Secondary synthesis method of calcium sulfoaluminate minerals in metasilicate cement clinker

A technology of calcium sulfoaluminate minerals and Portland cement, which is applied in the field of secondary synthesis of calcium sulfoaluminate minerals in Portland cement clinker, can solve the problems such as failure to reflect the early strength and other properties of Portland cement. , to achieve the effect of improving early and long-term performance, increasing content, and increasing the amount of incorporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

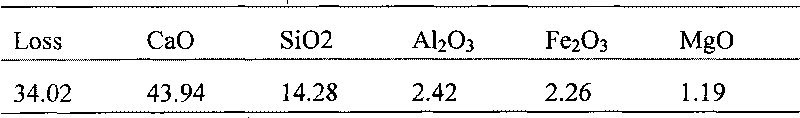

[0022] Add 0.30kg of gypsum (SO in gypsum) to the prepared 5kg of Portland cement raw meal (see Table 1 for the chemical analysis of raw meal) 3 The mass percentage is 32.90%), so that the SO in the raw meal 3 The mass percentage content is 1.86%;

[0023] (1) Raise the prepared raw meal to 1480℃, calcinate for half an hour, and cool; then increase the temperature at a rate of 5℃ per minute, keep it for 30 minutes when it rises to 1450℃, and then cool;

[0024] (2) Increase the temperature of the cooled clinker at a rate of 10°C per minute, hold it for 60 minutes when the temperature rises to 1200°C, and then cool it;

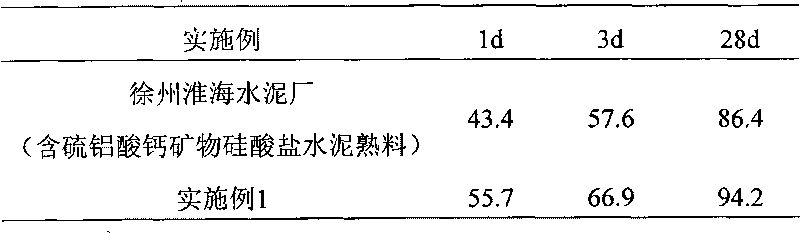

[0025] (3) Grind the cooled clinker with a ball mill to a specific surface area of 350m 2 / kg of powder; according to the measurement method disclosed in the patent (200710302594.1) applied by the inventor, the clinker (not heat-treated) in the Xuzhou Huaihai Cement Plant was measured The mass percentage content of the clinker is 0.5%. The mass percentage of 4.8%; ...

Embodiment 2

[0032] (1) Add 0.28kg of gypsum (SO in gypsum) to 5kg of Portland cement raw meal (see Table 1 for the chemical analysis of raw meal). 3 The content is 32.90%), so that the SO in the raw meal 3 The content is 1.74%;

[0033] (2) Raise the prepared raw meal to 1450°C and calcinate for 1 hour, cool it, and then increase the temperature at 10°C per minute, keep it at 1400°C for 50 minutes, and then cool it;

[0034] (3) Increase the temperature of the cooled clinker at a rate of 15°C per minute, hold it for 90 minutes when the temperature rises to 1250°C, and then cool it;

[0035] (4) Grind the cooled clinker with a ball mill to a specific surface area of 360m 2 / kg of powder;

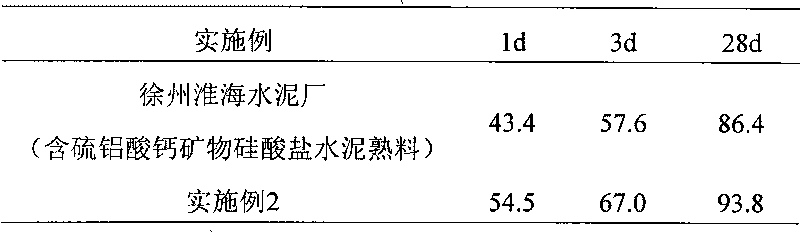

[0036] (5) Weigh 96g of final product clinker, add 4g of gypsum, mix well, add 29ml of water (water-cement ratio w / c=0.29), stir and shape, the size of the test block is 20×20×20mm, and measure 1d, 3d and 28d Compressive strength. The test block is cured for 24 hours in a curing box with a relative humidity o...

Embodiment 3

[0040] (1) Add 0.3kg of gypsum (SO in gypsum) to 5kg of Portland cement raw meal (see Table 1 for the chemical analysis of raw meal) 3 The content is 32.90%), so that the SO in the raw meal 3 The content is 1.86%;

[0041] (2) Raise the prepared raw meal to 1450°C and calcinate for 1 hour, cool it, then raise it to 1450°C at a rate of 5°C per minute, keep it for 30 minutes, and then enter the cooler to cool down at a rate of 55°C per minute;

[0042] (3) When the temperature is cooled to 1250°C, keep it warm for 60 minutes, then cool down;

[0043] (4) Grind the cooled clinker with a ball mill to a specific surface area of 340m 2 / kg of powder;

[0044] (5) Weigh 96g of final product clinker, add 4g of gypsum, mix well, add 29ml of water (water-cement ratio w / c=0.29), stir and shape, the size of the test block is 20×20×20mm, and measure 1d, 3d and 28d Compressive strength. The test block is cured for 24 hours in a curing box with a relative humidity of 90% and a temperature of 20±2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com