High-speed rail concrete base repairing material and repairing method thereof

A technology for repairing materials and base layers, which is used in tracks, track maintenance, construction, etc., and can solve problems such as high cost, inapplicability to high-speed rail concrete foundation repair construction, and complex construction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

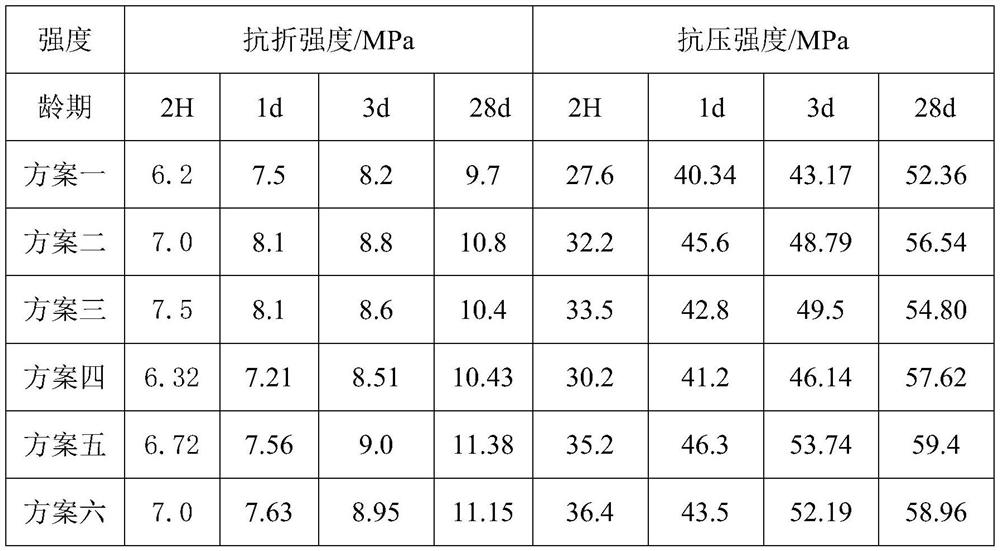

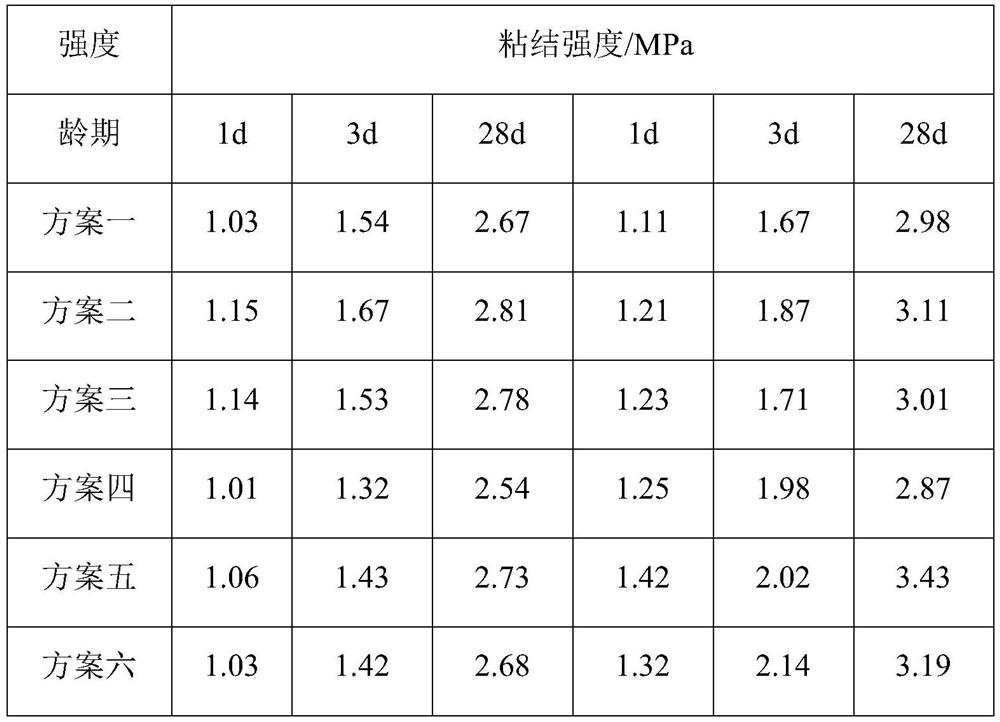

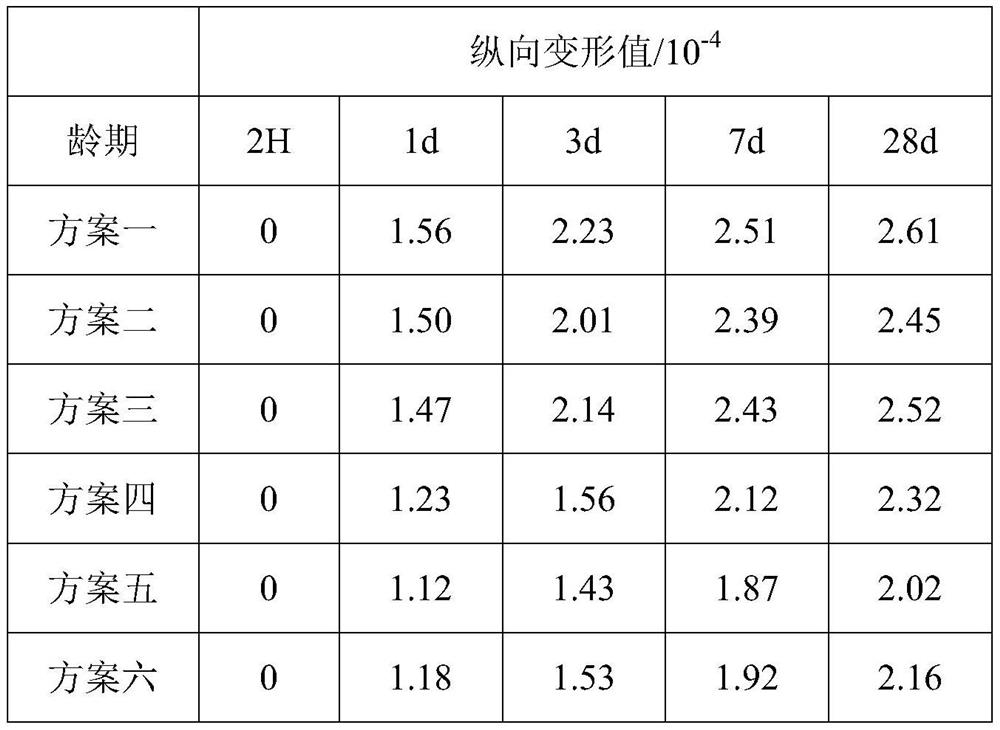

Embodiment 1

[0027] A high-iron Base concrete repair material, the repair material by the magnesium ammonium phosphate cement, additives, mineral admixtures, aggregate and fiber composite obtained by stirring in an aqueous environment, and magnesium ammonium phosphate cement and mineral admixture of water with a weight ratio of 1: 0.1; weight ratio of magnesium ammonium phosphate cement additive is 0.02: 1; fiber and magnesium ammonium phosphate cement volume ratio of 0.005: 1; magnesium ammonium phosphate cement powder made of magnesium oxide, ammonium dihydrogen phosphate, compound retarder composed of a retarder compound borax, disodium hydrogen phosphate, organic acids; liquid additive is sodium silicate, which modulus is 2.8 to 4.0; the use of mineral admixtures repairing material magnesium oxide powder equivalent alternative , an alternative to magnesium oxide powder in an amount of 0% by weight percentage, by weight percent basis, comprising fly ash mineral admixtures 0%, 0% metakaolin....

Embodiment 2

