grinding aid.

Embodiment 3

[0030] A liquid composite grinding aid for granulated blast furnace slag, which is prepared from triethanolamine, mixed alcohol, glycerol, molasses, potassium carbonate, sodium pyrophosphate, sodium sulfate and water, and the parts by weight of each substance are: 30 parts by weight of triethanolamine, 20 parts by weight of mixed alcohol, 10 parts by weight of glycerol, 5 parts by weight of molasses, 2 parts by weight of potassium carbonate, 2 parts by weight of sodium pyrophosphate, 4 parts by weight of sodium sulfate, and 50 parts by weight of water.

[0031] The granulated blast furnace slag liquid composite grinding aid of the present invention adopts a conventional preparation method, mixes the above-mentioned substances according to the proportion, and stirs evenly to obtain the granulated blast furnace slag liquid composite grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com