High alite silicate cement clinker and its preparation method

A technology of Portland cement and cement clinker, which is applied in the field of Portland cement clinker with high alite content and its preparation, and can solve the problems of restricting the application of cement, polluting the environment with sulfide and fluoride, and deteriorating the durability of cement. problems, to achieve the effects of improving durability, saving costs and energy consumption, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

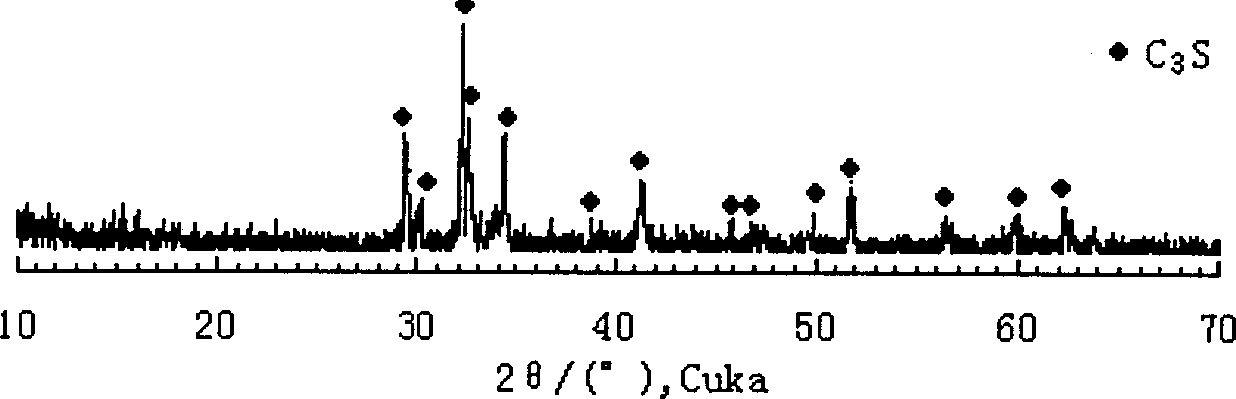

Embodiment 1

[0024] Shaanxi Xiushan Cement Co., Ltd. uses limestone, lead-zinc tailings, shale and iron ore as raw materials to prepare raw cement. The chemical composition of lead-zinc tailings and shale is shown in Table 1-1. Minerals in lead-zinc tailings are mainly quartz and calcite, etc. Minerals in shale are mainly quartz, mica, kaolinite and wurstite. The ratio of each raw material is shown in Table 1-2, in which all the data are in mass percentage. The designed clinker rate and mineral composition are listed in Table 1-3, where KH is the lime saturation coefficient, SM is the silicic acid rate, IM is the aluminum rate, C 3 S refers to tricalcium silicate (3CaO SiO2 ), C 2 S refers to dicalcium silicate (2CaO SiO 2 ), C 3 A refers to tricalcium aluminate (3CaO·Al 2 o 3 ), C 4 AF refers to tetracalcium aluminoferrite (4CaO·Al 2 o 3 · Fe 2 o 3 ), R 2 O refers to the alkali content. Mix and grind the raw material evenly until the sieve of 0.08mm is less than 10%, put it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com