[0043] A high-iron Base concrete repair material, the repair material by the magnesium ammonium phosphate cement, additives, mineral admixtures, aggregate and fiber composite obtained by stirring in an aqueous environment, and magnesium ammonium phosphate cement and mineral admixture of water with a weight ratio of 1: 0.1; weight ratio of magnesium ammonium phosphate cement additive is 0.02: 1; fiber and magnesium ammonium phosphate cement volume ratio of 0.005: 1; magnesium ammonium phosphate cement powder made of magnesium oxide, ammonium dihydrogen phosphate, compound retarder composed of a retarder compound borax, disodium hydrogen phosphate, organic acids; liquid additive is sodium silicate, which modulus is 2.8 to 4.0; the use of mineral admixtures repairing material magnesium oxide powder equivalent alternative , an alternative to an amount of 20% weight percent of magnesium oxide powder, by weight percentage basis, mineral admixture comprising 50% fly ash, metakaolin 50%. ...

Embodiment 3

[0059] A high-iron Base concrete repair material, the repair material by the magnesium ammonium phosphate cement, additives, mineral admixtures, aggregate and fiber composite obtained by stirring in an aqueous environment, and magnesium ammonium phosphate cement and mineral admixture of water with a weight ratio of 1: 0.1; weight ratio of magnesium ammonium phosphate cement additive is 0.01: 1; fiber and magnesium ammonium phosphate cement volume ratio of 0.005: 1; magnesium ammonium phosphate cement powder made of magnesium oxide, ammonium dihydrogen phosphate, compound retarder composed of a retarder compound borax, disodium hydrogen phosphate, organic acids; liquid additive is sodium silicate, which modulus is 2.8 to 4.0; the use of mineral admixtures repairing material magnesium oxide powder equivalent alternative , an alternative to an amount of 20% weight percent of magnesium oxide powder, by weight percentage basis, mineral admixture comprising 50% fly ash, metakaolin 50%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com