Alcohol ester cement grinding aid and method for producing the same

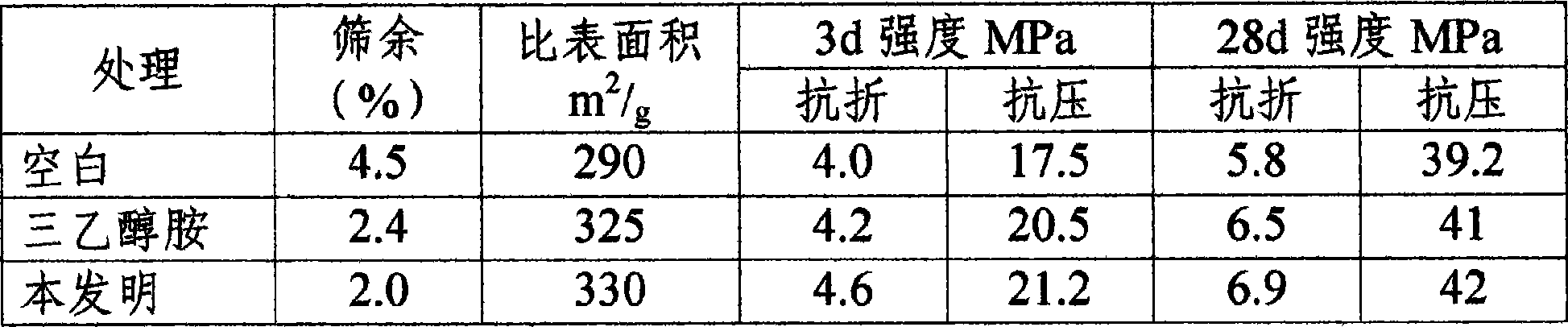

A technology of cement grinding aid and alcohol ester, applied in the field of cement process admixture and its preparation, can solve the problems such as alcohol ester sulfate which have not been seen yet, and achieves the advantages of saving energy, reducing consumption, reducing sieve allowance and reducing use cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

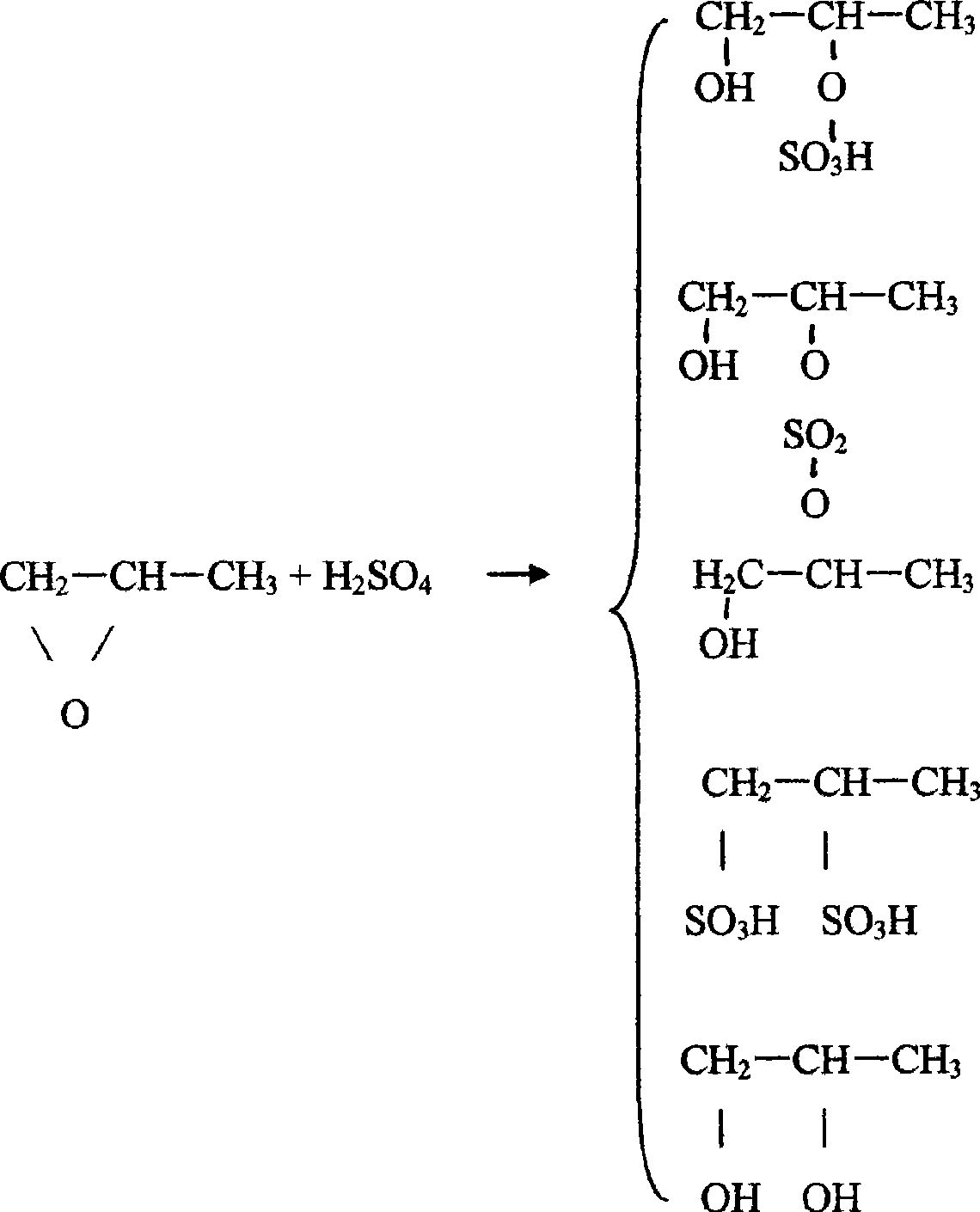

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the preparation of alcohol ester type cement grinding aid, a. get propylene oxide 10mol, H 2 SO 4 20mol spare, in which H 2 SO 4 Use sulfuric acid with a concentration not lower than 97-98%,

[0028] b. Put it into the reactor and heat it up to 70°C, pressurize it to 0.3MPa,

[0029] c. Slowly press propylene oxide into the reactor,

[0030] d. Keep the temperature at 70°C and continue the reaction for 2 hours,

[0031] e. Reduce to normal pressure and drop to normal temperature to take out the product.

Embodiment 2

[0032] Embodiment 2, the preparation of alcohol ester type cement grinding aid, a. get propylene oxide 10mol, H 2 SO 4 25mol standby, in which H 2 SO 4 Use sulfuric acid with a concentration not lower than 97-98%,

[0033] b. Put it into the reactor and heat it to 50°C, pressurize it to 0.25MPa,

[0034] c. Slowly press propylene oxide into the reactor,

[0035] d. Keep the temperature at 80°C and continue the reaction for 2.5 hours,

[0036] e. Reduce to normal pressure and drop to normal temperature to take out the product.

Embodiment 3

[0037] Embodiment 3, the preparation of alcohol ester type cement grinding aid, a. get propylene oxide 10mol, H 2 SO 4 15mol spare, in which H 2 SO 4 Use sulfuric acid with a concentration not lower than 97-98%,

[0038] b. Put it into the reactor and heat it up to 50°C, pressurize it to 0.2MPa,

[0039] c. Slowly press propylene oxide into the reactor,

[0040] d. Keep the temperature at 70-80°C and continue the reaction for 2 hours,

[0041] e. Reduce to normal pressure and drop to normal temperature to take out the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com